Pocketing Toolpath

The Pocket toolpath is used to remove large areas of material. It removes the areas contained inside the selected vectors.

Watch this video to see this in action:

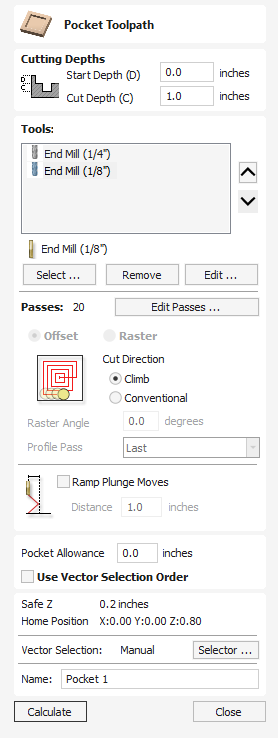

Cutting Depths

Cutting Depths

Start Depth (D)

Start Depth (D)

This specifies the depth at which the toolpath is calculated from.

When cutting directly into the surface of a job the Start Depth will often be 0. If machining into the bottom of an existing pocket or 3D region, the depth needs be entered.

Cut Depth (C)

Cut Depth (C)

The depth of the toolpath relative to the Start Depth.

Tool Selection

Tool Selection

In the pocketing toolpath you can select any number of tools you wish to use to perform your pocketing. When multiple tools are chosen then the first tool removes as much material as it can, all subsequent tools in the list will remove as much material as it can from any previously unmachined areas. If multiple tools are selected then the order of the tools in the list should match the order they will run on the machine.

Note

An allowance will always be left on for the final tool to remove.

Clicking the button opens the Tool Database from which the required clearance tool can be selected and added to the list.

Clicking the button will remove the selected tool from the list.

Clicking the button opens the Edit Tool form which allows the cutting parameters for the selected tool to be modified, without changing the master information in the database.

Clicking the up and down arrow buttons will move the selected tool up and down the list respectively.

Pass Depth Control

Pass Depth Control

When a toolpath is created, the Pass Depth value associated with the selected tool (part of the tool's description) is used to determine the number of passes needed to profile down to the specified Cut Depth. However, by default the software will also modify the precise step down by up to 15% in either direction, if by doing so it is able to total number of passes required to reach the desired cut depth. It is nearly always desirable to benefit from the significantly reduced machining time of cutting using less passes if possible. Nevertheless, there are some occasions where the exact step down for a given profile pass needs to be more precisely controlled - when cutting into laminated material, for example. The Passes section page indicates how many passes will be created with the current settings.Thebutton will open a new dialog that enables the specific number and height of passes to be set directly.

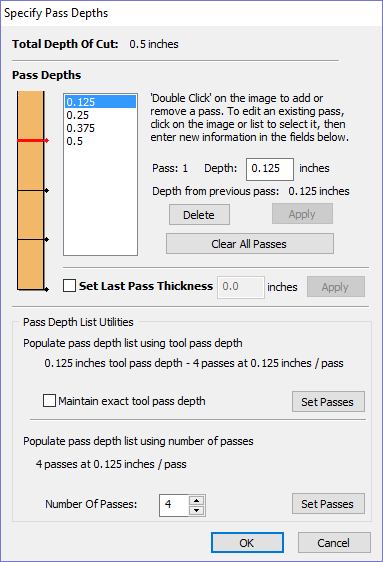

Specify Pass Depths

Specify Pass Depths

The Pass Depths section at the top of the form shows a list of the current pass depths. The relative spacing of the passes is indicated in the diagram next to the list. Left click on a depth value in the list, or a depth line on the diagram, to select it. The currently selected pass is highlighted in red on the diagram.

To edit the depth of the selected pass, change the value in the Depth edit box and click .

The button will delete the selected pass.

The Passes button will delete all the passes.

To add a new pass, double left click at the approximate location in the passes diagram that you wish to add the pass. A new pass will be added and automatically selected. Edit the precise Depth value if required and then click .

The Set Last Pass Thickness option will enable an edit box where you can specify the last pass in terms of the remaining thickness of material you wish to cut with the last pass (instead of in terms of its depth). This is often a more intuitive way to specify this value.

Pass Depth List Utilities

Pass Depth List Utilities

Note

Setting the number of passes with either of these utilities will discard any custom passes you may have added.

The first method simply sets the passes based on the Depth of Step property of the selected tool. By default, this is the method used by Aspire when initially creating profile passes. However, if the Maintain Exact Step Depth option is checked, the software will not vary the step size to try to optimize the number of passes (see above).

The second method creates evenly spaced passes based on the value specified in the Number of passes edit box.

To apply either method, click the Set Associated Passes button to create the resulting set of pass depths in the pass list and diagram.

Strategy Options

Strategy Options

There are two choices of the type of fill pattern that will be used to clear away the area to be machined with the Pocket Toolpath, Offset and Raster.

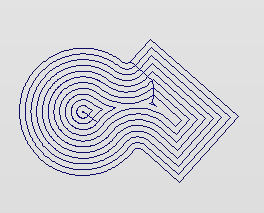

Offset

Offset

Calculates an offset area clearance fill pattern to machine inside the selected vector(s). Options for Cut Direction to be either: Climb (CCW) cutting direction Conventional (CW) cutting direction.

Note

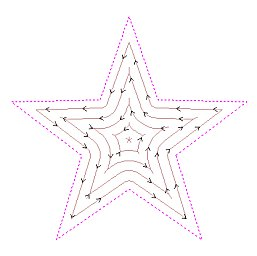

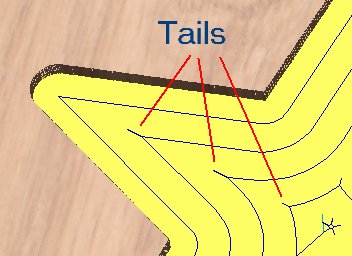

When the stepover for a pocket fill is greater than 50% of the cutter/tip diameter the software automatically adds 'Tail' moves to the corner regions on the toolpaths to ensure material is not left on the job. You can see these in the diagram of a star being pocket machined below:

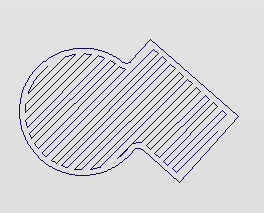

Raster

Raster

Calculates a Raster based area clearance fill pattern to machine inside the selected vector(s). Cut Direction only applies to profile pass and can be either:

- Climb (CCW) cutting direction

- Conventional (CW) cutting direction

Raster Angle

Raster Angle

Between 0 and 90°, where 0° is parallel to the X axis and 90° parallel to the Y axis.

Profile Pass

Profile Pass

Used to clean up the inside edge after machining the pocket. This can be done either before the rastering (First) or after the rastering (Last). If 'No Profile Pass' is selected, you will need to calculate a profile pass manually to machine the pocket to size.

Note:

When using multiple tools, selecting 'No Profile Pass' option will cause subsequent tool to machine areas that otherwise would have been cleaned up by the profile pass

Pocket Allowance

Pocket Allowance

This option is used to leave material on the inside of the pocket for the Profile Pass to clean-up. This is often very useful for ensuring the cutter does not mark the edge surface of the pocket when roughing out.

Ramp Plunge Moves

Ramp Plunge Moves

The cutter can be ramped over a distance into the pocket instead of plunging vertically. This approach reduces heat build-up that damages the cutter and also reduces the load on the spindle and z axis bearings.

Use Vector Selection Order

Use Vector Selection Order

If this option is checked, ✓ pockets will be machined in the order you selected them. If the option is not checked the program will optimize the order to reduce machining time.

Position and Selection Properties

Position and Selection Properties

Safe Z

Safe Z

The height above the job at which it is safe to move the cutter at rapid / max feed rate. This dimension can be changed by opening the Material Setup form.

Home Position

Home Position

Position from and to that the tool will travel before and after machining. This dimension can be changed by opening the Material Setup form.

Project toolpath onto 3D Model

Project toolpath onto 3D Model

This option is only available if a 3D model has been defined. If this option is checked, ✓ after the toolpath has been calculated, it will be projected (or 'dropped') down in Z onto the surface of the 3D model. The depth of the original toolpath below the surface of the material will be used as the projected depth below the surface of the model.

Note:

When a toolpath is projected onto the 3D model, its depth is limited so that it does not exceed the bottom of the material.

Vector Selection

Vector Selection

This area of the toolpath page allows you to automatically select vectors to machine using the vector's properties or position. It is also the method by which you can create Toolpath Templates to re-use your toolpath settings on similar projects in the future. For more information, see the sections Vector Selector and Advanced Toolpath Templates.

Name

Name

The name of the toolpath can be entered or the default name can be used.