Cut2D Laser Desktop User Manual

Version 9

Disclaimer

All CNC machines (routing, engraving, and milling) are potentially dangerous and because Vectric Ltd. has no control over how the software described in this manual might be used, Vectric Ltd. or any associated Resellers cannot accept responsibility for any loss or damage to the work piece, machine or any individual, howsoever caused by misusing the software. Extreme care should always be taken and the output from the software thoroughly checked before sending it to a CNC machine.

The information in this manual may be subject to change without any prior notice. The software described in this manual is supplied under the terms and conditions of the software license agreement and may only be used in accordance with the terms of this agreement.

Vectric Ltd.

Web: www.vectric.com

Email: info@vectric.com

Phone: +44 (0) 1527 850 323

Fax: +44 (0) 1527 850 323

Introduction

This manual is designed to provide a comprehensive description of all the functions, tools, menus and icons available within the Cut2D Laser Desktop software package.

Access this document from Cut2D Laser Desktop's Help Menu ► Help Contents or from the Cut2D Laser Desktop folder in the program section of your Windows Start menu.

At the bottom of the page you will see an area with View All Help. This will download all the Help Documentation as a single web page which is useful for searching or if you need to create a paper copy of the documentation.

User Guides, tutorial and training

Please note that this document is a Reference Manual. If you require more guidance, or are still learning how to use Cut2D Laser Desktop, please ensure that you view the Getting Started Video Tutorials in the Cut2D Laser Desktop Video Tutorial Browser when starting the software.

Cut2D Laser Desktop also includes an extensive selection of video tutorials, which are accessible from the Tutorial Video Browser link when application first starts. These tutorials cover every aspect of Cut2D Laser Desktop's functionality and range in complexity from a beginner's overview, to advanced features and principles. They are intended to be extremely accessible by level of experience or topic and use real-world examples throughout. Videos can be watched online, or installed locally.

We welcome any comments on this manual or the other training material, please email support@vectric.com with your feedback.

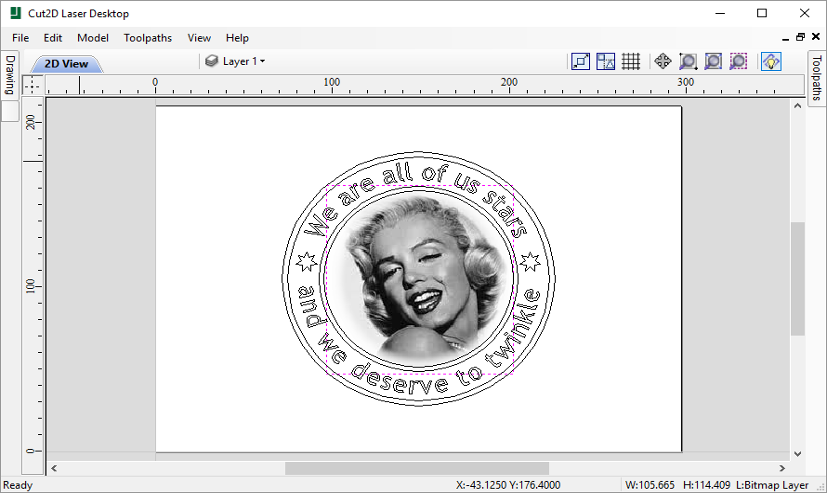

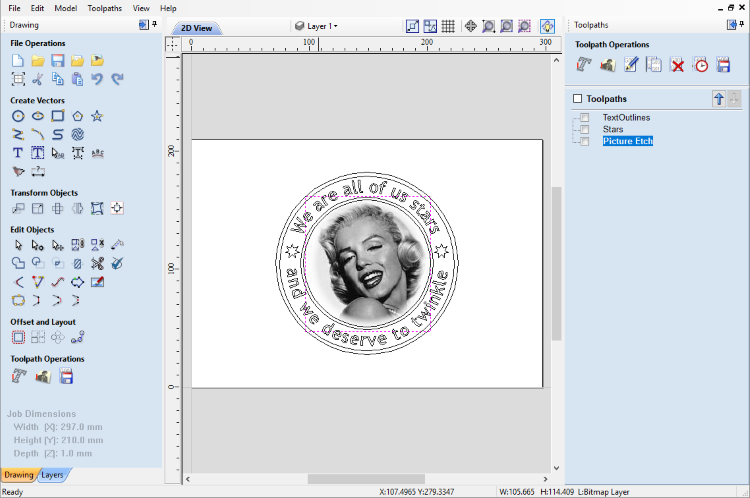

Overview of the Interface

- The Main Menu Bar (the Drop Down Menus) along the top of the screen (File, Edit, Model, Toolpaths, View, Gadgets, Help) provides access to most of the commands available in the software, grouped by function. Click on any of the choices to show a Drop-Down list of the available commands.

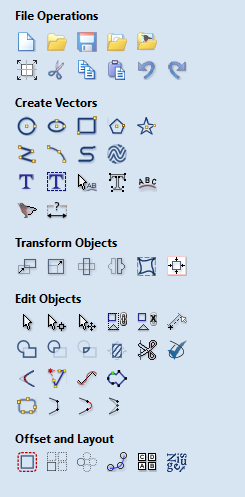

- The Design Panel is on the left side of the screen. This is where the Drawing and Layers tab can be accessed and the icons within the tabs to create a design.

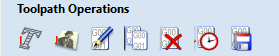

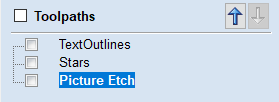

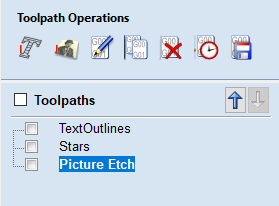

- The Toolpath Tab is on the right side of the screen. The Top section of the toolpaths tab houses all of the icons to create, edit and preview toolpaths. The bottom half shows you toolpaths that you have already created.

- The 2D Design window is where the design is drawn, edited and selected ready for machining. Designs can be imported or created directly in Cut2D Laser Desktop. This occupies the same area as the 3D View and the display can be toggled between the two using F2 and F3 or the tabs at the top of the window.

- The 3D View is where the toolpaths and the toolpath preview are displayed.

- If you wish to see the 2D and 3D views simultaneously, or you wish to switch your focus to the Toolpaths tab at a later stage of your design process, you can use the interface layout buttons (accessible in the 2D View Control section on the Drawing Tab) to toggle between the different preset interface layouts.

Managing the Interface

The Drawing, Layers and Toolpath tool pages have Auto-Hide / Show behavior which allows them to automatically close when not being used, thus maximizing your working screen area.

Cut2D Laser Desktop includes two default layouts, one for designing and one for machining, which can automatically and conveniently set the appropriate auto-hide behavior for each of the tools pages. Toggle layout buttons on each of the tools pages allow you to switch the interface as your focus naturally shifts from the design stage to the toolpathing stage of your project.

Accessing Auto-hidden tabs

If a tools page is auto-hidden (because it is currently unpinned, see pinning and unpinning tools pages, below), then it will only appear as a tab at the side of your screen. Move your mouse over these tabs to show the page temporarily. Once you have selected a tool from the page, it will automatically hide itself again.

Pinning and unpinning tools pages

The auto-hide behavior of each tools page can be controlled using the push-pin icons at the top right of the title area of each page.

|

Pinned Open (auto-hide disabled) |

||

|

Un-pinned (auto-hide enabled) |

Default layout for Design and Toolpaths

Cut2D Laser Desktop has two default tool page layouts that are designed to assist the usual workflow of design, followed by toolpath creation.

View Controls

Your project is represented using 2D and 3D workspaces, each viewed via independent windows called the 2D View and 3D View, respectively. This division usefully maps to the typical workflow in which you will initially focus on the 2D design and layout of your project before moving to the 3D stage of modeling, toolpathing and previewing your finished part.

You can switch between the views using the tabs at the top of each window. In addition the shortcut-keys F2 and F3 will toggle the display between the two windows.

It is sometimes useful to see both the 2D and 3D representations at the same time. The Page Up and Page Down keys will arrange the 2 views either horizontally or vertically so you can see both workspaces simultaneously. To return to the tabbed display, simply click on the standard Windows Maximize button in the top right corner of either view window.

Many of the controls for manipulating the view in your project are similar in both 2D and 3D.

From within each view you can also directly interact with the objects that make up your job using the Object Selection Tools.

2D View Controls

See also the Rulers, Guides and Snap Grid section.

Pan |

Click and hold the Left mouse button and drag the mouse about to Pan - Esc to cancel mode Shortcut: Click and drag the Middle mouse button or if using a 2 button mouse, Hold Ctrl + drag with Right Mouse button. |

|

Zoom Interactive |

Mouse with Middle Wheel - Scroll wheel in / out Mouse without Middle Wheel - Hold Shift + Push / Pull with Right Mouse button. |

|

Zoom Box |

Click top left corner, hold mouse down and drag to bottom right corner and release. Clicking the left mouse button will zoom in, Shift + click will zoom out. |

|

Zoom Extents |

Zooms to show material limits in the 2D window |

|

Zoom Selected |

With objects selected Zooms to the bounding box of the selection |

How to Get Started

The first stage in any project is to create a new blank part or import some existing data to work with. At this stage a number of parameters need to be defined relating to the size of the part and its position relative to the datum location on the CNC machine. Later, once the part has been defined and you have started working, you may want to change the size of the material, import additional data and generally manage the project operation. In this section of the manual the initial creation of a part will be covered along with all the icons which appear under the File Operations section of the Drawing Tab.

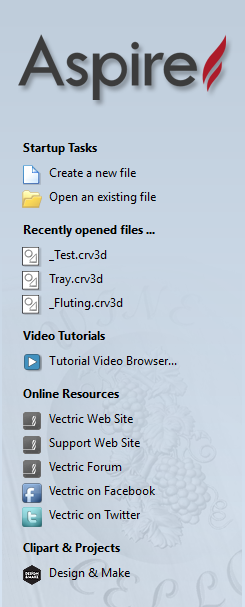

When you first start the program you will see the Startup Task options on the left hand tab and also a list of your 4 most recently opened Cut2D Laser Desktop parts (this is a rolling list that will be populated each time you run the software and may initially be empty).

Startup Tasks and Recently Opened Files

When you first start the program you will see the Startup Task options on the left hand tab and also a list of your most recently opened Cut2D Laser Desktop parts.

The first choice is whether you want to Create a new file or Open an existing one. Creating a new file allows you specify a size and location for a blank work area, set your material thickness and also set the model quality and even the shading color/material. The process to do this will be covered in the next section (Job Setup Form Options).

The second choice, Open an Existing File, will allow you to open a pre-created file from your computer. This may be a file you previously created in Aspire (*.crv3d), or a VCarve Pro job (*.crv). Alternatively, it might be a 2D vector layout from another CAD system (*.dxf, *.eps, *.ai and *.pdf). A CRV3D or CRV file will have the necessary information for material size etc. already embedded in it. The 2D formats will import the data at the size and position it was created but will require you to go through the Job Setup form to verify/edit all the parameters for the part.

Video Tutorials

The Tutorial Video Browser will open your default web browser (typically Internet Explorer, Chrome or Firefox - depending on your Windows setup and personal preference). The web browser offers a number of tutorial videos and associated files, presented either by project or feature category to help you to learn about the software. You will initially need internet access to watch or download the videos or files, but, once downloaded, the materials can be used offline.

Online Resources

This section includes direct links to useful websites and web resources - including clipart and projects for you to purchase, download and incorporate into your own designs. These links will also open in your default web browser and you will need internet access to use them.

Two-Sided Machining

Cut2D Laser Desktop has the ability to create a project where your design requires you to cut both sides of your material. Typically you will cut the top surface of your material, then manually turn the material block over on your machine, whilst maintaining a common registration position, and cut the bottom surface using a second set of toolpaths. By specifying a two-sided project using the Job Setup form and indicating how you intend to flip the material over on your machine, you can allow the registration and organisation of the geometry, toolpaths and previews relating to each side of the design to be managed by the software. During the design process you can then switch between the top and bottom surface of your design, create toolpaths for each side and view a preview of the material - including after it has been cut from both directions. Once you are happy with the result you can then save the toolpaths relating to each side independently.

Two-Sided Job Setup

In the Job Setup dialog, you can pick whether you want to create a single-sided or a double-sided job. You can change this setting later if you wish.

The initial Z-Zero Position you will be using for the toolpaths relating to each side is set from the Job Setup dialog. You can choose to Z-Zero from the same material surface for both sides, the machine bed for both sides or you can opt to Z-Zero from each side indepenendently. Your choice depends on the nature of your design. Typically, if you are only intending to carve into the surface on each side then you will Z-Zero each independently after you have physically positioned the material on your machine. If your design involves cutting through the material and the Z depths for each side must coincide precisely, however, then you will usually wish to use a common Z position for both sides. You can change the Z-Zero settings for each side subsequently using the Material Setup form.

The X Y Datum Position applies to both sides of the material.

In order to correctly manage the alignment of the geometry relating to each side, it is important that the software knows whether material will be flipped vertically or horizontally during the physical machining process. Flip Direction Between Sides determines the automatic transformation of the drawings, models or toolpaths associated with each side. If the material block will be flipped horizontally then the software will automatically mirror your data to mimick the relative positions each side.

When you create or open a two-sided project, Cut2D Laser Desktop will display two new icons in the 2D View Toolbar. The first icon indicates which flip direction option has been specified for this project. It will ininitially be set to display the Top Side of your design. Any drawing or toolpath creation will be associated with the Top Side and this is known as the active side. To work on the other side of your design you will first need to make the Bottom Side active. Click on the Toggle Side button in the View Toolbar to switch the active side between top and bottom. Alternatively, you can use the number key shortcuts: 1 will make Top Side active and pressing 2 will make the Bottom Side active.

Two-Sided Toolpath Management

When toolpaths are created in a two-sided job they are automatically associated with the active side from which they were created. This helps you to keep track of which side of your job each toolpath is for. The toolpath list will only display the toolpaths for the current active side and this is indicated in the heading, which will read Toolpaths (Top) or Toolpaths (Bottom) accordingly. Changing the active side (using 1 or 2, for example) will cause the toolpaths list to also swap the displayed set of toolpaths.

Two-Sided Toolpath Previewing

The Preview Toolpaths form now includes a button. This will simulate toolpaths cutting both sides of your job (regardless of the currently active side) so that you can see the combined result of your toolpaths in a single, solid, 3D representation of the final job.

Two-Sided Toolpath Saving

Saving your toolpaths from a two-sided job is done independently for each side. Save the toolpaths for the currently active side, then make the other side active (using 1 or 2) and save out the toolpaths for the other side.

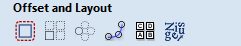

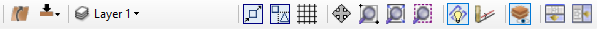

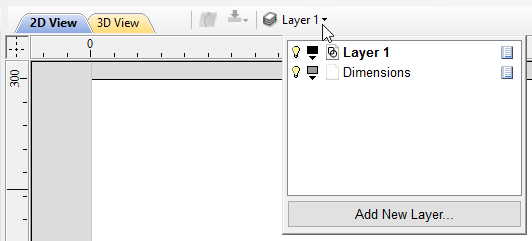

The View Toolbar

Above the view window is a handy toolbar that allows easier access to common tools. With the ability to create a double sided project you have easy access to switch between the Top and Bottom Sides of your project. The Layers Drop down bar has now moved from the drawing tab to the View Toolbar, making it accessible at all times. The other icons displayed in order of left to right are as follows:

Snapping Toggle Options

View Controls

Toggle Pan / Twiddle View

Toggle Pan / Twiddle View Zoom to box

Zoom to box Zoom to drawing

Zoom to drawing Zoom to selection

Zoom to selection

Toolpath Drawing Toggle

Toggle 2D Toolpath Drawing

Toggle 2D Toolpath Drawing Toggle solid 2D Toolpath Drawing

Toggle solid 2D Toolpath Drawing

Two-Sided Machining

When you are working on a two-sided job additional icons will appear on the View Toolbar. On the left you will see an icon indicating whether the job you are working on will be flipped horizontally or vertically. This is important because the software will automatically mirror your toolpaths and geometry around different axes depending on this setting. To maintain the correct alignment of your toolpaths you must physically turn the material on your CNC machine in the same direction as you have specified during the design process.

Turn horizontally from left to right.

Turn horizontally from left to right. Turn vertically, end over end.

Turn vertically, end over end.

The next button indicates which side you are currently working on. It is a toggle button that can be clicked. Clicking this button swaps the active side of your job.

Top side is active, all operations will apply to the Top side.

Top side is active, all operations will apply to the Top side. Bottom side is active, all operations will apply to the Bottom side.

Bottom side is active, all operations will apply to the Bottom side.

The final additional tool for two-sided job is on the right hand side of the View Toolbar and it allows you to toggle the 3D composite relief to show either the currently active side or your model only, or both sides of your model as a single solid block.

Toggle Two-Sided View

Toggle Two-Sided View

2D Design and Management

The 2D View is used to design and manage the layout of your finished part. Different entities are used to allow the user to control items that are either strictly 2D or are 2D representations of objects in the 3D View. A list of these 2D View entities are described briefly below and more fully in later sections of this manual.

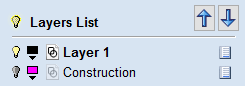

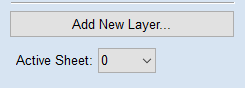

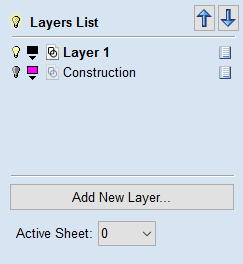

Ultimately the point of all these different types of objects is to allow you to create the toolpaths you need to cut the part you want on your CNC. This may mean that they help you to create the basis for the 3D model or that they are more directly related to the toolpath such as describing its boundary shape. The different applications and uses for these 2D items mean that organization of them is very important. For this reason Cut2D Laser Desktop has a Layer function for managing 2D data. The Layers are a way of associating different 2D entities together to allow the user to manage them more effectively. Layers will be described in detail later in the relevant section of this manual. If you are working with a 2 Sided project you can switch between the 'Top' and 'Bottom' sides in the same session, enabling you to create and edit data on each side, and using the 'Multi Sided View' option you can view the vectors on the opposite side. 2 Sided Setup will be described in detail later in the relevant section of this manual.

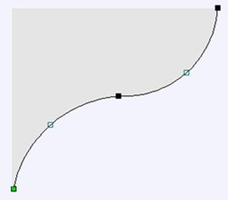

Vectors

Vectors are lines, arcs and curves which can be as simple as a straight line or can make up complex 2D designs. They have many uses in Cut2D Laser Desktop, such as describing a shape for a toolpath to follow or being a controlling 2D shape for use with one of the 3D modeling functions such as the 2 Rail Sweep. Cut2D Laser Desktop contains a number of vector creation and editing tools which are covered in this manual.

As well as creating vectors within the software many users will also import vectors from other design software such as Corel Draw or AutoCAD. Cut2D Laser Desktop supports the following vector formats for import: *.dxf, *.eps, *.ai, *.pdf, *skp and *svg. Once imported, the data can be edited and combined using the Vector Editing tools within the software.

Bitmaps

Although bitmap is a standard computer term for a pixel based image (such as a photo) in *.bmp, *.jpg, *.gif, *.tif, *.png and *.jpeg. These file types are images made up of tiny squares (pixels) which represent a scanned picture, digital photo or perhaps an image taken from the internet.

To make 3D models simple to create, Cut2D Laser Desktop uses a method which lets the user break the design down into manageable pieces called Components. In the 2D View a Component is shown as a Grayscale shape, this can be selected and edited to move its position, change its size etc. Working with the Grayscale's will be covered in detail later in this manual. As with bitmaps, many of the vector editing tools will also work on a selected Component Grayscale.

Vectors

Vectors have two very important uses:

- To describe the shape/boundary/direction of a toolpath

- To control 3D shapes created using the icons under the Modeling Tools

As they are such an important part of two of the fundamental areas of the software there are a lot of tools to create, edit and manage them. In this section all these tools and vectors options will be briefly described. For practical examples of these tools you should review the tutorial videos.

Vector Import

Decorative vector designs and shapes will often be imported from another drawing package such as Corel Draw, AutoCAD etc.

rather than being completely drawn in Cut2D Laser Desktop.

The Vector Import icon ![]() is located in the File Operations area of the Drawing Tab.

Once a vector has been imported then the imported vector shape(s) can be modified, moved, scaled, rotated, mirrored or deleted the same as vectors created within the software.

is located in the File Operations area of the Drawing Tab.

Once a vector has been imported then the imported vector shape(s) can be modified, moved, scaled, rotated, mirrored or deleted the same as vectors created within the software.

The following Vector file formats can imported

SVG |

SVG files are two dimensional vector graphics which can be created within Vectric software but also from other CAD packages such as Inkscape or Adobe Illustrator. If you open this file type from File ► Open, this will automatically import the vectors and open up the Job Setup Form. If opened from the File ► Import ► Import Vectors, this will import the vectors directly into the current job. |

DXF and DWG |

Files from other CAD or graphics software packages such as AutoCAD will be opened in the original size and position. The Job Setup Form is automatically opened showing the maximum X and Y dimensions of the opened design. The actual size of the material can then be specified along with the required thickness and appropriate X0, Y0 and Z0 origins. |

EPS |

Files from typical design software such as Corel Draw can be opened. The Job Setup form will automatically be opened so the required material size can be specified. By default the EPS file will be placed with the lower left corner of the design at X0, Y0. |

AI |

Files from typical design software such as Adobe Illustrator and Corel Draw can be opened. The Job Setup form will automatically be opened so the required material size can be specified. The AI file will be placed with the lower left corner of the design at X0, Y0 |

|

Software such as the Adobe product range can be used to convert files from other design and word processing software into the industry standard PDF file format. The text and vector content of PDF files is extracted when imported into Cut2D Laser Desktop. When importing multiple page PDF documents each page is placed on a separate layer. |

While every endeavor is made to keep up with other software companies' changes in their file format it is possible that files in the above formats may not always be readable in Cut2D Laser Desktop. In that case going back to the original design systems and saving the file in an earlier version may enable it to be loaded into Cut2D Laser Desktop. In addition Cut2D Laser Desktop may not support the import of special entities such as dimensions, hatching, text, numbers etc. from some vector file types. It may be possible to adjust the formatting for these objects in their original design program. This is often done using a command called Convert to Curves. This will change this type of data to regular vectors that can then be exported in a compatible format for import.

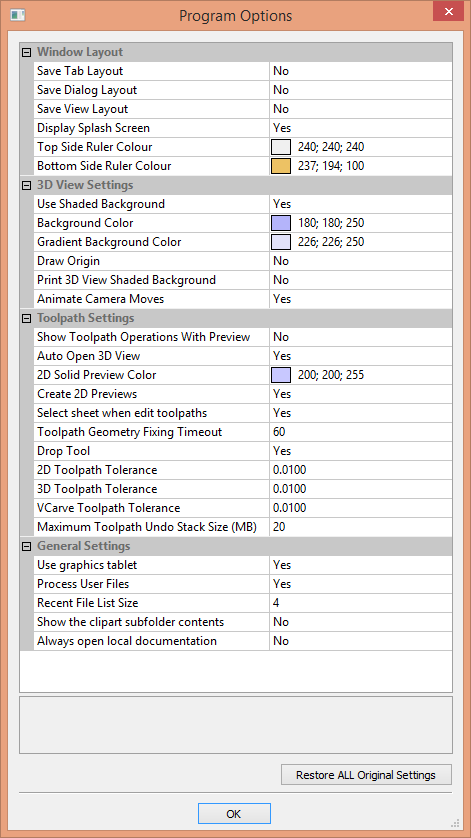

Program Options

The options fall into four categories:

The options fall into four categories:

Window Layout

| Save Tab Layout | Save the layout and the 'pinned' state of the command and toolpath fly out tabs. |

| Save Dialog Layout | Save the size, position and visibility for dialogs such as the Layer control and Toolpath Control dialogs. |

| Save View Layout | Save the layout of the 2D and 3D view windows. |

| Display Splash Screen | Display the program Splash Screen, while the program is loading. |

| Top Side Ruler Color | The colour of the ruler on the top side in a two-sided project. |

| Bottom Side Ruler Color | The colour of the ruler on the bottom side in a two-sided project. |

Toolpath Settings

| Show Toolpath Operations with Preview | When the toolpath Preview form is visible, keep the 'Toolpath Operations' section visible (requires more screen space). |

| Auto Open 3D view | Automatically swap to 3D view after calculating a toolpath. |

| 2D Solid Preview Color | Color used to draw the solid 2D toolpath preview with. |

| Create 2D Previews | Create 2D previews of toolpaths in 2D view. |

| Select Sheet When Edit Toolpaths | If a toolpath is associated with a sheet, select sheet when edit toolpath |

| Toolpath Geometry Fixing Timeout | Number of seconds the program will spend trying to fix problems with geometry when calculating toolpaths. |

| Drop Tool | When projecting a toolpath onto the model, drop the tool on surface rather than project. If this is set, the toolpath will follow the surface of the model better, but could be slower to calculate. |

| 2D Toolpath Tolerance | Tolerance to apply to 2D toolpaths after calculating to reduce file size. |

| 3D Toolpath Tolerance | Tolerance to apply to 3D toolpaths after calculating to reduce file size. |

| VCarve Toolpath Tolerance |

Tolerance to apply to VCarve toolpaths after calculating to reduce file size.

Note: We strongly recommend that the Toolpath Tolerance should be

left at their default settings unless different values are recommended by your machine tool manufacturer.

If you do have a machine which struggles with the default settings, try doubling the values and cutting

a test-piece to assess the tradeoff between machining times, file size and final machined quality.

We have done some limited testing and on a sample complex 3D model, increasing the '3D Toolpath Tolerance'

to 0.001 inches gave a 40% decrease in file size and no noticeable difference in quality on the test machine

and job. In the test case there was no measurable difference in machining time on the CNC machine

the test was carried out on.

|

| Maximum Toolpath Undo Stack Size (MB) | Maximum size in MB of Toolpath data undo stack for storing toolpath delete state. |

General Settings

| Use Graphics tablet | Switch on support for graphics tablet drivers, if installed - for use with the sculpting tool. |

| Process User Files | Enable/disable processing of files in the 'Vectric Files' folder in your common user document folder. |

| Recent File List Size | This sets the maximum number of items that will be displayed in the Recently opened files... list in left hand side bar of the interface when there is no file currently loaded. The list will not increase in size until the software has been re-started and more files have been opened and/or saved. |

| Show the clipart Subfolder Contents | If set to Yes then this will show the contents within the selected Folder in the Clip Art browser along with up to 3 sub-folders if they exist and contain appropriate file types. If set to No it will only display the contents of the selected folder, not sub-folders. |

| Always open local documentation | Force open the local copy of the documentation when accessed through the Help menu. Cut2D Laser Desktop automatically opens the local documentation if you have no internet connection or if the server is taking too long to respond. |

Rulers, Guide Lines and Snapping

To help with drawing, construction and layout, the 2D View has Rulers which are displayed along the top and down the left side of the window. In addition to the Rulers there is the option to use Guidelines and The Smart Cursor to help with construction of vectors or positioning of other objects in the 2D View.

Rulers↓

The Rulers are permanently displayed in the 2D view to help with positioning, sizing and alignment. The graduated scale automatically uses the units set for the project and zooming in / out shows the sizes in 10ths.

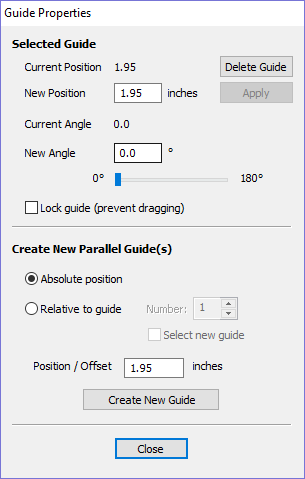

←Guidelines

Guide Lines are used to help layout designs and make it very easy to sketch shapes by clicking on the intersections of Guides. Guide Lines are easily be added to the 2D view by pressing the left mouse button down on the appropriate ruler (left if you want a vertical guide and top if you want a horizontal guide) then holding the button down and dragging the mouse into the 2D view.

While dragging a Guide into position it automatically Snaps to the units displayed on the ruler. This snapping behavior can be overridden by holding down a Shift key while dragging the guide. After positioning a Guide it can easily be moved to a new position by clicking the right mouse button on the guide to open the Guide Properties form as shown later in this section. If you hover the mouse over a Guideline then its current position is displayed next to the cursor

Additional guide lines can be added relative to an existing guide line by interactively placing the cursor over an existing guide (the cursor changes to 2 horizontal arrows), Holding a Ctrl key and dragging to the required position. The incremental distance between the guide lines is displayed next to the cursor. Releasing a Ctrl key changes to display the absolute distance from the material origin.

Guides can also be added and other edits made by right clicking on the Guideline which will bring up the Guide Properties form:

The exact position can be specified by entering a New Position.

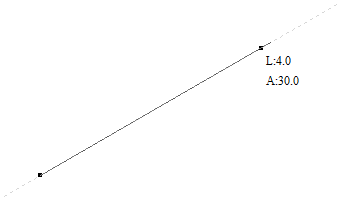

Guides can be given an angle by either entering an angle into the New Angle box or dragging the slider and clicking . Angles are measured in degrees counterclockwise from the x-axis. From an angled guide you can only create relative parallel guides.

Guide lines can be locked in position to stop them from being inadvertently moved by ticking the Lock Guide option.

Additional Guide Lines can be added that are positioned using absolute or incremental coordinates. Enter the Absolute or relative positions and Click .

Guides can quickly be toggled visible / invisible by clicking in the Top Left Corner of the 2D view:

Alternatively the visibility can be changed using View Menu ► Guide Lines from the Main Menu. Guide Lines can be Deleted by selecting View Menu ► Guide Lines ► Delete All Guides from the Main Menu. Individual Guide Lines can be deleted by clicking and dragging them out of the 2D View Window.

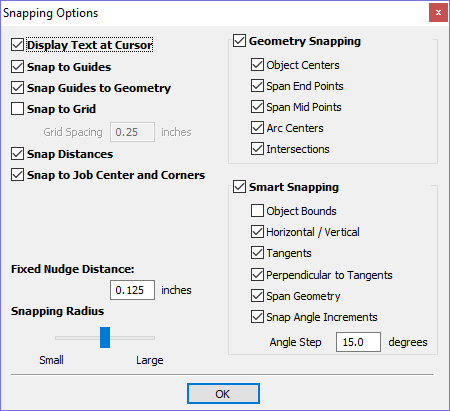

Snapping Options

These options can be used to help create and edit vector geometry.

The Snapping Options form can be accessed by selecting Edit ► Snap Options from the Main Menu or by pressing F4.

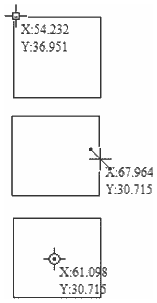

Display Text at Cursor

Displays the XY coordinates on the cursor making it easy to see the position for each point

Snap to Guides

When this option is checked ✓ drawing and positioning vectors will snap onto any horizontal or vertical guide lines visible in the 2D view.

Snap Guides to Geometry

When checked, ✓ the Guide Lines can snap to Geometry while being dragged.

Snap to Grid

Displays a grid of points separated by the Grid Spacing which can be snapped to when drawing or editing vectors and other objects in the 2D View.

Snap Distances

Snap to fixed lengths based on your zoom level. This occurs when creating shapes, dragging nodes or vectors.

Snap to Job Center and Corners

Snap to the job corners and center. This, also, control the job smart snapping.

Fixed Nudge Distance

Objects can be moved small, fixed distances (nudged) by holding Ctrl+Shift and tapping the arrow keys. The Fixed Nudge Distance specifies the distance to move selected objects with each nudge.

Snapping Radius

The snap radius (pixels) will adjust how close the cursor must get to vector geometry in order to snap it. If you work quickly and grab and throw geometry at speed, you may prefer a larger Snapping Radius to pick up geometry that is vaguely near the mouse. If you work precisely or have complex overlapping geometry, you may prefer a smaller Snapping Radius to avoid having to zoom in to select one geometry in an area that has many nearby vectors.

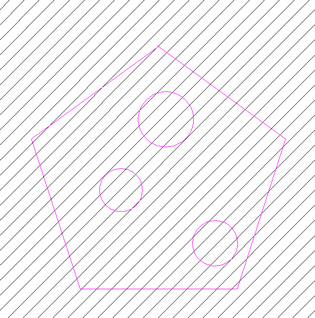

Geometry Snapping

Used to control the position at which the cursor will snap when drawing and moving objects. When drawing, the cursor will snap to items on vector geometry depending what options you have selected in the form under this section.

Object centers, Span End points, Span Mid-points, Arc centers, intersections Horizontally, Vertically and the specified Angle and Distance Guide lines and the intersection of Guides

Snap to Nodes, mid-points, centers

Snap to Guides, matching horizontal and

vertical points, plus angle and distance

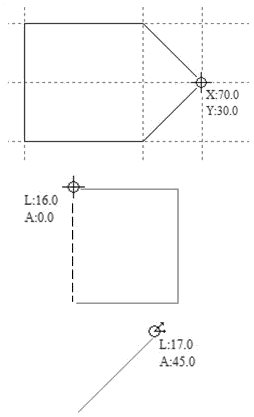

Smart Snapping

Smart snapping works by snapping the cursor to imaginary lines related to vectors and/or nodes. These lines will appear as dashed, and sometimes coloured, lines that go through the vector or node and the cursor point. You can snap to the intersection of those lines by hovering over the nodes that you're interested in. This reduces the need to create construction geometry (for example, for aligning nodes or vectors), and can be used in almost all the shape creation tools, node editing and transforming vectors.

Snapping lines can be drawn from:

- Nodes that were woken up by hovering the mouse over them or their span

- Vector properties, such as their bounding box or center point

- Material properties, such as extensions from the edge and the middle

| Cursor | Type | Color | Description |

|---|---|---|---|

|

Object Bounds | The theoretical bounding box surrounding the active vector |

|

|

Horizontal and Vertical Lines |

Horizontal and vertical lines passing through a node or a span midpoint. |

|

|

Tangents | Tangents originating from a node or a span midpoint. |

|

|

Perpendicular to Tangents | Lines which are perpendicular to tangents from nodes or span midpoints. |

|

|

Connecting Lines | Lines connecting two nodes. Includes mid-point |

|

|

Span Geometry | (No line) | Snap to the geometry of the vector |

|

Angular Constraints | Snapping to specific angles, as defined in the snap options F4 |

|

|

Job | Horizontal and vertical lines through the center of the job. |

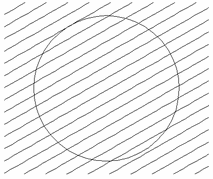

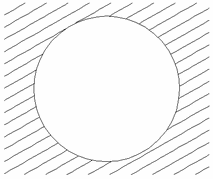

Object Bounds

These snap lines appear on the bounding box edges of the vector, and in the middle horizontally and vertically.

Bounding Box

Object Centre

Vertical and Horizontal Lines

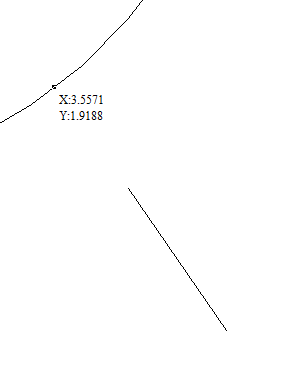

- Nodes

- The snap lines appear when the cursor is near the horizontal or vertical line passing through the woken nodes.

- Vectors

- Snap lines become available while moving vectors so that it is used for aligning them with other vectors.

Vertical

Horizontal

Tangents

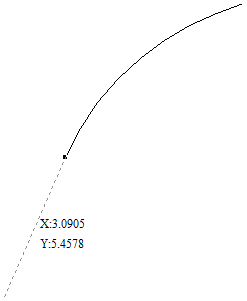

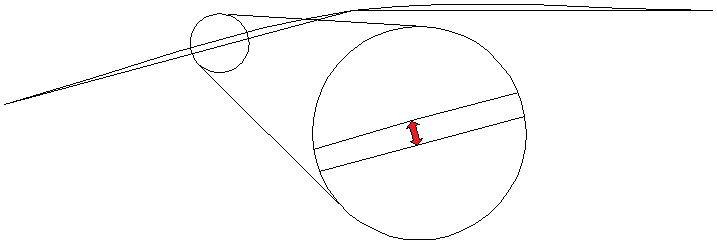

These snap lines originate from the woken node and will appear as an extension along the end of the belonging span.

Tangent

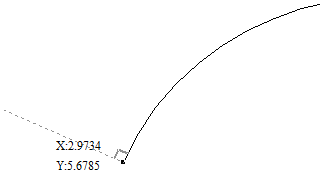

Perpendicular to Tangents

These snap lines will be 90° from the tangent snap line, and they both

Perpendicular

Connecting Lines

If you wake two or more nodes, you could snap to the line connecting them. You could, also, snap to the mid-point of that line.

Connecting Lines

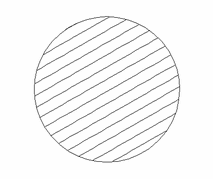

Span Geometry

This allows you to snap to the geometry of the vectors.

Span geometry

Angular Constraints

Angular Constraints eg. 30° (Angle step 15°)

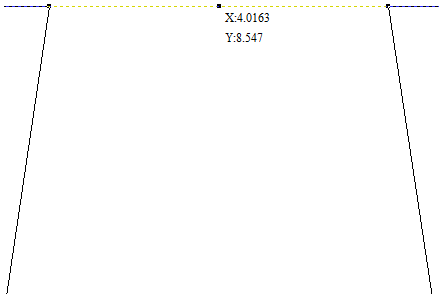

Job Edges & Centre

If you have the job snapping enabled, you could snap to the horizontal and vertical middle lines. This, also, includes the lines extending from the job's edges.

Job Center

Toolbar Snapping Options

Geometry Snapping, Smart Snapping and Grid Snapping can be switched on and off from the View Toolbar

Any change to the snap settings F4, through the Main Menu, or the toggles on View Toolbar will be remembered for subsequent sessions.

Snapping can be temporarily disabled by holding down the Shift key.

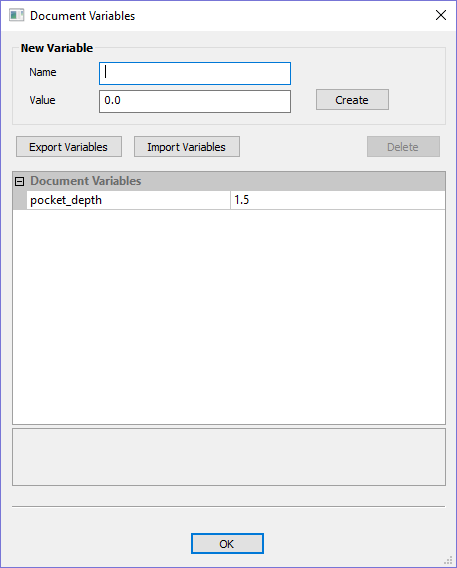

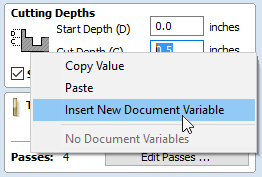

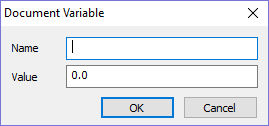

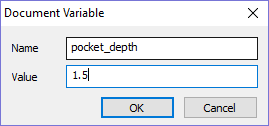

Document Variables

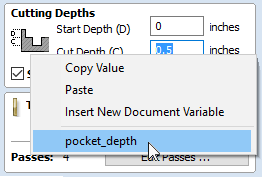

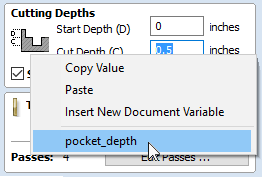

Document Variables provide a mechanism for defining values that can be used in Cut2D Laser Desktop's Document Variables. They can either be created in the Document Variables dialog (right) which is accessible under the Edit menu, or created from any Calculation Edit Box which supports variables by right clicking and selecting Insert New Document Variable from the Popup Menu.

Naming Document Variables

Right-click an edit-box to insert a new or existing Document Variable:

New Document Variable names must begin with a letter and then may consist of letter, number and underscore characters. Once created, they may be edited in the table beneath the New Variable section fo the Document Variables Dialog.

Variables can be exported to a text file and imported into another job. When importing, any existing variable values with the same name will be replaced.

Deleting Document Variables

Variables may be deleted if they're not being used in any toolpath calculations but only when there are no toolpath creation forms open.

Using Document Variables

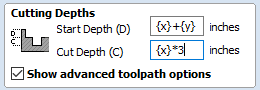

Once created a Document Variable may be used in any Calculation Edit Box by enclosing its name within a pair of curly braces as illustrated in the figure below.

Right clicking in a Calculation Edit Box provides a Popup Menu that provides shortcuts for creating new Variables and inserting existing variables into the Edit Box.

Once a Document Variable has been created from the Popup Menu it will be inserted into the Edit Box.

Accessing Document Variables

Declared Document Variables can be easily accessed from a calculation edit box. Right-click on the calculation edit box and you will be presented with a menu showing the document variables available currently, as well as an option to quickly insert a new document variable.

Calculation Edit Boxes

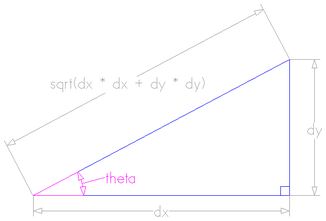

Numerical edit boxes generally support simple calculations.

A sum can be entered directly into the edit box:

Having typed an equation, pressing the = key will perform the entered calculation and fill the edit box with the answer.

Special Calculation Characters

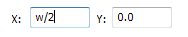

As well as the simple numerical calculations, such as 3+(4/5), several of Cut2D Laser Desktop's stored values can be accessed by using certain letters (which are not case-sensitive): When used, Cut2D Laser Desktop substitutes the character with the appropriate value in the calculation.

Character |

Name |

Example |

Description |

|---|---|---|---|

W or X |

Material Width |

w/2= |

Half of the material width |

H or Y |

Material Height |

H*2= |

Twice the height of the material |

T or Z |

Material Thickness |

t-0.25= |

0.25 units less than the material thickness |

P |

PI (3.141593) |

P*10^2= |

Area of a 10 radius circle (π.r2) |

I |

Imperial Conversion |

25.4*i= |

Converts 25.4mm to inches |

M |

Metric Conversion |

2*M= |

Converts 2 inches to millimetres |

' |

Feet |

2'+10= |

34 inches (2 feet and 10 inches) |

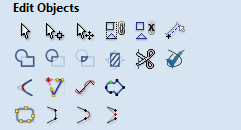

The Drawing Tab

Cut2D Laser Desktop includes drawing and editing tools that allow designs to be created and modified, which can ultimately be used directly for toolpath creation.

Commands for vector creation and editing are very easy to use and multiple design elements can also be drawn or imported, scaled, positioned and interactively edited to make a new design.

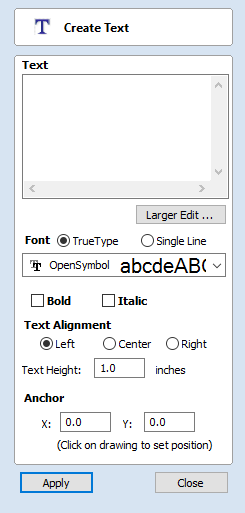

Text can also be created using any TrueType or OpenType fonts installed on your computer, or the single stroke engraving fonts supplied with the software.

File Operations

Click on an icon to learn more about it:

| File Operations | |||||

New, Open and Save

|

Create a New File |

This option opens the Job Setup form (below), which is used to create a new blank job of the width (X), height (Y), and thickness (Z) required. The relative origins for X0, Y0 and Z0 are also specified at this point, and the measurement units can be set in either inches or metric. The Modeling Resolution and default 3D shading color/material can also be set at this stage. |

|

Open a File |

This option opens the File Open dialog window, allowing Cut2D Laser Desktop files (CRV) and importable 2D vector files to be selected and opened. |

|

Save a File |

This option opens the File Save As dialog window and allows the job to be saved as a Cut2D Laser Desktop file. Navigate to the required folder, enter a suitable name for the job and click the Save button. |

|

Import Vectors |

This opens the File Open dialog window and allows 2D DXF, EPS and AI and PDF files to be imported into the 2D View. The imported vectors will always be read in at the size and scale they were created in their original design software. Once open they can be scaled and edited in the same way as vectors created in Cut2D Laser Desktop. All the Vector tools will be dealt with in that section of this manual. To import toolpaths from PhotoVCarve and Cut3D (.PVC and .V3D file extensions), use File ► Import... ► Import PhotoVCarve or Cut3D Toolpaths from the main menu bar. Any Toolpath data saved as .PVC or .V3D files can be imported and will be visible in the Toolpath List. |

|

Import Bitmap |

This opens the File Open dialog window and allows image files to be selected and imported into the current open job. File types - BMP, JPG, TIF, GIF, PNG Images are imported to sketch vectors over the top of them, generate traced vectors. |

File Types

CRV |

Files previously created and saved in Cut2D Laser Desktop will be opened and displayed in the 2D Design window. All calculated toolpaths are stored/opened from the CRV file. |

DXF |

Files from other CAD or graphics software packages such as AutoCAD will be opened in the original size and position. The Job Setup Form is automatically opened showing the maximum X and Y dimensions of the opened design. The actual size of the material can then be specified along with the required thickness and appropriate X0, Y0 and Z0 origins. |

EPS |

Files from typical design software such as Corel Draw can be opened. The Job Setup form will automatically be opened so the required material size can be specified. By default the EPS file will be placed with the lower left corner of the design at X0, Y0. |

AI |

Files from typical design software such as Adobe Illustrator and Corel Draw can be opened. The Job Setup form will automatically be opened so the required material size can be specified. The AI file will be placed with the lower left corner of the design at X0, Y0 |

|

Software such as the Adobe product range can be used to convert files from other design and word processing software into the industry standard PDF file format. The text and vector content of PDF files is extracted when imported into Cut2D Laser Desktop. When importing multiple page PDF documents each page is placed on a separate layer. |

|

SKP |

SketchUp files with a .SKP extension (see www.sketchup.com) can be imported as 2D data suitable for machining. |

SketchUp Files

SketchUp files with a .SKP extension (see www.sketchup.com) can be imported as 2D data suitable for machining into a Cut2D Laser Desktop job using the File ► Import Vectors... command from the menu bar or the import vectors ![]() icon on the Drawing tab.

To import data from a SketchUp file you must already have created or opened a job to import the data into.

icon on the Drawing tab.

To import data from a SketchUp file you must already have created or opened a job to import the data into.

As a SketchUp model is usually a 3D representation of the part, the SketchUp importer offers a number of options to allow you to start manufacturing the model.

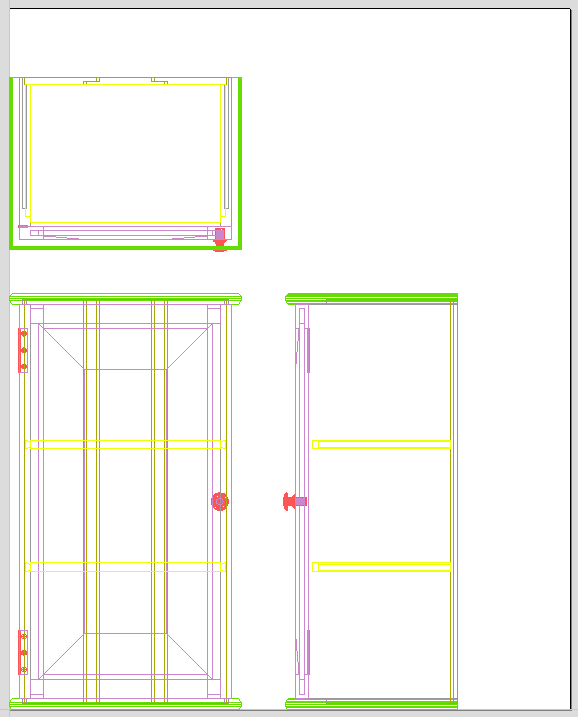

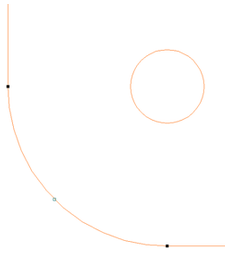

We will illustrate the two main choices for how the model will be imported using the SketchUp model shown to the left.

The model shown in the screenshots is a cabinet constructed by following the instructions in the Fine Woodworking 'Google SketchUp guide for Woodworkers: The Basics' DVD which is available via the Fine Woodworking site at www.finewoodworking.com. Vectric have no affiliation with Fine Woodworking, we are just using screenshots of the model constructed while following their tutorials to illustrate the process of importing a SketchUp model.

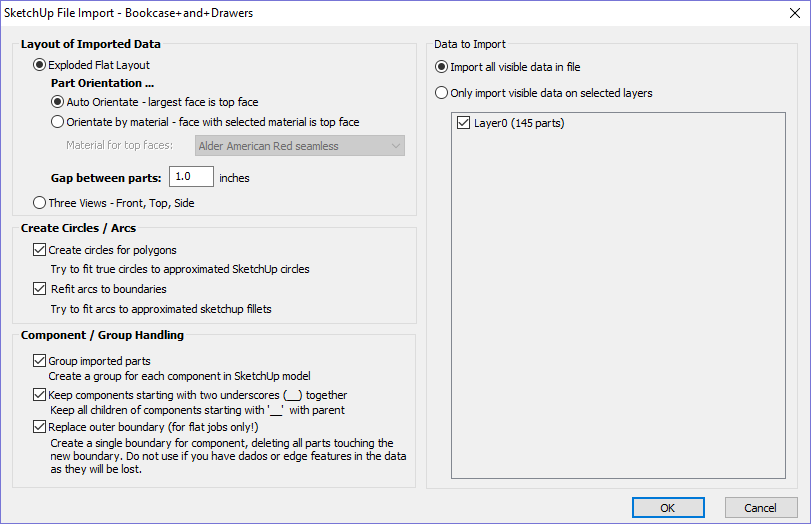

When the SketchUp model is selected from the File Import dialog, the following dialog will be displayed.

Although this initially looks complex, the dialog is divided into four logical sections which will be describe below.

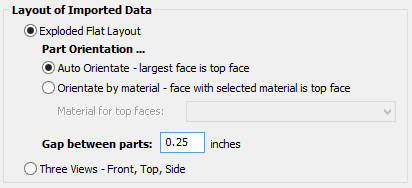

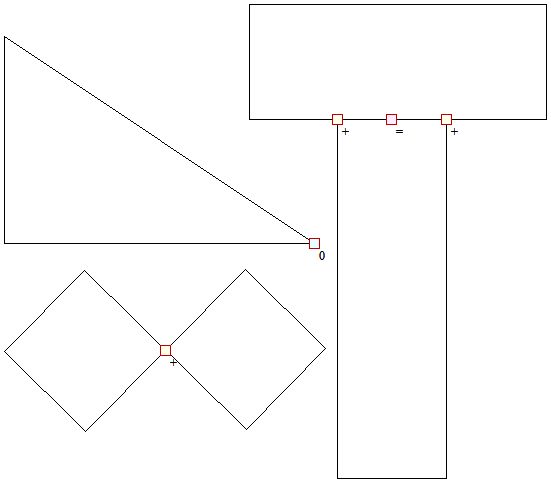

Layout of Imported Data

In the first section there are two main choices for how the data from the model will be imported, 'Exploded Flat Layout' and 'Three Views - Front, Top, Side' as shown below.

We will describe the 'Three Views - Front, Top, Side' option first as it is the simplest.

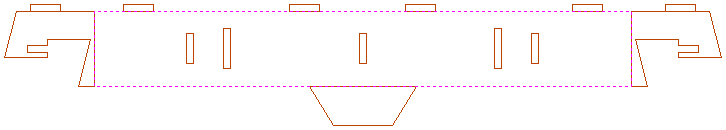

Three Views - Front, Top, Side

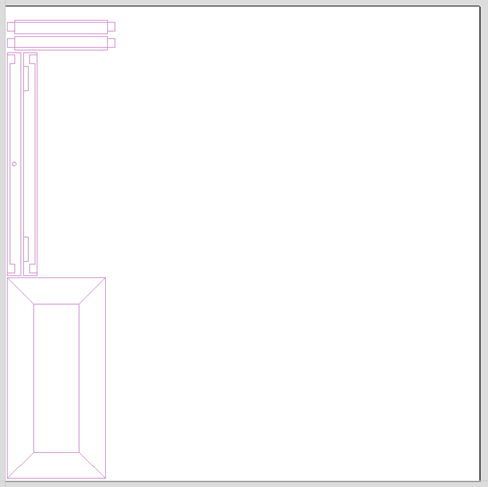

This option will create an 'engineering drawing' style layout of the SketchUp model as shown in the screenshot below.

The size of the model is preserved and it is relatively simple to pick up dimensions for parts you are going to manufacture from the various views. The colors of the lines you see are taken from the colors of the original SketchUp layers the various parts of the model are on.

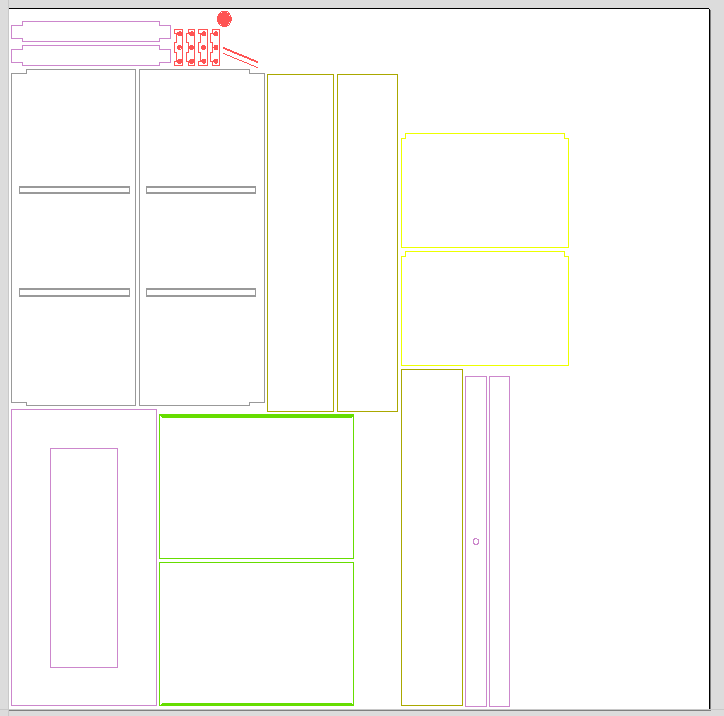

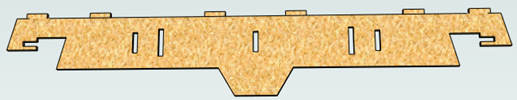

Exploded Flat Layout

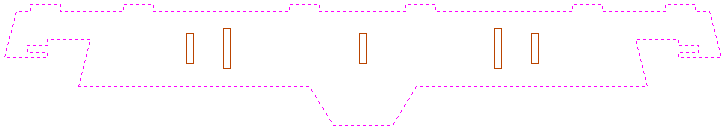

This option will take each component in the model and orientate it flat ready for machining as shown in the screenshot below.

Once this option is selected a number of sub-options also become available.

Part Orientation

This section controls what Cut2D Laser Desktop considers to be the 'top' face of each part.

Auto Orientate

If this option is selected, for each part in the model, the 'face' with the largest area based on its outer perimeter (i.e. ignoring holes etc.) is considered to be the 'top' face and the part is automatically rotated so that this face is facing upwards in Z. This strategy works very well for models which are to be manufactured from sheet goods where there are no features on particular faces which need to be on the 'top' (such as pockets).

Orientate by material

This option allows the user to control more explicitly the orientation of each part in the model. Within SketchUp the user can 'paint' the face of each component/group with a material/color of their choice to indicate which face will be orientated on top when the model is imported. When this option is selected simply chose the material which has been used to indicate the top face from the drop down list. If a part is found in the model which does not have a face with the specified material, that part will be oriented by making the largest face the top.

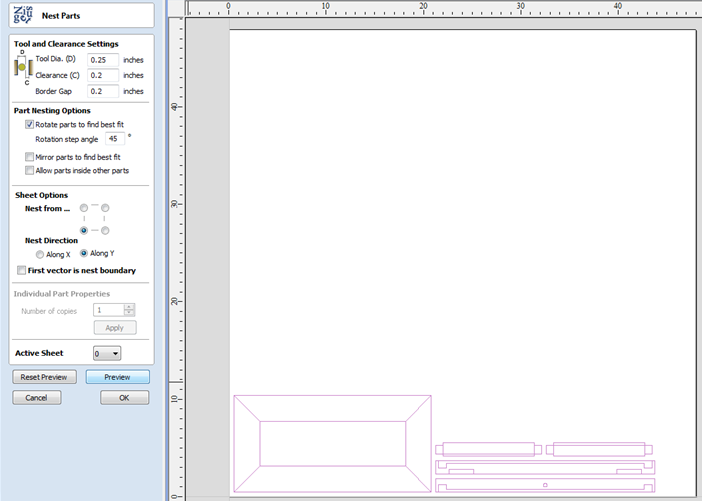

Gap between parts

This field lets the user specify the gap between parts when they are first imported. After importing, the nesting functions within Cut2D Laser Desktop can be used to layout the parts with more control and across multiple sheets.

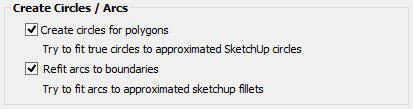

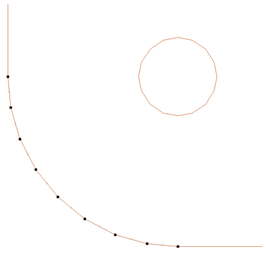

Create Circles / Arcs

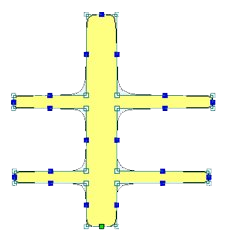

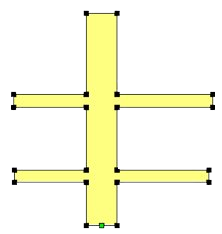

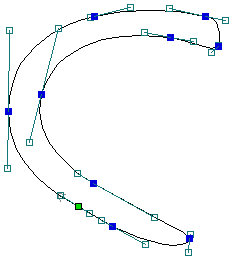

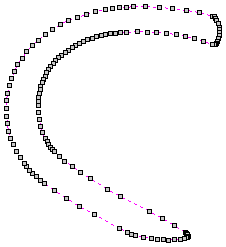

SketchUp does not maintain true arc or circle information for the boundaries of its parts. This is a problem when it comes to machining as the 'polygonal' SketchUp representation can give very poor machining results. For this reason, Cut2D Laser Desktop offers the option to refit circles and arcs to imported data.

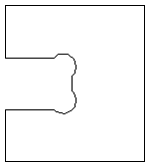

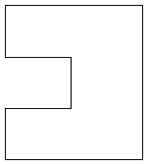

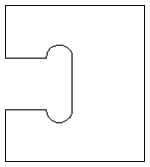

Options Checked ✓

Options Unchecked

The screenshot above left shows the results of importing a part with a filleted corner and hole with these options unchecked. The 'fillet' is made up of a series of straight line segments and the circular 'hole' is actually a polygon made up of straight lines.

The screen shot above right shows the same part imported with both these options checked ✓. The 'fillet' now consists of a single smooth arc and the circular 'hole' now also consists of arcs rather than straight line segments. Both these features will machine more cleanly in this form.

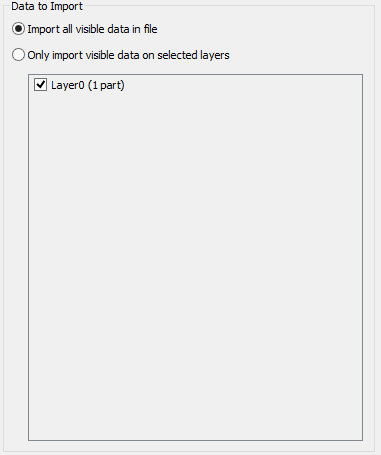

Data to Import

A SketchUp model will often contain parts that you do not wish to machine (such as hinges, knobs etc.) or data which will be cut from different thicknesses of material and hence different parts need to be imported into different Cut2D Laser Desktop jobs. To allow control over what is imported you can choose to only import parts of the model which are on particular layers using this section of the dialog.

To only import data from selected layers, choose the 'import visible data on selected layers' option and click the check box next to each layer to indicate if you want to import data from that layer. Note that the number of parts on each layer is displayed next to the layer name.

It is very easy to assign different parts of the model to different layers within SketchUp to help with the import process into Cut2D Laser Desktop. The screenshot below shows the result of only importing data on the 'Door' layer from the example.

As long as the 'Group imported parts' option is selected, these parts can then be easily nested ready for machining as shown in the image below (the 'Group imported parts' option is explained later in this section).

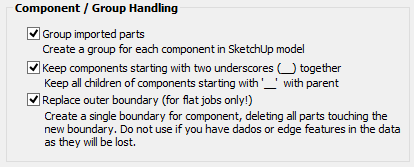

Component / Group Handling

This section of the form allows advanced handling of how 'parts' within the SketchUp model are identified and treated on import.

Group imported parts

This option is normally selected for all but the simplest models as it allows each 'part' of the model to be selected, moved and nested easily after import. You will need to ungroup the imported data after nesting etc. to allow individual features to be machined. By default, Cut2D Laser Desktop will treat each SketchUp group / component as a single part UNLESS it contains other groups or components within it, in which case each lowest level group / component will be treated as a separate part.

Items which you retain in groups can be ungrouped at any time in the usual ways.

If the right-click menu-option to Ungroup back onto original object layers is used (which is the default option when using the icon or shortcut U) then the software will place the ungrouped items back onto the original layers they were created on in SketchUp.

Keep components starting with two underscores (__) together

If you have a complex model which contain 'parts' which are made up of other groups / components, you will need to do some work on your model to identify these parts for Cut2D Laser Desktop. The way this is done is by setting the name of the groups / components that you wish to be treated as a single part to start with__ (two underscore characters). For example, if you had a model of a car and you wanted the wheels / tires / hub nuts to be treated as a single part even though the Tire, Wheel and other parts were separate components, you would group the parts together and name them something like __WheelAssembly in SketchUp. When this model was imported, and Cut2D Laser Desktop reached the group/component with a name starting with __ it would treat all subsequent child objects of that object as being the same part.

Replace outer boundary (for flat jobs only!)

There is a style of 'building' with SketchUp where individual 'parts' are made up of several components 'butted' against each other. The screenshot below shows such a component.

This object is made up of many smaller components representing the tabs on the top, the connectors at the end and the support at the bottom as shown below.

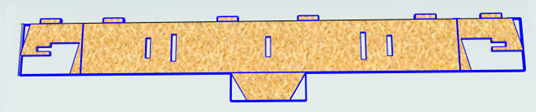

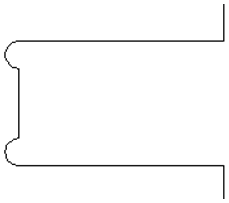

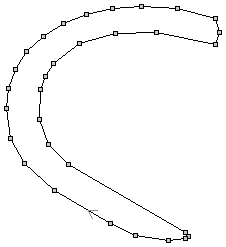

Although when can treat this as a single 'part' when imported by starting its name with __ (two underscores), the imported part is still going to be difficult to machine. The screenshot below shows the part imported into Cut2D Laser Desktop without the 'Replace outer boundary' option checked ✓. The part in the image has been ungrouped and the central vector selected.

As you can see, the outer boundary is made up of separate segments for each 'feature'. Cut2D Laser Desktop does have the ability to create an outer boundary for vectors but this can be time consuming if it has to be done manually. If the 'Replace outer boundary' option is checked, ✓ for every part Cut2D Laser Desktop will try to create a single outer boundary and delete all the vectors which were part of this boundary. The screenshot below shows the result of importing the same data with this option checked, ✓ this time the part has been ungrouped and the outer vector selected.

This data is now ready to be machined directly. It is important to understand the limitations of this option. It can be substantially slower. Creating robust boundaries for each part can consume a lot of processing power. Any feature which shares an edge with the boundary will be deleted. If the tabs on the top of this part were to have been machined 'thinner', this approach would not have been suitable as the bottom edge of the tabs has been removed.

The new features will help a lot of SketchUp users dramatically reduce the time it takes to go from a SketchUp design to a machinable part using Cut2D Laser Desktop.

It is important to understand though that while these options provide a useful set of tools, in many cases there will still be additional editing required to ensure the part is ready to toolpath.

Understanding the options and how they work will allow the part to be designed in SketchUp with these in mind and therefore help to minimize the time to machine once the data is imported.

Cut, Copy and Paste

The Cut, Copy and Paste functions in Cut2D Laser Desktop can be used on

|

Cut |

The Cut tool removes the selected objects from a design in a similar way to pressing the Delete key, but the selected objects are copied to the clipboard and can be Pasted into either the current file or a new file if required. Only one item can be Cut or Copied at a time. |

|

Copy |

The Copy tool copies selected objects to the clipboard, leaving the original in place and allows duplicates to be made and re-used in the design by pressing the Paste icon. Only one item can be Cut or Copied at a time. |

|

Paste |

This Paste option places the contents of the clipboard (created by Cut or Copy) into the design, allowing elements to be re-used in different areas of a design or in other Cut2D Laser Desktop parts. |

|

Undo |

Clicking this option steps backwards through the design changes made by the user. |

|

Redo |

Clicking this option steps forward through design steps that have been Undone using the Undo command (see above) to get back to stage that the user started using the Undo function. |

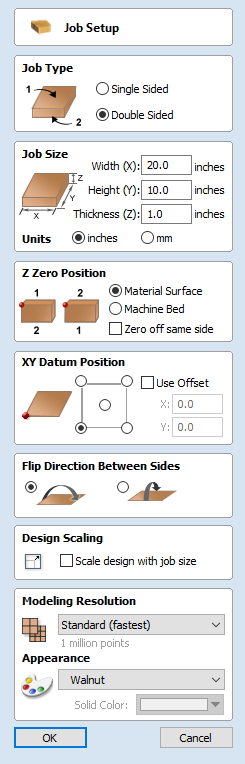

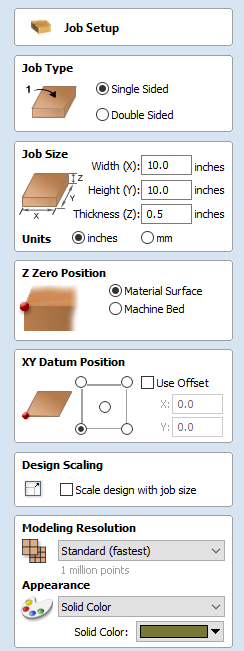

Job Setup

The Job Setup form is displayed whenever a new job is being created, or when the size and position of an existing job is edited.

Job Type

Select Single Sided if your design only requires the material to be cut from one side. This is the simplest type of job to design and machine.

If your design requires you to cut both sides of your material then Cut2D Laser Desktop also allows you to visualise and manage the creation and cutting process of both sides of your design within a single project file. Select Double Sided if you need this additional functionality.

Job Size

This section of the form defines the dimensions of the material block you will be using for your project in terms of width (along the X axis), height (along the Y axis) and thickness (along the Z axis).

It also allows you to select which units of measurement you prefer to design in - either inches (Imperial/English) or millimeters (Metric).

Height

The material length along the Y axis

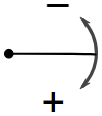

Z Zero Position

Indicates whether the tip of the tool is set off the surface of the material (as shown in the diagram) or off the bed / table of the machine for Z = 0.0.

XY Datum Position

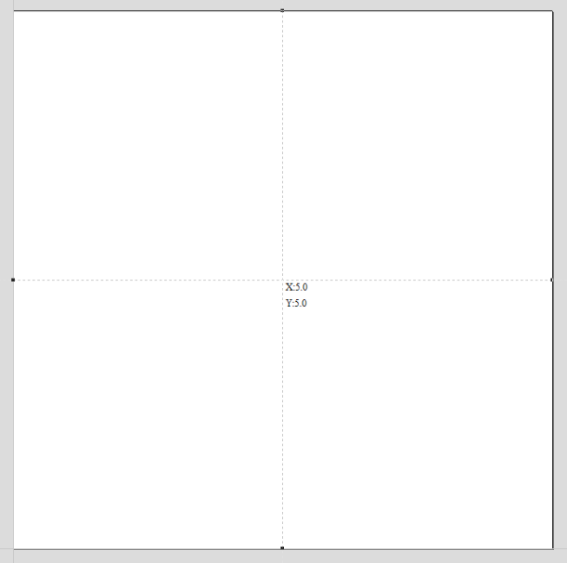

This datum can be set at any corner, or the middle of the job. This represents the location, relative to your design, that will match the machine tool when it is positioned at X0, Y0. While this form is open, a red square is drawn in the 2d view to highlight the datum's position.

Use Offset

This option allows the datum position to be set to a value other than X0, Y0.

Design Scaling

When editing the Job Size parameters of an existing job, this option determines whether any drawings you have already created will be scaled proportionally to match the new job dimensions. If you wish to preserve the existing size of your drawings, even after the job size has changed, leave this option unchecked. With this option checked, your drawings will be re-sized to remain in the same proportion and relative position within your new material extents when you click .

Modeling Resolution

This sets the resolution/quality for the 3D model. When working with 3D models a lot of calculation and memory may be required for certain operations. Setting the Resolution allows you to choose the best balance of quality and speed for the part you are working on. The better the resolution quality chosen, the slower the computer will perform.

As this is completely dependent on the particular part you are working on and your computer hardware performance, it is difficult in a document like this to recommend what the setting should be. Generally speaking, the Standard (fastest) setting will be acceptable for the majority of parts that Cut2D Laser Desktop users make. If the part you are making is going to be relatively large (over 18 inches) but still has small details, you may want to choose a higher Resolution such as High (3 x slower) and for very large parts (over 48 inches) with small details then the Highest (7 x slower) setting may be appropriate.

The reason that the detail of your part needs to be taken into account is that if you were making a part with one large item in it (e.g. a fish) then the standard resolution would be OK but if it was a part with many detailed items in it (e.g. a school of fish) then the High or Highest setting would be better. As previously stated these are extremely general guidelines as on slower/older computers operations with the highest setting may take a long time to calculate.

As the Resolution is applied across your whole work area it is important to set the size of your part to just be big enough to contain the part you plan to carve. It would not be advisable to set your material to be the size of your machine - e.g. 96 x 48 if the part you plan to cut is only 12 x 12 as this would make the resolution in the 12 x 12 area very low.

Appearance

This sets the color or material effect which will be applied to the base 3D model. It is possible to change this at any time and also to apply different colors and materials to different Components using the Component manager.

In most cases a new job represents the size of the material the job will be machined into or at least an area of a larger piece of material which will contain the part which is going to be cut. Clicking OK creates a new empty job, which is drawn as a gray rectangle in the 2D View. Dotted horizontal and vertical Grey lines are drawn in the 2D design window to show where the X0 and Y0 point is positioned.

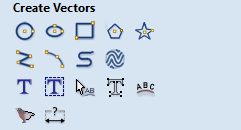

The Create Vectors Tool Group

Click on an icon to learn more about it:

| Create Vectors | |||||

| Closed Shapes | |||||

| Open Shapes | |||||

| Creating Text | |||||

| Trace Bitmap Dimensions | |||||

Drawing Shapes

Each tool gives you the option of dynamically drawing with the mouse in the 2D View, or entering precise data using the form. When you click on a shape tool icon its associated form will open on the Drawing tab. Here you can see the precise dimensions of the shape you are working on, which you can edit directly, as well as other options specific to the type of shape you are editing.

If you click on a shape drawing tool when nothing is selected in the 2D View, you will be able to create new shapes using the button. If you select a previously created shape, you will be able to modify its properties using the same form and update the shape using the button.

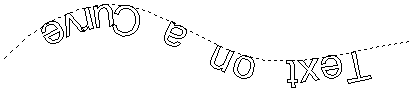

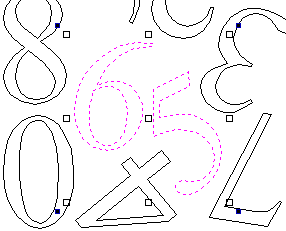

Creating Text

There are a number of tools dedicated to the creation and editing of text. These can be found on the Drawing tab, below the shape creation tools.

Cut2D Laser Desktop can make use of any TrueType font already installed on your computer, as well as Vectric's own single-line fonts designed specifically for CNC machining.

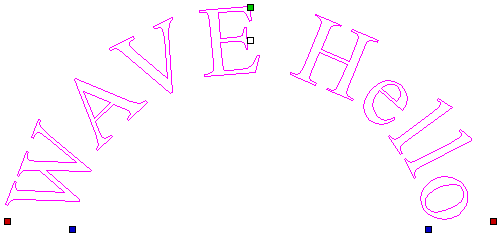

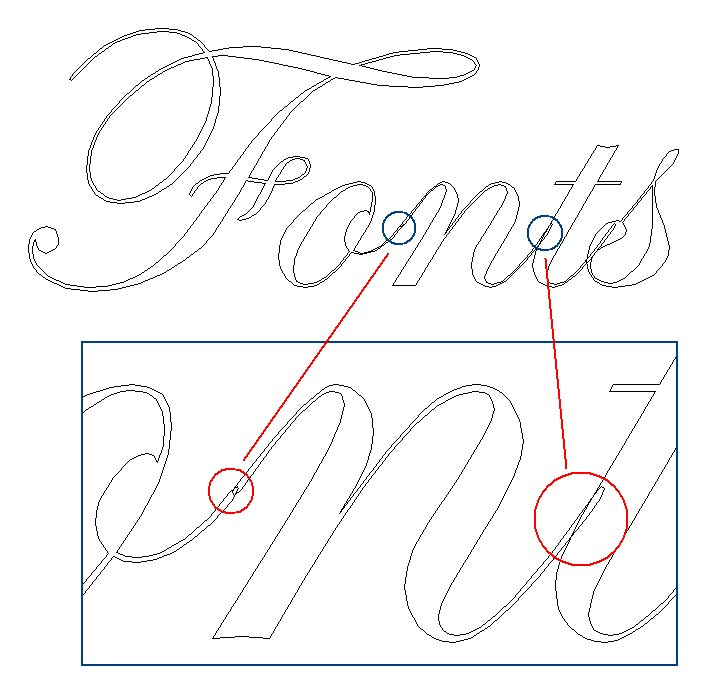

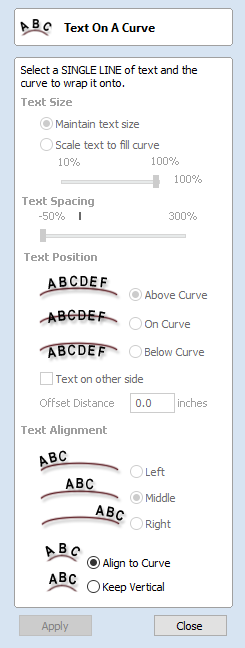

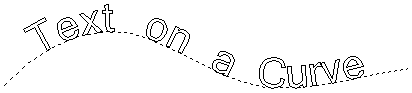

Use the Draw Text, or Draw Auto Text, to create text within your design. The Text selection tool then allows you to dynamically alter the text positioning, spacing or even to bend your text into an arc. For even more flexibility, use the Text on Curve tool to place your text along any vector curve or line that you have drawn. The Convert Text to Curves tool allows you to then use Node Editing to fine tune the vectors of the text to any shape required.

The text tools are accessed using the following icons:

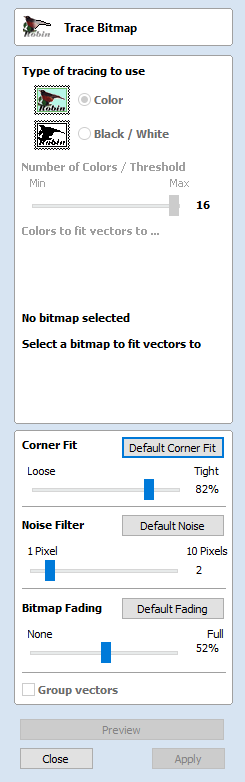

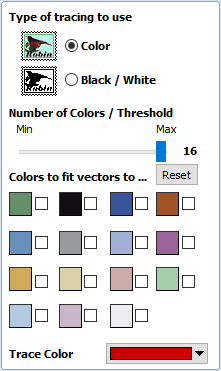

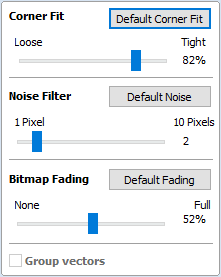

Trace Bitmap

Trace Bitmap tool allows you to automatically trace imported bitmaps using a variety of options within the tool to control the vectors that are created.

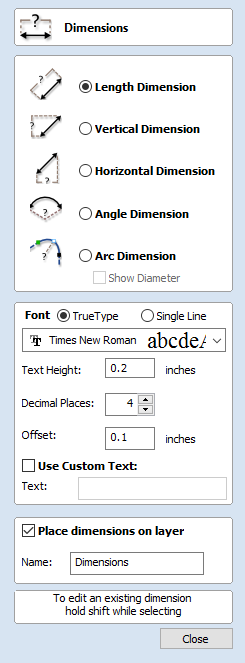

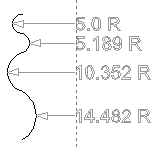

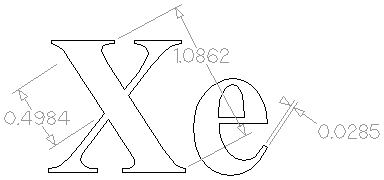

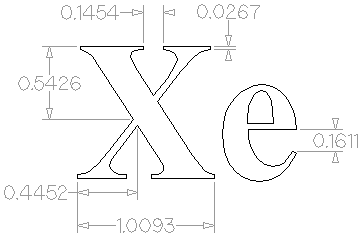

Dimensions

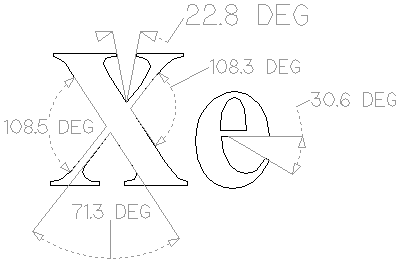

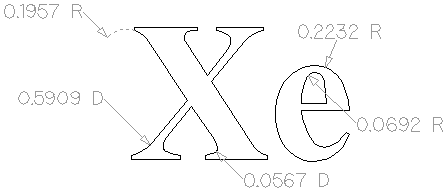

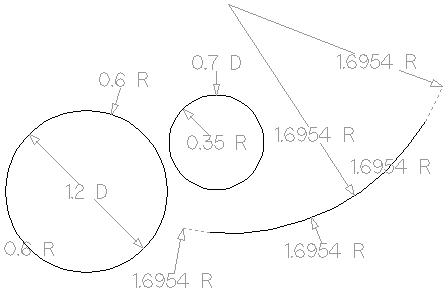

The dimensions tool allows you to add a variety of dimensioning annotations to your vector drawing.

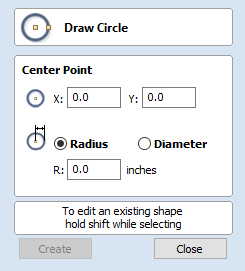

Draw Circle

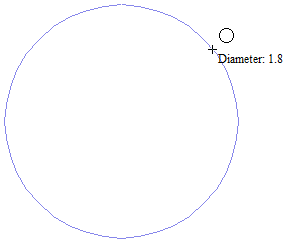

Circles can be created interactively with the cursor and Quick Keys or by entering the exact coordinates and diameter / radius with typed input.

Interactive

Cursor

The default mode and the procedure for drawing circle is:

Click and drag the Left mouse to indicate the center point followed by releasing the button at the required radius / diameter (depends on what is set on the form).

As the cursor is dragged across the screen the radius is dynamically updated. The increments will depend upon your snap radius and the job size.

Quick Keys

The radius or diameter can be specified while dragging out a circle:

Type the value while dragging followed, by D if it's a diameter, or R if it's a radius:

| Keys | Result |

|---|---|

| 12R | Radius 12 |

| 2R | Radius 2 |

| 1D | Diameter 1 |

Exact Size

Circles can also be drawn by entering the required XY origin, selecting either Radius or Diameter and entering the required size on the form.

Click to update the circle.

Edit

Open the Draw Circle form and select the circle to modify.

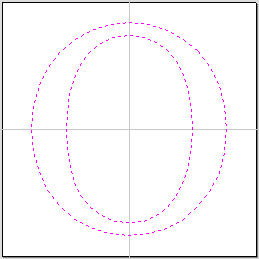

The selected circle is displayed as a dotted magenta line. Edit the Center Point and Radius or Diameter

Click to update the circle

To modify another circle without closing the form hold a Shift key down and select the next circle.

Close the form

To finish drawing with the tool, you can:

- Click on the form

- Press the Esc key

- Click the Right mouse button in the 2D View.

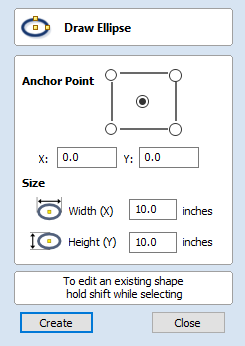

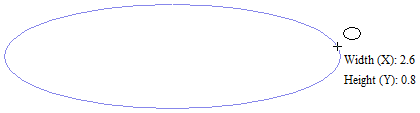

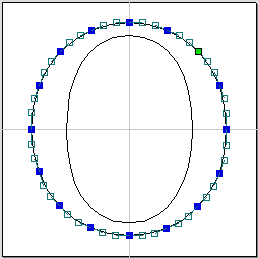

Draw Ellipse

Ellipse / ovals can be created interactively with the cursor and Quick Keys or by entering the exact coordinates for the center point, height and width with typed input.

Interactive - Cursor

The quickest and simplest way to draw an ellipse is:

- Click and drag the left mouse button in the 2D View to begin drawing the ellipse from its corner.

- While holding the left mouse button, drag to the required size.

- Releasing the left mouse button.

Holding Alt and dragging creates an ellipse from the middle point.

Holding Ctrl and dragging creates a circle.

Quick Keys

Instead of releasing the left mouse button when you have dragged your shape to the required size, you can also type exact values during the dragging process and set properties precisely.

- Left-click and drag out your shape in the 2D View.

- With the left mouse button still pressed, enter a quick key sequence detailed below.

- Release the left mouse button.

Default

By default, two values separated by a comma, will be used to set width and height of your ellipse. One value will create a circle with the given diameter. While you are dragging out the ellipse, type Width Value,Height ValueEnter or Diameter,Enter to create an ellipse with the specified dimensions.

Example

| Keys | Result |

|---|---|

| 2.5,1Enter | Creates ellipse with a width of 2.5 and a height of 1. |

Specifying Further Properties

By using specific letter keys after your value, you can also indicate precisely which property it relates to.

| Quick Keys | Result |

|---|---|

| ValueX | Creates an ellipse at the current dragged height, but with the width set to the entered value. |

| ValueY | Creates an ellipse at the current dragged width, but with the height set to the entered value. |

| ValueWValueH | Creates an ellipse with a specified width (W) and height (H). |

Examples

| Keys | Result |

|---|---|

| 1X | Current dragged height with width (X) of 1. |

| 1Y | Current dragged width and height (Y) of 1. |

| 1W2H | A width (W) of 1 and height (H) of 2. |

Exact Size

Accurate ellipses can also be drawn by entering the required XY origin point with the Width and Height of the oval. Click to create the ellipse.

Edit

- Select the ellipse to modify and open the Draw Ellipse form.

- The selected shape is displayed as a dotted magenta line.

- Edit the Width and Height values.

- Click to update the ellipse.

To modify another ellipse without closing the form hold a Shift key down and select the next ellipse.

Close the form

To finish drawing with the tool, you can:

- Click on the form

- Press the Esc key

- Click with the Right-mouse button in the 2D View

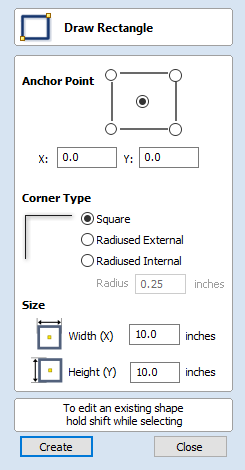

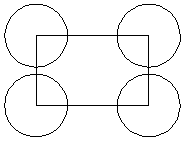

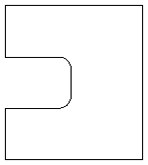

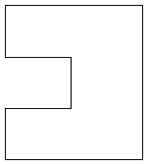

Draw Rectangle

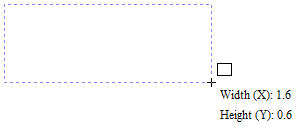

Rectangles can be created by using the Draw Polyline tool or using the Draw Rectangle Tool. The latter tool allows rectangles to be created interactively with the cursor and Quick Keys or by entering the exact coordinates, type of corners (square, internal or external radius) and Width and Height using typed input.

Interactive - Cursor

The quickest and simplest way to draw a rectangle is:

- Click and drag the left mouse button in the 2D View to begin drawing the rectangle from its first corner.

- While holding the left mouse button, drag to the required size.

- Releasing the left mouse button.

Holding Alt and dragging creates a rectangle from the middle point.

Holding Ctrl and dragging creates a square.

As the cursor is dragged across the screen so the XY size is dynamically updated. The increments will depend upon your snap radius and the job size.

Quick Keys

Instead of releasing the left mouse button when you have dragged your shape to the required size, you can also type exact values during the dragging process and set properties precisely.

- Left-click and drag out your shape in the 2D View.

- With the left mouse button still pressed, enter a quick key sequence detailed below.

- Release the left mouse button.

Default

By default, two values separated by a comma, will be used to set width and height of your rectangle. One value will create a square with that side length. While you are dragging out the rectangle corner, type Width Value,Height ValueEnter or Side Length,Enter to create a rectangle with the specified width and height.

Example

| Keys | Result |

|---|---|

| 1,2.5Enter | Creates rectangle with a width of 1 and a height of 2.5. |

Specifying Further Properties

By using specific letter keys after your value, you can also indicate precisely which property it relates to.

| Quick Keys | Result |

|---|---|

| ValueX | Creates a rectangle at the current dragged height, but with the width set to the entered value. |

| ValueY | Creates a rectangle at the current dragged width, but with the height set to the entered value. |

| ValueRValueX | Creates a rectangle with a radius (R) and width (X) set by the two entered values, but using the currently dragged height. |

| ValueRValueY | Creates a rectangle with a radius (R) and height (Y) set by the two entered values, but using the currently dragged width. |

| ValueWValueH | Creates a rectangle with a specified width (W) and height (H). No radiused corners. |

| ValueRValueWValueH | Create a rectangle with radius (R), width (W) and height (H) all specified by the entered values. |

Examples

| Keys | Result |

|---|---|

| 1X | Current dragged height with width (X) of 1. |

| 1Y | Current dragged width and height (Y) of 1. |

| 0.1R1X | A corner radius (R) of 0.1, a width (X) of 1 and the current dragged height. |

| 0.1R1Y | A corner radius (R) of 0.1, a height (Y) of 1 and the current dragged width. |

| 1W2H | A width (W) of 1 and height (H) of 2, no corner radius. |

| 0.1R1W2H | A corner radius (R) of 0.1, width (W) of 1 and height (H) of 2 |

Exact Size

Rectangles can also be drawn by entering the required XY origin point with the Width and Height of the rectangle.

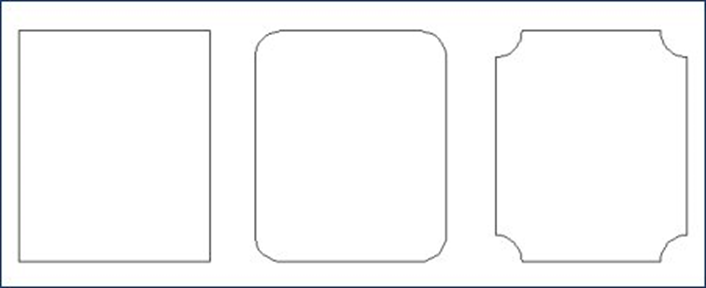

Corner Type

Corners of the rectangle can be Square, Radiused Externally or Radiused Internally.

Edit

- Select the rectangle to modify and open the Draw Rectangle form.

- The selected shape is displayed as a dotted magenta line.

- Edit the Width and Height values.

- Click to update the rectangle.

To modify another rectangle without closing the form hold a Shift key down and select the next rectangle.

Close the form

To finish drawing with the tool, you can:

- Click on the form

- Press the Esc key

- Click the Right mouse button in the 2D View.

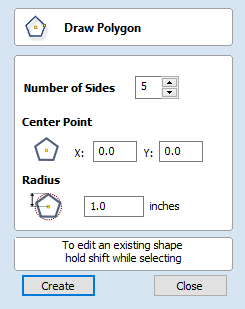

Draw Polygon

Polygons (e.g. Triangles, Pentagons, Hexagons etc.) can be created interactively with the cursor and Quick Keys or by entering the number of sides, exact coordinates and radius using typed input.

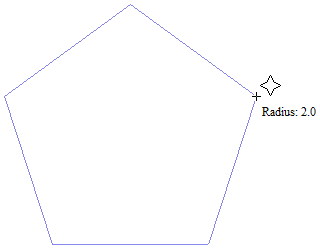

Interactive - Cursor

The quickest and easiest way to draw a polygon is by using the mouse in the 2D View.- Click and hold the left mouse button to indicate the center point.

- Drag the mouse while holding down the left mouse to required radius.

- Release the left mouse button to complete the shape.

As the cursor is dragged across the screen so the radius is dynamically updated. The increments will depend upon your snap radius and the job size.

Quick Keys

Instead of releasing the left mouse button when you have dragged your shape to the required size, you can also type exact values during the dragging process and set properties precisely.

- Left-click and drag out your shape in the 2D View.

- With the left mouse button still pressed, enter a quick key sequence detailed below.

- Release the left mouse button.

Default

By default, entering a single values will be used to set the radius of your polygon. While you are dragging out the polygon, type Radius ValueEnter to create a polygon with the precisely specified radius.

Example

| Keys | Result |

|---|---|

| 2.5Enter | Creates a polygon with a radius of 2.5, all other settings as per the form. |

Specifying Further Properties

By using specific letter keys after your value, you can also indicate precisely which property it relates to.

| Quick Keys | Result |

|---|---|

| ValueD | Creates a polygon with the diameter (D) specified, with all other properties as per the form. |

| ValueSValueR | Creates a polygon with the specified number of sides (S) and the outer radius (R). |

| ValueSValueD | Creates a polygon with the specified number of sides (S) and the outer diameter (D). |

Examples

| Keys | Result |

|---|---|

| 1R | Outer radius (R) 1, number of sides as per form. |

| 1D | Outer diameter (D) 1, number of sides as per form. |

| 8S1R | An 8 sided (S) polygon with an outer radius (R) of 1. |

| 6S2.5D | A 6 sided (S) polygon with an outer diameter (R) of 2.5. |

Exact Size

Polygons can also be drawn by entering the required XY origin , selecting either Radius or Diameter and entering the required size.

- Click to update the circle.

Edit

Open the Draw Polygon form and select the circle to modify.

The selected circle is displayed as a dotted magenta line.

- Edit the Number of Sides and Radius.

- Click to update the circle.

To modify another polygon without closing the form hold the Shift key down and select the next polygon.

Close the form

To finish drawing with the tool, you can:

- Click on the form

- Press the Esc key

- Click the Right mouse button in the 2D View.

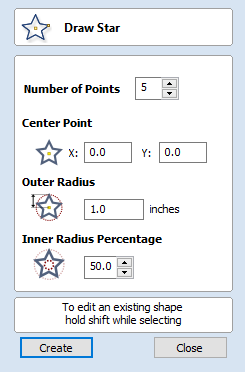

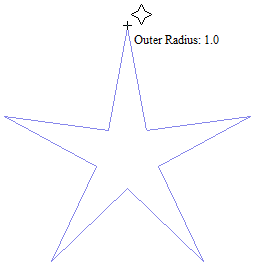

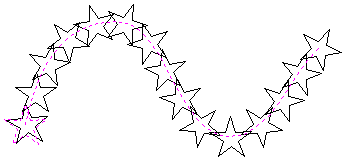

Draw Star

Stars can be created interactively with the cursor and Quick Keys, or by entering the number of points, exact coordinates and outer radius and inner radius percentage using typed input.

Interactive - cursor

The quickest and easiest way to create a star is by clicking and dragging the shape to size in the 2D View using the mouse.

- Click and hold the left mouse button to indicate the center point.

- Drag the mouse while holding down the left mouse to required radius.

- Release the left mouse button to complete the shape.

As the cursor is dragged across the screen so the outer radius is dynamically updated. The increments will depend upon your snap radius and the job size.

Quick Keys

Instead of releasing the left mouse button when you have dragged your shape to the required size, you can also type exact values during the dragging process and set properties precisely.

- Left-click and drag out your shape in the 2D View.

- With the left mouse button still pressed, enter a quick key sequence detailed below.

- Release the left mouse button.

Default

By default, entering a single value will be used to set the outer radius of your star. While you are dragging out the star, type Radius ValueEnter to create a star with the precisely specified outer radius.

Example

| Quick Keys | Result |

|---|---|

| 2.5Enter | Creates a star with an outer radius of 2.5, all other settings as per the form. |

Specifying Further Properties

By using specific letter keys after your value, you can also indicate precisely which property it relates to.

| Quick Keys | Result |

|---|---|

| ValueD | Creates a star with the outer diameter (D) specified, with all other properties as per the form. |

| ValueIValueR | Creates a start with the inner radius percentage (I) and the outer radius (R). The inner radius is defined in terms of a percentage of the outer radius or diameter. All other properties are as per the form. |

| ValuePValueR | Creates a star with the specified number of points (P) and the outer radius (R). |

| ValuePValueIValueR | Creates a star with the specified number of points (P), inner radius percentage (I) and the outer radius (R). |

Examples

| Quick Keys | Result |

|---|---|

| 1R | Outer radius (R) 1, other proporties as per form. |

| 1D | Outer diameter (D) 1, other properties as per form. |

| 6P1R | An 6 pointed (P) star with an outer radius (R) of 1. |

| 6P1D | An 6 pointed (P) star with an outer diameter (D) of 1. |

| 6P25I4D | A 6 pointer (P) star with an outer diameter (D) of 4 and an inner diameter that is 25% of the outer (i.e. 1). |

Exact Size

Stars can also be drawn by entering the Number of Points, Center Point, Outer Radius and Inner Radius Percentage.

- Click to update the star.

Edit

- Select the star to modify and open the Draw Star form.

The selected shape is displayed as a dotted magenta line.

- Edit the required parameters.

- Click to update the star.

To modify another star without closing the form hold a Shift key down and select the next star.

Close the form

To finish drawing with the tool, you can:

- Click on the form

- Press the Esc key

- Click the Right mouse button in the 2D View.

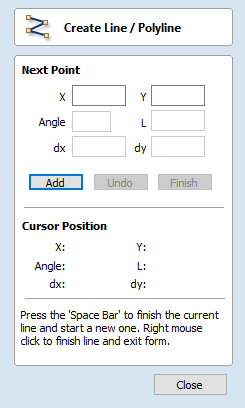

Draw Polyline

This tool creates continuous straight lines through points clicked, entered coordinates, tangent between a point and an arc or tangent to two arcs.

Interactive - cursor

The quickest and easiest way to draw a line is by clicking within the 2D View using the mouse.

- Click the left mouse button to indicate the start point of your line.

- Move the mouse pointer and click again to set the next point in your line.

- Repeat this process to add as many line segments as you require.

- Right-click or press Esc to finish your polyline and exit the form.

- Alternatively press the Spacebar to complete this polyline but keep the form open and begin drawing another polyline.

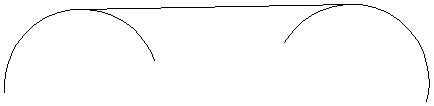

Creating Tangent Lines

The polyline tool can also be used create lines that are tangent to arcs in your existing drawing.

From A Point To An Arc

To create a line tangent from a point to an arc simply enter the initial point and then hover the cursor over the arc and press T.

From An Arc To A Point

To create a line tangent from an arc to a point click on the arc to insert a point and then hover the cursor over the next point position and press T.

From An Arc To Another Arc

To create a line tangent from one arc to another click on the arc to insert a point and then hover the cursor over the second arc and press T.

Quick Keys

Instead of releasing the left mouse button when you have dragged your shape to the required size, you can also type exact values during the dragging process and set properties precisely.

- Left-click and drag out your shape in the 2D View.

- With the left mouse button still pressed, enter a quick key sequence detailed below.

- Release the left mouse button.

Default

By default, entering a single value will be used to add a point at the specified distance along the line direction currently indicated by the mouse pointer position, relative to the preceding point. With polyline drawing underway, move the mouse pointer in the direction you wish to create a new line segment and type Length ValueEnter to extend the line by the specified distance in that direction.

By default two values, separated by a comma, will create the next line point at the absolute X Y coordinate indicated by the two values, respectively. While drawing, type X Value,Y ValueEnter to place the next point precisely at specified X and Y position.

Example

| Keys | Result |

|---|---|