Aspire Help

Version 9

Disclaimer

All CNC machines (routing, engraving, and milling) are potentially dangerous and because Vectric Ltd. has no control over how the software described in this manual might be used, Vectric Ltd. or any associated Resellers cannot accept responsibility for any loss or damage to the work piece, machine or any individual, howsoever caused by misusing the software. Extreme care should always be taken and the output from the software thoroughly checked before sending it to a CNC machine.

The information in this manual may be subject to change without any prior notice. The software described in this manual is supplied under the terms and conditions of the software license agreement and may only be used in accordance with the terms of this agreement.

Vectric Ltd.

Web:

www.vectric.com

Email: info@vectric.com

Phone: +44 (0) 1527 850 323

Fax: +44 (0) 1527 850 323

Aspire Reference Manual

Introduction

This manual is designed to provide a comprehensive description of all the functions, tools, menus and icons available within the Aspire software package.

Access this document from Aspire's Help Menu ► Help Contents or from the Aspire folder in the program section of your Windows Start menu.

At the bottom of the page you will see an area with View All Help. This will download all the Help Documentation as a single web page which is useful for searching or if you need to create a paper copy of the documentation.

User Guides, tutorial and training

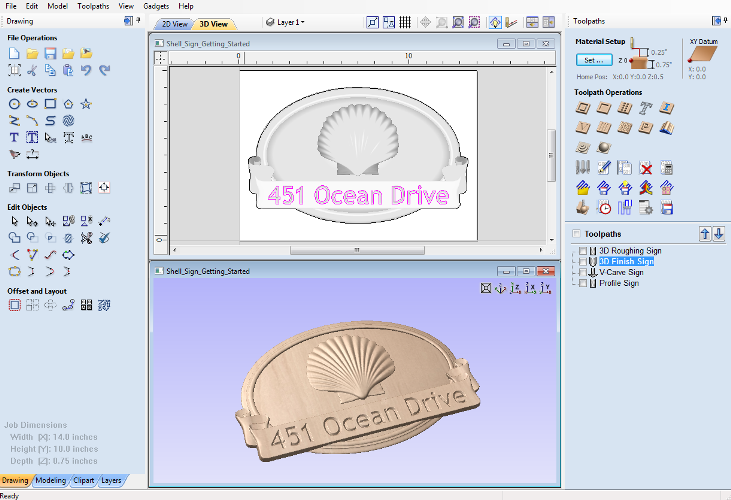

Please note that this document is a Reference Manual. If you require more guidance, or are still learning how to use Aspire, please ensure that you view the Getting Started Video Tutorials in the Aspire Video Tutorial Browser when starting the software, or go to the User Manual section.

Aspire also includes an extensive selection of video tutorials, which are accessible from the Tutorial Video Browser link when application first starts. These tutorials cover every aspect of Aspire's functionality and range in complexity from a beginner's overview, to advanced features and principles. They are intended to be extremely accessible by level of experience or topic and use real-world examples throughout. Videos can be watched online, or installed locally.

We welcome any comments on this manual or the other training material, please email support@vectric.com with your feedback.

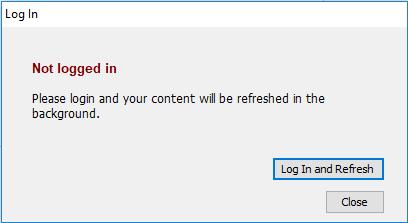

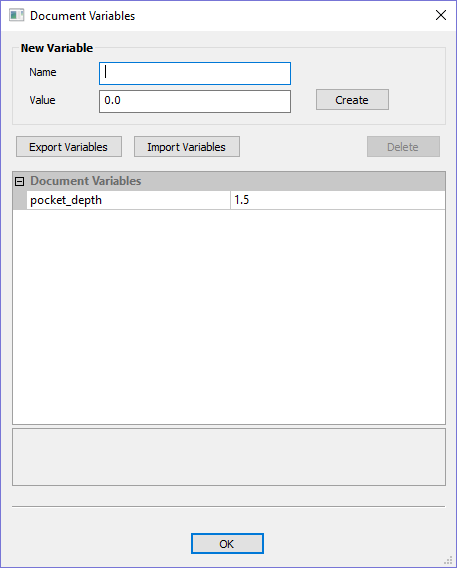

License Dialog

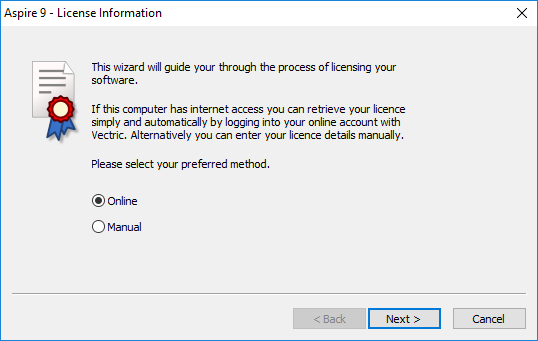

The License Dialog is used to set the details you need to activate the software. This dialog can also be used to activate optional modules. The page that initially appears will give you the option to set your license details either automatically from your V&Co account or manually.

The 'Online Method' section below covers the process to follow if Online is selected.

The 'Manual Method' section below shows the process to follow if you wish to type in your license details manually or do not have an Internet connection available.

Online Method

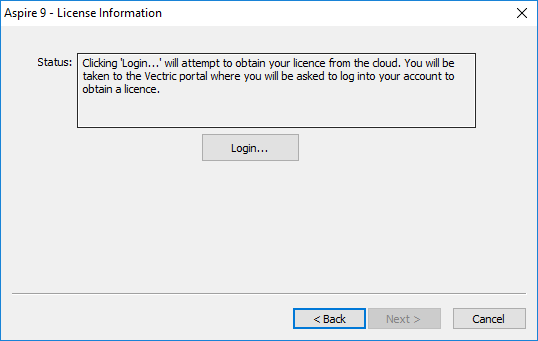

This method will allow you to retrieve your details automatically from your V&Co account. To use this select 'Online' and then click on the form. The online section of the form will then be displayed.

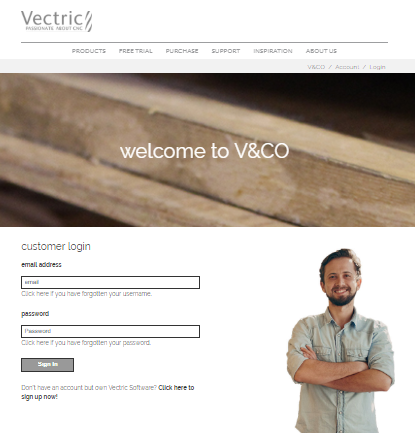

Pressing on this dialog will launch a web browser which will take you to the V&Co login page if authentication is required.

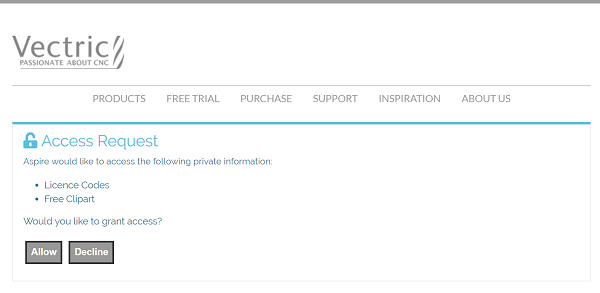

After logging in here with your V&Co account details another page may appear asking for permission for Aspire to access your license details.

This page will only appear if you have not already granted access. If this appears you should select 'Allow' to enable Aspire to retrieve your license details automatically.

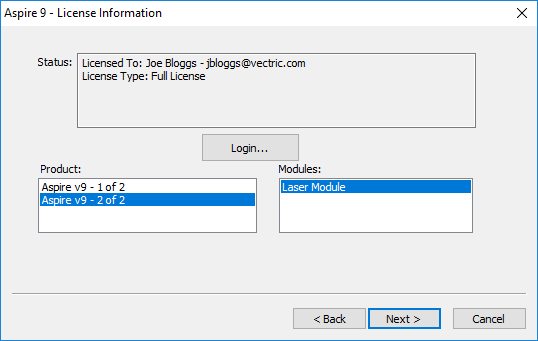

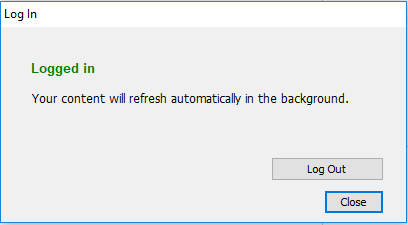

At this point Aspire should be being displayed and the dialog should be automatically populated with any licenses available on your account.

You can select any of the product licenses available and information on the type of license will be displayed in the status area. Once the license and any modules have been selected by clicking on them can be pressed to activate these and proceed to the summary page.

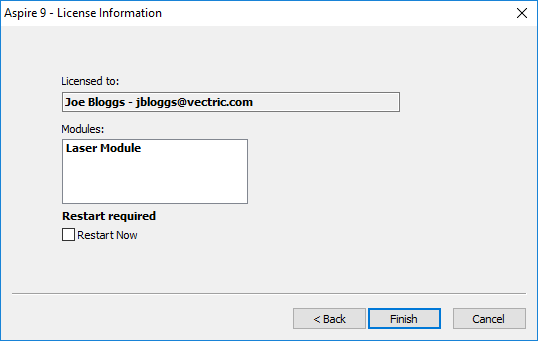

This page displays the selected license and module details. If you are changing current license details or adding a module a restart will be required for these to fully take effect. In this case a check box will appear allowing you to restart automatically. If this is checked then when you press Aspire will automatically be restarted to apply the license changes. If you do not select this option the license changes take effect the next time Aspire is restarted.

Manual Method

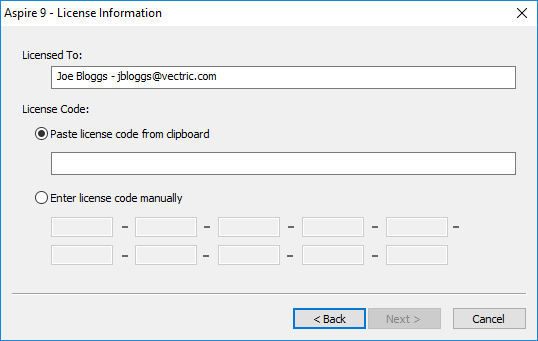

The manual method allows entry of license details without requiring an Internet connection. Selecting 'Manual' and clicking will cause the manual entry form to be displayed.

The 'Registered User Name' from your license information should be entered into the 'Licensed To' area of the form and the license code can either be copied and pasted into the middle row of the dialog or manually typed into the lower section if 'Enter license code manually' is selected. The button will become available when a code of the expected length has been entered.

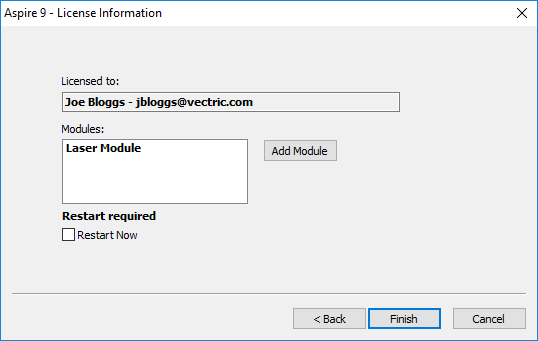

If the product is already licensed then a module code can be entered at this stage instead of the product code. If you wish to manually activate both a product and module code the product code should be added here and there will be an opportunity to add the module code later. Pressing will set the license and display the summary screen.

The summary screen shows the current licensed user and has an button to allow additional modules to be added. Pressing this button will display the manual entry form again and allow the module details to be entered.

If the licensed user is changed or a new module is added a restart will be required for these to take full effect. In this case a check box will appear allowing you to restart automatically. If this is checked then when you press the finish button the program will automatically be restarted to apply the license changes. If you do not select this option the license changes take effect the next time the program is restarted.

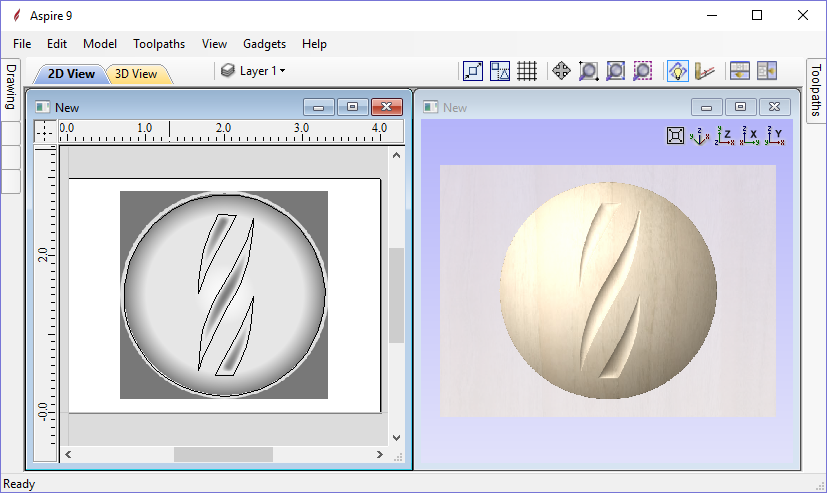

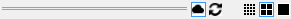

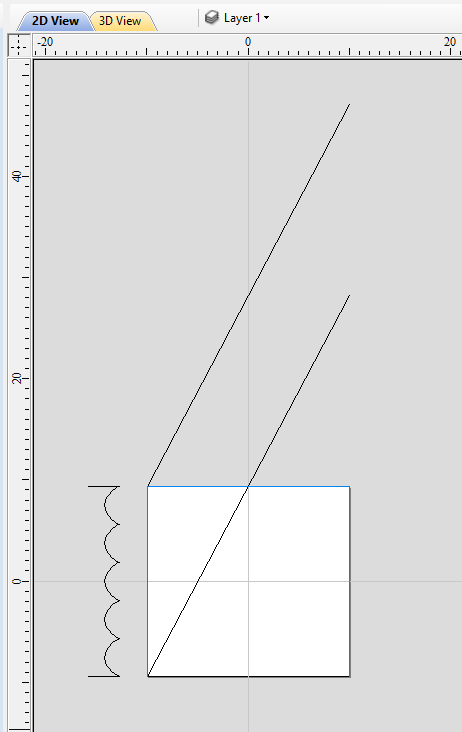

View Controls

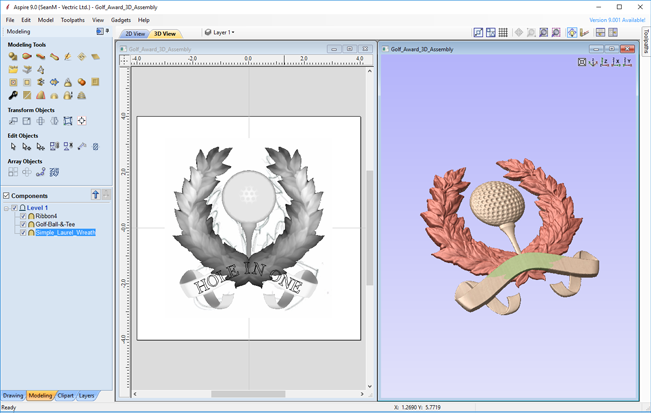

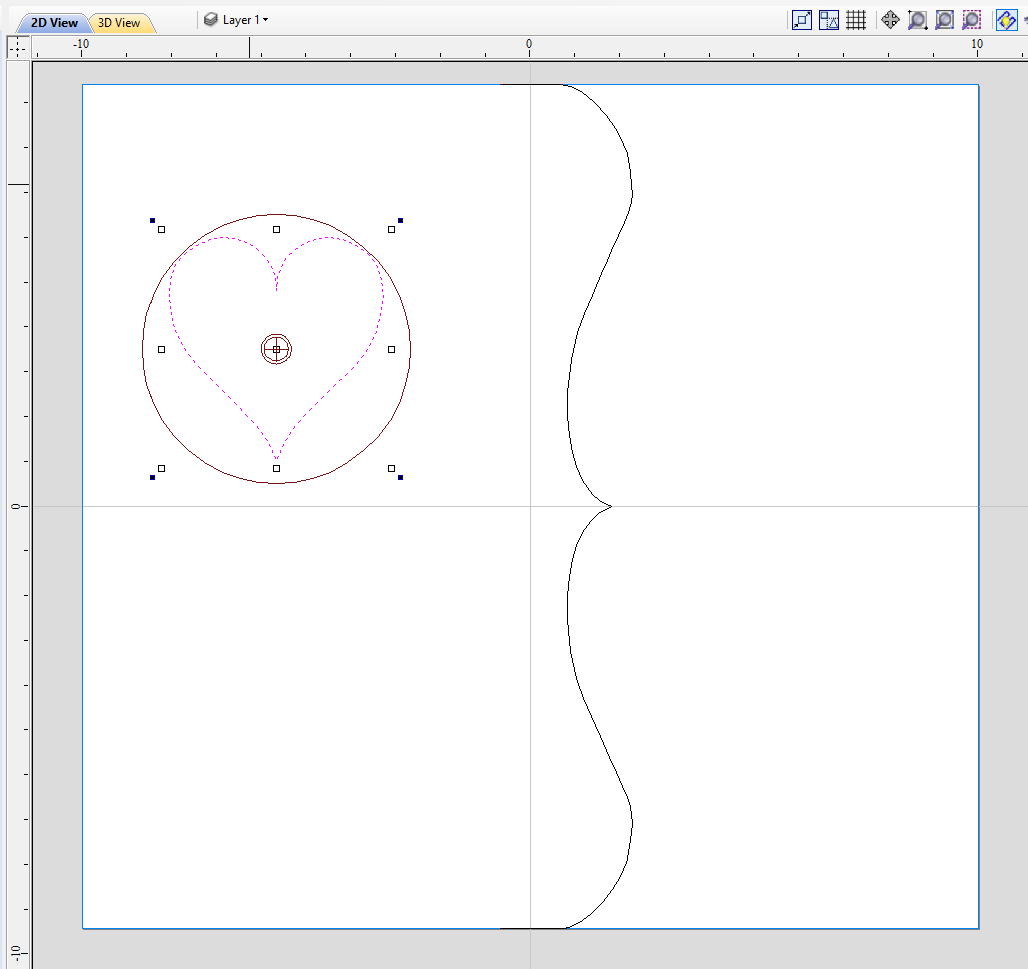

Your project is represented using 2D and 3D workspaces, each viewed via independent windows called the 2D View and 3D View, respectively. This division usefully maps to the typical workflow in which you will initially focus on the 2D design and layout of your project before moving to the 3D stage of modeling, toolpathing and previewing your finished part.

You can switch between the views using the tabs at the top of each window. In addition the shortcut-keys F2 and F3 will toggle the display between the two windows.

It is sometimes useful to see both the 2D and 3D representations at the same time. The Page Up and Page Down keys will arrange the 2 views either horizontally or vertically so you can see both workspaces simultaneously. To return to the tabbed display, simply click on the standard Windows Maximize button in the top right corner of either view window.

Many of the controls for manipulating the view in your project are similar in both 2D and 3D.

From within each view you can also directly interact with the objects that make up your job using the Object Selection Tools.

2D View Controls

See also the Rulers, Guides and Snap Grid section.

Pan |

Click and hold the Left mouse button and drag the mouse about to Pan - Esc to cancel mode Shortcut: Click and drag the Middle mouse button or if using a 2 button mouse, Hold Ctrl + drag with Right Mouse button. |

|

Zoom Interactive |

Mouse with Middle Wheel - Scroll wheel in / out Mouse without Middle Wheel - Hold Shift + Push / Pull with Right Mouse button. |

|

Zoom Box |

Click top left corner, hold mouse down and drag to bottom right corner and release. Clicking the left mouse button will zoom in, Shift + click will zoom out. |

|

Zoom Extents |

Zooms to show material limits in the 2D window |

|

Zoom Selected |

With objects selected Zooms to the bounding box of the selection |

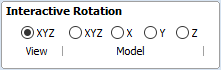

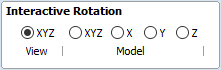

3D View Controls

3D Twiddle |

Click and drag Left mouse button in the 3D window |

|

Zoom |

Right mouse button - Push / Pull Mouse with Middle Wheel - Rotate wheel |

|

Pan |

Click and drag Right mouse button and hold Ctrl. Click and drag Right and Left mouse button Click Middle mouse button |

|

Zoom to Fit |

Zooms the whole 3D part to fit within the current 3D View window |

|

Isometric View |

Shows the model in a 3D isometric view in the 3D window |

|

Plan View (Down Z) |

Shows the top view of the model in the 3D View looking down the Z axis. Press Shift to show the bottom. |

|

Side View (Along X) |

Shows the side view of the model in the 3D View looking along the X axis. Press Shift to show the opposite side. |

|

Side View (Along Y) |

Shows the side view of the model in the 3D View looking along the Y axis. Press Shift to show the opposite side. |

|

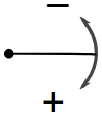

Rotate around model (Rotary) |

Rotate clockwise / anti-clockwise around the model (Available only in a Rotary project with Wrapped View on). |

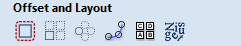

The View Toolbar

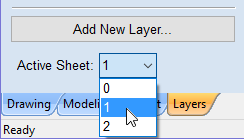

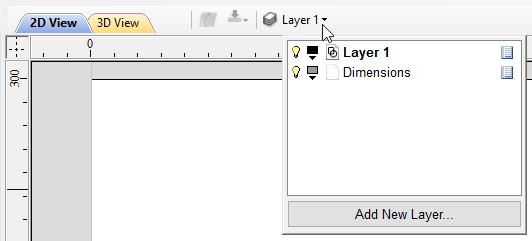

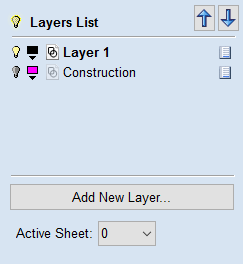

Above the view window is a handy toolbar that allows easier access to common tools. With the ability to create a double sided project you have easy access to switch between the Top and Bottom Sides of your project. The Layers Drop down bar has now moved from the drawing tab to the View Toolbar, making it accessible at all times. The other icons displayed in order of left to right are as follows:

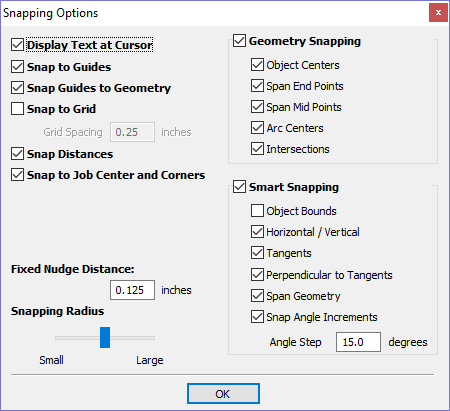

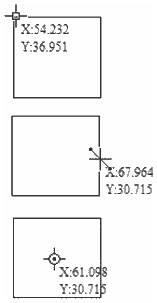

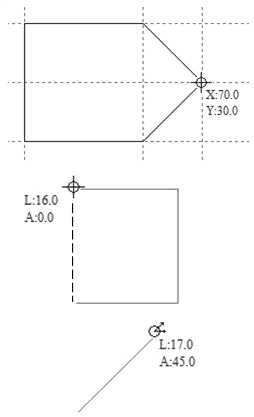

Snapping Toggle Options

View Controls

Toggle Pan / Twiddle View

Toggle Pan / Twiddle View Zoom to box

Zoom to box Zoom to drawing

Zoom to drawing Zoom to selection

Zoom to selection

Toolpath Drawing Toggle

Toggle 2D Toolpath Drawing

Toggle 2D Toolpath Drawing Toggle solid 2D Toolpath Drawing

Toggle solid 2D Toolpath Drawing

3D Drawing

Toggle drawing of material block

Toggle drawing of material block

Tile 2D & 3D View Windows

Stack 2D and 3D View windows vertically

Stack 2D and 3D View windows vertically Stack 2D and 3D View windows horizontally

Stack 2D and 3D View windows horizontally

Two-Sided Machining

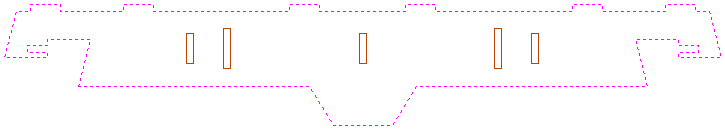

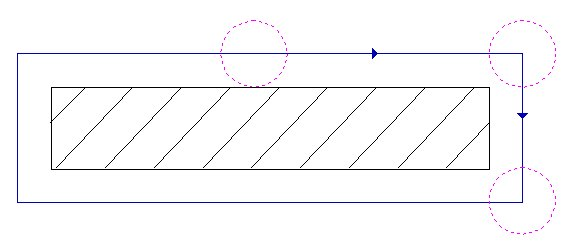

When you are working on a two-sided job additional icons will appear on the View Toolbar. On the left you will see an icon indicating whether the job you are working on will be flipped horizontally or vertically. This is important because the software will automatically mirror your toolpaths and geometry around different axes depending on this setting. To maintain the correct alignment of your toolpaths you must physically turn the material on your CNC machine in the same direction as you have specified during the design process.

Turn horizontally from left to right.

Turn horizontally from left to right. Turn vertically, end over end.

Turn vertically, end over end.

The next button indicates which side you are currently working on. It is a toggle button that can be clicked. Clicking this button swaps the active side of your job.

Top side is active, all operations will apply to the Top side.

Top side is active, all operations will apply to the Top side. Bottom side is active, all operations will apply to the Bottom side.

Bottom side is active, all operations will apply to the Bottom side.

The final additional tool for two-sided job is on the right hand side of the View Toolbar and it allows you to toggle the 3D composite relief to show either the currently active side or your model only, or both sides of your model as a single solid block.

Toggle Two-Sided View

Toggle Two-Sided View

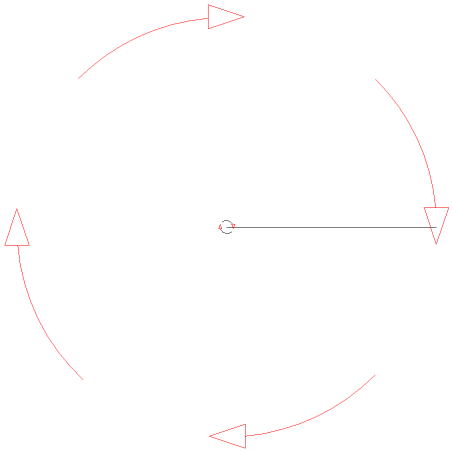

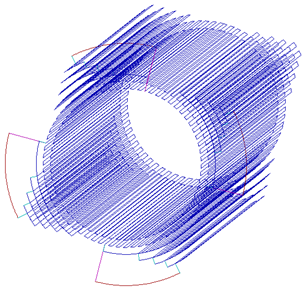

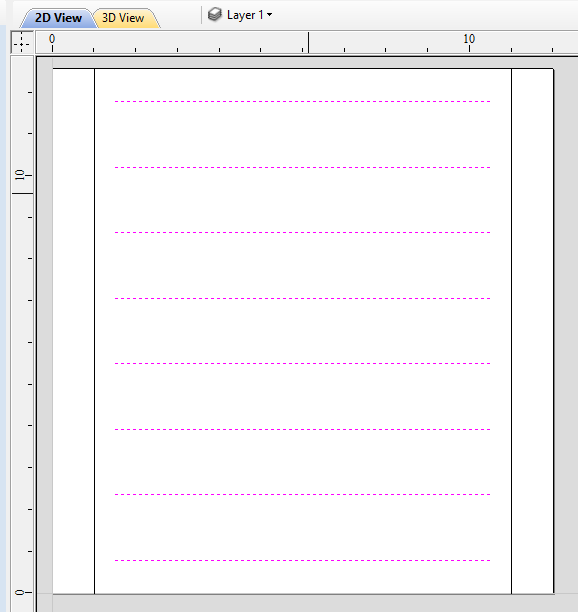

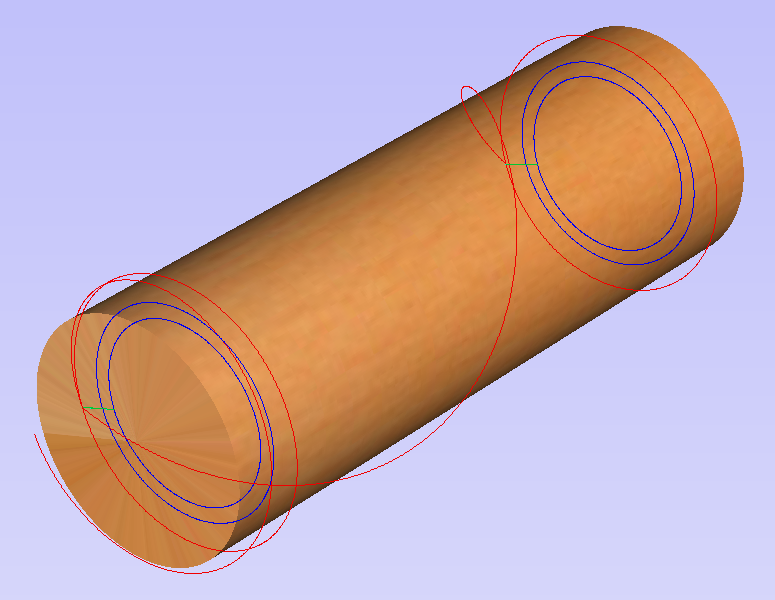

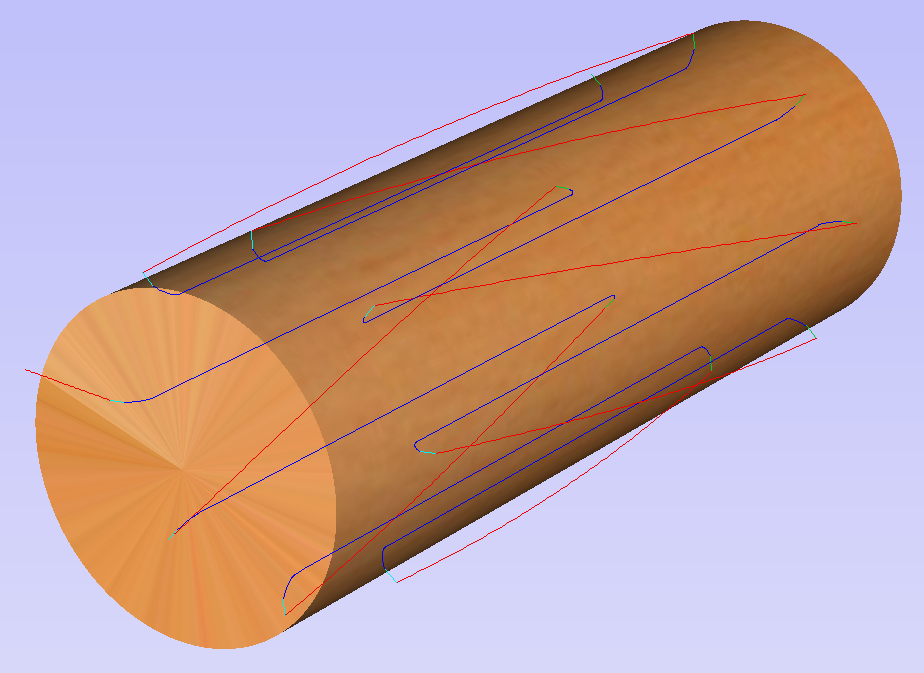

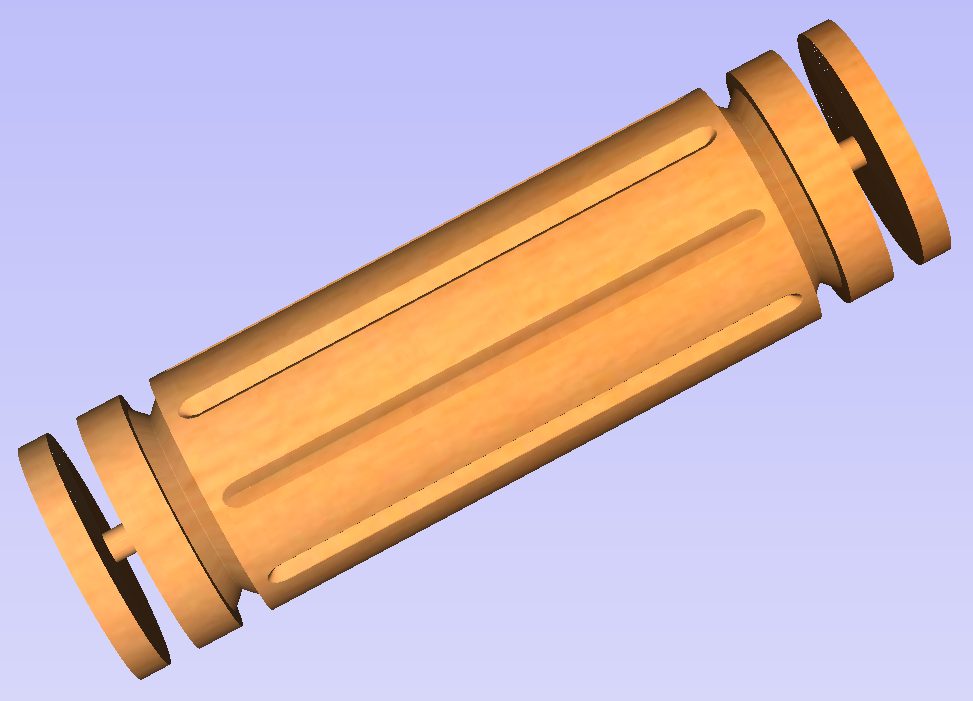

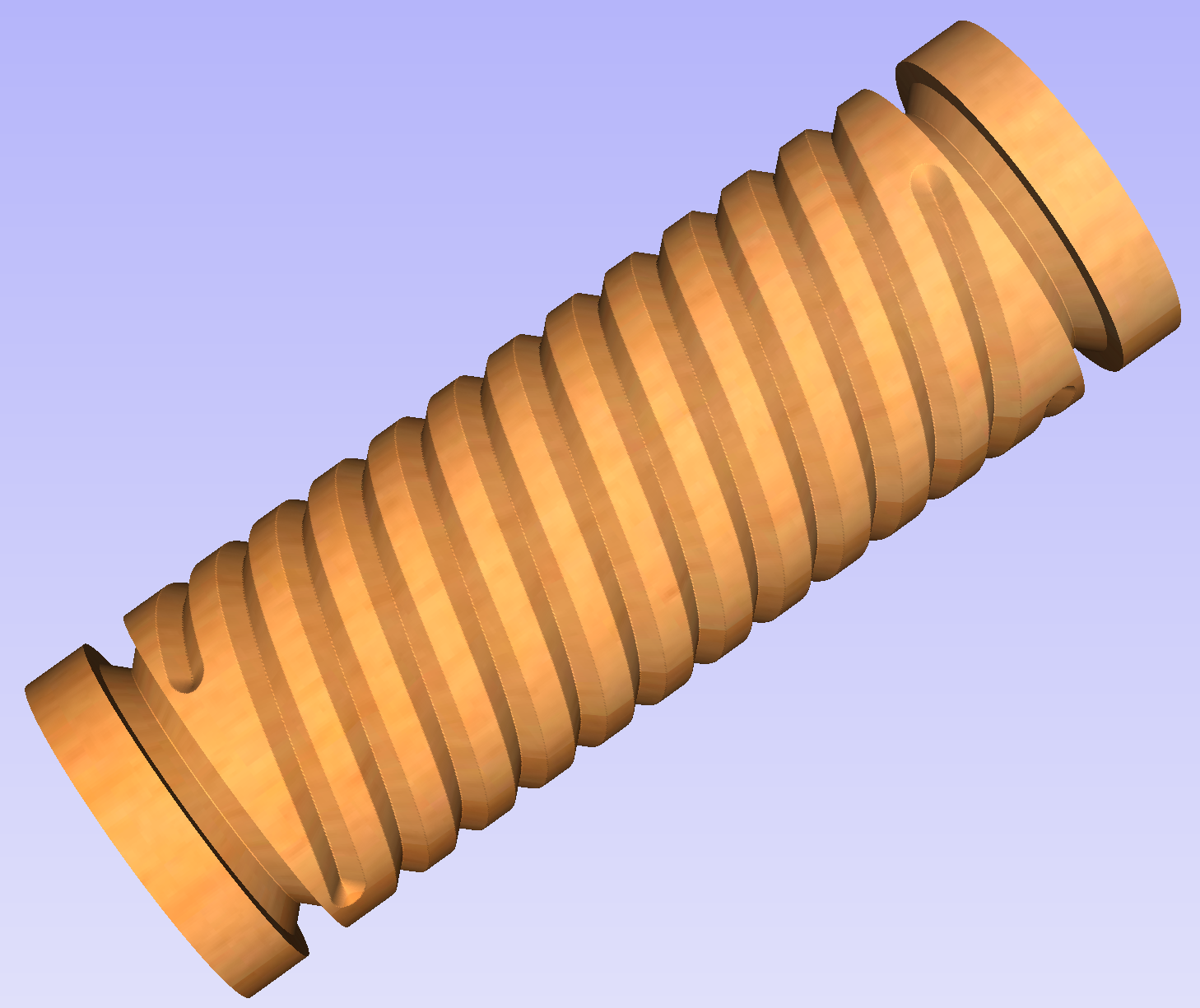

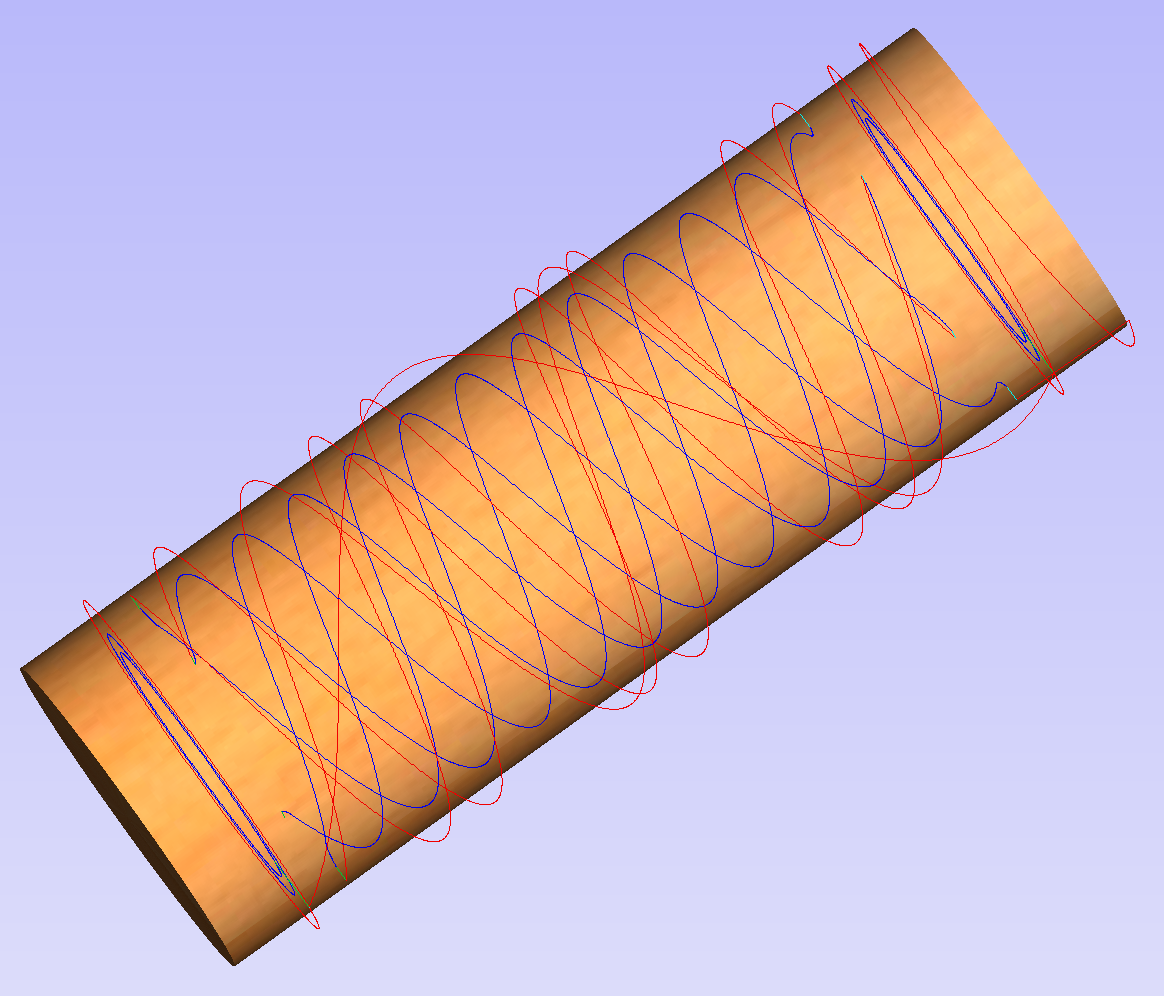

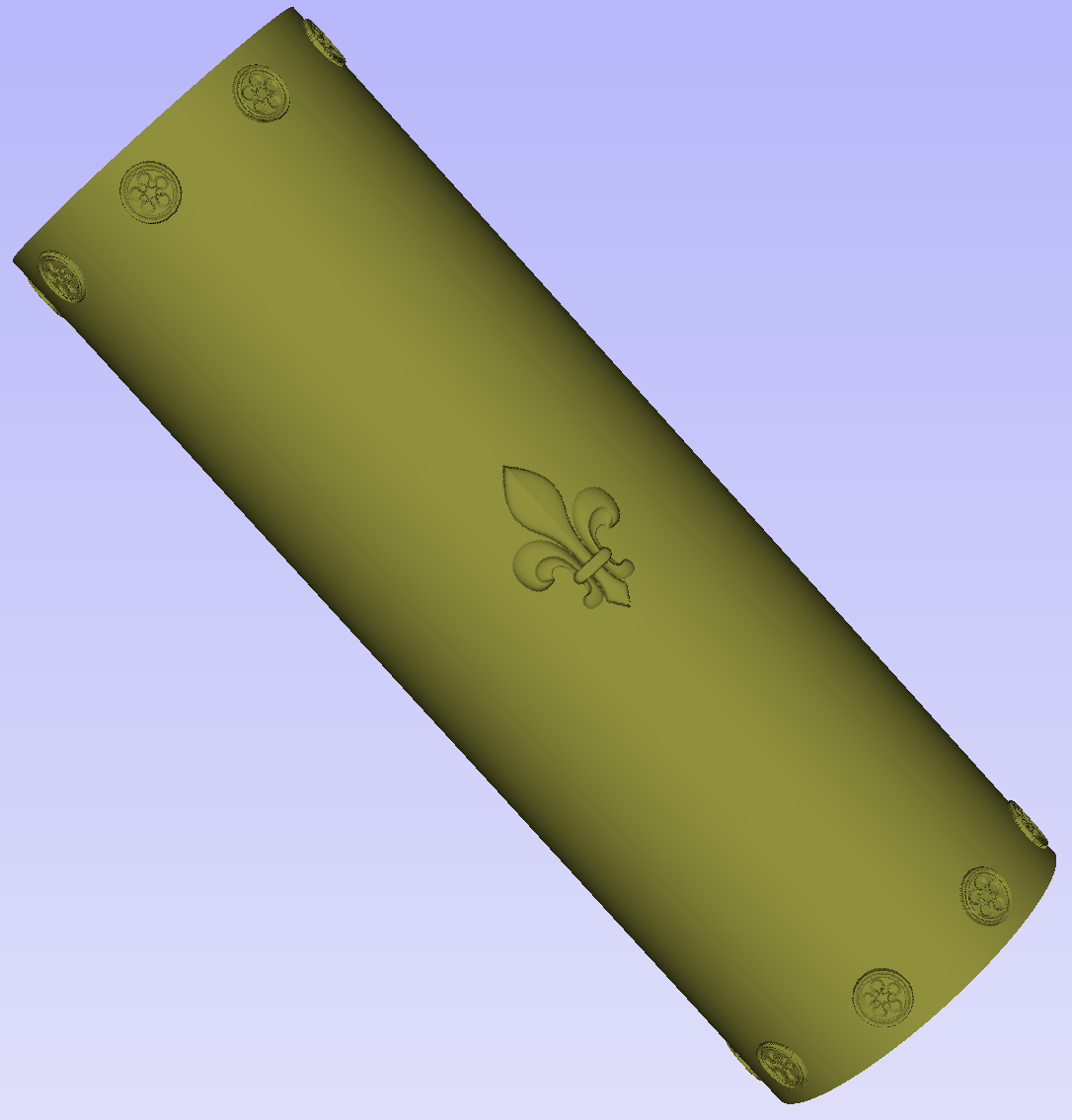

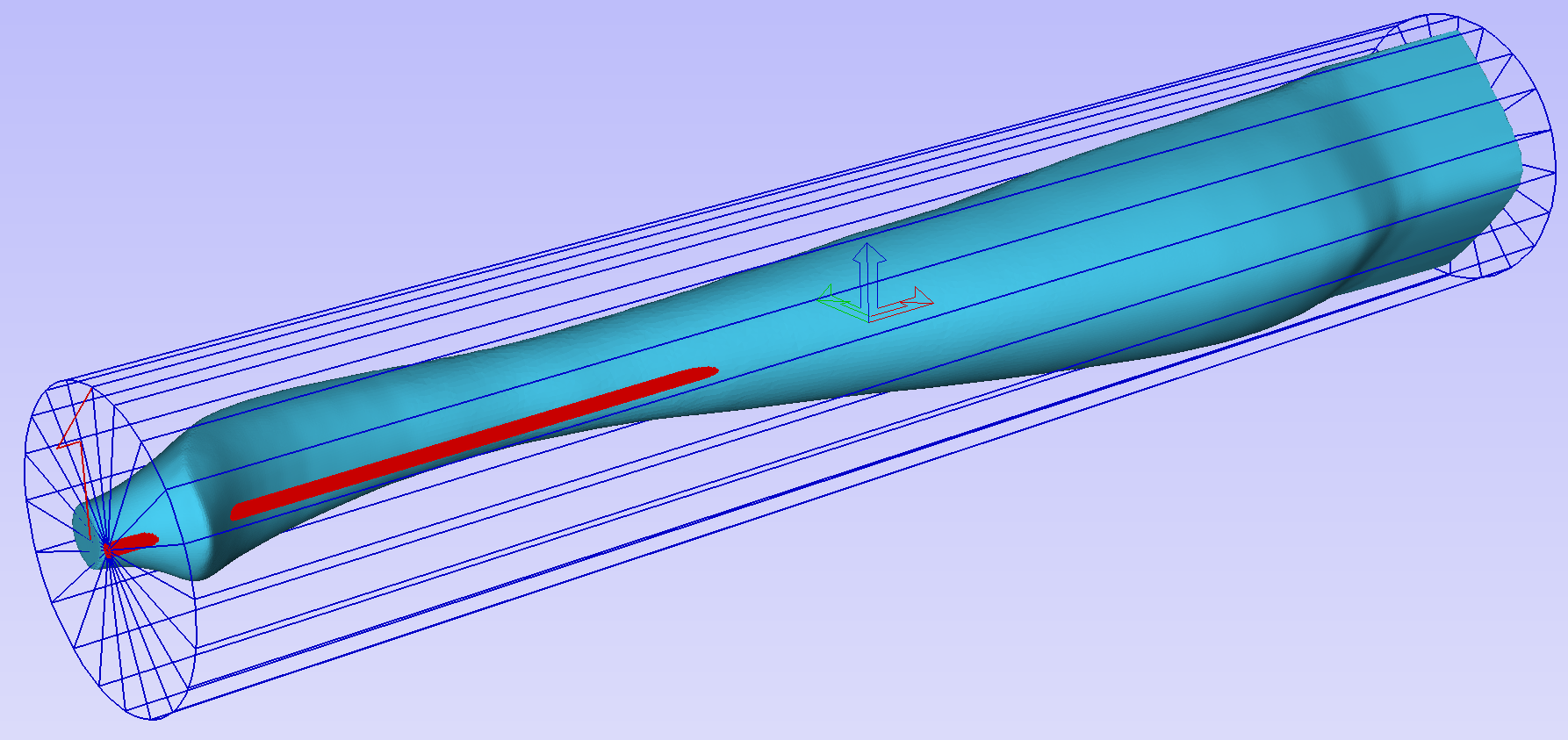

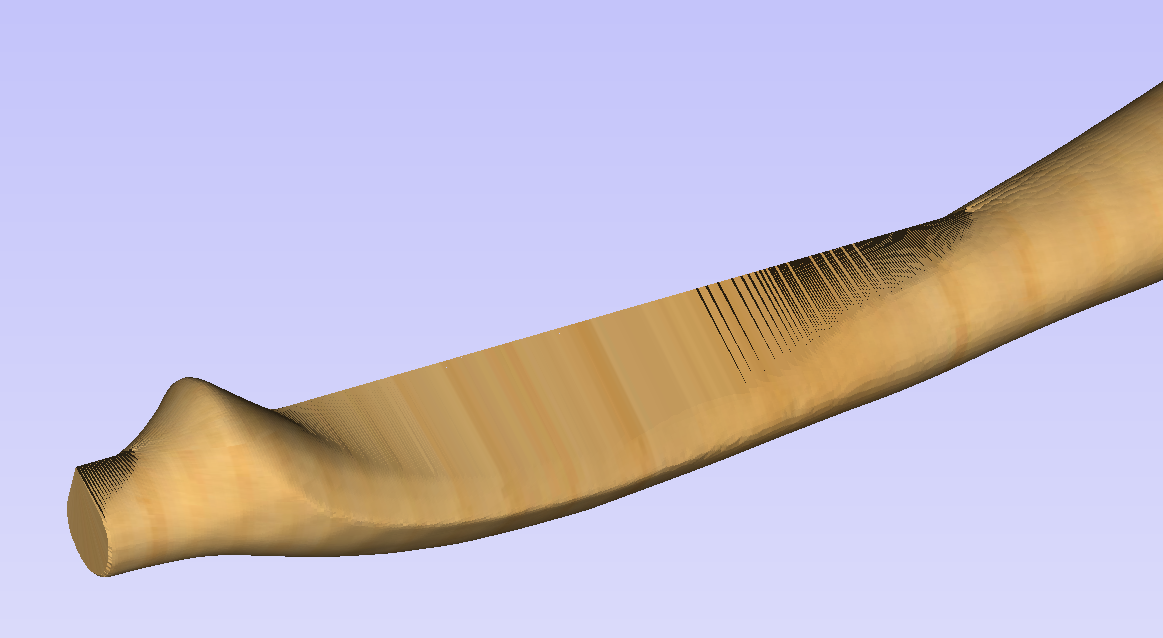

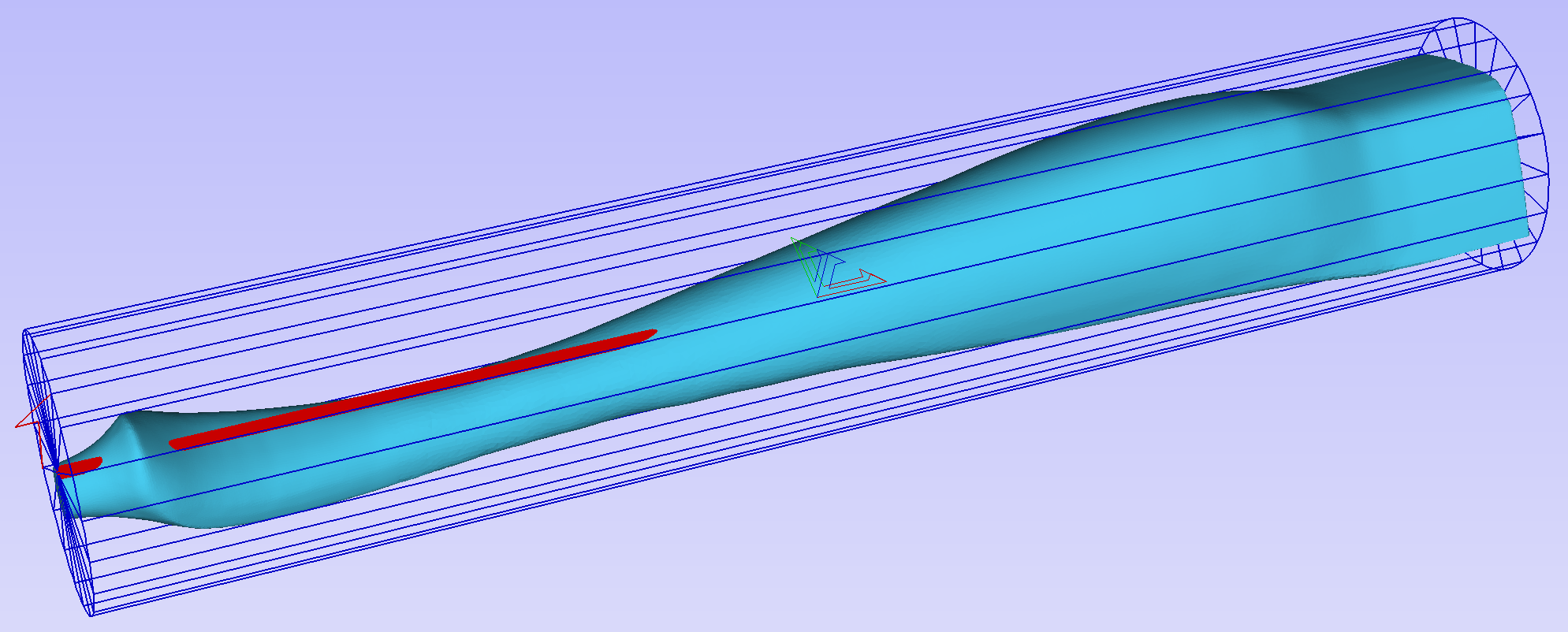

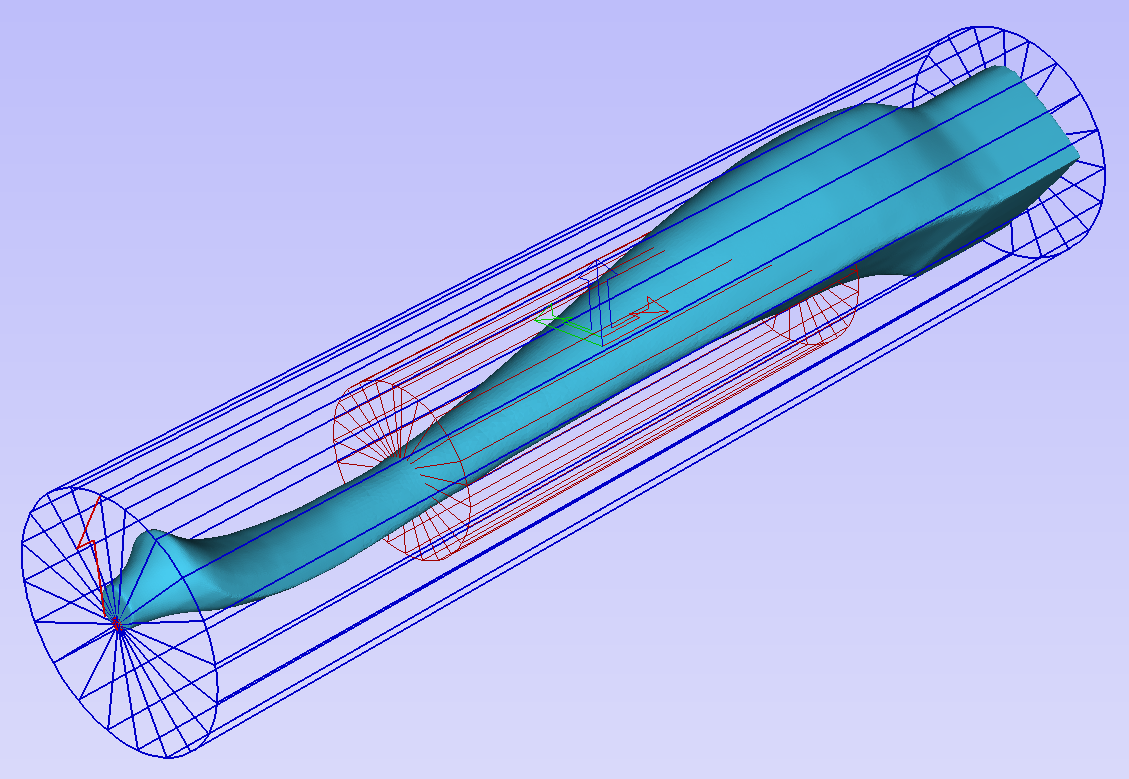

Rotary Machining

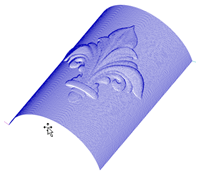

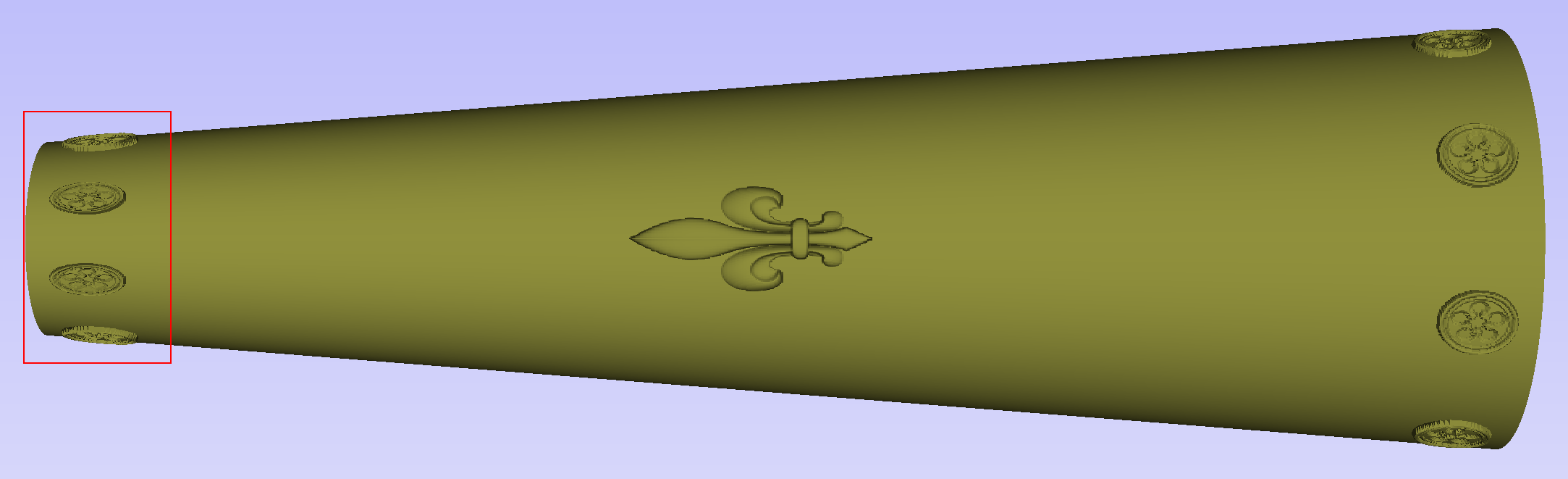

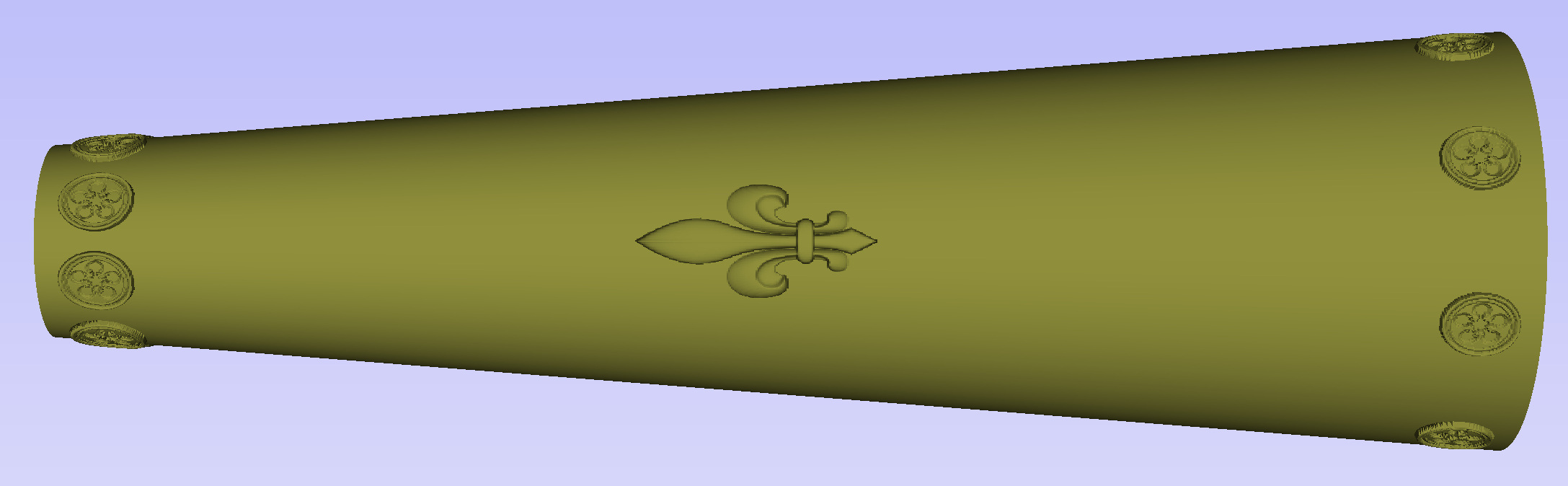

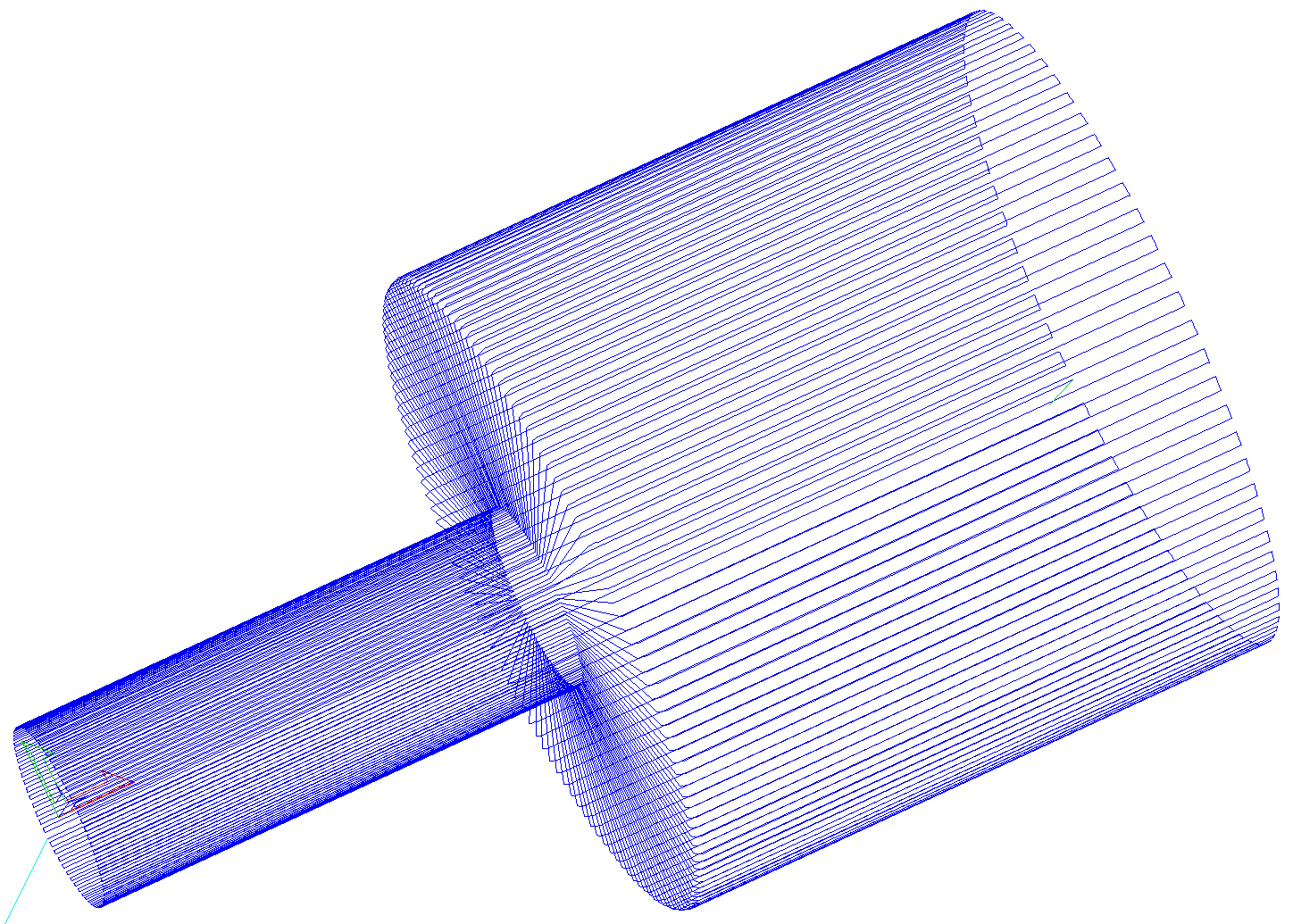

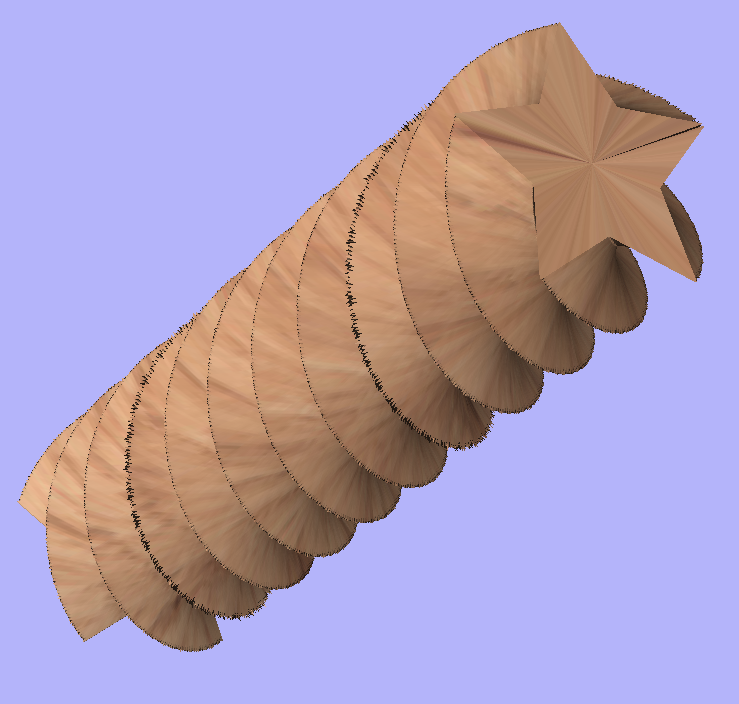

When you are working on a rotary job an additional icon will appear. This button allows you to toggle the 3D view between wrapped display mode and flat display mode.

Toggle Wrapped 3D view.

Toggle Wrapped 3D view.

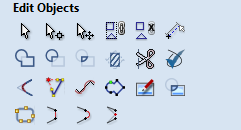

The Drawing Tab

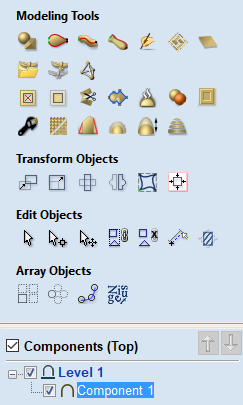

Aspire includes drawing and editing tools that allow designs to be created and modified, which can ultimately be used directly for toolpath creation or as part of the 3D Modeling creation.

Commands for vector creation and editing are very easy to use and multiple design elements can also be drawn or imported, scaled, positioned and interactively edited to make a new design.

Text can also be created using any TrueType or OpenType fonts installed on your computer, or the single stroke engraving fonts supplied with the software.

File Operations

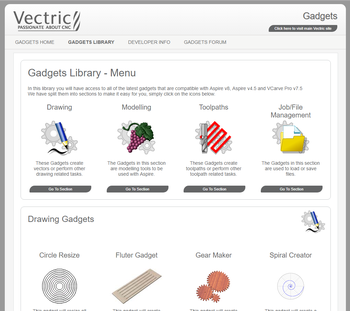

Click on an icon to learn more about it:

| File Operations | |||||

New, Open and Save

|

Create a New File |

This option opens the Job Setup form, which is used to create a new blank job of the specified dimensions and type. The relative origins for X0, Y0 and Z0 are also specified at this point, and the measurement units can be set in either inches or metric. The Modeling Resolution and default 3D shading color/material can also be set at this stage. |

|

Open a File |

This option opens the File Open dialog window, allowing Aspire files (CRV) and importable 2D vector files to be selected and opened. |

|

Save a File |

This option opens the File Save As dialog window and allows the job to be saved as a Aspire file. Navigate to the required folder, enter a suitable name for the job and click the Save button. You can also change the Save As Type using the Dropdown menu. This will allow you to save your file in the .CRV VCarve Pro file type. Saving with this file type will remove all 3D clipart and other 3D Data that is not usable in VCarve Pro, and will allow you to open a file from Aspire in VCarve Pro. |

|

Import Vectors |

This opens the File Open dialog window and allows 2D DXF, EPS and AI and PDF files to be imported into the 2D View. The imported vectors will always be read in at the size and scale they were created in their original design software. Once open they can be scaled and edited in the same way as vectors created in Aspire. All the Vector tools will be dealt with in that section of this manual. To import toolpaths from PhotoVCarve and Cut3D (.PVC and .V3D file extensions), use File ► Import... ► Import PhotoVCarve or Cut3D Toolpaths from the main menu bar. Any Toolpath data saved as .PVC or .V3D files can be imported and will be visible in the Toolpath List. See the 3D Toolpath Files section for detailed instructions on importing PhotoVCarve(*.pvc), Cut3D(*.v3d) or Vectric 3D Machinist(*.v3m) files. |

|

Import Bitmap |

This opens the File Open dialog window and allows image files to be selected and imported into the current open job. File types - BMP, JPG, TIF, GIF, PNG Images are imported to sketch vectors over the top of them, generate traced vectors or to be used to generate a 3D Component directly from the image. These functions will be covered in more detail in the 2D and 3D design section of this manual. |

File Types

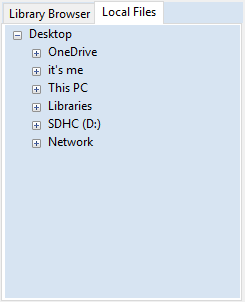

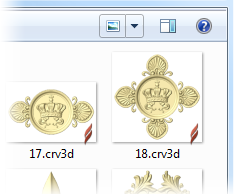

CRV3D |

Files previously created and saved in Aspire will be opened and displayed in the 2D Design window and 3D View if they contain 3D data. All calculated toolpaths are stored/opened from the CRV3D file. |

CRV |

Files previously created and saved in Aspire will be opened and displayed in the 2D Design window. All calculated toolpaths are stored/opened from the CRV file. |

DXF |

Files from other CAD or graphics software packages such as AutoCAD will be opened in the original size and position. The Job Setup Form is automatically opened showing the maximum X and Y dimensions of the opened design. The actual size of the material can then be specified along with the required thickness and appropriate X0, Y0 and Z0 origins. |

EPS |

Files from typical design software such as Corel Draw can be opened. The Job Setup form will automatically be opened so the required material size can be specified. By default the EPS file will be placed with the lower left corner of the design at X0, Y0. |

AI |

Files from typical design software such as Adobe Illustrator and Corel Draw can be opened. The Job Setup form will automatically be opened so the required material size can be specified. The AI file will be placed with the lower left corner of the design at X0, Y0 |

|

Software such as the Adobe product range can be used to convert files from other design and word processing software into the industry standard PDF file format. The text and vector content of PDF files is extracted when imported into Aspire. When importing multiple page PDF documents each page is placed on a separate layer. |

|

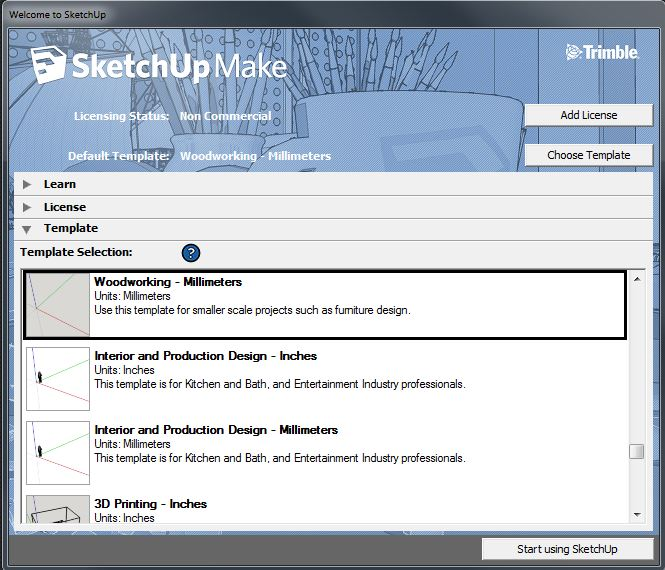

SKP |

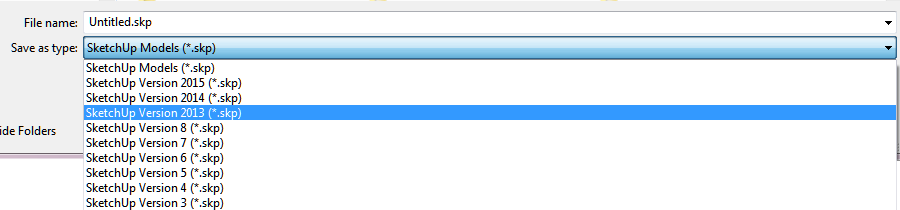

SketchUp files with a .SKP extension (see www.sketchup.com) can be imported as 2D data suitable for machining. |

SketchUp Files

SketchUp files with a .SKP extension (see www.sketchup.com) can be imported as 2D data suitable for machining into a Aspire job using the File ► Import Vectors... command from the menu bar or the import vectors ![]() icon on the Drawing tab.

To import data from a SketchUp file you must already have created or opened a job to import the data into.

icon on the Drawing tab.

To import data from a SketchUp file you must already have created or opened a job to import the data into.

As a SketchUp model is usually a 3D representation of the part, the SketchUp importer offers a number of options to allow you to start manufacturing the model.

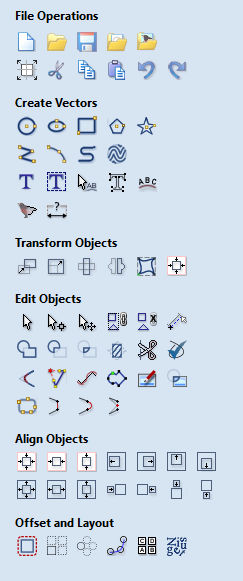

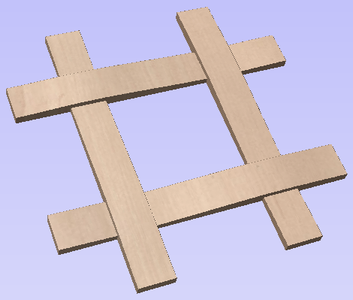

We will illustrate the two main choices for how the model will be imported using the SketchUp model shown to the left.

The model shown in the screenshots is a cabinet constructed by following the instructions in the Fine Woodworking 'Google SketchUp guide for Woodworkers: The Basics' DVD which is available via the Fine Woodworking site at www.finewoodworking.com. Vectric have no affiliation with Fine Woodworking, we are just using screenshots of the model constructed while following their tutorials to illustrate the process of importing a SketchUp model.

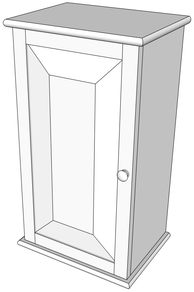

When the SketchUp model is selected from the File Import dialog, the following dialog will be displayed.

Although this initially looks complex, the dialog is divided into four logical sections which will be describe below.

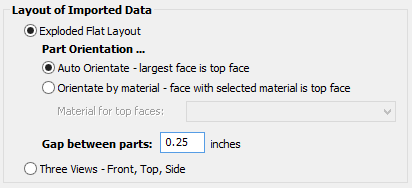

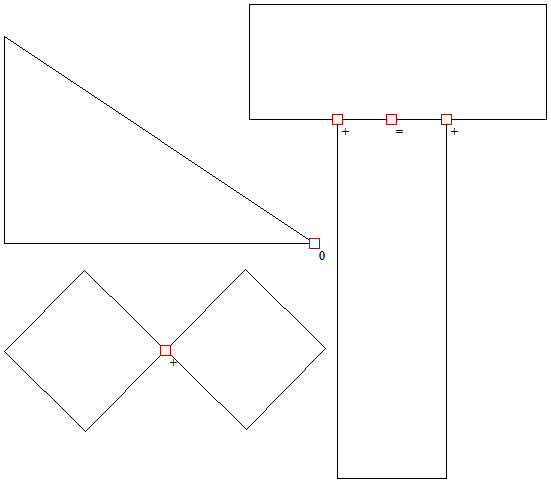

Layout of Imported Data

In the first section there are two main choices for how the data from the model will be imported, 'Exploded Flat Layout' and 'Three Views - Front, Top, Side' as shown below.

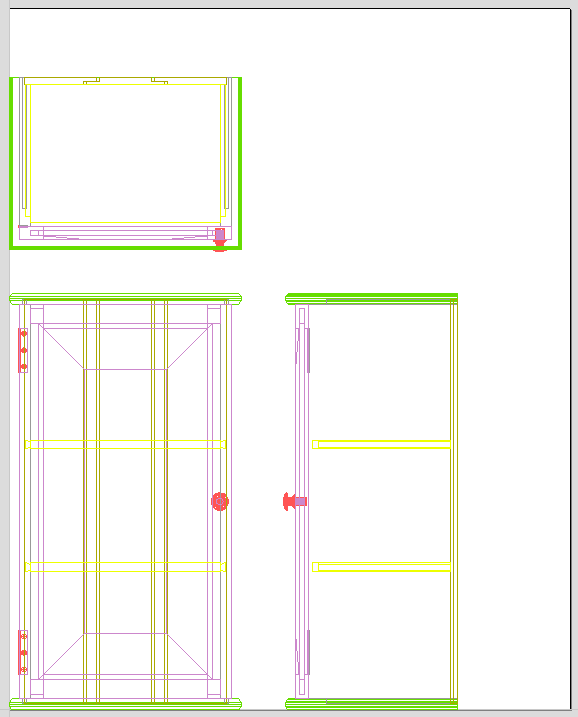

We will describe the 'Three Views - Front, Top, Side' option first as it is the simplest.

Three Views - Front, Top, Side

This option will create an 'engineering drawing' style layout of the SketchUp model as shown in the screenshot below.

The size of the model is preserved and it is relatively simple to pick up dimensions for parts you are going to manufacture from the various views. The colors of the lines you see are taken from the colors of the original SketchUp layers the various parts of the model are on.

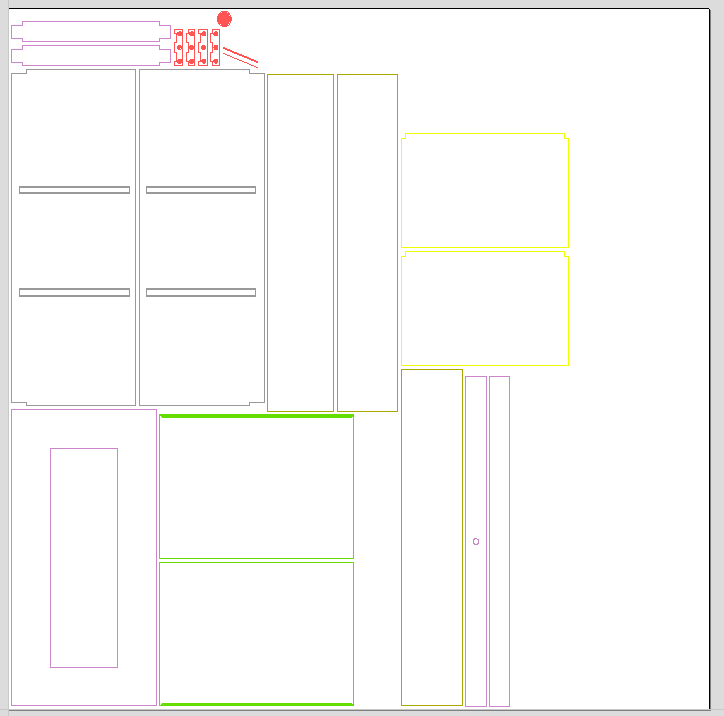

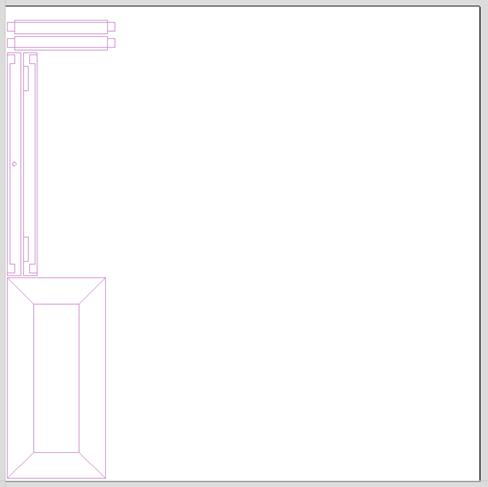

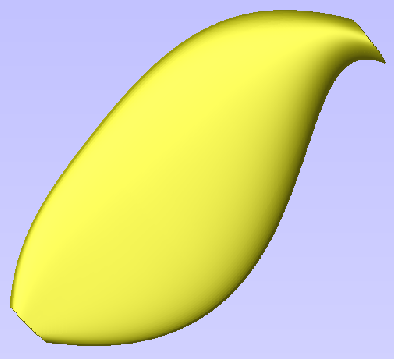

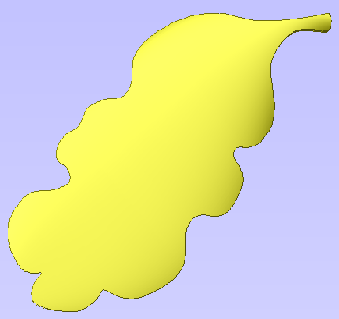

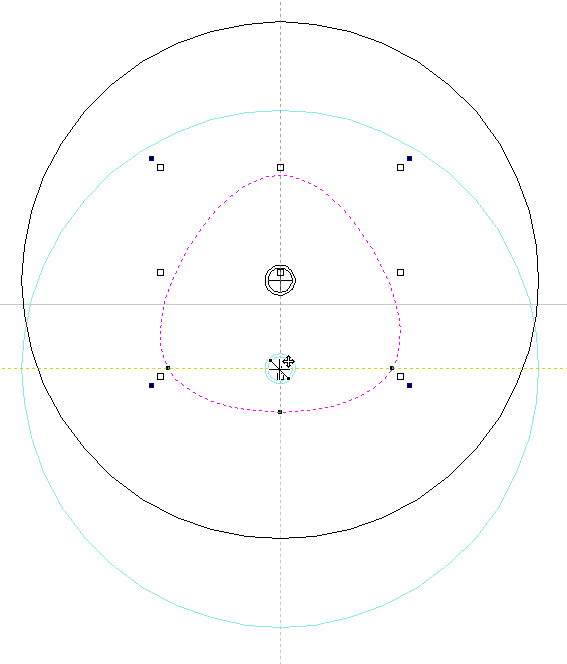

Exploded Flat Layout

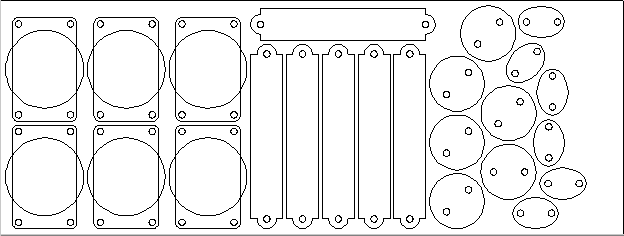

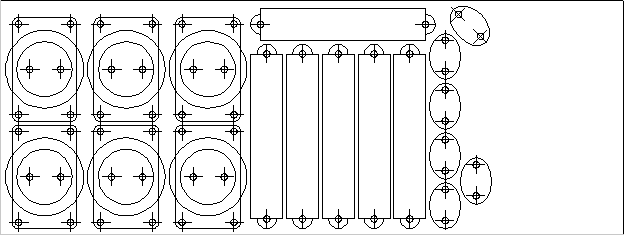

This option will take each component in the model and orientate it flat ready for machining as shown in the screenshot below.

Once this option is selected a number of sub-options also become available.

Part Orientation

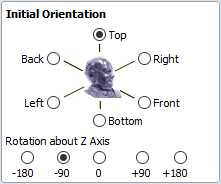

This section controls what Aspire considers to be the 'top' face of each part.

Auto Orientate

If this option is selected, for each part in the model, the 'face' with the largest area based on its outer perimeter (i.e. ignoring holes etc.) is considered to be the 'top' face and the part is automatically rotated so that this face is facing upwards in Z. This strategy works very well for models which are to be manufactured from sheet goods where there are no features on particular faces which need to be on the 'top' (such as pockets).

Orientate by material

This option allows the user to control more explicitly the orientation of each part in the model. Within SketchUp the user can 'paint' the face of each component/group with a material/color of their choice to indicate which face will be orientated on top when the model is imported. When this option is selected simply chose the material which has been used to indicate the top face from the drop down list. If a part is found in the model which does not have a face with the specified material, that part will be oriented by making the largest face the top.

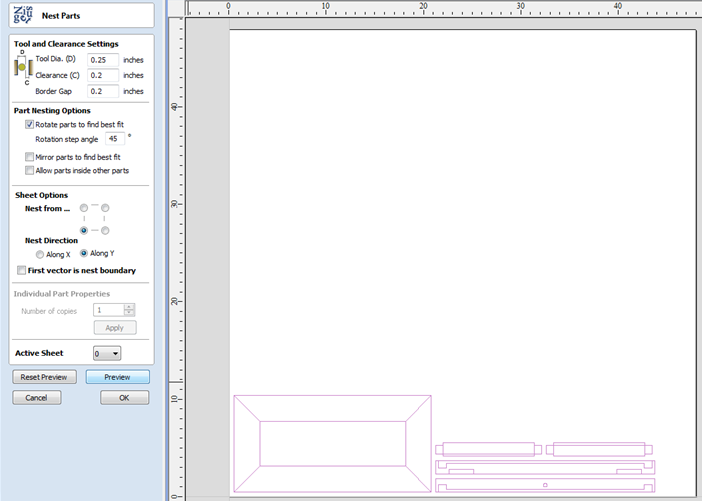

Gap between parts

This field lets the user specify the gap between parts when they are first imported. After importing, the nesting functions within Aspire can be used to layout the parts with more control and across multiple sheets.

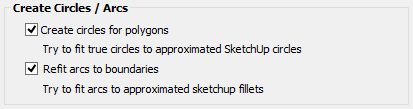

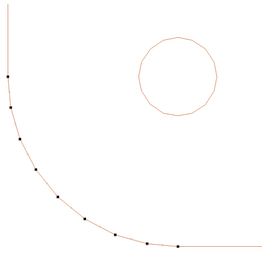

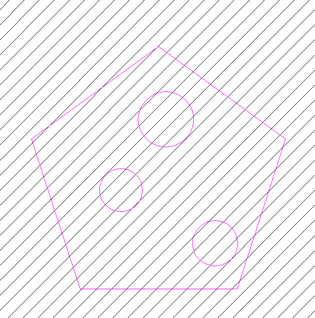

Create Circles / Arcs

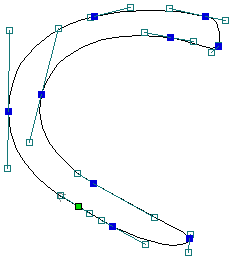

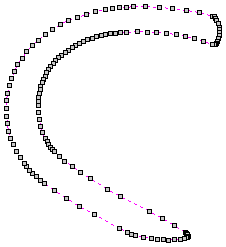

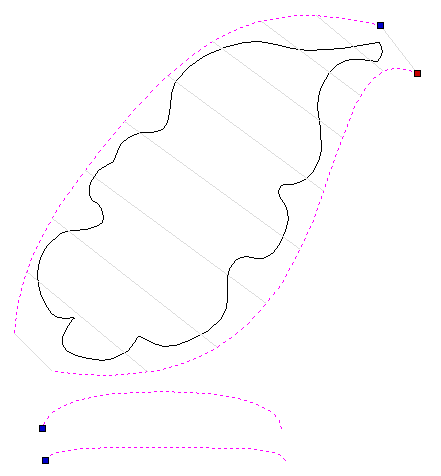

SketchUp does not maintain true arc or circle information for the boundaries of its parts. This is a problem when it comes to machining as the 'polygonal' SketchUp representation can give very poor machining results. For this reason, Aspire offers the option to refit circles and arcs to imported data.

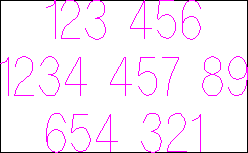

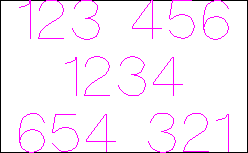

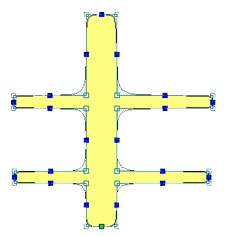

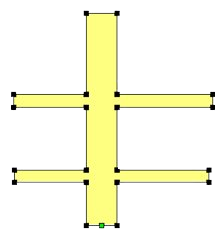

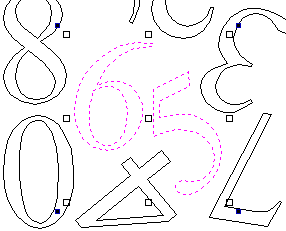

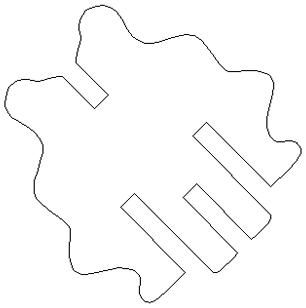

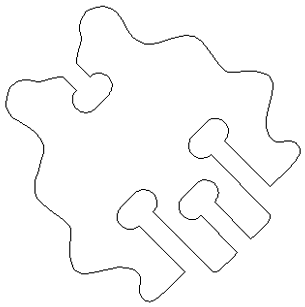

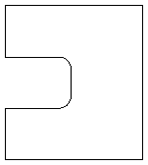

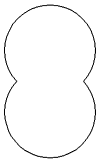

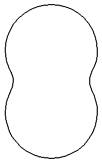

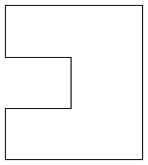

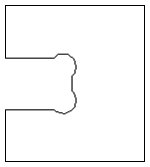

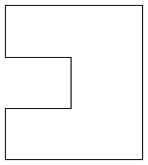

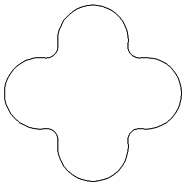

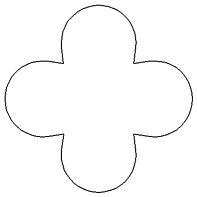

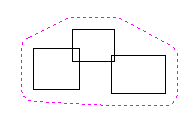

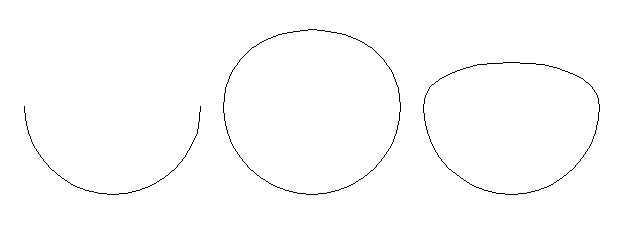

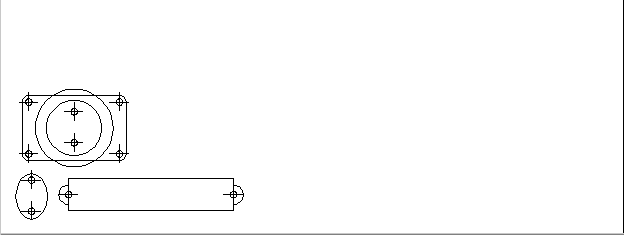

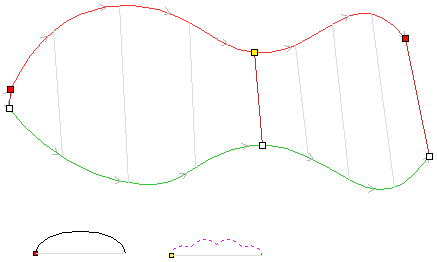

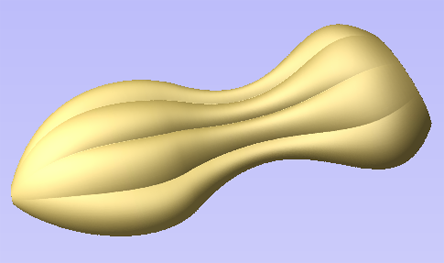

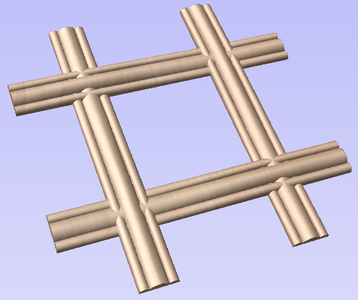

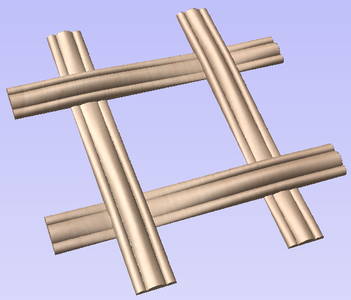

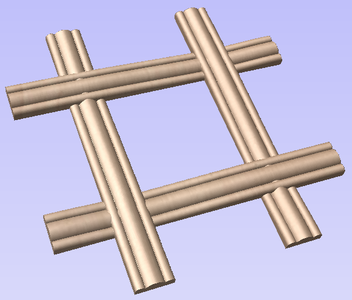

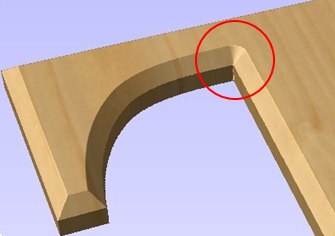

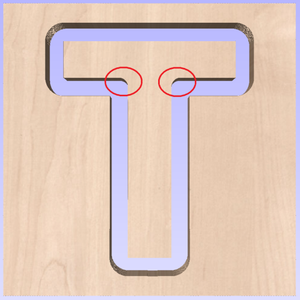

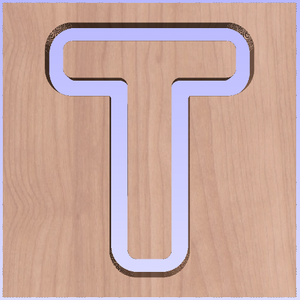

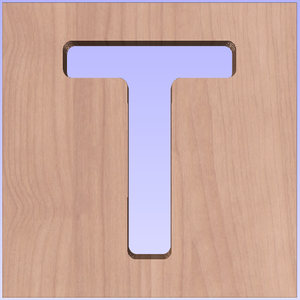

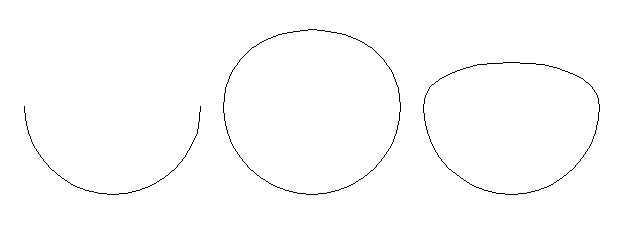

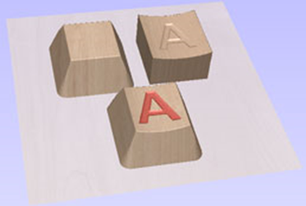

Options Checked ✓

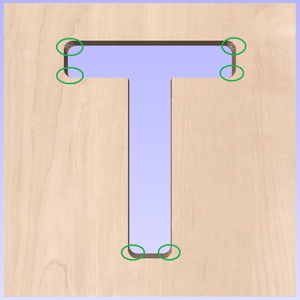

Options Unchecked

The screenshot above left shows the results of importing a part with a filleted corner and hole with these options unchecked. The 'fillet' is made up of a series of straight line segments and the circular 'hole' is actually a polygon made up of straight lines.

The screen shot above right shows the same part imported with both these options checked ✓. The 'fillet' now consists of a single smooth arc and the circular 'hole' now also consists of arcs rather than straight line segments. Both these features will machine more cleanly in this form.

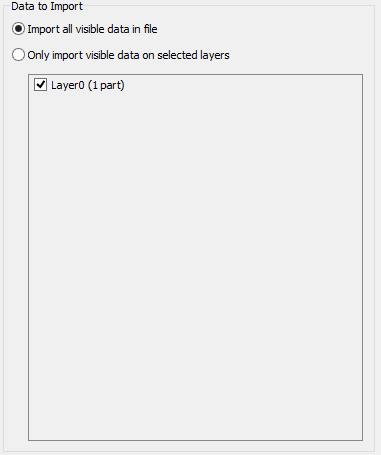

Data to Import

A SketchUp model will often contain parts that you do not wish to machine (such as hinges, knobs etc.) or data which will be cut from different thicknesses of material and hence different parts need to be imported into different Aspire jobs. To allow control over what is imported you can choose to only import parts of the model which are on particular layers using this section of the dialog.

To only import data from selected layers, choose the 'import visible data on selected layers' option and click the check box next to each layer to indicate if you want to import data from that layer. Note that the number of parts on each layer is displayed next to the layer name.

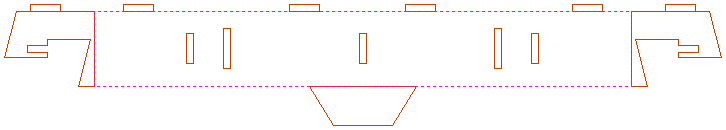

It is very easy to assign different parts of the model to different layers within SketchUp to help with the import process into Aspire. The screenshot below shows the result of only importing data on the 'Door' layer from the example.

As long as the 'Group imported parts' option is selected, these parts can then be easily nested ready for machining as shown in the image below (the 'Group imported parts' option is explained later in this section).

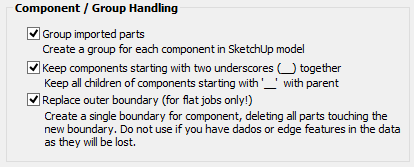

Component / Group Handling

This section of the form allows advanced handling of how 'parts' within the SketchUp model are identified and treated on import.

Group imported parts

This option is normally selected for all but the simplest models as it allows each 'part' of the model to be selected, moved and nested easily after import. You will need to ungroup the imported data after nesting etc. to allow individual features to be machined. By default, Aspire will treat each SketchUp group / component as a single part UNLESS it contains other groups or components within it, in which case each lowest level group / component will be treated as a separate part.

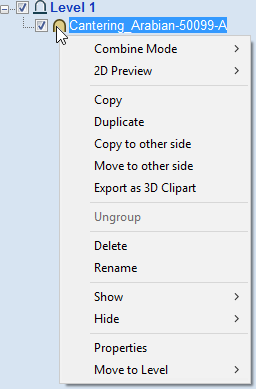

Items which you retain in groups can be ungrouped at any time in the usual ways.

If the right-click menu-option to Ungroup back onto original object layers is used (which is the default option when using the icon or shortcut U) then the software will place the ungrouped items back onto the original layers they were created on in SketchUp.

Keep components starting with two underscores (__) together

If you have a complex model which contain 'parts' which are made up of other groups / components, you will need to do some work on your model to identify these parts for Aspire. The way this is done is by setting the name of the groups / components that you wish to be treated as a single part to start with__ (two underscore characters). For example, if you had a model of a car and you wanted the wheels / tires / hub nuts to be treated as a single part even though the Tire, Wheel and other parts were separate components, you would group the parts together and name them something like __WheelAssembly in SketchUp. When this model was imported, and Aspire reached the group/component with a name starting with __ it would treat all subsequent child objects of that object as being the same part.

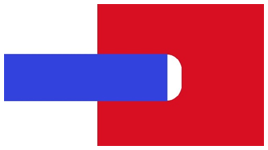

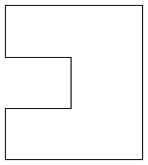

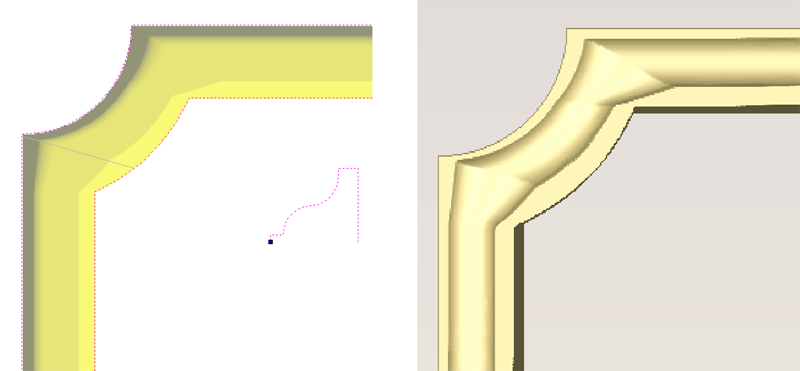

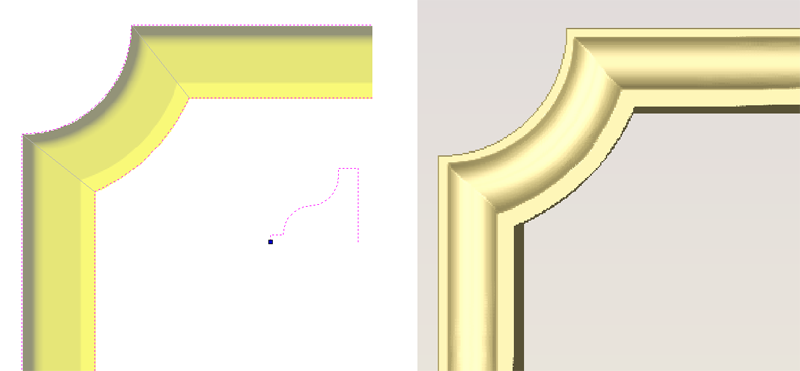

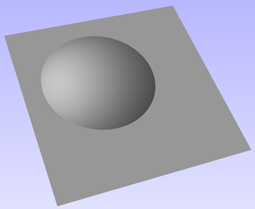

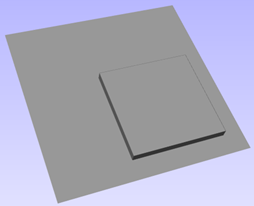

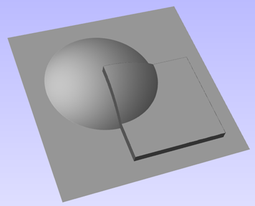

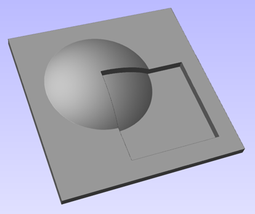

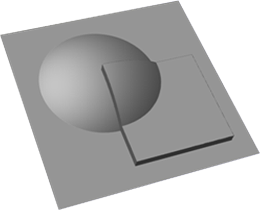

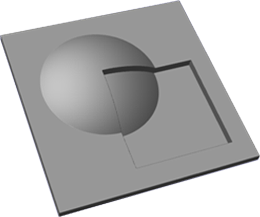

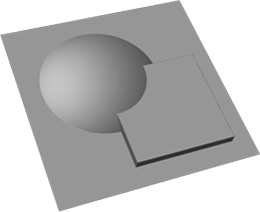

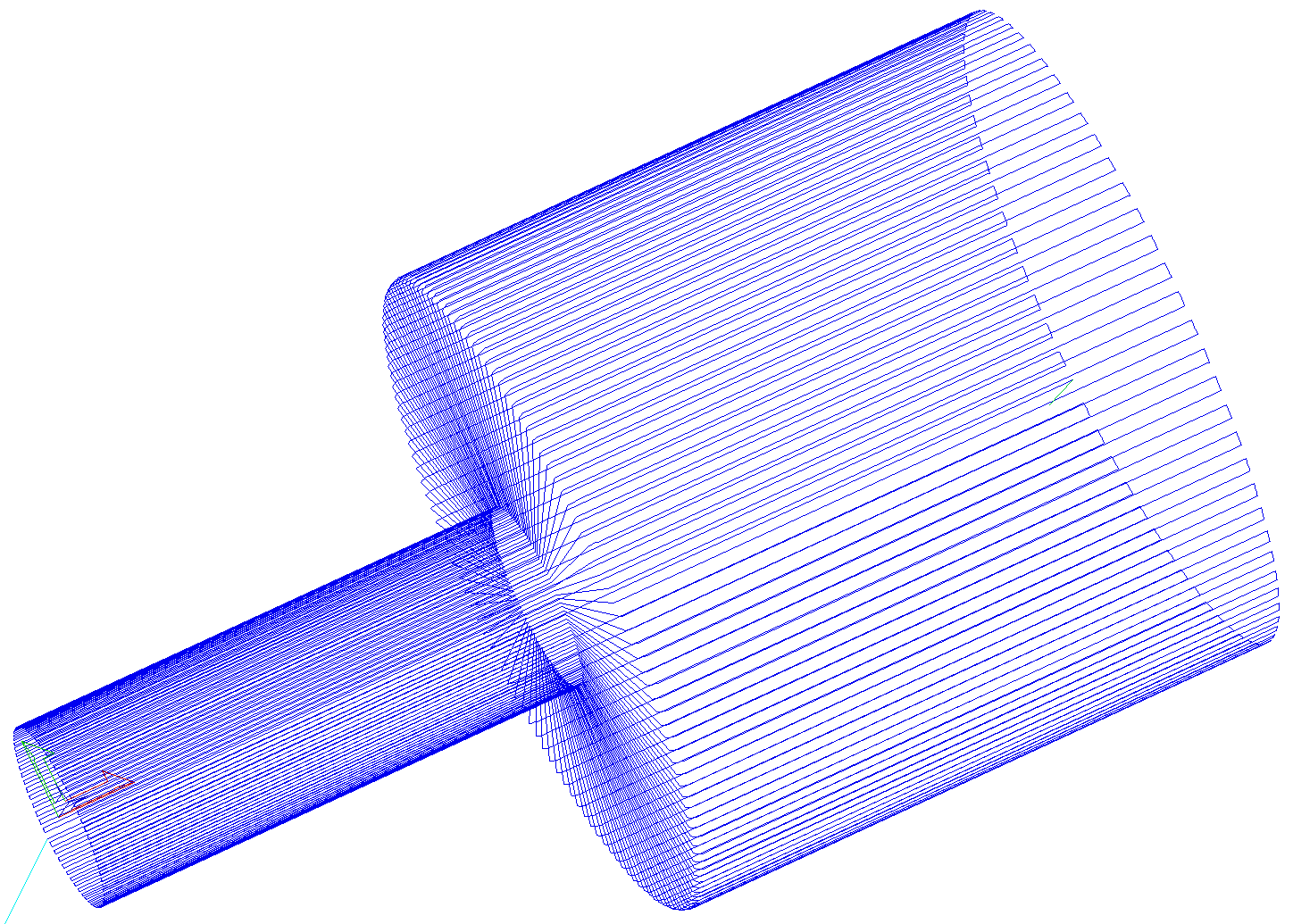

Replace outer boundary (for flat jobs only!)

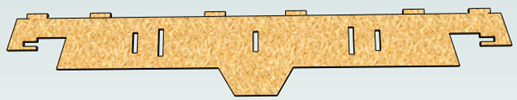

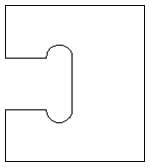

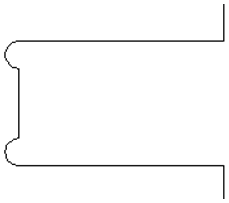

There is a style of 'building' with SketchUp where individual 'parts' are made up of several components 'butted' against each other. The screenshot below shows such a component.

This object is made up of many smaller components representing the tabs on the top, the connectors at the end and the support at the bottom as shown below.

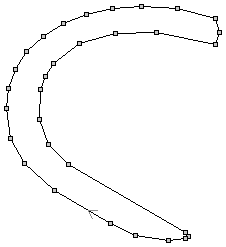

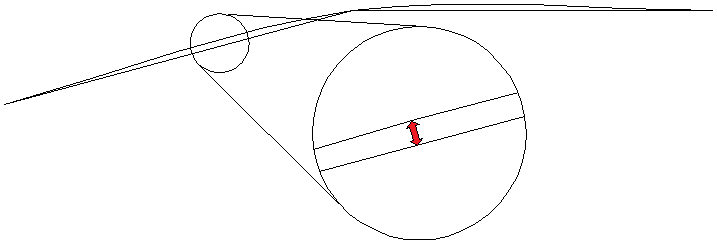

Although when can treat this as a single 'part' when imported by starting its name with __ (two underscores), the imported part is still going to be difficult to machine. The screenshot below shows the part imported into Aspire without the 'Replace outer boundary' option checked ✓. The part in the image has been ungrouped and the central vector selected.

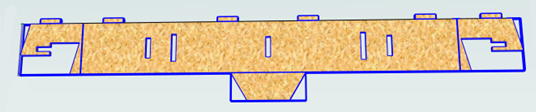

As you can see, the outer boundary is made up of separate segments for each 'feature'. Aspire does have the ability to create an outer boundary for vectors but this can be time consuming if it has to be done manually. If the 'Replace outer boundary' option is checked, ✓ for every part Aspire will try to create a single outer boundary and delete all the vectors which were part of this boundary. The screenshot below shows the result of importing the same data with this option checked, ✓ this time the part has been ungrouped and the outer vector selected.

This data is now ready to be machined directly. It is important to understand the limitations of this option. It can be substantially slower. Creating robust boundaries for each part can consume a lot of processing power. Any feature which shares an edge with the boundary will be deleted. If the tabs on the top of this part were to have been machined 'thinner', this approach would not have been suitable as the bottom edge of the tabs has been removed.

The new features will help a lot of SketchUp users dramatically reduce the time it takes to go from a SketchUp design to a machinable part using Aspire.

It is important to understand though that while these options provide a useful set of tools, in many cases there will still be additional editing required to ensure the part is ready to toolpath.

Understanding the options and how they work will allow the part to be designed in SketchUp with these in mind and therefore help to minimize the time to machine once the data is imported.

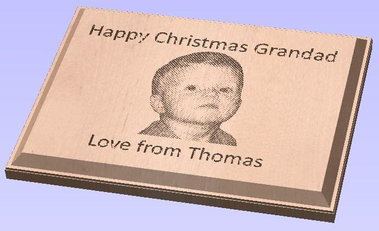

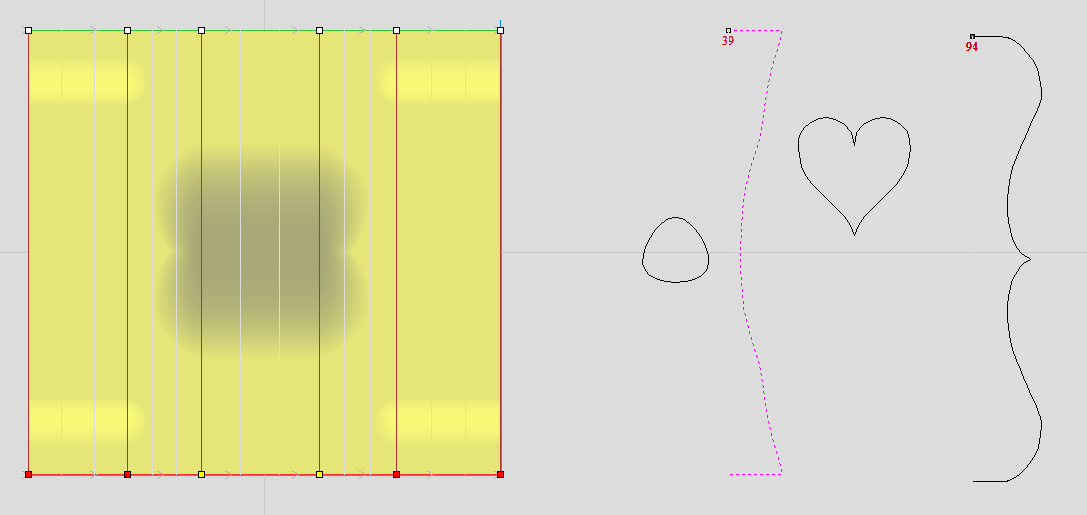

3D Toolpath Files

Files from Vectric's Cut3D, PhotoVCarve and Design and Make Machinist that include 3D toolpaths can be imported into Aspire using the main menu command: File ► Import ► PhotoVCarve, Machinist or Cut3D Toolpaths.

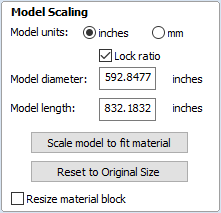

The 3D file must first be scaled to the required size before toolpaths are calculated, and then the complete file saved ready for importing into Aspire. These files can only be moved and positioned inside Aspire but cannot be scaled.

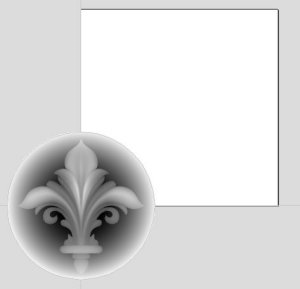

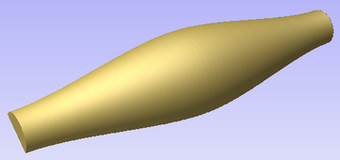

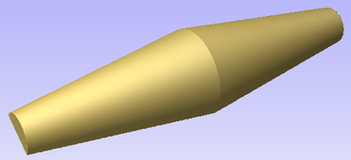

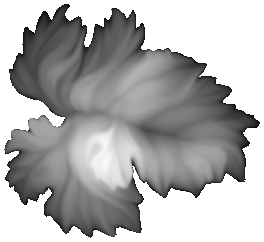

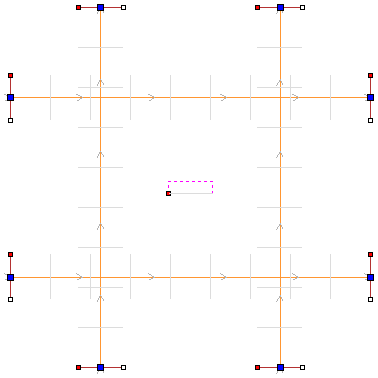

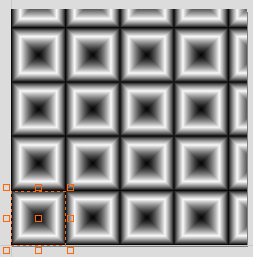

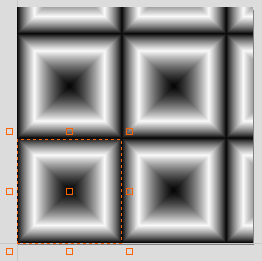

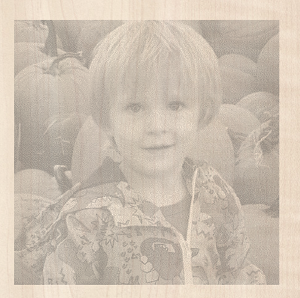

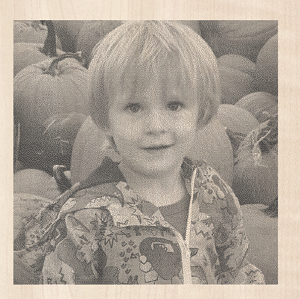

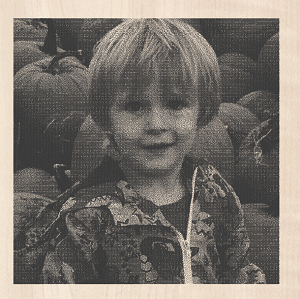

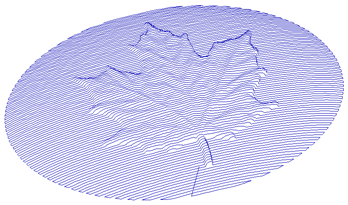

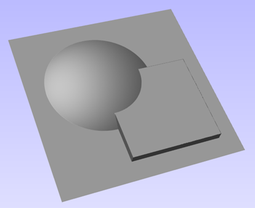

A Grayscale thumbnail of the 3D job is drawn in the 2D View with the X0 Y0 origin at the position it was set in Cut3D, PhotoVCarve or Design and Make Machinist. The associated toolpath(s) are also drawn in the 3D window and the names appear in the Toolpath list.

Positioning

To move the 3D design toolpaths:

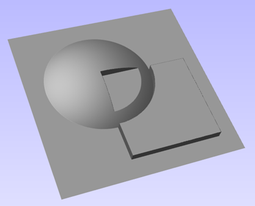

Open the 2D Window, Click the Left mouse Twice on grayscale image (turns light Blue to indicate it's selected) Drag to the required position Or use the Move or Alignment tools for accurate positioning.The toolpath(s) are automatically moved in the 3D window to the same XY position as the image.

Origin for the 3D data at X0 Y0

Grayscale image moved to middle of job

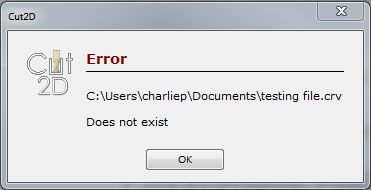

Toolpaths for the example above have been calculated with the X0 Y0 in the middle of the 3D design. When imported into Cut2D the data is automatically positioned using the same coordinates, which places three quarters of the design off the job. In the second image the grayscale image has been moved to the middle of the job.

The 2D mirror and rotate drawing tools can also be used to edit the 3D data set.

3D toolpaths can also be copied using the ![]() Duplicate Toolpath command on the Toolpaths Tab making it very easy to use multiple elements from a single design on a job.

The thumbnail preview is also copied for each toolpath, making it very easy to position additional copies of a 3D toolpath.

Duplicate Toolpath command on the Toolpaths Tab making it very easy to use multiple elements from a single design on a job.

The thumbnail preview is also copied for each toolpath, making it very easy to position additional copies of a 3D toolpath.

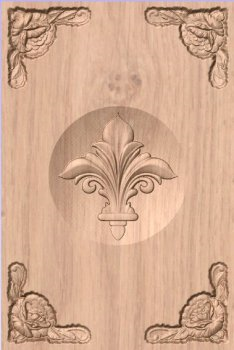

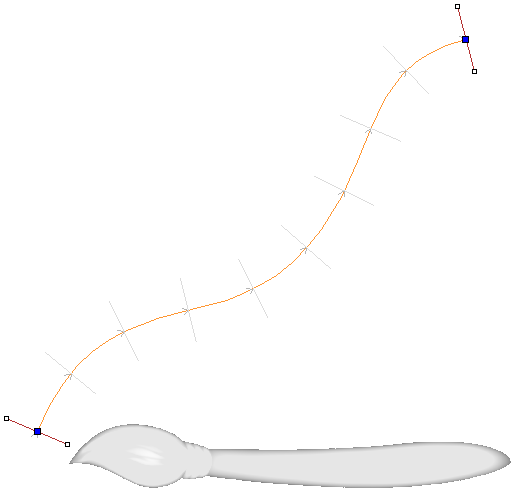

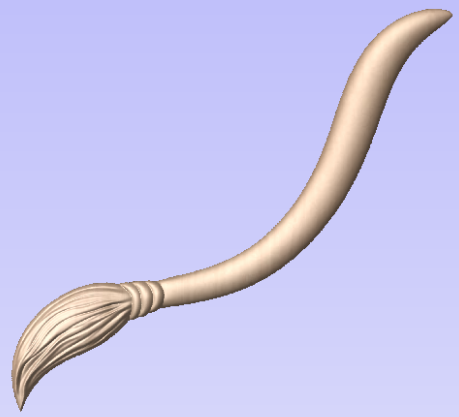

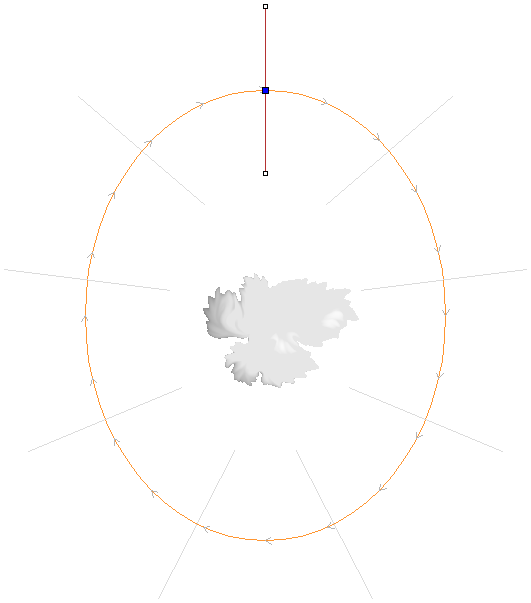

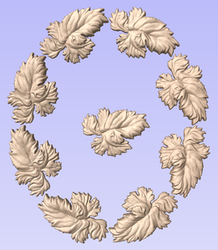

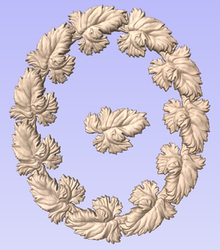

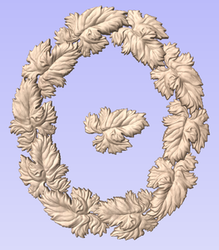

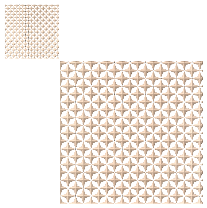

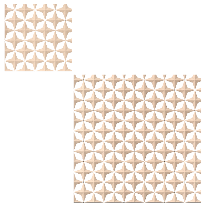

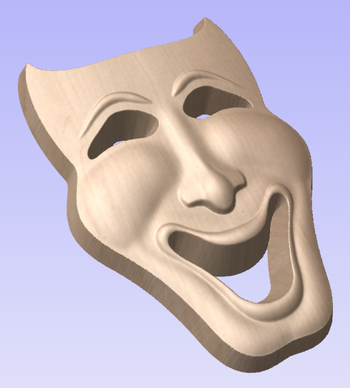

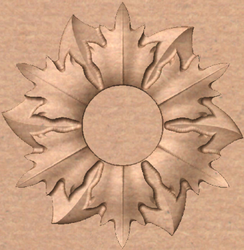

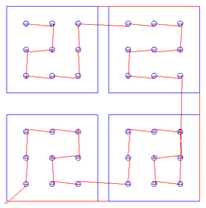

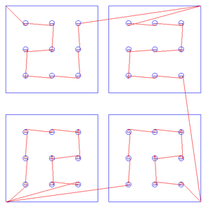

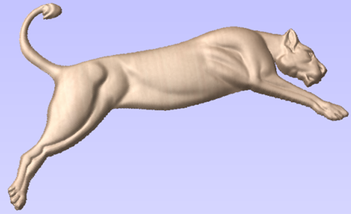

For example, a single design can be copied and mirrored to create Left and Right versions of a 3D design or to place multiple copies of a decorative design in the corners of a cabinet door panel as shown below.

The 4 corner roses are all copied from a single file

Toolpaths for the 3D elements can be previewed along with the conventional Profile, Pocketing and Drilling toolpaths, and everything will be saved ready for machining.

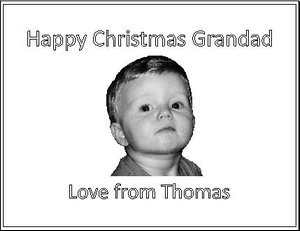

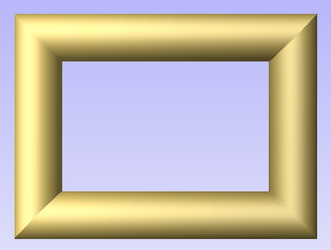

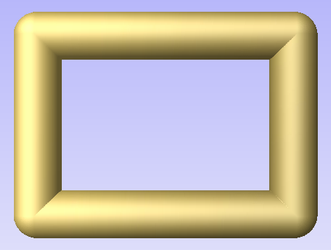

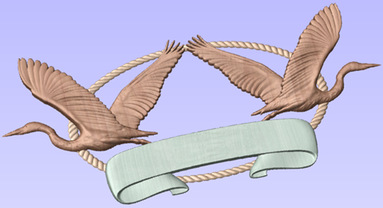

A good example of where this functionality might be used in conjunction with PhotoVCarve is for making personalized picture frames that include the PhotoVCarve grooves plus descriptive engraved text and a decorative Profiled or Beveled border. As shown below:

2D window showing thumbnail previews,

text and decorative border

3D window previewing the completed job

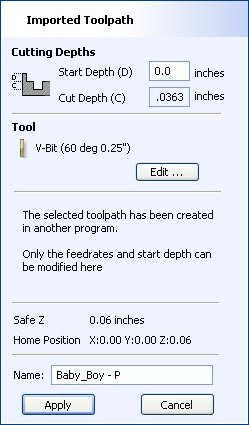

Options

Imported toolpaths can also be edited to position them inside the material or to change the cutting parameters - speeds and feed rates can be changed.

Click the Edit toolpath icon or Double click on the toolpath name to open the edit form.

For example, after machining a half-inch deep pocket a PhotoVCarve design can then be edited to have a Start Depth = 0.5 inches and this will carve the photograph onto the base of the pocket surface.

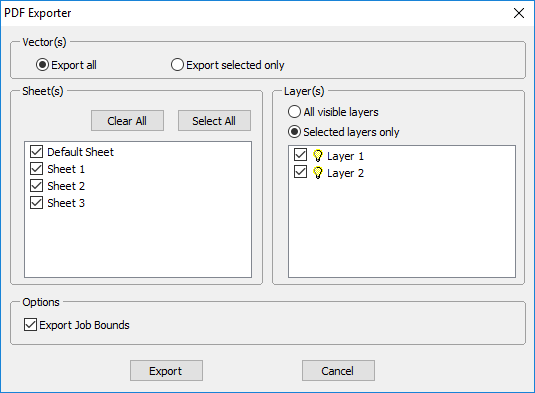

PDF Export

The PDF Export form allows vectors within your drawings to be exported into PDF format.

Vector(s)

Selecting Export All will export all of the vectors contained on the specified sheets and layers.

Selecting Export Selected Only will export only the vectors which are currently selected and on the specified sheets and layers.

Sheets

The sheets you wish to be exported to PDF can be selected from within this section. Clicking will deselect all of the sheets and clicking will cause all of the sheets to become selected. You can also manually select/deselect individual sheets by clicking on the check box to the left of the sheet name.

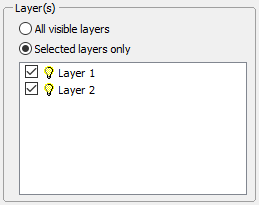

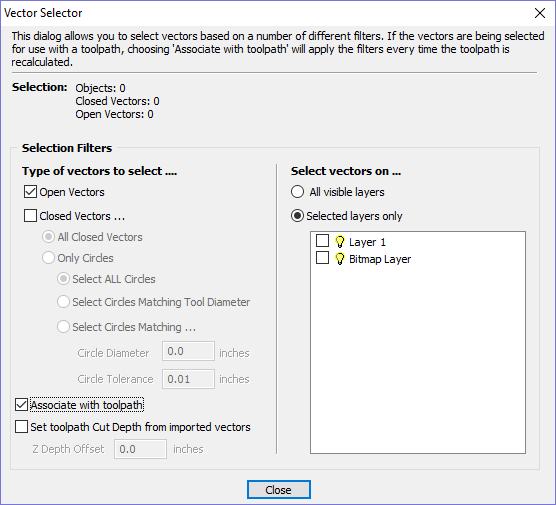

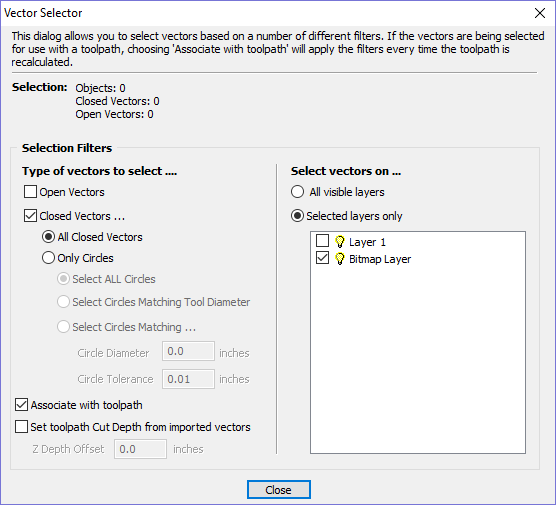

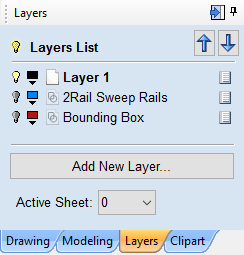

Layers

The layers you wish to be exported to PDF can be selected from within this section. All the visible layers with content on them will show up in this list.

When All visible layers is chosen all of the vector layers will be selected. Only vectors on the layers selected will be exported into the PDF file. When Selected layers only is chosen individual layers can be manually selected/deselected by clicking on the check box to the left of the layer name.

Options

Export Job Bounds - If this option is selected a vector representing the boundary of the job will also be output to the PDF file.

Clicking will prompt you to choose a filename and location for your file and save your drawing in PDF format at that location.

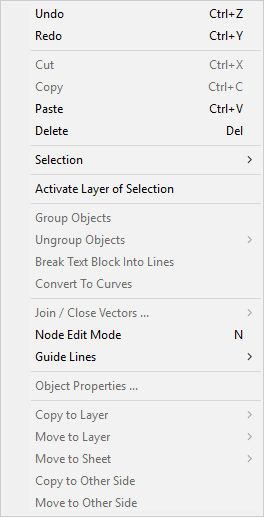

Cut, Copy and Paste

The Cut, Copy and Paste functions in Aspire can be used on Vectors, Bitmaps and also 3D Component Grayscales. When a Component Grayscale is pasted, the 3D data associated with it will also be pasted into the 3D View and the Component Tree.

|

Cut |

The Cut tool removes the selected objects from a design in a similar way to pressing the Delete key, but the selected objects are copied to the clipboard and can be Pasted into either the current file or a new file if required. Only one item can be Cut or Copied at a time. |

|

Copy |

The Copy tool copies selected objects to the clipboard, leaving the original in place and allows duplicates to be made and re-used in the design by pressing the Paste icon. Only one item can be Cut or Copied at a time. |

|

Paste |

This Paste option places the contents of the clipboard (created by Cut or Copy) into the design, allowing elements to be re-used in different areas of a design or in other Aspire parts. |

|

Undo |

Clicking this option steps backwards through the design changes made by the user. |

|

Redo |

Clicking this option steps forward through design steps that have been Undone using the Undo command (see above) to get back to stage that the user started using the Undo function. |

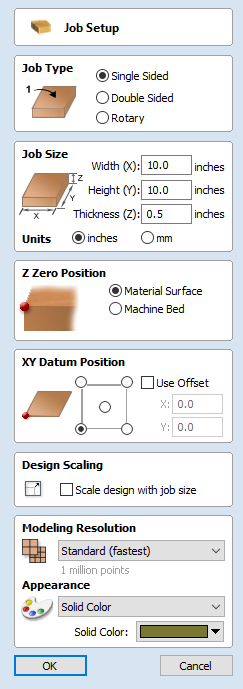

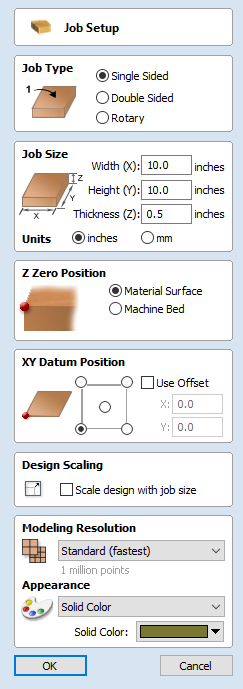

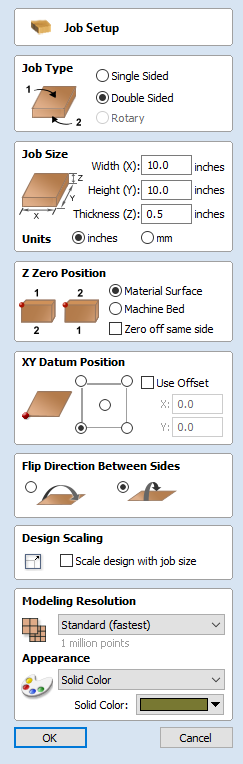

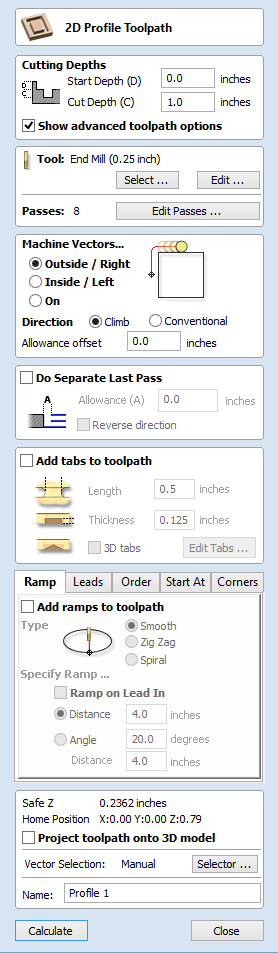

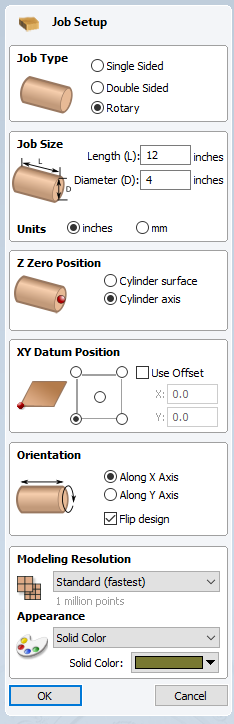

Job Setup

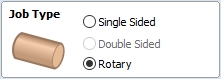

The Job Setup form is displayed whenever a new job is being created, or when the size and position of an existing job is edited. It allows to create following types of job:

Job Setup - Single Sided

The Job Setup form is displayed whenever a new job is being created, or when the size and position of an existing job is edited.

Job Type

Single Sided job type should be used when design only requires the material to be cut from one side. This is the simplest type of job to design and machine.

For more information about Double Sided job type see Job Setup - Double Sided.

For more information about Rotary job type see Job Setup - Rotary.

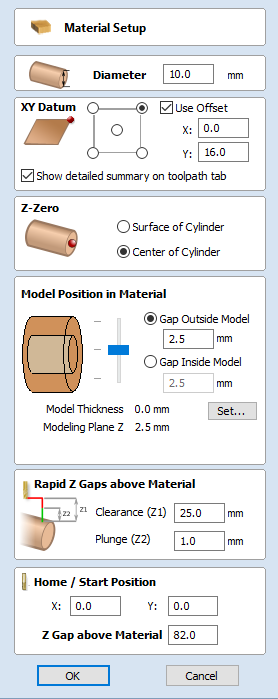

Job Size

This section of the form defines the dimensions of the material block you will be using for your project in terms of width (along the X axis), height (along the Y axis) and thickness (along the Z axis).

It also allows you to select which units of measurement you prefer to design in - either inches (Imperial/English) or millimeters (Metric).

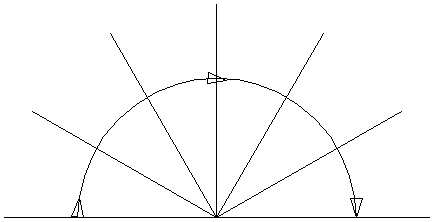

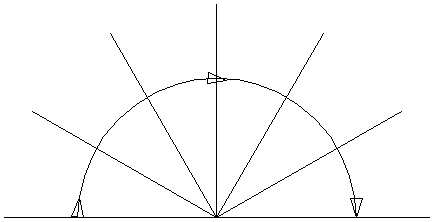

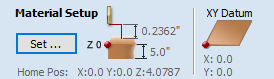

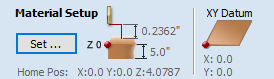

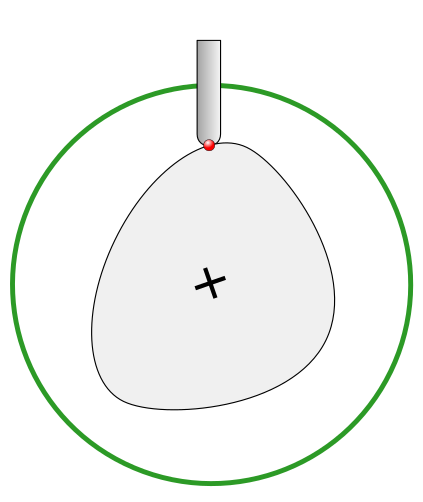

Z Zero Position

Indicates whether the tip of the tool is set off the surface of the material (as shown in the diagram) or off the bed / table of the machine for Z = 0.0.

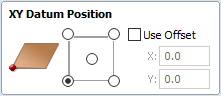

XY Datum Position

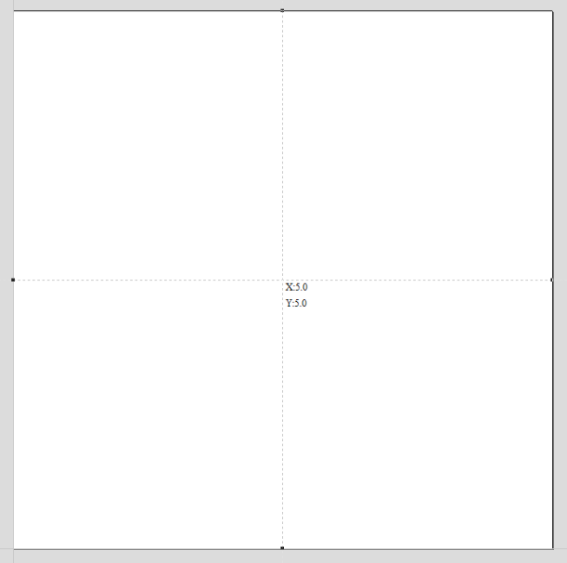

This datum can be set at any corner, or the middle of the job. This represents the location, relative to your design, that will match the machine tool when it is positioned at X0, Y0. While this form is open, a red square is drawn in the 2d view to highlight the datum's position.

Use Offset

This option allows the datum position to be set to a value other than X0, Y0.

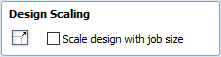

Design Scaling

When editing the Job Size parameters of an existing job, this option determines whether any drawings you have already created will be scaled proportionally to match the new job dimensions. If you wish to preserve the existing size of your drawings, even after the job size has changed, leave this option unchecked. With this option checked, your drawings will be re-sized to remain in the same proportion and relative position within your new material extents when you click .

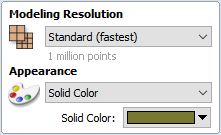

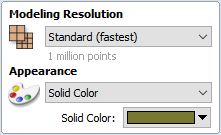

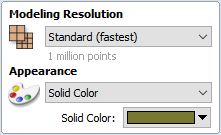

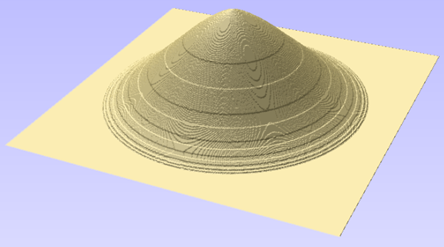

Modeling Resolution

This sets the resolution/quality for the 3D model. When working with 3D models a lot of calculation and memory may be required for certain operations. Setting the Resolution allows you to choose the best balance of quality and speed for the part you are working on. The better the resolution quality chosen, the slower the computer will perform.

As this is completely dependent on the particular part you are working on and your computer hardware performance, it is difficult in a document like this to recommend what the setting should be. Generally speaking, the Standard (fastest) setting will be acceptable for the majority of parts that Aspire users make. If the part you are making is going to be relatively large (over 18 inches) but still has small details, you may want to choose a higher Resolution such as High (3 x slower) and for very large parts (over 48 inches) with small details then the Highest (7 x slower) setting may be appropriate.

The reason that the detail of your part needs to be taken into account is that if you were making a part with one large item in it (e.g. a fish) then the standard resolution would be OK but if it was a part with many detailed items in it (e.g. a school of fish) then the High or Highest setting would be better. As previously stated these are extremely general guidelines as on slower/older computers operations with the highest setting may take a long time to calculate.

As the Resolution is applied across your whole work area it is important to set the size of your part to just be big enough to contain the part you plan to carve. It would not be advisable to set your material to be the size of your machine - e.g. 96 x 48 if the part you plan to cut is only 12 x 12 as this would make the resolution in the 12 x 12 area very low.

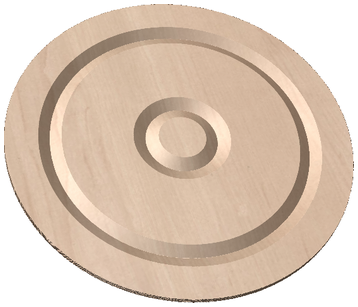

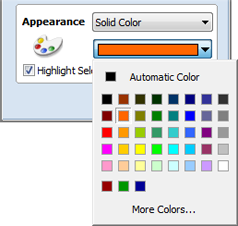

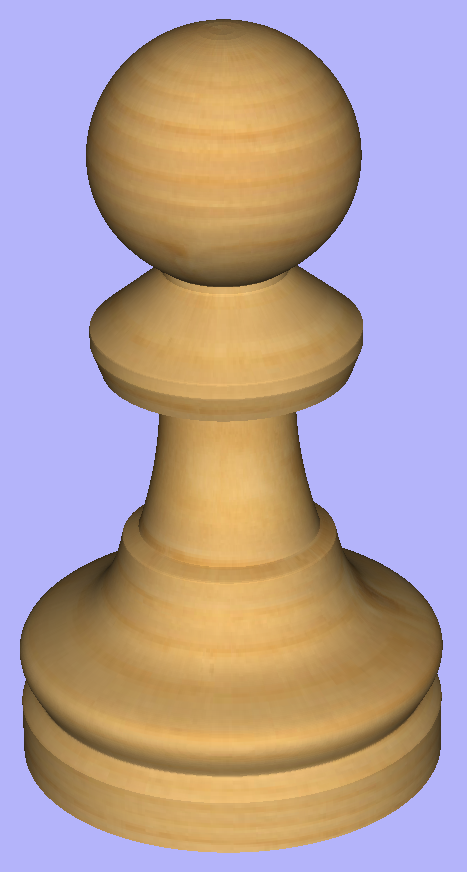

Appearance

This sets the color or material effect which will be applied to the base 3D model. It is possible to change this at any time and also to apply different colors and materials to different Components using the Component manager.

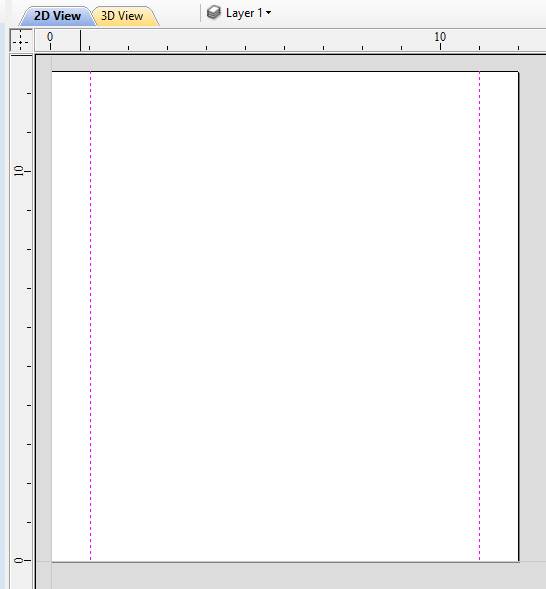

In most cases a new job represents the size of the material the job will be machined into or at least an area of a larger piece of material which will contain the part which is going to be cut. Clicking OK creates a new empty job, which is drawn as a gray rectangle in the 2D View. Dotted horizontal and vertical Grey lines are drawn in the 2D design window to show where the X0 and Y0 point is positioned.

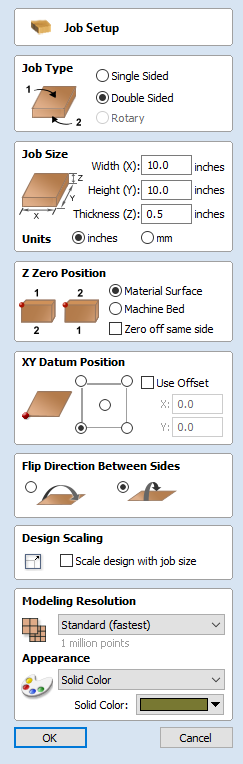

Job Setup - Double Sided

The Job Setup form is displayed whenever a new job is being created, or when the size and position of an existing job is edited.

Job Type

Double Sided job type is useful when it is desired to cut both sides of your material. Aspire allows you to visualise and manage the creation and cutting process of both sides of your design within a single project file.

For more information about Single Sided job type see Job Setup - Single Sided.

For more information about Rotary job type see Job Setup - Rotary.

Job Size

This section of the form defines the dimensions of the material block you will be using for your project in terms of width (along the X axis), height (along the Y axis) and thickness (along the Z axis).

It also allows you to select which units of measurement you prefer to design in - either inches (Imperial/English) or millimeters (Metric).

Z Zero Position

Indicates whether the tip of the tool is set off the surface of the material (as shown in the diagram) or off the bed / table of the machine for Z = 0.0.

Zero off same side

This option allows Z Zero to reference the same physical location, regardless whether material is flipped or not

XY Datum Position

This datum can be set at any corner, or the middle of the job. This represents the location, relative to your design, that will match the machine tool when it is positioned at X0, Y0. While this form is open, a red square is drawn in the 2d view to highlight the datum's position.

Use Offset

This option allows the datum position to be set to a value other than X0, Y0.

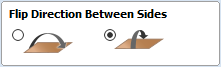

Flip Direction Between Sides

This section gives choice between horizontal and vertical flipping when changing machining side. Aspire uses that information to correctly manage the alignment of the geometry relating to each side.

Design Scaling

When editing the Job Size parameters of an existing job, this option determines whether any drawings you have already created will be scaled proportionally to match the new job dimensions. If you wish to preserve the existing size of your drawings, even after the job size has changed, leave this option unchecked. With this option checked, your drawings will be re-sized to remain in the same proportion and relative position within your new material extents when you click .

Modeling Resolution

This sets the resolution/quality for the 3D model. When working with 3D models a lot of calculation and memory may be required for certain operations. Setting the Resolution allows you to choose the best balance of quality and speed for the part you are working on. The better the resolution quality chosen, the slower the computer will perform.

As this is completely dependent on the particular part you are working on and your computer hardware performance, it is difficult in a document like this to recommend what the setting should be. Generally speaking, the Standard (fastest) setting will be acceptable for the majority of parts that Aspire users make. If the part you are making is going to be relatively large (over 18 inches) but still has small details, you may want to choose a higher Resolution such as High (3 x slower) and for very large parts (over 48 inches) with small details then the Highest (7 x slower) setting may be appropriate.

The reason that the detail of your part needs to be taken into account is that if you were making a part with one large item in it (e.g. a fish) then the standard resolution would be OK but if it was a part with many detailed items in it (e.g. a school of fish) then the High or Highest setting would be better. As previously stated these are extremely general guidelines as on slower/older computers operations with the highest setting may take a long time to calculate.

As the Resolution is applied across your whole work area it is important to set the size of your part to just be big enough to contain the part you plan to carve. It would not be advisable to set your material to be the size of your machine - e.g. 96 x 48 if the part you plan to cut is only 12 x 12 as this would make the resolution in the 12 x 12 area very low.

Appearance

This sets the color or material effect which will be applied to the base 3D model. It is possible to change this at any time and also to apply different colors and materials to different Components using the Component manager.

In most cases a new job represents the size of the material the job will be machined into or at least an area of a larger piece of material which will contain the part which is going to be cut. Clicking OK creates a new empty job, which is drawn as a gray rectangle in the 2D View. Dotted horizontal and vertical Grey lines are drawn in the 2D design window to show where the X0 and Y0 point is positioned.

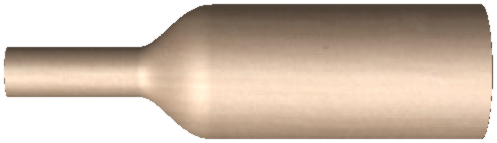

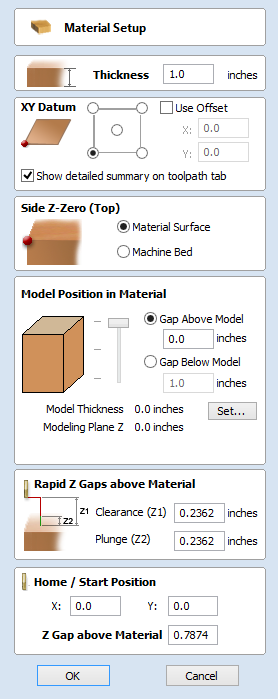

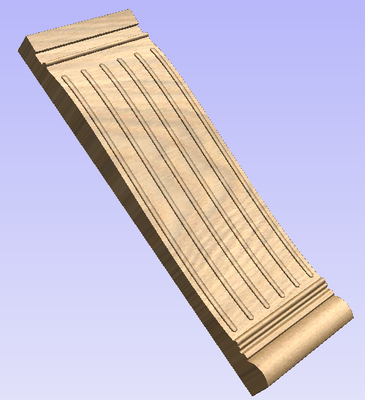

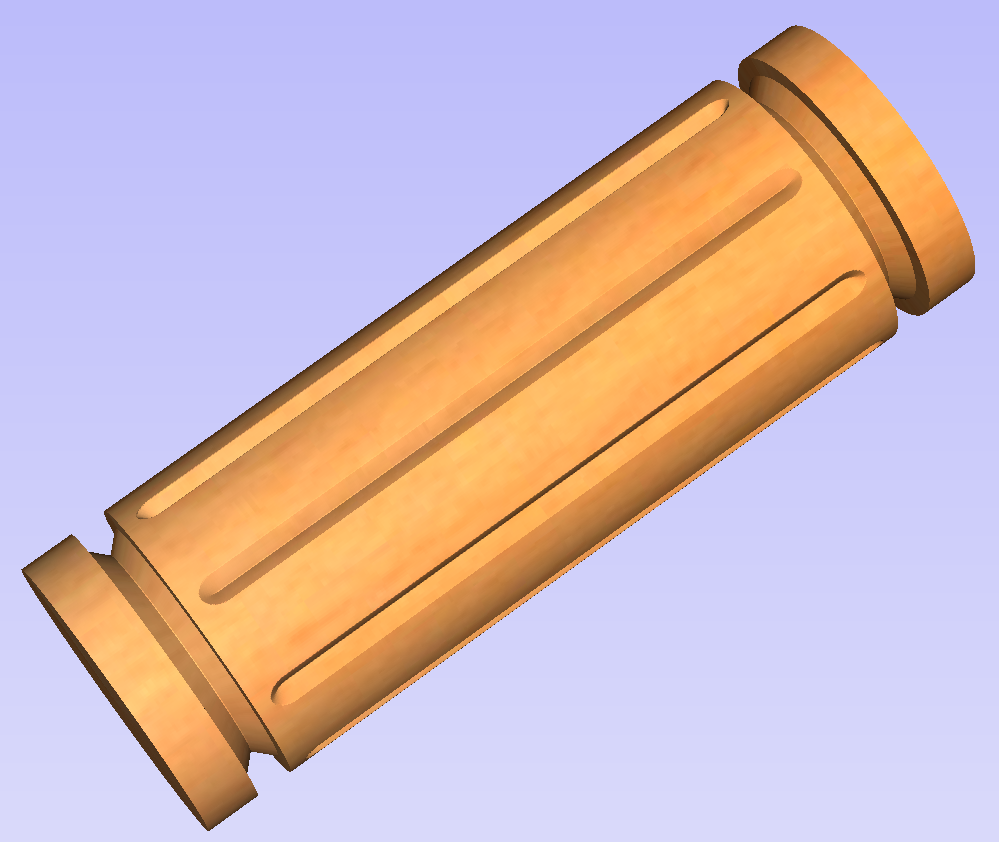

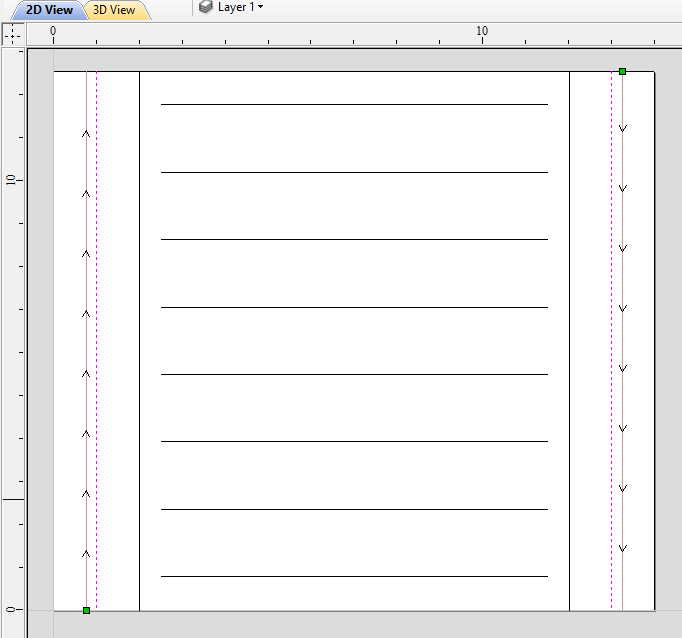

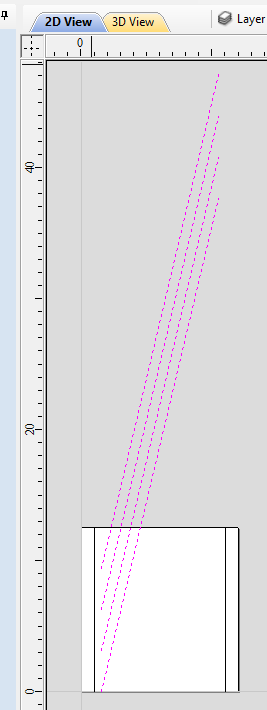

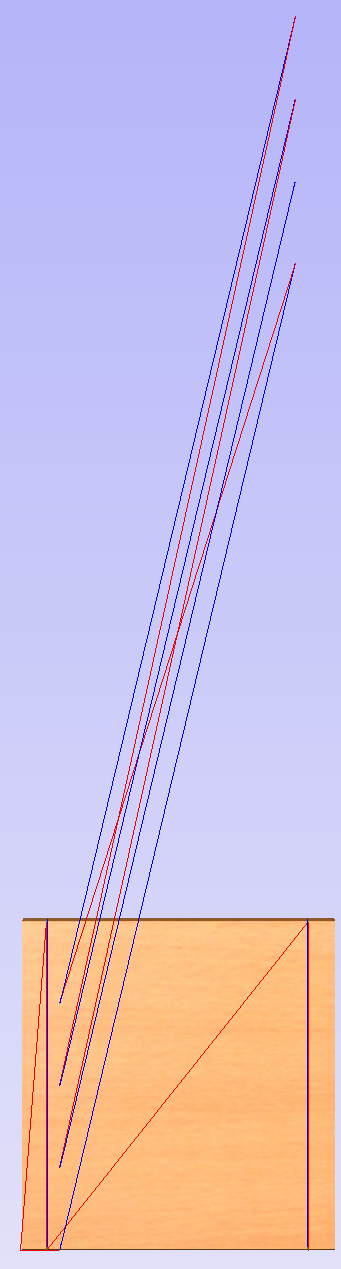

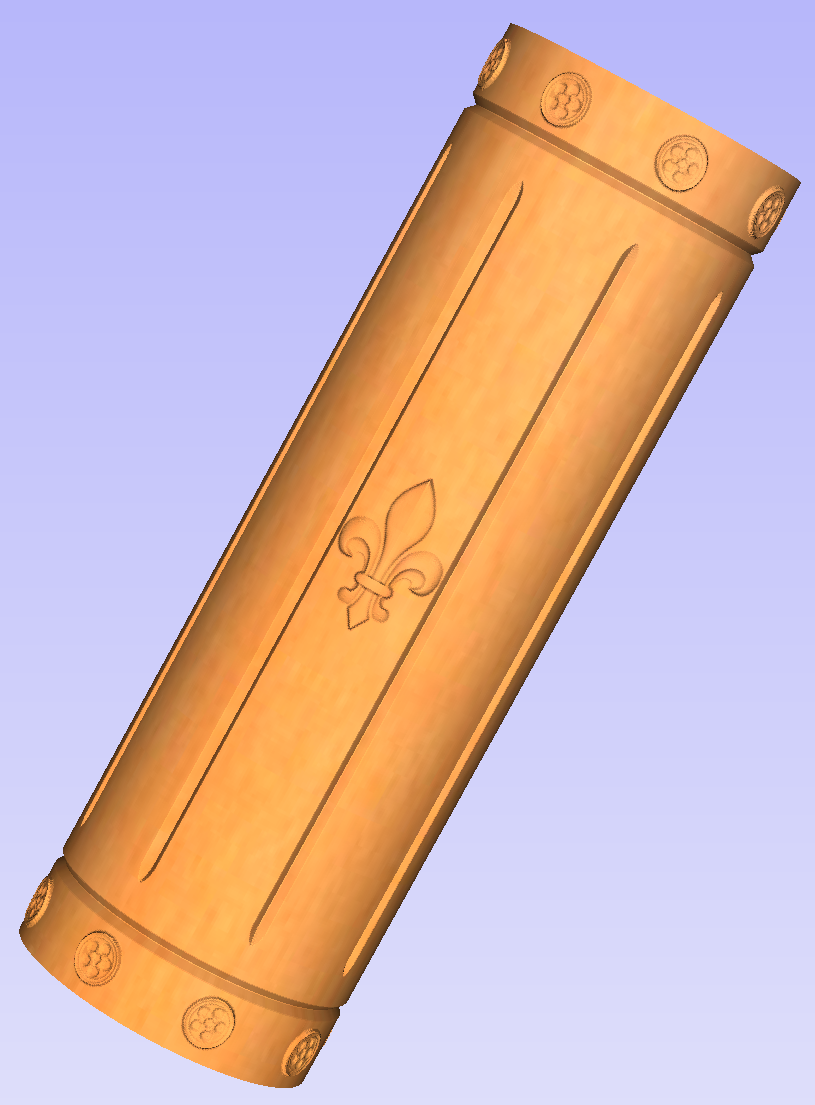

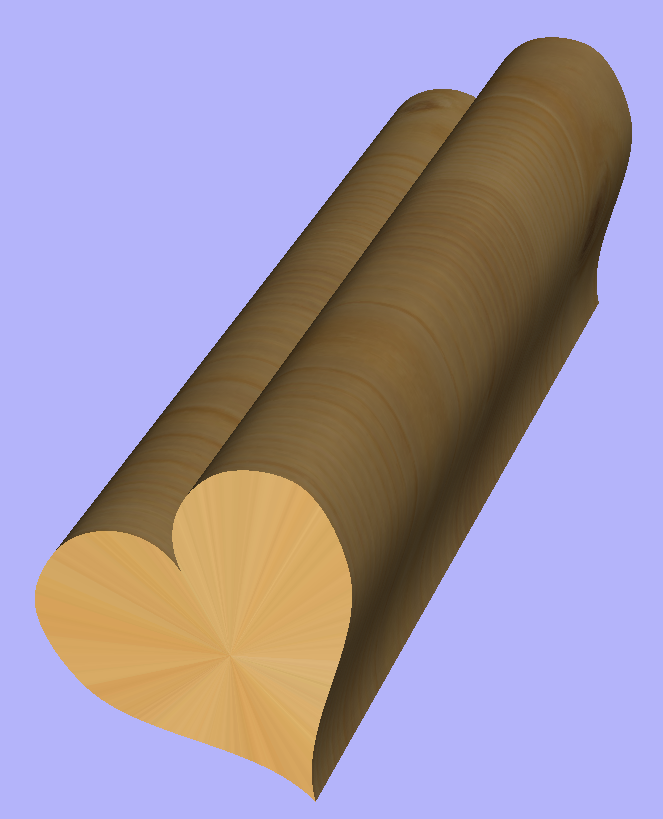

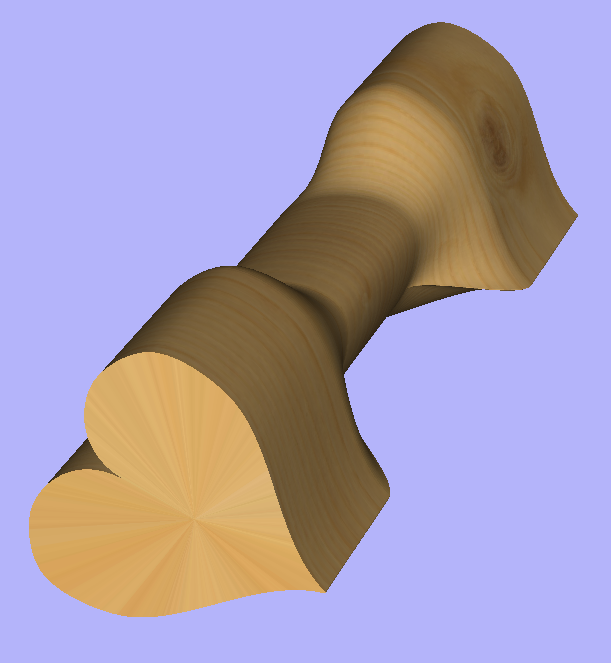

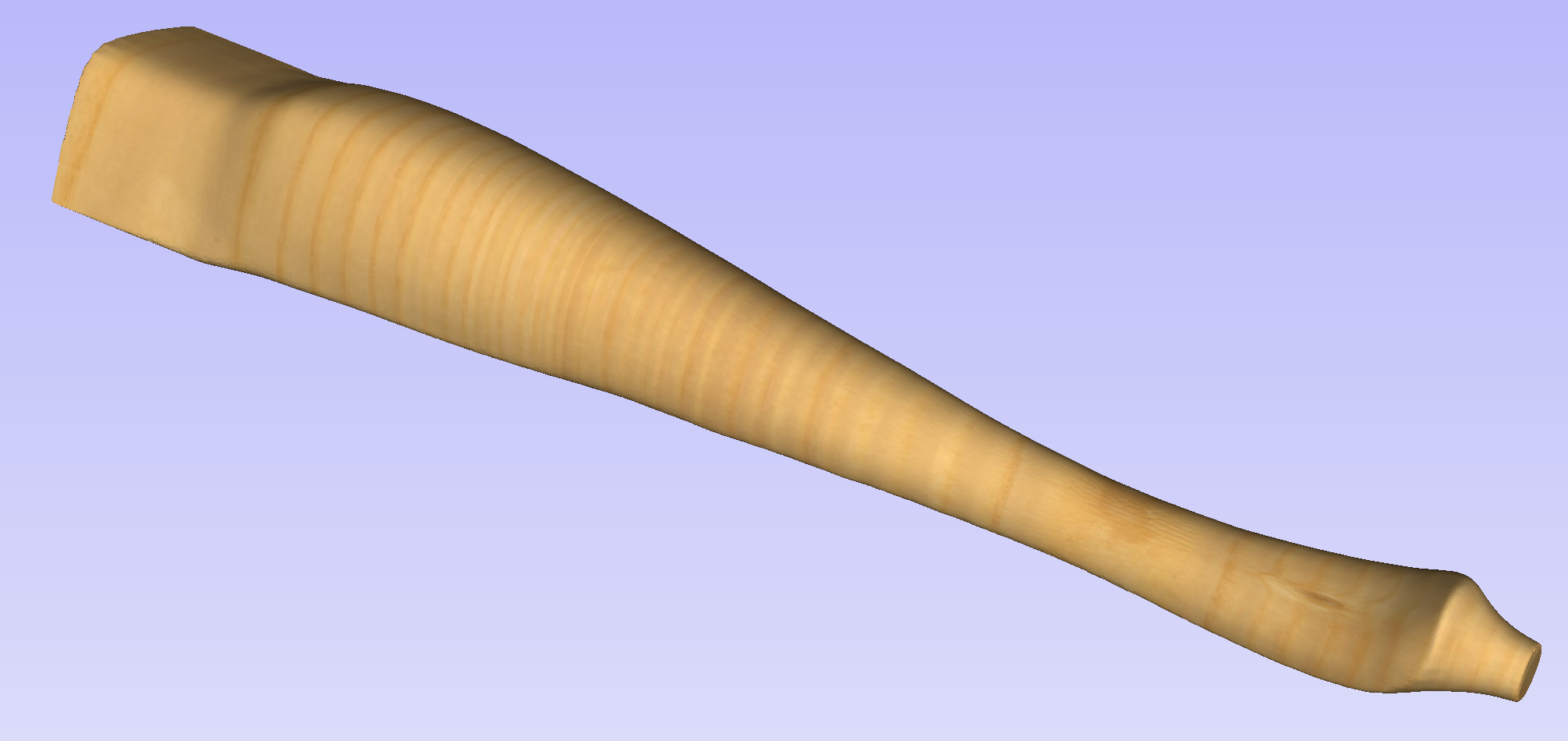

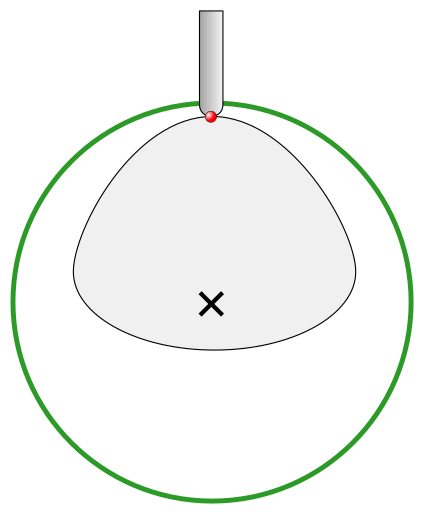

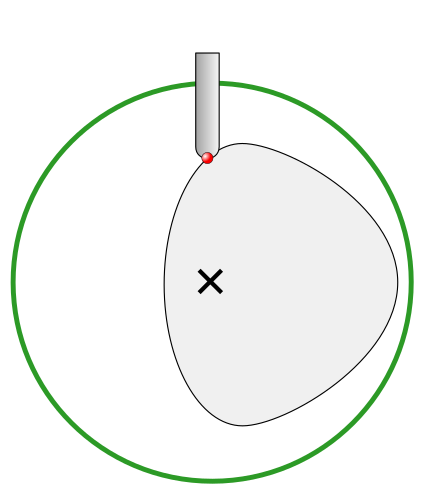

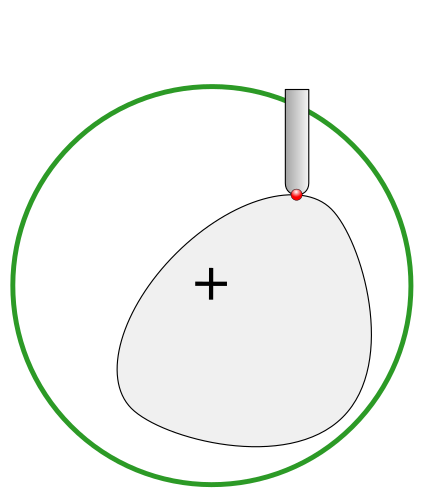

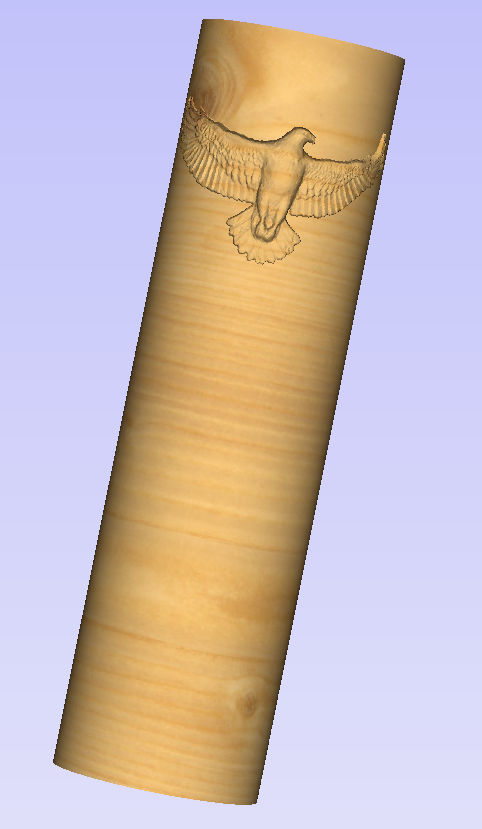

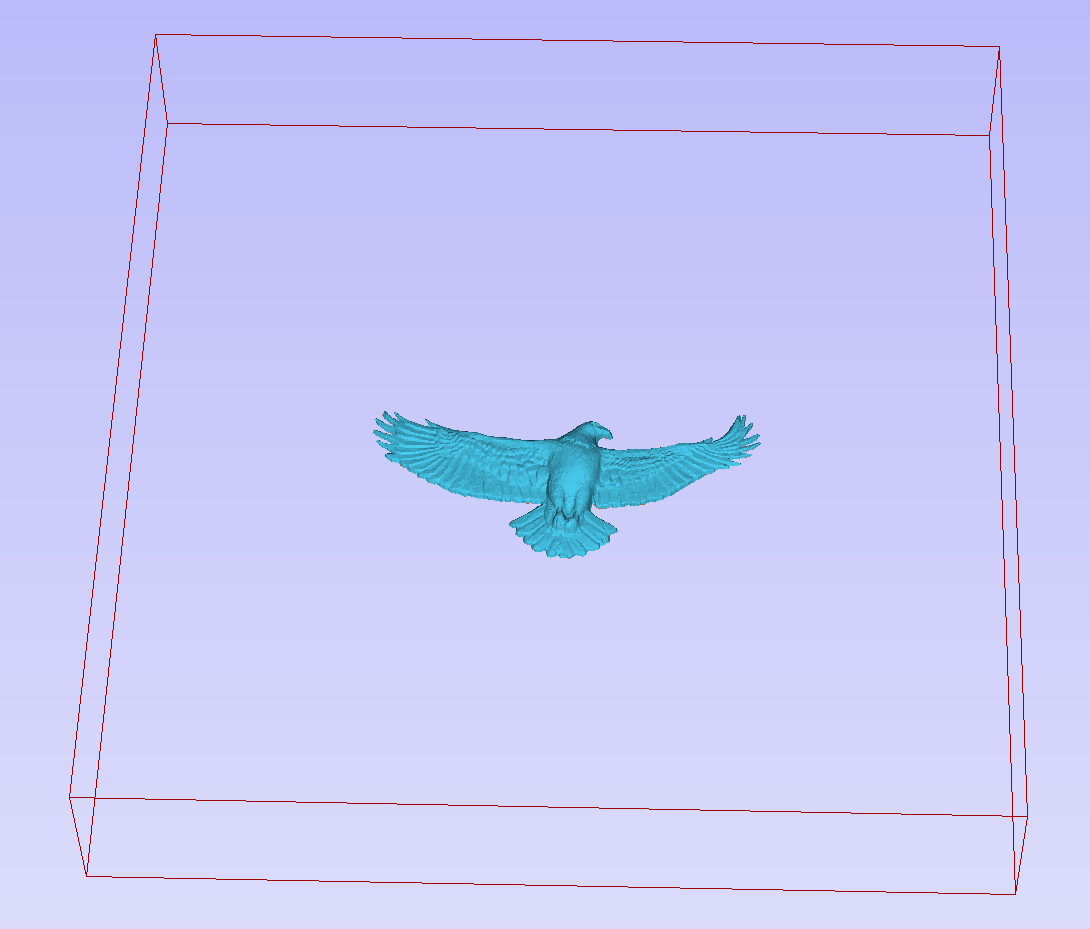

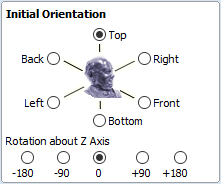

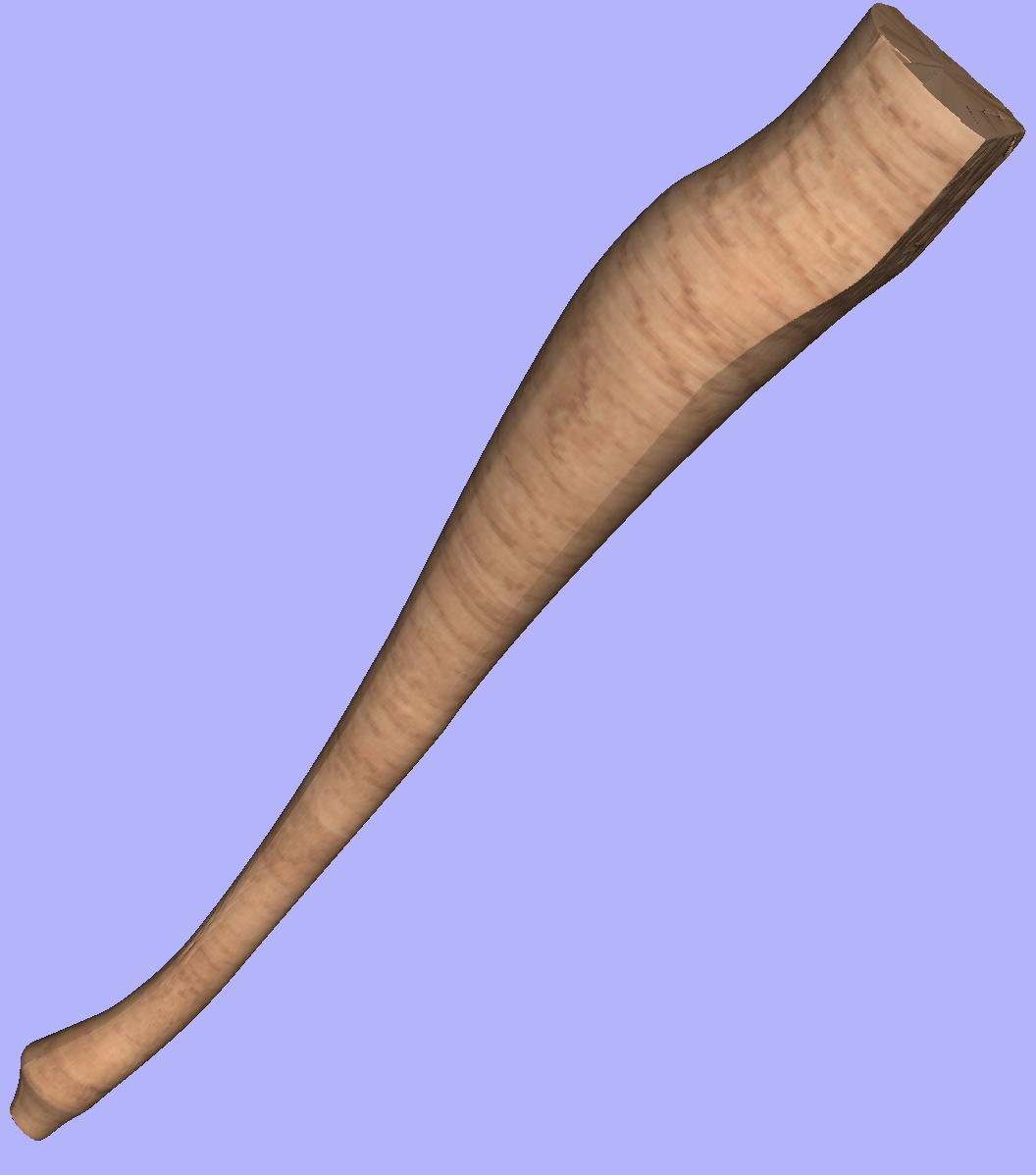

Job Setup - Rotary

The Job Setup form is displayed whenever a new job is being created, or when the size and position of an existing job is edited.

Job Type

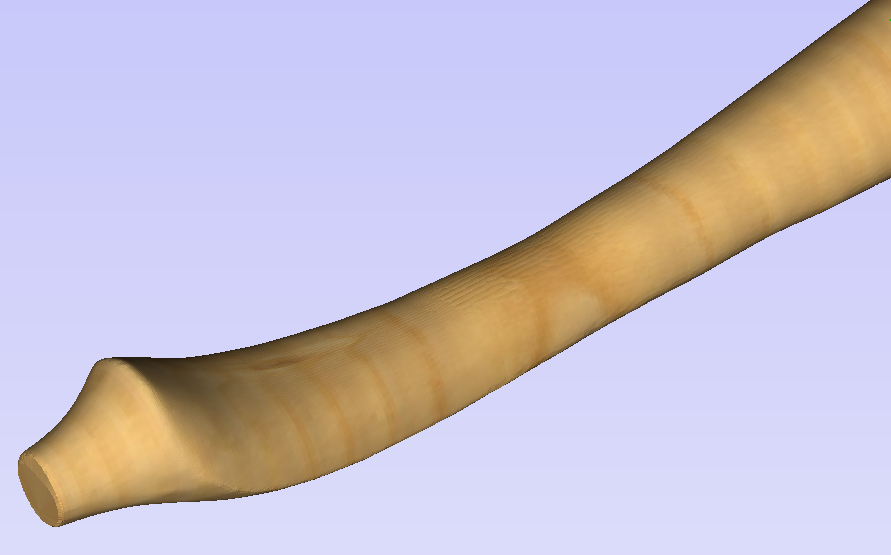

Rotary job type enables the use of arotary axis (also called a 4th axis or indexer). Aspire will provide alternative visualisation, simulation and tools appropriate for rotary designs.

For more information about Single Sided job type see Job Setup - Single Sided.

For more information about Double Sided job type see Job Setup - Double Sided.

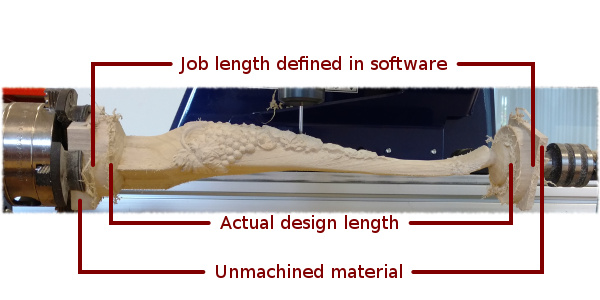

Job Size

Length

Length of the materialDiameter

Diameter of the material

Units

Whether the job units are measured in mm or inches

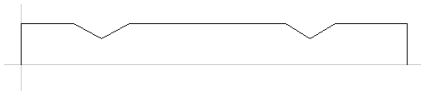

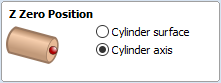

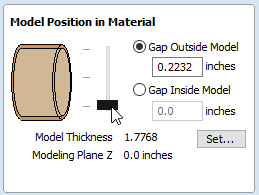

Z Zero Position

Indicates whether the tip of the tool is set off the rotation axis (as shown in the diagram) or off the surface of material for Z = 0.0. For the best accuracy using Cylinder Axis option is recommended

XY Datum Position

This datum can be set at any corner, or the middle of the job, when viewed as a flat 2d drawing. This represents the location, relative to your design, that will match the machine tool when it is positioned at X0, Y0. While this form is open, a red square is drawn in the 2d view to highlight the datum's position.

Use Offset

This option allows the datum position to be set to a value other than X0, Y0.

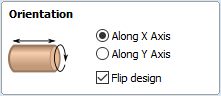

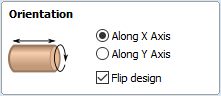

Orientation

This option selects along which axis the material block will rotate.

- Selecting Along X Axis means that X coordinates represent movement along the cylinder, whereas Y coordinates represent the angle around the cylinder.

- Selecting Along Y Axis means that Y coordinates represent movement along the cylinder, whereas X coordinates represent the angle around the cylinder.

Flip Design

When this option is enabled, the design will be flipped when the orientation is changed

Design Scaling

When editing the Job Size parameters of an existing job, this option determines whether any drawings you have already created will be scaled proportionally to match the new job dimensions. If you wish to preserve the existing size of your drawings, even after the job size has changed, leave this option unchecked. With this option checked, your drawings will be re-sized to remain in the same proportion and relative position within your new material extents when you click .

Modeling Resolution

This sets the resolution/quality for the 3D model. When working with 3D models a lot of calculation and memory may be required for certain operations. Setting the Resolution allows you to choose the best balance of quality and speed for the part you are working on. The better the resolution quality chosen, the slower the computer will perform.

As this is completely dependent on the particular part you are working on and your computer hardware performance, it is difficult in a document like this to recommend what the setting should be. Generally speaking, the Standard (fastest) setting will be acceptable for the majority of parts that Aspire users make. If the part you are making is going to be relatively large (over 18 inches) but still has small details, you may want to choose a higher Resolution such as High (3 x slower) and for very large parts (over 48 inches) with small details then the Highest (7 x slower) setting may be appropriate.

The reason that the detail of your part needs to be taken into account is that if you were making a part with one large item in it (e.g. a fish) then the standard resolution would be OK but if it was a part with many detailed items in it (e.g. a school of fish) then the High or Highest setting would be better. As previously stated these are extremely general guidelines as on slower/older computers operations with the highest setting may take a long time to calculate.

As the Resolution is applied across your whole work area it is important to set the size of your part to just be big enough to contain the part you plan to carve. It would not be advisable to set your material to be the size of your machine - e.g. 96 x 48 if the part you plan to cut is only 12 x 12 as this would make the resolution in the 12 x 12 area very low.

Appearance

This sets the color or material effect which will be applied to the base 3D model. It is possible to change this at any time and also to apply different colors and materials to different Components using the Component manager.

In most cases a new job represents the size of the material the job will be machined into or at least an area of a larger piece of material which will contain the part which is going to be cut. Clicking OK creates a new empty job, which is drawn as a gray rectangle in the 2D View. Dotted horizontal and vertical Grey lines are drawn in the 2D design window to show where the X0 and Y0 point is positioned.

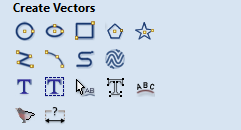

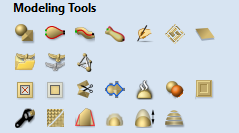

The Create Vectors Tool Group

Click on an icon to learn more about it:

| Create Vectors | |||||

| Closed Shapes | |||||

| Open Shapes | |||||

| Creating Text | |||||

| Trace Bitmap Dimensions | |||||

Drawing Shapes

Each tool gives you the option of dynamically drawing with the mouse in the 2D View, or entering precise data using the form. When you click on a shape tool icon its associated form will open on the Drawing tab. Here you can see the precise dimensions of the shape you are working on, which you can edit directly, as well as other options specific to the type of shape you are editing.

If you click on a shape drawing tool when nothing is selected in the 2D View, you will be able to create new shapes using the button. If you select a previously created shape, you will be able to modify its properties using the same form and update the shape using the button.

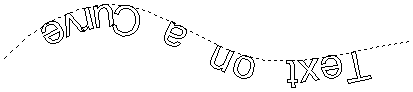

Creating Text

There are a number of tools dedicated to the creation and editing of text. These can be found on the Drawing tab, below the shape creation tools.

Aspire can make use of any TrueType font already installed on your computer, as well as Vectric's own single-line fonts designed specifically for CNC machining.

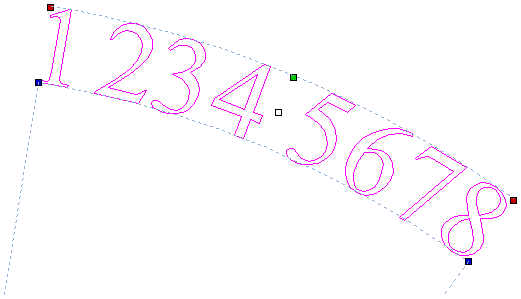

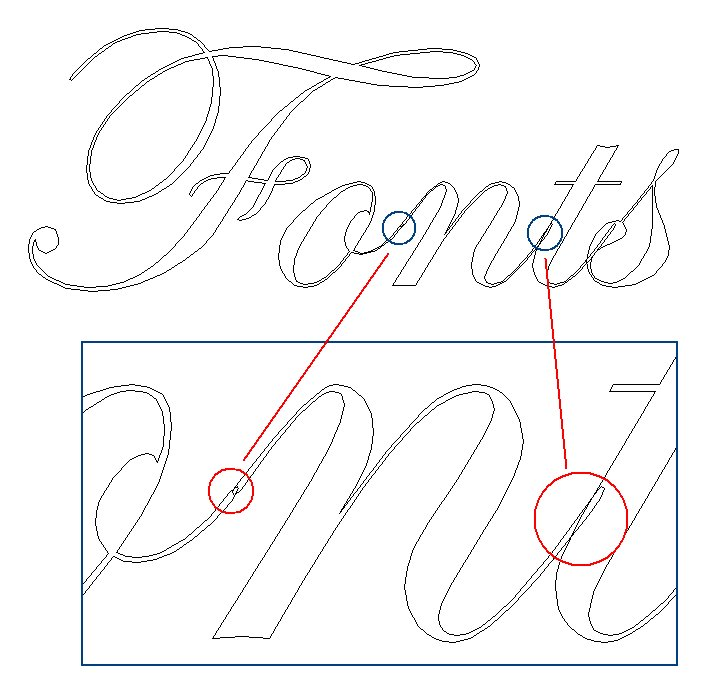

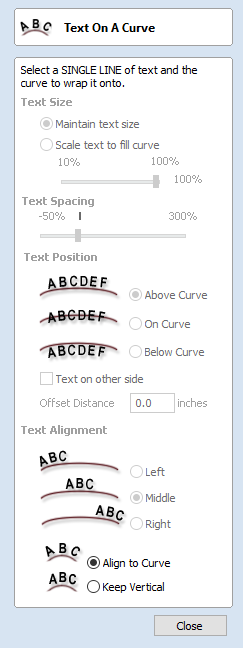

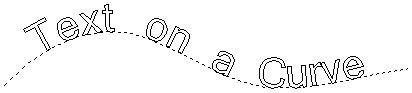

Use the Draw Text, or Draw Auto Text, to create text within your design. The Text selection tool then allows you to dynamically alter the text positioning, spacing or even to bend your text into an arc. For even more flexibility, use the Text on Curve tool to place your text along any vector curve or line that you have drawn. The Convert Text to Curves tool allows you to then use Node Editing to fine tune the vectors of the text to any shape required.

The text tools are accessed using the following icons:

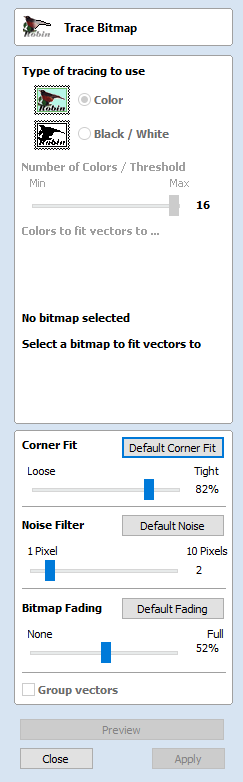

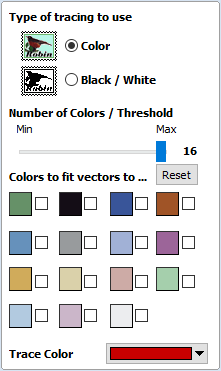

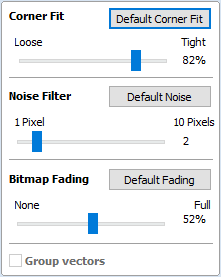

Trace Bitmap

Trace Bitmap tool allows you to automatically trace imported bitmaps using a variety of options within the tool to control the vectors that are created.

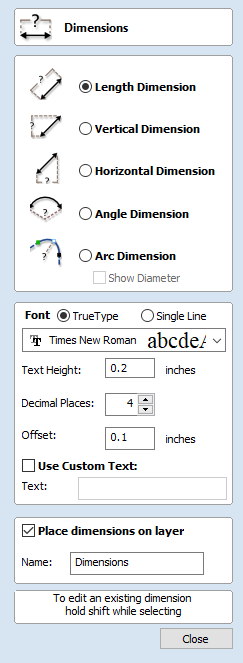

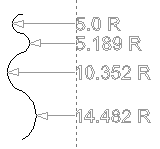

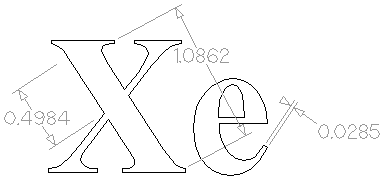

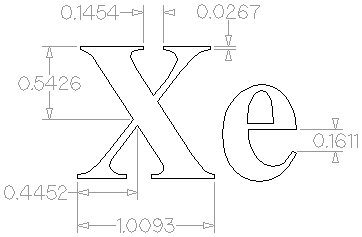

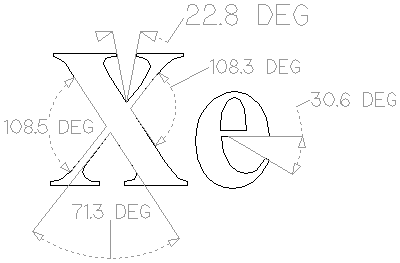

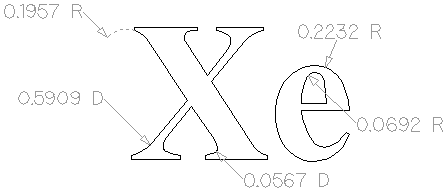

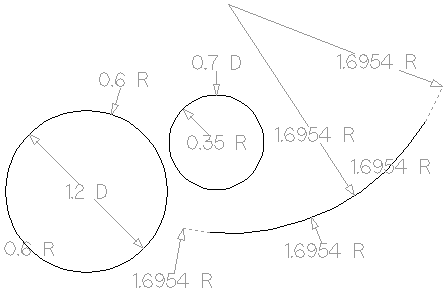

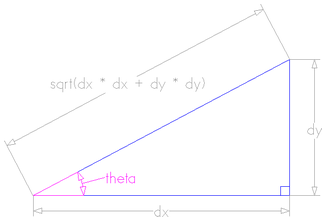

Dimensions

The dimensions tool allows you to add a variety of dimensioning annotations to your vector drawing.

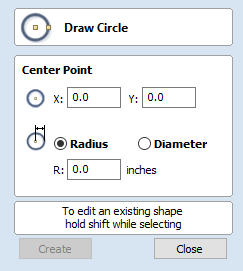

Draw Circle

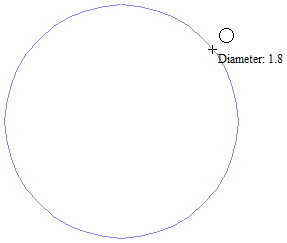

Circles can be created interactively with the cursor and Quick Keys or by entering the exact coordinates and diameter / radius with typed input.

Interactive

Cursor

The default mode and the procedure for drawing circle is:

Click and drag the Left mouse to indicate the center point followed by releasing the button at the required radius / diameter (depends on what is set on the form).

As the cursor is dragged across the screen the radius is dynamically updated. The increments will depend upon your snap radius and the job size.

Quick Keys

The radius or diameter can be specified while dragging out a circle:

Type the value while dragging followed, by D if it's a diameter, or R if it's a radius:

| Keys | Result |

|---|---|

| 12R | Radius 12 |

| 2R | Radius 2 |

| 1D | Diameter 1 |

Exact Size

Circles can also be drawn by entering the required XY origin, selecting either Radius or Diameter and entering the required size on the form.

Click to update the circle.

Edit

Open the Draw Circle form and select the circle to modify.

The selected circle is displayed as a dotted magenta line. Edit the Center Point and Radius or Diameter

Click to update the circle

To modify another circle without closing the form hold a Shift key down and select the next circle.

Close the form

To finish drawing with the tool, you can:

- Click on the form

- Press the Esc key

- Click the Right mouse button in the 2D View.

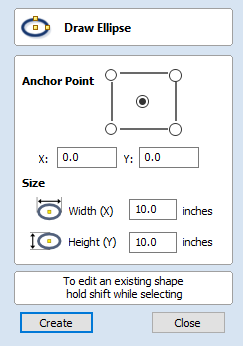

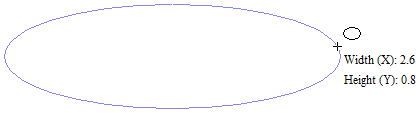

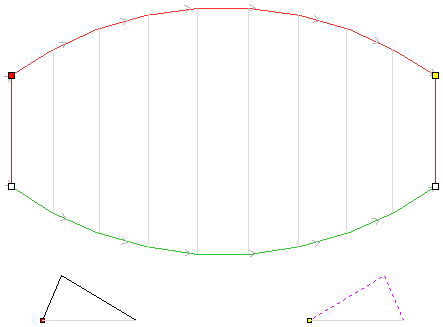

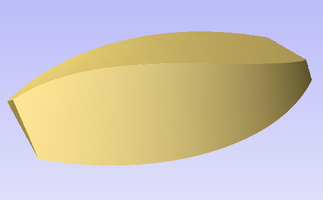

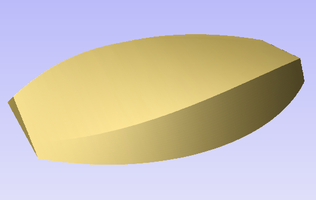

Draw Ellipse

Ellipse / ovals can be created interactively with the cursor and Quick Keys or by entering the exact coordinates for the center point, height and width with typed input.

Interactive - Cursor

The quickest and simplest way to draw an ellipse is:

- Click and drag the left mouse button in the 2D View to begin drawing the ellipse from its corner.

- While holding the left mouse button, drag to the required size.

- Releasing the left mouse button.

Holding Alt and dragging creates an ellipse from the middle point.

Holding Ctrl and dragging creates a circle.

Quick Keys

Instead of releasing the left mouse button when you have dragged your shape to the required size, you can also type exact values during the dragging process and set properties precisely.

- Left-click and drag out your shape in the 2D View.

- With the left mouse button still pressed, enter a quick key sequence detailed below.

- Release the left mouse button.

Default

By default, two values separated by a comma, will be used to set width and height of your ellipse. One value will create a circle with the given diameter. While you are dragging out the ellipse, type Width Value,Height ValueEnter or Diameter,Enter to create an ellipse with the specified dimensions.

Example

| Keys | Result |

|---|---|

| 2.5,1Enter | Creates ellipse with a width of 2.5 and a height of 1. |

Specifying Further Properties

By using specific letter keys after your value, you can also indicate precisely which property it relates to.

| Quick Keys | Result |

|---|---|

| ValueX | Creates an ellipse at the current dragged height, but with the width set to the entered value. |

| ValueY | Creates an ellipse at the current dragged width, but with the height set to the entered value. |

| ValueWValueH | Creates an ellipse with a specified width (W) and height (H). |

Examples

| Keys | Result |

|---|---|

| 1X | Current dragged height with width (X) of 1. |

| 1Y | Current dragged width and height (Y) of 1. |

| 1W2H | A width (W) of 1 and height (H) of 2. |

Exact Size

Accurate ellipses can also be drawn by entering the required XY origin point with the Width and Height of the oval. Click to create the ellipse.

Edit

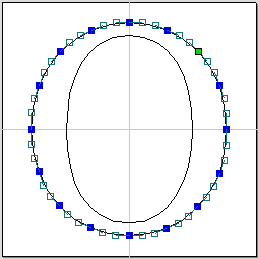

- Select the ellipse to modify and open the Draw Ellipse form.

- The selected shape is displayed as a dotted magenta line.

- Edit the Width and Height values.

- Click to update the ellipse.

To modify another ellipse without closing the form hold a Shift key down and select the next ellipse.

Close the form

To finish drawing with the tool, you can:

- Click on the form

- Press the Esc key

- Click with the Right-mouse button in the 2D View

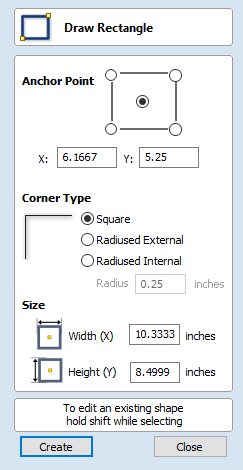

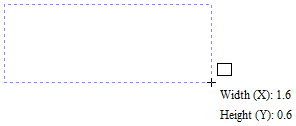

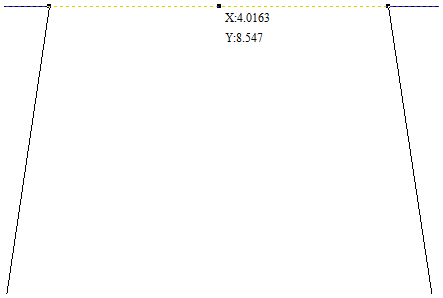

Draw Rectangle

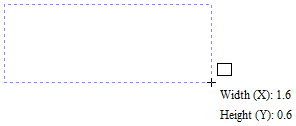

Rectangles can be created by using the Draw Polyline tool or using the Draw Rectangle Tool. The Draw Rectangle Tool allows rectangles to be created interactively with the cursor and Quick Keys or by entering the exact coordinates, type of corners (square, internal or external radius) and Width and Height using typed input.

Interactive - Cursor

The quickest and simplest way to draw a rectangle is:

- Click and drag the left mouse button in the 2D View to begin drawing the rectangle from its first corner.

- While holding the left mouse button, drag to the required size.

- Releasing the left mouse button.

Holding Alt and dragging creates a rectangle from the middle point.

Holding Ctrl and dragging creates a square.

As the cursor is dragged across the screen so the XY size is dynamically updated. The increments will depend upon your snap radius and the job size.

Quick Keys

Instead of releasing the left mouse button when you have dragged your shape to the required size, you can also type exact values during the dragging process and set properties precisely.

- Left-click and drag out your shape in the 2D View.

- With the left mouse button still pressed, enter a quick key sequence detailed below.

- Release the left mouse button.

Default

By default, two values separated by a comma, will be used to set width and height of your rectangle. One value will create a square with that side length. While you are dragging out the rectangle corner, type Width Value,Height ValueEnter or Side Length,Enter to create a rectangle with the specified width and height.

Example

| Keys | Result |

|---|---|

| 1,2.5Enter | Creates rectangle with a width of 1 and a height of 2.5. |

Specifying Further Properties

By using specific letter keys after your value, you can also indicate precisely which property it relates to.

| Quick Keys | Result |

|---|---|

| ValueX | Creates a rectangle at the current dragged height, but with the width set to the entered value. |

| ValueY | Creates a rectangle at the current dragged width, but with the height set to the entered value. |

| ValueRValueX | Creates a rectangle with a radius (R) and width (X) set by the two entered values, but using the currently dragged height. |

| ValueRValueY | Creates a rectangle with a radius (R) and height (Y) set by the two entered values, but using the currently dragged width. |

| ValueWValueH | Creates a rectangle with a specified width (W) and height (H). No radiused corners. |

| ValueRValueWValueH | Create a rectangle with radius (R), width (W) and height (H) all specified by the entered values. |

Examples

| Keys | Result |

|---|---|

| 1X | Current dragged height with width (X) of 1. |

| 1Y | Current dragged width and height (Y) of 1. |

| 0.1R1X | A corner radius (R) of 0.1, a width (X) of 1 and the current dragged height. |

| 0.1R1Y | A corner radius (R) of 0.1, a height (Y) of 1 and the current dragged width. |

| 1W2H | A width (W) of 1 and height (H) of 2, no corner radius. |

| 0.1R1W2H | A corner radius (R) of 0.1, width (W) of 1 and height (H) of 2 |

Exact Size

Rectangles can also be drawn by entering the required XY origin point with the Width and Height of the rectangle.

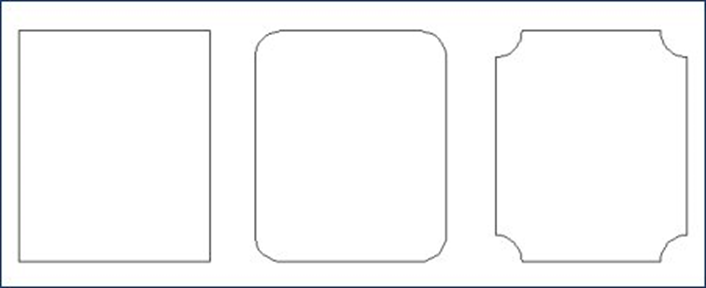

Corner Type

Corners of the rectangle can be Square, Radiused Externally or Radiused Internally.

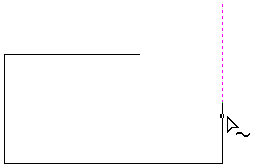

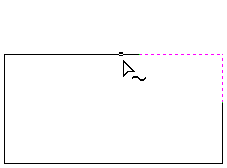

Edit

- Select the rectangle to modify and open the Draw Rectangle form.

- The selected shape is displayed as a dotted magenta line.

- Edit the Width and Height values.

- Click to update the rectangle.

To modify another rectangle without closing the form hold a Shift key down and select the next rectangle.

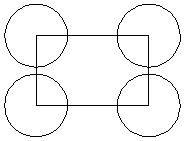

If you hold a Shift key down and select an object that isn't a rectangle (so if you click text or a polyline, for example) a Rectangle will be created as a bounding box of the clicked object:

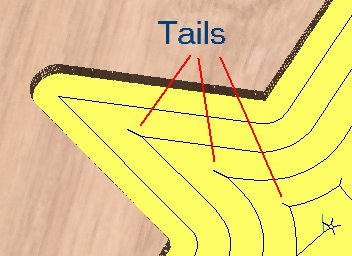

Holding a Shift key down and clicking

the Star creates the bounding rectangle.

Just click to draw the bounding box.

You could then offset his box to have an even boundary around the selection.

Close the form

To finish drawing with the tool, you can:

- Click on the form

- Press the Esc key

- Click the Right mouse button in the 2D View.

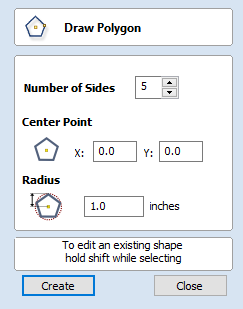

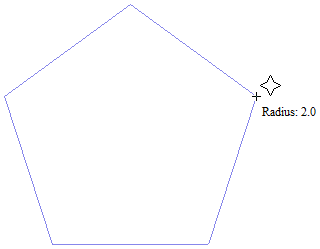

Draw Polygon

Polygons (e.g. Triangles, Pentagons, Hexagons etc.) can be created interactively with the cursor and Quick Keys or by entering the number of sides, exact coordinates and radius using typed input.

Interactive - Cursor

The quickest and easiest way to draw a polygon is by using the mouse in the 2D View.- Click and hold the left mouse button to indicate the center point.

- Drag the mouse while holding down the left mouse to required radius.

- Release the left mouse button to complete the shape.

As the cursor is dragged across the screen so the radius is dynamically updated. The increments will depend upon your snap radius and the job size.

Quick Keys

Instead of releasing the left mouse button when you have dragged your shape to the required size, you can also type exact values during the dragging process and set properties precisely.

- Left-click and drag out your shape in the 2D View.

- With the left mouse button still pressed, enter a quick key sequence detailed below.

- Release the left mouse button.

Default

By default, entering a single values will be used to set the radius of your polygon. While you are dragging out the polygon, type Radius ValueEnter to create a polygon with the precisely specified radius.

Example

| Keys | Result |

|---|---|

| 2.5Enter | Creates a polygon with a radius of 2.5, all other settings as per the form. |

Specifying Further Properties

By using specific letter keys after your value, you can also indicate precisely which property it relates to.

| Quick Keys | Result |

|---|---|

| ValueD | Creates a polygon with the diameter (D) specified, with all other properties as per the form. |

| ValueSValueR | Creates a polygon with the specified number of sides (S) and the outer radius (R). |

| ValueSValueD | Creates a polygon with the specified number of sides (S) and the outer diameter (D). |

Examples

| Keys | Result |

|---|---|

| 1R | Outer radius (R) 1, number of sides as per form. |

| 1D | Outer diameter (D) 1, number of sides as per form. |

| 8S1R | An 8 sided (S) polygon with an outer radius (R) of 1. |

| 6S2.5D | A 6 sided (S) polygon with an outer diameter (R) of 2.5. |

Exact Size

Polygons can also be drawn by entering the required XY origin , selecting either Radius or Diameter and entering the required size.

- Click to update the circle.

Edit

Open the Draw Polygon form and select the circle to modify.

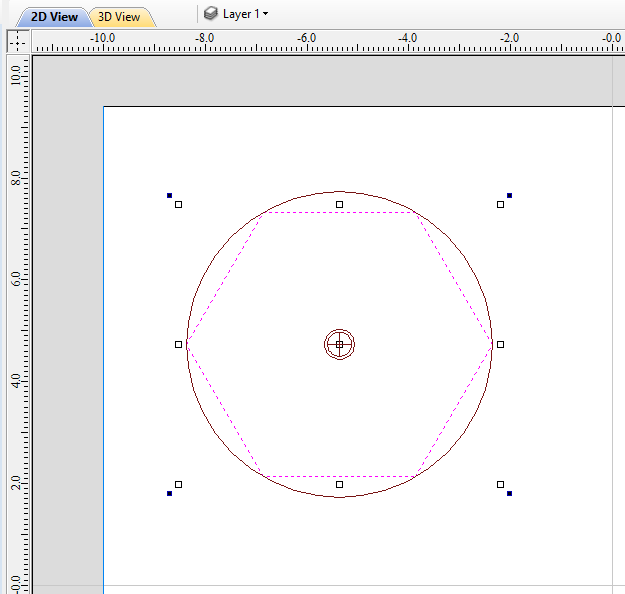

The selected circle is displayed as a dotted magenta line.

- Edit the Number of Sides and Radius.

- Click to update the circle.

To modify another polygon without closing the form hold the Shift key down and select the next polygon.

Close the form

To finish drawing with the tool, you can:

- Click on the form

- Press the Esc key

- Click the Right mouse button in the 2D View.

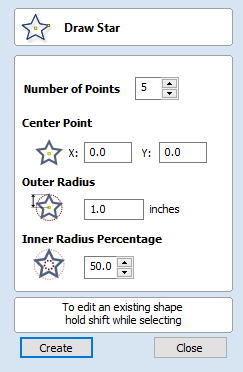

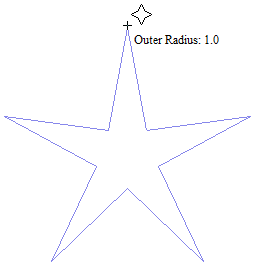

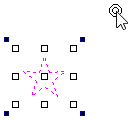

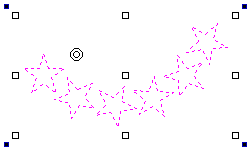

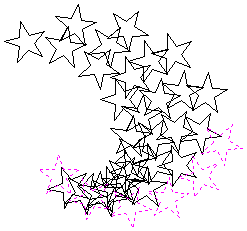

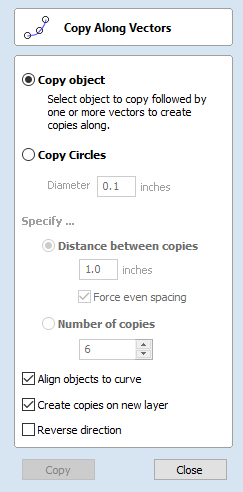

Draw Star

Stars can be created interactively with the cursor and Quick Keys, or by entering the number of points, exact coordinates and outer radius and inner radius percentage using typed input.

Interactive - cursor

The quickest and easiest way to create a star is by clicking and dragging the shape to size in the 2D View using the mouse.

- Click and hold the left mouse button to indicate the center point.

- Drag the mouse while holding down the left mouse to required radius.

- Release the left mouse button to complete the shape.

As the cursor is dragged across the screen so the outer radius is dynamically updated. The increments will depend upon your snap radius and the job size.

Quick Keys

Instead of releasing the left mouse button when you have dragged your shape to the required size, you can also type exact values during the dragging process and set properties precisely.

- Left-click and drag out your shape in the 2D View.

- With the left mouse button still pressed, enter a quick key sequence detailed below.

- Release the left mouse button.

Default

By default, entering a single value will be used to set the outer radius of your star. While you are dragging out the star, type Radius ValueEnter to create a star with the precisely specified outer radius.

Example

| Quick Keys | Result |

|---|---|

| 2.5Enter | Creates a star with an outer radius of 2.5, all other settings as per the form. |

Specifying Further Properties

By using specific letter keys after your value, you can also indicate precisely which property it relates to.

| Quick Keys | Result |

|---|---|

| ValueD | Creates a star with the outer diameter (D) specified, with all other properties as per the form. |

| ValueIValueR | Creates a start with the inner radius percentage (I) and the outer radius (R). The inner radius is defined in terms of a percentage of the outer radius or diameter. All other properties are as per the form. |

| ValuePValueR | Creates a star with the specified number of points (P) and the outer radius (R). |

| ValuePValueIValueR | Creates a star with the specified number of points (P), inner radius percentage (I) and the outer radius (R). |

Examples

| Quick Keys | Result |

|---|---|

| 1R | Outer radius (R) 1, other proporties as per form. |

| 1D | Outer diameter (D) 1, other properties as per form. |

| 6P1R | An 6 pointed (P) star with an outer radius (R) of 1. |

| 6P1D | An 6 pointed (P) star with an outer diameter (D) of 1. |

| 6P25I4D | A 6 pointer (P) star with an outer diameter (D) of 4 and an inner diameter that is 25% of the outer (i.e. 1). |

Exact Size

Stars can also be drawn by entering the Number of Points, Center Point, Outer Radius and Inner Radius Percentage.

- Click to update the star.

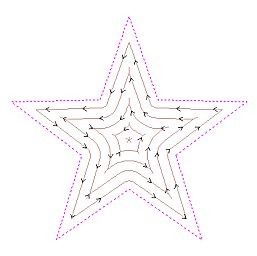

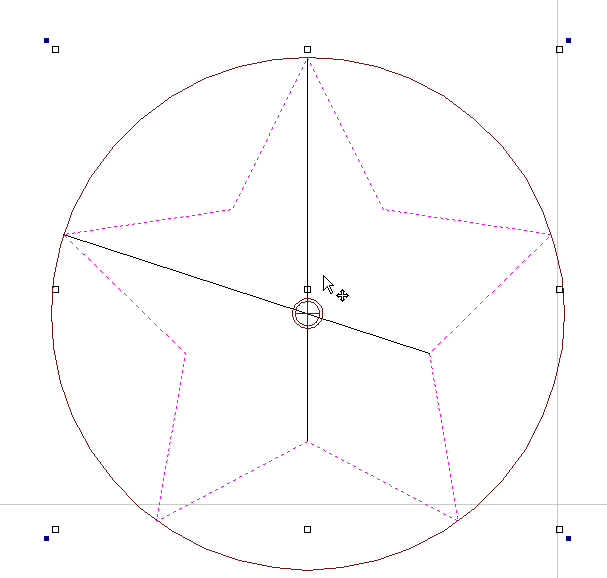

Edit

- Select the star to modify and open the Draw Star form.

The selected shape is displayed as a dotted magenta line.

- Edit the required parameters.

- Click to update the star.

To modify another star without closing the form hold a Shift key down and select the next star.

Close the form

To finish drawing with the tool, you can:

- Click on the form

- Press the Esc key

- Click the Right mouse button in the 2D View.

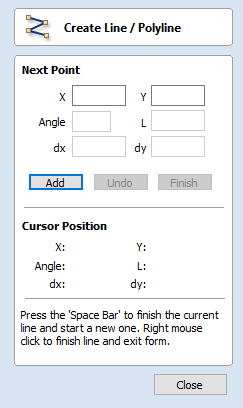

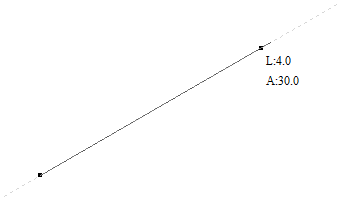

Draw Polyline

This tool creates continuous straight lines through points clicked, entered coordinates, tangent between a point and an arc or tangent to two arcs.

Interactive - cursor

The quickest and easiest way to draw a line is by clicking within the 2D View using the mouse.

- Click the left mouse button to indicate the start point of your line.

- Move the mouse pointer and click again to set the next point in your line.

- Repeat this process to add as many line segments as you require.

- Right-click or press Esc to finish your polyline and exit the form.

- Alternatively press the Spacebar to complete this polyline but keep the form open and begin drawing another polyline.

Creating Tangent Lines

The polyline tool can also be used create lines that are tangent to arcs in your existing drawing.

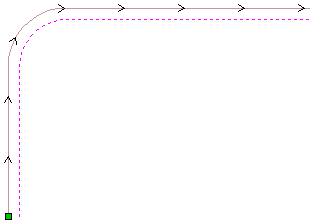

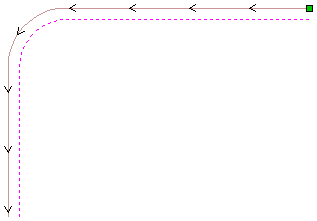

From A Point To An Arc

To create a line tangent from a point to an arc simply enter the initial point and then hover the cursor over the arc and press T.

From An Arc To A Point

To create a line tangent from an arc to a point click on the arc to insert a point and then hover the cursor over the next point position and press T.

From An Arc To Another Arc

To create a line tangent from one arc to another click on the arc to insert a point and then hover the cursor over the second arc and press T.

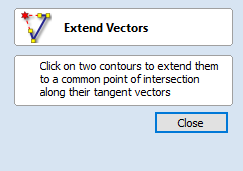

Extending Contours

An existing open contour can be extended by holding down the Ctrl key and then clicking on either its start or end point.

Quick Keys

Instead of releasing the left mouse button when you have dragged your shape to the required size, you can also type exact values during the dragging process and set properties precisely.

- Left-click and drag out your shape in the 2D View.

- With the left mouse button still pressed, enter a quick key sequence detailed below.

- Release the left mouse button.

Default

By default, entering a single value will be used to add a point at the specified distance along the line direction currently indicated by the mouse pointer position, relative to the preceding point. With polyline drawing underway, move the mouse pointer in the direction you wish to create a new line segment and type Length ValueEnter to extend the line by the specified distance in that direction.

By default two values, separated by a comma, will create the next line point at the absolute X Y coordinate indicated by the two values, respectively. While drawing, type X Value,Y ValueEnter to place the next point precisely at specified X and Y position.

Example

| Keys | Result |

|---|---|

| 3.5Enter | Adds the next point at a distance of 3.5 along the line direction indicated by the current mouse pointer position. |

| 1,2.5Enter | Adds the next point at the absolute position 1 in X and 2.5 in Y |

Specifying Further Properties

By using specific letter keys after your values, you can also specify the line segment in terms of angle and length.

| Quick Keys | Result |

|---|---|

| ValueAValueL | Creates the next line segment at an angle (A) degrees from the last point and with a length (L). |

Examples

| Keys | Result |

|---|---|

| 45A3L | A line segment at 45 degrees (A) and a length (L) of 3. |

| 15A2.5L | A line segment at a 15 degree angle (A) and a length (L) of 2.5. |

Next Point

You can also use the form to enter values for each line segment as you go along. The segments can be defined using:

- The absolute X Y position of the next point

- The Angle and Length to the next point

- The relative offset in X (dx) and Y (dy) to the next point.

Once you have entered the values you wish to use:

- Click the button to enter a new point.

- The button deletes the last point entered and allows a new point to be added.

- The button completes drawing the current line and leaves the form open to allow additional lines to be drawn.

The Angle, Length and dx/dy positions are incremental from the current position.

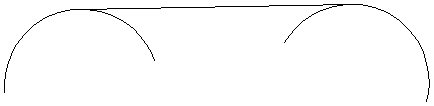

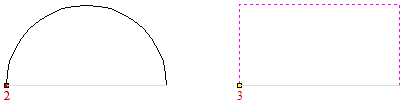

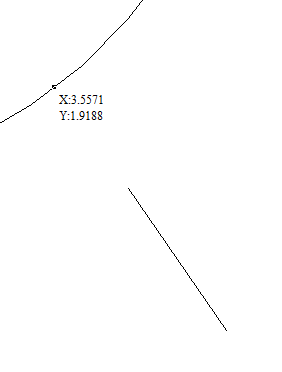

Create Arc

The Create Arc tool allows a single arc span to be created using precise values, or dynamically within the 2D View.

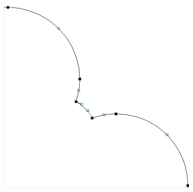

Through 3 Points

- Left click the mouse in the 2D View to set the start point of an arc.

- Click again to set the end point position.

- Move the mouse and click a third point to set the arc's radius.

Center, Start and End

- Left click the mouse in the 2D View to set the center point of the arc.

- Click again to set the start point of the arc.

- Move the mouse and click a third point to set the end point of the arc.

Exact Size

Precise values for the start and end point positions (in absolute X Y coordinates) and either the radius or the height of the arc can be entered in the form directly. Click to draw and arc using these values.

Editing An Existing Arc

The properties of an arc can be edited at any time by selecting the arc before choosing the Create Arc tool.

This opens the form with the current properties and position of the selected arc and these values can then be edited.

Click to update the selected arc with the new values.

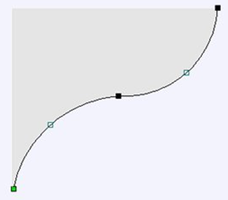

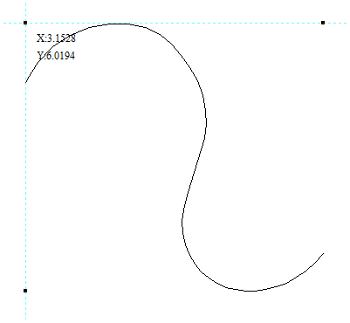

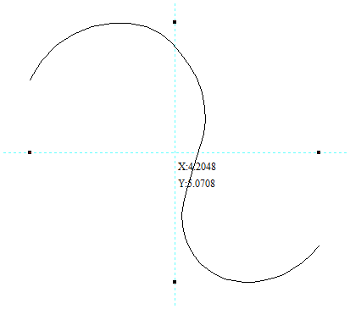

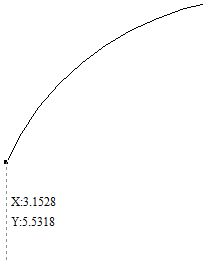

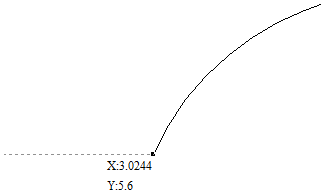

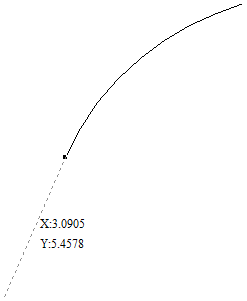

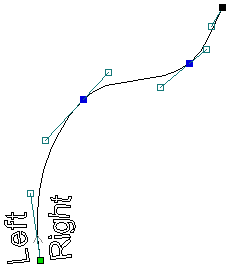

Draw Curve

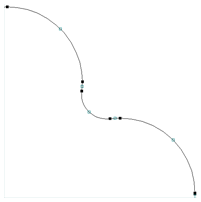

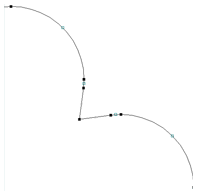

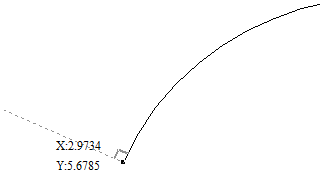

This tool creates a smooth, flowing, continuous curve through clicked points.

- Click in the 2D View to begin drawing at the clicked point.

- Move the mouse pointer within the 2D View and click the left button to insert as many points as you require. A curve will be created that smoothly joins your points.

- Click the right mouse button or press Esc to finish drawing your curve and close the tool.

- Alternatively, press Space Bar to finish drawing one curve, but keep the tool active so that you can immediately begin drawing another curve.

Extending Contours

An existing open contour can be extended by holding down the Ctrl key and then clicking on either its start or end point.

Create Vector Texture

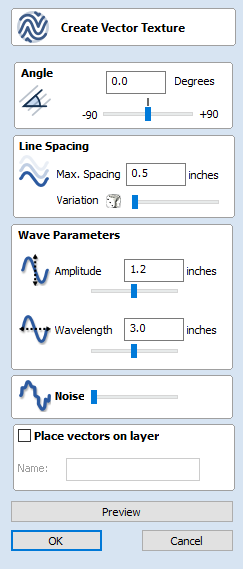

Repeating texture patterns can be created using the Create Vector Texture tool. These vectors can be machined in a variety of ways to create attractive textures.

To use the tool click the icon on the drawing tab. If required, select any contours that you wish the pattern to be created within. By using the sliders and edit boxes on the form the style of the created pattern can be varied. Click to see a preview your created texture as you adjust the form's parameters. When you are happy with the preview, click to create the pattern.

Angle

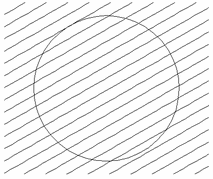

The lines in the texture are created at an angle. This value can be set to any value between -90 degrees and 90 degree.

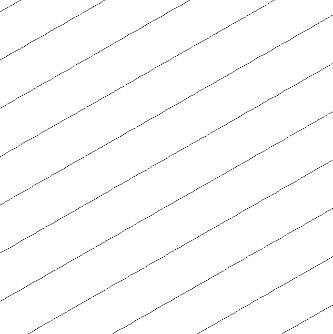

Angle of 30°

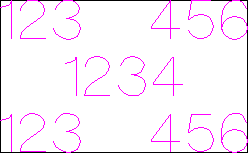

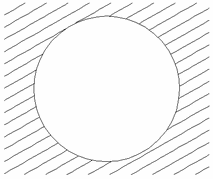

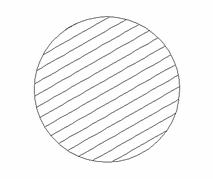

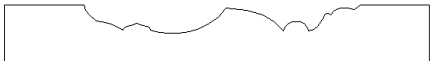

Line Spacing

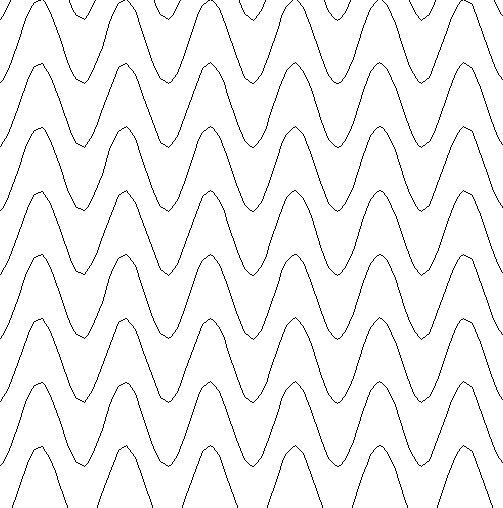

The line spacing controls the distance between the contours created by the tool. Use the edit box labeled Max. Spacing to enter a maximum value of line spacing. The slider underneath the edit box controls the degree of variation in the line spacing. If the slider is to the far left then this mean variation is at a minimum and so the lines are evenly spaced. If the slider is to the far right the variation is highest and so the distance between created contours varies between zero and the maximum spacing specified.

Minimum variation

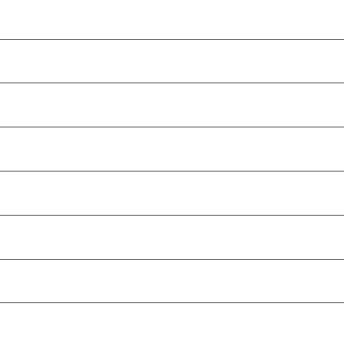

Maximum Variation

Wave Parameters

Within this section of the form the created pattern can be made to behave in a wave-like fashion. This wave is controlled by two parameters: the amplitude and wavelength.

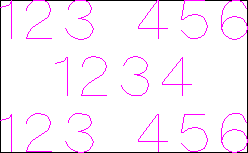

Wavelength

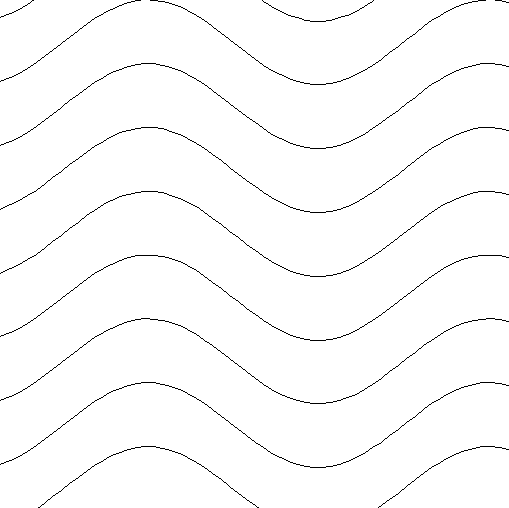

The wavelength describes the length over which the contours shape repeats itself. A bigger wavelength gives a long wave while a small wavelength gives a short wave.

Short wavelength

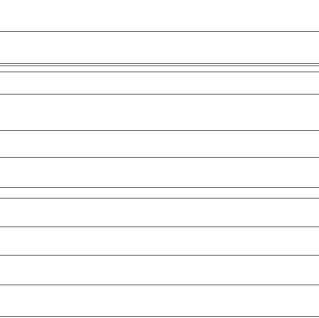

Long wavelength

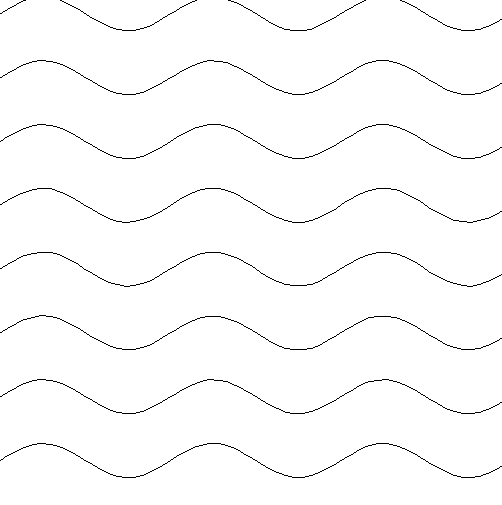

Amplitude

The amplitude describes the height of the wave. Larger amplitude means a taller wave and smaller amplitude means a shallow wave.

Small amplitude

Large Amplitude

Noise

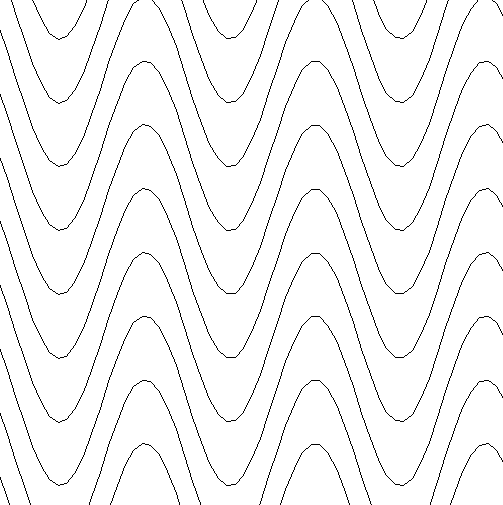

The noise slider controls the degree of randomness applied to the above values and can be used to create less regular patterns.

No noise

Medium noise

High noise

Vector Layer

To create the vectors on a new layer make sure the check box labeled Place Vectors on Layer is checked ✓ and enter the layer name into the edit box labeled Name.

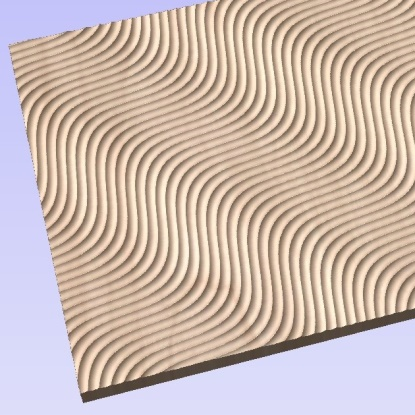

Applications

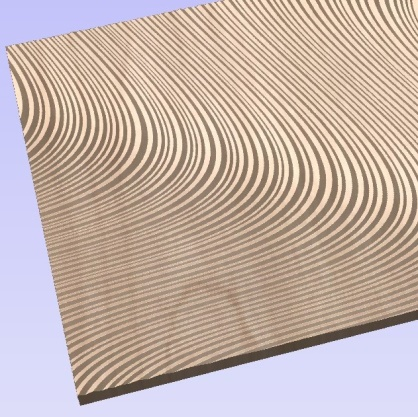

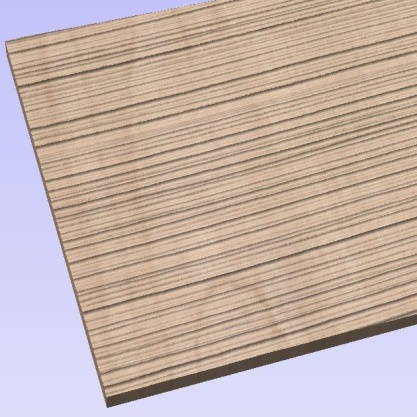

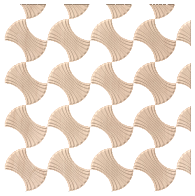

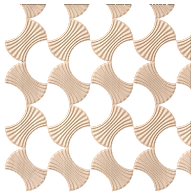

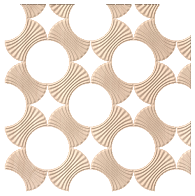

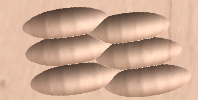

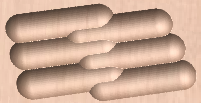

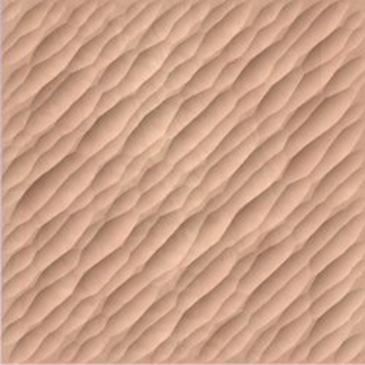

The vectors created by this function have many applications but a key one is to combine them with either a Profile Toolpath or where available the Texture Toolpath to create decorative panels and background textures, a small selection of the possible results you can derive from this combination are shown in the images below.

Ball Nose Tool - Wave Pattern

V-Bit Tool - Swirl Pattern

Ball Nose Tool - Grain Pattern

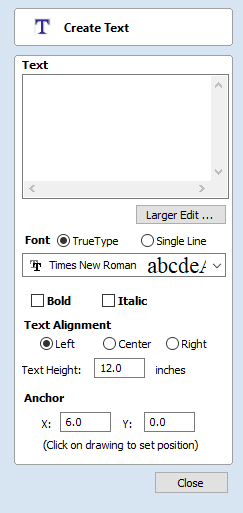

Create Text

This form allows text to be created at a specified point and height.

Text is edited in-place including Arc Text and Text on a Curve, even if it has been moved, scaled and rotated.

If the form is opened with no selection, the new text is placed somewhere on the material (if possible) between the center of the material and the center of the view to help keep it visible. An empty box is drawn in the view which helps visualize the currently specified text height and anchor point.

Text height and position guide for empty text

Existing text has guide lines showing the height of the top line of text. Some fonts will descend below the lower line like handwriting on a note pad.

Clicking selected text while editing, changes the anchor point to a box which can be dragged and dropped with snap.

The view is updated shortly after the user stops changing the form properties (e.g. mouse-wheel scrolling through the font list).

Changing the justification maintains the anchor point

Custom kerning and spacing (adjusted using the Kerning and Spacing tool) is maintained through the edit where possible.

- See Also:

- The Auto Layout Text form (text in a box).

- Arc Text.

- The Text On A Curve form.

- Kerning and Spacing.

- Convert Text To Curves.

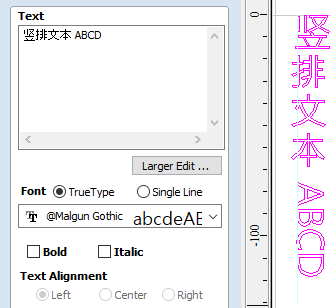

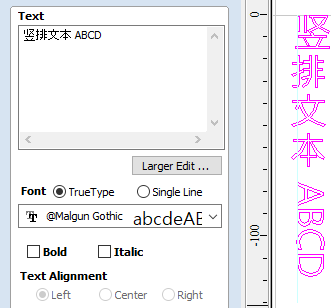

Vertical Fonts

Fonts that start with the @ character are drawn vertically downwards and are always left justified.

Vertical Text

Engraving Fonts

The Single Line Radio Button changes the Fonts list to show a selection of fonts that are very quick to engrave.

Options

The button opens a larger text entry window that makes it easier to enter text that needs to run on longer line lengths. Clicking accepts any text entered into the window and will throw away any changes.

Text Alignment

Positions text relative to the full body of text, this only has a noticeable effect when writing multiple lines of text.

Anchor

Sets the position of your text block. Either enter values directly and click , or click in the 2D View with the mouse cursor to set the position values interactively. Clicking in the 2D View will begin a new block of text, set to the new Anchor point.

Edit Text

To edit text properties or content of previously created text:

If the Create Text form is open, hold the Shift key down and click the text you wish to edit or

If the Create Text form is closed, click the left mouse button on the text in the 2D View to select it before opening this form.

The form will now allow you to edit the properties of the selected text.

Click the button to update the changes in the 2D View. Click the button to finish or cancel the editing and close the form.

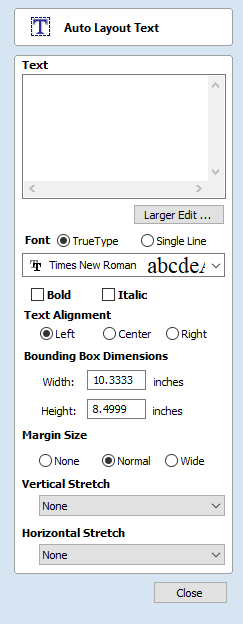

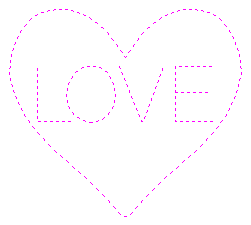

Auto Layout Text

This option automatically sizes a block of text to fit inside the bounding box (width and height limits) of a selected vector. If no vector is selected the text is scaled to fit the size of the material.

When the Text form is open, the Dimensions for the Width and Height of the selected vectors or job dimensions are shown, and these are used to constrain the font size of the text.

- See Also:

- The Create Text form.

- Arc Text.

- The Text On A Curve form.

- Kerning and Spacing.

- Convert Text To Curves.

Entering Text

The procedure for Drawing Text in the 2D Window is:

- Select the vector inside which the text is to be fitted

- Click the Draw Text icon

- Enter the required text content

- Select the font either True Type or Single Line as required and alignment options

- Click

Vertical Fonts

Fonts that start with the @ character are drawn vertically downwards and are always left justified.

Vertical Text

Engraving Fonts

The Single Line Radio Button changes the Fonts list to show a selection of fonts that are very quick to engrave.

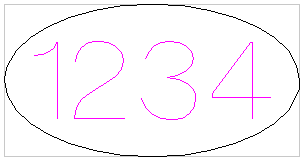

This example shows text (in an Engraving Font) drawn in an ellipse. The bounding box of the ellipse is used for the layout:

Options

The button opens a larger text entry window that makes it easier to enter text that needs to run on longer line lengths.

Clicking accepts any text entered into the window and will throw away any changes.

Text Alignment

Positions text relative to the selected bounding box or material size with options for left, center and right aligned.

Bounding Box Dimensions

These are the actual size of the box into which the text will be fitted. If the text is scaled interactively (by left clicking twice on the text) or precisely using the scale tool, the new bounding box is updated and displayed as a light gray rectangle.

Margin Size

The distance between the text and the bounding box where:

- None - Scales text to fit the rectangle width or height of the bounding box

- Normal - Scales text to fit within 80% of the bounding leaving a 10% border to the left and right.

- Wide - Reduces the size to 60% of the rectangle width leaving a 20% border to the left and right.

None

Normal

Wide

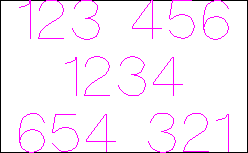

Vertical Stretch

When the text fits the width of the box and there is space above and below it, the text can be made to fill that vertical space using one these methods:

No Vertical Stretch

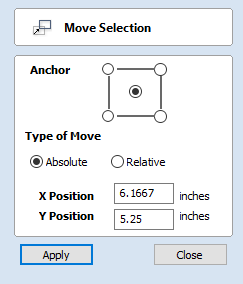

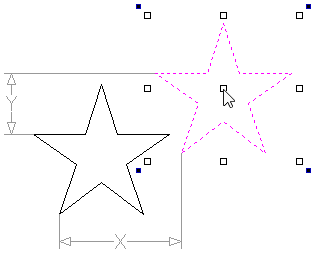

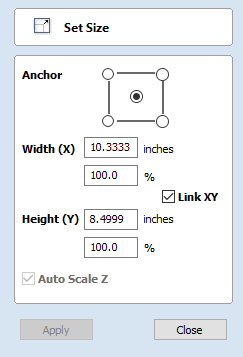

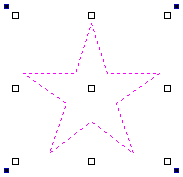

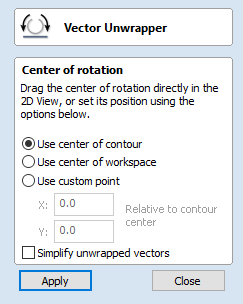

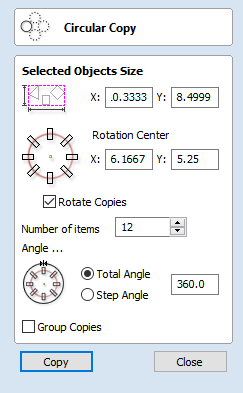

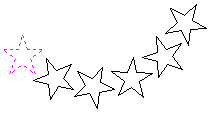

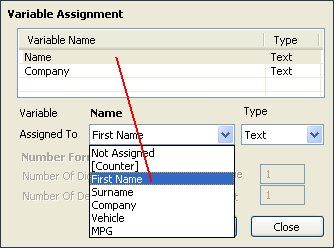

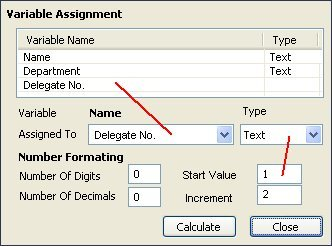

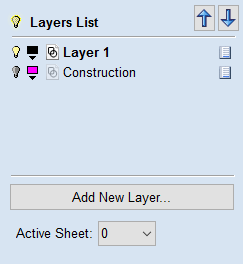

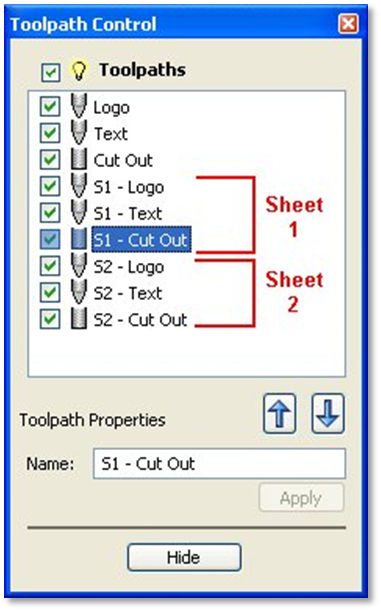

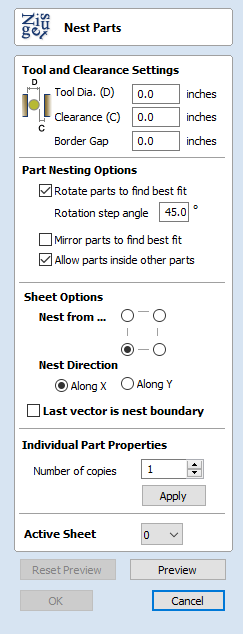

Stretch Line Space to fit