Toolpaths

The ultimate purpose (in almost all applications) of VCarve Pro is to allow you to generate toolpaths which can be run on a CNC machine to machine the finished part in the material of choice. This requires, at a minimum, some vectors to describe the area to which a toolpath will be limited to or perhaps a combination of both vectors and a 3D Model. The process for creating toolpath is as follows:

Prepare vectors for machining

Optionally organize the vectors you will be using for machining onto appropriate layers.

Create outline vectors around any 3D data using the drawing tools or the 'Create vector boundary from selected components' icon.

Check the 3D data

Make sure you have the right combination of 3D Components displayed. Everything you see in the 3D View - the result of all the visible Components will be machined. Check the depth of the combined 3D model to make sure it fits into the material you plan to use, edit this using the Scale Model Height function if necessary.

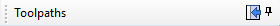

Set up the Material

Check the overall material size (Job Setup) to ensure it matches or exceeds the size of the finished product.

Use the Material setup form from the Toolpaths Tab to set the reference Z datum for the part relevant to the CNC machine and to position the 3D part within the material.

Create the Toolpaths

Work through the toolpath strategy icons you wish to use to machine the job to calculate all the required toolpaths.

Preview the Toolpaths

Either after you create each toolpath or at the end of calculating them all, the user has the option to preview the toolpaths to see what they will actually look like in the 3D view. This is a very important step to verify position, detail and the look of the overall finished part.

Save the Toolpaths for the CNC machine

After choosing the appropriate Postprocessor from the list, the toolpaths can be saved in a format which is ready for the CNC to cut. Depending on the toolpaths calculated and the options the Postprocessor/CNC you are using supports, you may be able to save a single file or it may need multiple files to be saved - one for each tool type.

All the stages will be covered in the supplied Tutorial videos that include Machining. It should be noted Stages 1 and 2 are done through icons already covered from the Drawing and Modeling Tabs. Stages 3 to 6 use icons from the Toolpath Tab (on the right hand side of the screen). These will be covered in the next section.

Additional Toolpath Tab Features

Switch to Drawing Tab

Closes the Toolpath Tab (right hand screen form) and opens the Drawing Tab (left hand drawing form)

The pin icon is described in the section: Accessing Auto-hidden tabs

Toolpath Summary Area

When a toolpath is selected from the Toolpath list with no other function being used in the Toolpath Tab a text summary of the toolpaths settings is shown in the body of the Toolpath Tab below the icons. This is a very useful way to recall settings for a toolpath without opening it.