User Guide

- 01. Interface Overview

- 02. Getting Started - Introduction

- 03. Getting Started - The CNC Workflow

- 04. Getting Started - One-Time Setup

- 05. Getting Started - Example Project

- 06. Intermediate - 2D Design and Management

- 07. Intermediate - 3D Design and Management

- 08. Intermediate - Creating a Rotary Job

- 09. Intermediate - Simple Rotary Modelling using 2D Toolpaths

- 10. Advanced - Rotary Machining and Wrapping

- 11. Advanced - Importing External Models in a Rotary Project

- 12. Advanced - Modelling 3D Rotary Projects

- 13. Advanced - Advanced Modelling of 3D Rotary Projects

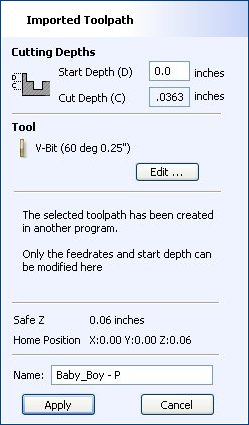

- 14. Advanced - Imported 3D Toolpath Files

- 15. Advanced - Post-Processor Editing

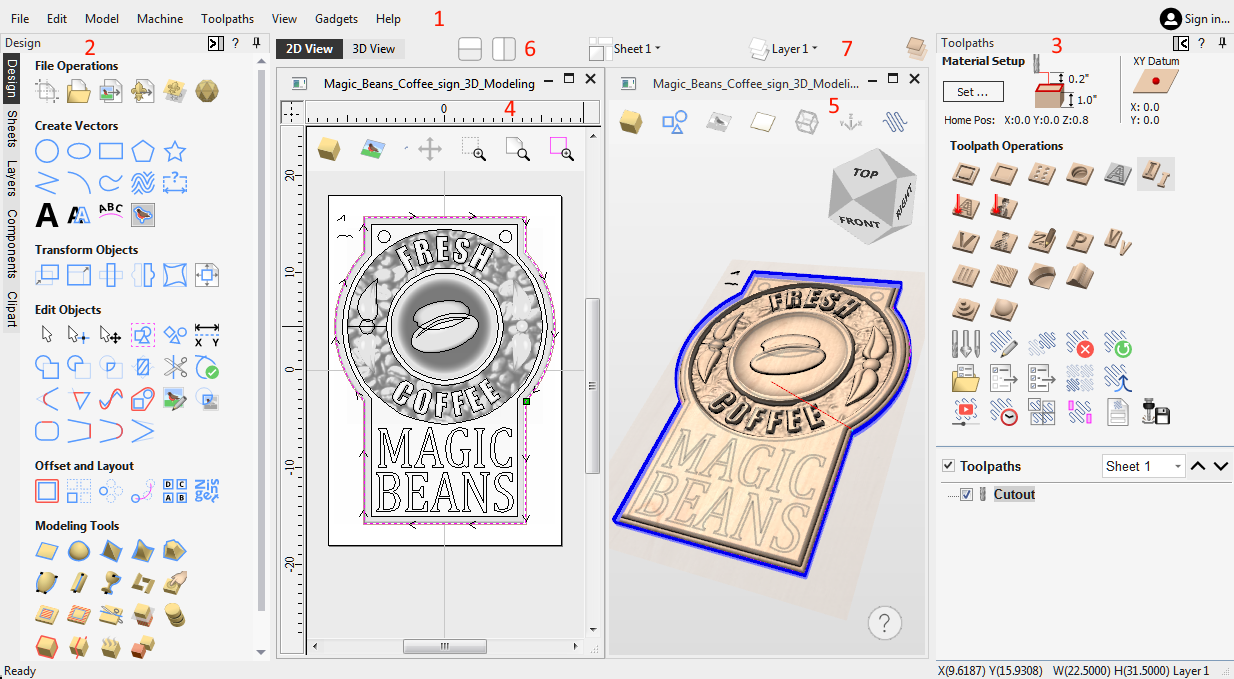

01. Interface Overview

- The Main Menu Bar (the Drop Down Menus) along the top of the screen (File, Edit, Model, Machine, Toolpaths, View, Gadgets, Help) provides access to most of the commands available in the software, grouped by function. Click on any of the choices to show a Drop-Down list of the available commands.

- The Design Panel is on the left side of the screen. This is where the design tabs can be accessed and the icons within the tabs to create a design.

- The Toolpath Tab is on the right side of the screen. The Top section of the toolpaths tab houses all of the icons to create, edit and preview toolpaths. The bottom half shows you toolpaths that you have already created.

- The 2D Design window is where the design is drawn, edited and selected ready for machining. Designs can be imported or created directly in the software. This occupies the same area as the 3D View and the display can be toggled between the two using F2 and F3 or the tabs at the top of the window.

- The 3D View is where the composite model, toolpaths and the toolpath preview are displayed, and can also be used to create your Vectors, 3D models and edit them both.

- If you wish to see the 2D and 3D views simultaneously, or you wish to switch your focus to the Toolpaths tab at a later stage of your design process, you can use the interface layout buttons (accessible in the 2D View Control section on the Drawing Tab) to toggle between the different preset interface layouts.

- Quick Drop down menus can be accessed here to change the current Layer, Sheet or Component Level you are working on.

Managing the Interface

Managing the Interface

The tool pages have Auto-Hide / Show behavior which allows them to automatically close when not being used, thus maximizing your working screen area.

The software includes two default layouts, one for designing and one for machining, which can automatically and conveniently set the appropriate auto-hide behavior for each of the tools pages. Toggle layout buttons on each of the tools pages allow you to switch the interface as your focus naturally shifts from the design stage to the toolpathing stage of your project.

Accessing Auto-hidden tabs

Accessing Auto-hidden tabs

If a tools page is auto-hidden (because it is currently unpinned, see pinning and unpinning tools pages, below), then it will only appear as a tab at the side of your screen. Move your mouse over these tabs to show the page temporarily. Once you have selected a tool from the page, it will automatically hide itself again.

Pinning and unpinning tools pages

Pinning and unpinning tools pages

The auto-hide behavior of each tools page can be controlled using the push-pin icons at the top right of the title area of each page.

Default layout for Design and Toolpaths

Default layout for Design and Toolpaths

Aspire has two default tool page layouts that are designed to assist the usual workflow of design, followed by toolpath creation.

In all three of the tools tabs there are 'Switch Layout' buttons. In the Drawing and Modeling tabs, these buttons will shift the interface's focus to toolpath tasks by 'pinning-out' the Toolpaths tools tab, and 'unpinning' the Drawing and Modeling tools tabs. In the toolpaths tab, the button reverses the layout - unpinning the toolpaths page, and pinning-out the Drawing and Modeling pages.You can toggle between these two modes using the F11 and F12 shortcut keys.

Help ?

Help ?

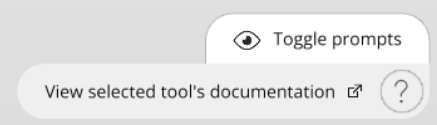

In all forms is a ? Icon which will take you to the appropriate Help Contents page to cover the tool form you are on in detail.

3D View Help Prompts

3D View Help Prompts

The Help Prompts will track your current tool or action and offer quick access to relevant Help documentation or tips on the current tool.

02. Getting Started - Introduction

Getting Started

Welcome to the vibrant Vectric community! You've made a great choice for getting the most from your CNC machine by using Vectric software. This short guide should help you to get your CNC machine cutting correctly in less than hour. Along the way we will highlight key concepts and tools in our full Reference Manual. These links will help you review each step in more detail and begin to develop your skills.

Overview

In the first section of this guide we will describe the main principles of CNC toolpath creation using Vectric software. All CNC projects follow a similar workflow and our software is designed to reflect these steps naturally and intuitively.

Next we will complete your one-time setup to licence your product and give you access to Vectric's online portal, V&Co, which we will use to automatically configure the software for your specific CNC machine.

In the final section we will run through a simple, but complete, CNC project from start to finish step-by-step. At the end of the project you should be confident that your CNC machine is correctly configured and you can cut vector drawings using a simple profile toolpath strategy.

03. Getting Started - The CNC Workflow

The Vectric Workflow

The Example Project will step you through all the stages of creating, toolpathing and cutting a simple line drawing. Most CNC projects share many common concepts and steps so before we complete our practical project, let's run through them.

The structure of a Vectric Job

All the information needed to describe a single CNC project is contained in a Vectric Job document (when saved they have the file suffixes *.crv or *.crv3d). A new job always begins by defining the area of a sheet of physical material that you intend to cut with your CNC machine.

Most jobs typically only involve one sheet of material, but more complicated projects may comprise multiple materials. Don't worry, your job's primary material sheet can be updated or new sheets of material added to your job later, as your design develops.

The drawings & images used to work on a material sheet can be created on layers to help manage more complicated designs. Similarly 3D model components can also be organised onto levels. By default there is always at least one layer and one level for each sheet in a new job. You can add more layers and levels to help organise more complicated projects.

Once your material sheet has been created in the Job Setup form, the software will show you a 2D & 3D view of your design space (which matches the dimensions of your current material sheet), each in their own window.

Above the view windows is the main toolbar which allows you to navigate through the structure of your CNC job and see what is currently being displayed in view windows below. It shows you the material sheet, design layer and 3D model level that you are currently working on (referred to as 'active').

What you see in the 2D & 3D design views below will reflect these current settings and any new shapes, components or toolpaths will be created in the active locations indicated. You can also change the active sheet, active layer or active level at any time directly from these controls.

More advanced projects can also represent both sides of a sheet of material. For a two-sided project an additional control above the views shows which side of the sheet is currently active. You can view the drawings, models and toolpaths associated with the top and bottom surface of each material sheet and swap the active side of the sheet in a consistent way to the other controls.

Initially your job will be empty and so your views will be blank, but in due course, Vectric's view windows will show all the layered drawings & images, 3D model components & toolpaths for the currently active material sheet.

The currently active locations are the same for both the 2D & 3D views i.e. creating a vector shape will place it on the same active sheet and active layer regardless of whether the 2D or 3D view is used.

You can, however, toggle the visibility of object types in each view independently using the visible items toolbar at the top of each view. This is helpful for focusing on different areas of your job at each stage of creating your CNC project.

Many of the software's tools can be used directly in either the 2D or 3D view.

In V12 some tools have not yet been extended to allow full interaction in the 3D - this is an ongoing transition. If in doubt, try click

Import, Draw or Trace artwork

Computer images are most often represented as a grid of coloured squares - these images are referred to as bitmaps and their constituent coloured squares are called pixels. Except for a few very specific cases, this representation is not *directly* useful for toolpath creation. Computer drawings (from CAD or illustration applications) are very different and are instead built from mathematically defined lines & curves.

This type of representation is referred to as vector or contour artwork. Vectric software can use both bitmap and vector artwork, but most types of toolpath can only be created from vector drawings. Suitable bitmaps with bold regions of similar colour (for example logos, cartoons, icons or signs) can, however, be used to create vectors from which many types of toolpath can then be generated - this process is called bitmap tracing.

Some external artwork file types contain only bitmaps (e.g. BMP, PNG, JPG), some contain only vectors but many can contain both (e.g. PDF, SVG, DWG/DXF).

Use the design artwork to create toolpaths

We use the vector artwork to define the shapes we want to cut. It is important to emphasise that the toolpath (the actual cutting moves your machine must make to leave your intended shape) is rarely, if ever, a direct conversion of the original artwork. The toolpath must be created taking into account a complex interaction of the material, your CNC machine's capabilities and the shape of your cutting tool.

"Sculpture, per se, is the simplest thing in the world. All you have to do is to take a big chunk of marble and a hammer and chisel, make up your mind what you are about to create and chip off all the marble you don’t want." - Paris Gaulois, 1879.

Toolpaths are therefore generated from source vector artwork but once created they are almost entirely indepenendent of the artwork that created them. Moving, editing or even deleting the source artwork used to generate a toolpath will not affect the toolpath - it must be actively re-calculated to reflect any changes.

This is a carefully considered Vectric design principle - although you may be prompted that a significant alteration to your job has occurred - your toolpaths will never change automatically 'behind your back'!

That said, toolpaths do retain a handy reference to the artwork that created them. If you choose to edit a toolpath it will try to locate it's orginal source artwork and re-select it. At this point you can simply recalculate it to reflect any changes you have made to that source artwork, but you can also choose to select additional or entirely different artwork.

Preview

As we've discussed, the actual motion of your CNC machine (the toolpath) required to cut al shape can be complex and difficult to interpret.

Luckily your software provides an extremely accurate preview of any toolpaths that you create by simulating them in a block of virtual material. In the Example Project we will use the Toolpath Preview to verify that the toolpaths are producing the shapes we want (and we can easily corrected them if not)!

This simulated preview is a hugely beneficial step that ensures you minimise costly mistakes in the real world (we all make them from time to time) but it also allows you to check the surface finish you can expect from different strategies under different conditions.

The Toolpath Preview uses exactly the same data that will be sent to your CNC machine. You can be confident that any cutting and surface finish issues that occur at the machine but which are not visible in the Toolpath Preview are almost always caused by a physical problem with the machine setup or tooling, which makes finding and fixing them a lot quicker!

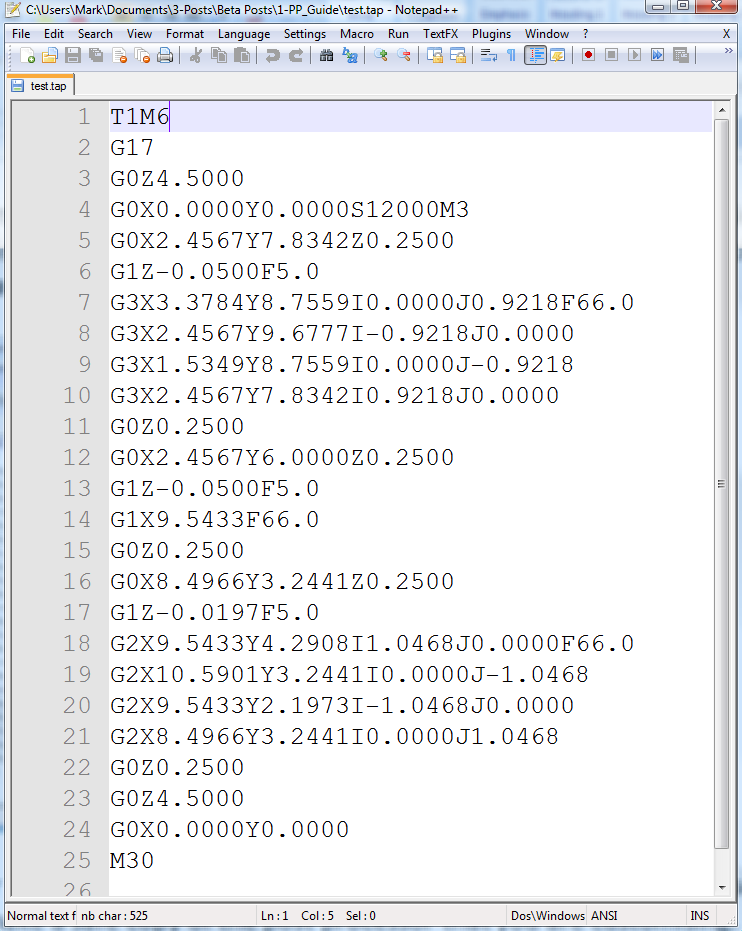

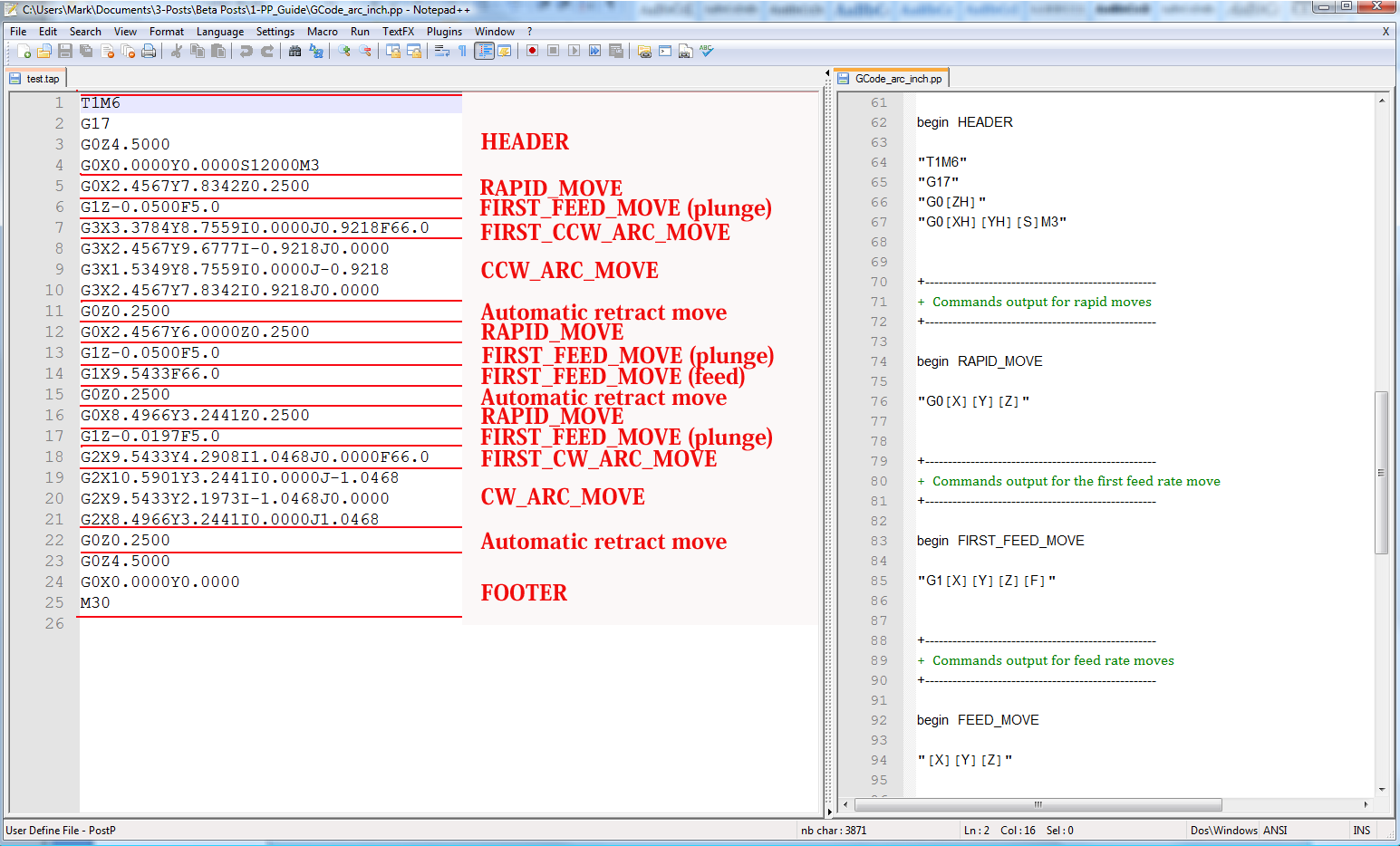

Exporting the toolpath

Now we will be ready to export the toolpath, in the right format, ready to be loaded into our CNC machine's controller. Saving the toolpath will make use of a Post-Processor that is specific to your CNC machine. It will translate the movements contained in the toolpath into a toolpath file that is in the specific format required by your CNC machine's controller to load and run.

04. Getting Started - One-Time Setup

One-time setup

Before we can begin, however, we must complete a couple of one-time steps to ensure your newly installed software is correctly configured. We will start by showing you how to log in to Vectric's online portal, V&Co. Here you will be able to download many other tutorials & projects, clipart packs and software updates. It is also the place you will find your personal product license code and you can return to it any time should you need to recover this licence information or use the main product installer again for any reason in the future. We will also use V&Co to access our online Machine Database. We can use this to automatically configure your software for the make and model of your CNC machine. Licensing and configuring your software typically only needs to be completed once and if you are online they can both be completed almost entirely automatically with just a few clicks.

Licence Management & Your V&Co Account

It is important that your investment in our high quality CNC software is protected and that Vectric can continue to create great software in the future - you will, therefore, have a unique personal licence for the software that you have purchased.

This licence is associated with your Vectric V&Co account, and can be accessed at anytime via https://portal.vectric.com. To log in to your V&Co account you will need to use the email address (which must be uniquely yours) and password that you registered with us when your account was created - please keep these details safe. Your registered email address is the way by which we can verify your ownership of the software.

Important Note: you can reset your password at any time using your registered email account and the forgotten password link provided on the V&Co log in page. If you need to change your registered email address it is important to do this before you lose access to the one to which the software is registered. If you can no longer access your registered email, you will need to contact us directly at support@vectric.com but please note that you will now need to be able to provide independent and alternative proof of your identity and purchase.

Within your V&Co account there is a unique digital code for each piece of Vectric software you have purchased. When you first run our software on your laptop or PC you will be prompted to provide this information. If you are installing onto a computer that is online (i.e. with unrestricted internet access available) you can complete this process almost entirely automatically - this is the fastest and easiest method.

The software will simply launch your web browser and prompt you to log in to your portal account. The software will then show the appropriate license that is available to be linked. Simply accept the link and you're good to go!

Once you have completed this process after initial install you will not be required to do it again unless you change computers or need to re-install the software afresh. Your software is now uniquely licenced to you and your details will always be shown in the main interface - even when you are offline, or online but not logged-in.

You can also log into your V&Co account from within the software at any time when you are connected to the internet to enable additional online features and services such as your clipart collection or online tool database.

When logged-in, your software will indicate this in the top right corner of the main window. Please note, the one-time licensing of your software and routinely logging in when using your software are independent concepts. Your personal product licensing is unaffected by your V&Co logged-in status.

We have also ensured that you can complete the software licensing process without having a live internet connection. The process is less automatic and details of the steps can be found here.

CNC Machine Tool Configuration

The software supports hundreds of different types of CNC machine, so the the next thing we will need to do is configure the software for your particular make and model. Correct configuration comprises two elements - appropriate tool settings in the tool database for your CNC machine and setting the 'translation' file (the Post-Processor) needed to create a toolpath file that your specific machine tool controller can understand.

Tool Database

Configuring the software will create a default tool database with tool definitions include cutter movement speeds ("feedrates") that *should* be a reasonable starting point for you to edit the entries for the tool types that you have, according to the recommendations from your CNC machine manufacturer for each material. Appropriate tool settings are the result of a complex interaction of the tool's shape and design, the nature of the material you intend to cut and the strength and power of your CNC machine. Don't use any default settings without first considering whether they are appropriate for your circumstances.

We will look at the Tool Database in more detail in the Toolpath Creation section below.

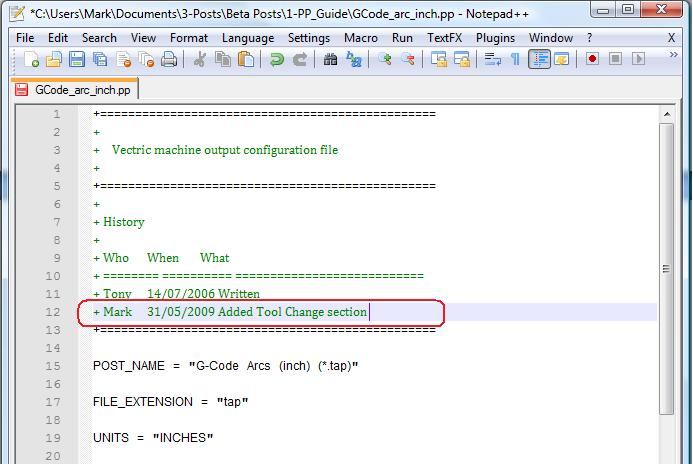

Post Processors

Your software can create toolpath files for hundreds of different CNC machines and controllers. To achieve this, the software creates an internal representation of a toolpath. Only when this toolpath is saved does it get 'translated' into the specific format required by your CNC machine.

The translation instructions are contained in file called a Post-Processor (because it *processes* the toolpath *after* it has been created).

Post-Processors also determing whether the toolpath movements will be presented to the machine using metric or imperial units. This must typically match the units mode you have set on your CNC machine's controller (seek advice from the manufacturer if needed). Note, however, it doesn't matter what units where used to create the original toolpath within the software - any required conversion is automatically applied when the toolpath is saved through the Post-Processor.

Job Setup - Axis Orientation

Our software is specifically designed for 3-axis CNC Machines (with additional support for an optional rotary axis). As you look at your CNC machine, the normal conventional is that left and right movement is controlled by the X-axis, forward and backward movement controlled by the Y-axis and up and down movement is controlled by the Z-axis.

In our software the width of your job will typically be equivalent to the X-axis of your CNC machine and the height of your job to its Y-axis.

Be aware that some machines are orientated so that the X & Y axes are swapped as you look at them - left to right movement may be controlled by the Y-axis and vice versa.

Use your machine's control software to jog your machine independently in each axis to make sure your expectations are correct.

Although unusual, it is possible that some post-processors will swap the X & Y toolpath coordinates after you have created your toolpaths - effectively changing the apparent orientation of you job - but this is only recommended for users who are confident of their machine's configuration and usage and not recommended for the majority of users who might not be aware of the other issues this can cause. Check with your machine tool manufacturer if you have any doubts.

It can help Orientate yourself so that when you stand before the machine, when you jog the machine to move to a higher X position, it is moving Left to Right infront of you. This can help visualise how the project design you have made in the software will translate to the bed of your machine.

05. Getting Started - Example Project

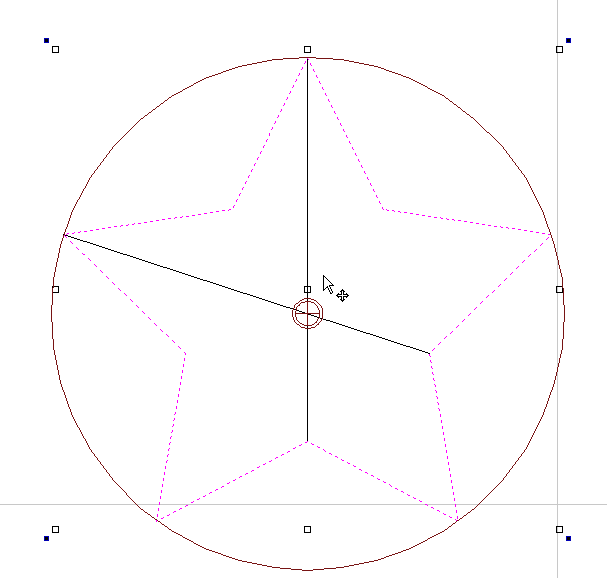

Cutting a Calibration Pattern

For our quick introduction we are going to us a 2D Profile toolpath strategy to engrave a precisely sized and aligned rectangle, circle and star. This pattern will use all the steps we have outlined in The CNC Workflow. It will also allow us to check that the CNC machine is working correctly using some simple but important features of the design:

- The rectangle, circle & star should not appear warped or distorted.

- The dimensions of the carved shapes should exactly match the design.

- The alignment points of the 3 shapes should not show any discrepancies.

- The star is rotated slightly clock-wise and the carving should match the original orientation of the design with no unexpected reflections in X or Y.

At the end of this guide we will review these checks and suggest some troubleshooting tips if any of them are not as they should be.

Material, Tooling & Hold-Down

The XY dimensions of the design will be 100mm (4") so you will need a piece of material approximately 150mm (6") square or larger.

The precise thickness of material is not too important as the design will simply be carved into its surface at a depth of 1.5mm (1/16"). Any piece that is 3mm (1/8") thick or greater will therefore be fine. An offcut of plywood or mdf board would be ideal.

To avoid any chance of collision with clamps or cutting into a screw, the best starting method to hold down a small piece of material like this is to use double sided tape. Any heavy duty 'carpet' type tape will work, but you may need to experiment to find a brand that secures well, but can also be cleanly removed once the job is complete.

The toolpth will be created based on a V-bit, but the precise tool angles are not important. If you don't have a V-bit tool, then a small (3mm, 1/8" diameter or less) end mill or ball nose tool will also work but the cuts will be the broader so the calibration pattern may be a little bit more difficult to interpret.

To avoid any chance of collision with clamps or cutting into a screw, the best starting method to hold down a small piece of material like this is to use double sided tape.

Create the Job

- Click `Create a new file` to get started.

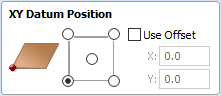

This opens the `Job Setup` form. All projects start with a job setup. Here is where we consider the physical dimensions of our design. Note that you do not necessarily need to define the whole material block at this point, just that area needed for your design - the design area can be subsequently positioned anywhere on a larger physical material block using the `XY Datum Position`, which your CNC machine will use as its reference starting point.

Like all forms in the software, you should simply work from the top to the bottom of the `Job Setup` form. Forms are typically laid out with the most significant, non-optional or most commonly updated fields at the top. Sensible defaults are provided for most form fields the first time they are accessed (fields will generally remember their previous setting, once you edit them) so initially you can simply ignore any fields you are not sure about. At the bottom of most forms are the buttons to (accept), or any changes you have made.

- The job setup form allows for projects that will be cut from both sides or using a rotary axis, but for now we will simply select `Single Sided`.

We will set the `Job Size` units according to your preference.

Note that your CNC machine controller will be set to expect toolpaths defined in either metric or imperial units and you will need to refer to your CNC manufacturer to determine your particular setting - the Post-Processor you select later will need to match the toolpath to the controller's requirements but this is entirely independent of the units you prefer for designing within the software - everything will be automatically converted, if necessary, when the toolpath file is created.

- Set the width & height of your new job to both be 150mm (6")

- Set the

- Click OK

Design the Calibration Artwork

Your project needs to start with design drawing. On the left-hand side of the screen there are a number of tabbed panels that provide access to various tools to help you to draw your design.

In due course, we will use our design to begin creating toolpaths for our CNC machine. The functions relating to toolpaths and toolpath strategies are located in another panel on the right-hand side of the screen. Initially this panel is hidden. Once our design is largely complete we will switch our focus to the toolpath panel on the right.

This is the typical workflow when creating a CNC project and so the software interface makes this switching of focus easy and intuitive.

For now let's continue to focus on the tools available in left-hand design panel.

The first thing we will do is create a simple 100mm Square, using the Rectangle tool in the Design Panel on the left. Witht he Rectangle tool open, click into the 3D View to place a default rectangle, and in the Edit Boxes on the Right nd Bottom of the rectangle, click into each one and type 100.

This will create your Rectangle to be 100m x 100mm.

Now press the F9 key on the keyboard, and your Rectangle Vector will now be centered in your work space.

Create our First Toolpaths

Now that our design drawing is complete we are ready to consider what toolpath strategy we should use to cut this shape accurately and efficiently.

The software interface can automatically hide the design tools panel and show the toolpath strategy tools panel using the 'Switch to Toolpath commands' button.

- Click on the 'Switch to Toolpath commands' button at the top of the 'Design' tab.

The toolpaths tab will now open on the right-hand side of the software. Here you will find all the tools relating to the creation, editing and saving of toolpaths.

Selecting the most appropriate toolpath strategy for a particular job is one of the toughest aspects of initially learning how to use your CNC effectively. Over time you will explore the different strategies available within this tab and our extensive tutorials and practical examples will to understand what each is used for.

For now we are going to use just the first strategy availble under the Toolpaths Operations - this is the Profile Toolpath.

Click on the Profile Toolpath button to open the 2D Profile Toolpath form.

Saving and Loading the Project

At this point we should probably save our project. Saving the project document using the File->Save menu, or the Ctrl+S shortcut-keys, is just like saving any other conventional application document (i.e. Microsoft Word etc.) and it will include all of your 2D design elements, 3D models and toolpath strategy settings in a `*.crv` or `*.crv3d` file. This is the file that you can come back to any time at a later date to continue your work or to duplicate as the basis of a new project.

Note that this is *not* the file that your CNC machine will read. Saving Toolpaths (see below) is the indepenendent process by which you specifically save the file from this project that your CNC machine needs. It may be helpful to think of the toolpath saving process as more like creating PDF files *from* your Word document - PDF files aren't typically reloaded or edited but they are ready for 'printing'.

Previewing the Toolpath

Before we begin getting our toolpath files over to our CNC machine there is still a *very* important step for us to do in the software. We can preview exactly how our CNC machine will move and what the material should look like after each toolpath is completed using the Preview Toolpaths command.

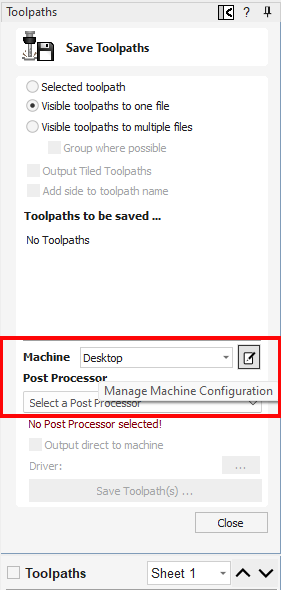

Saving Toolpaths - Post Processing

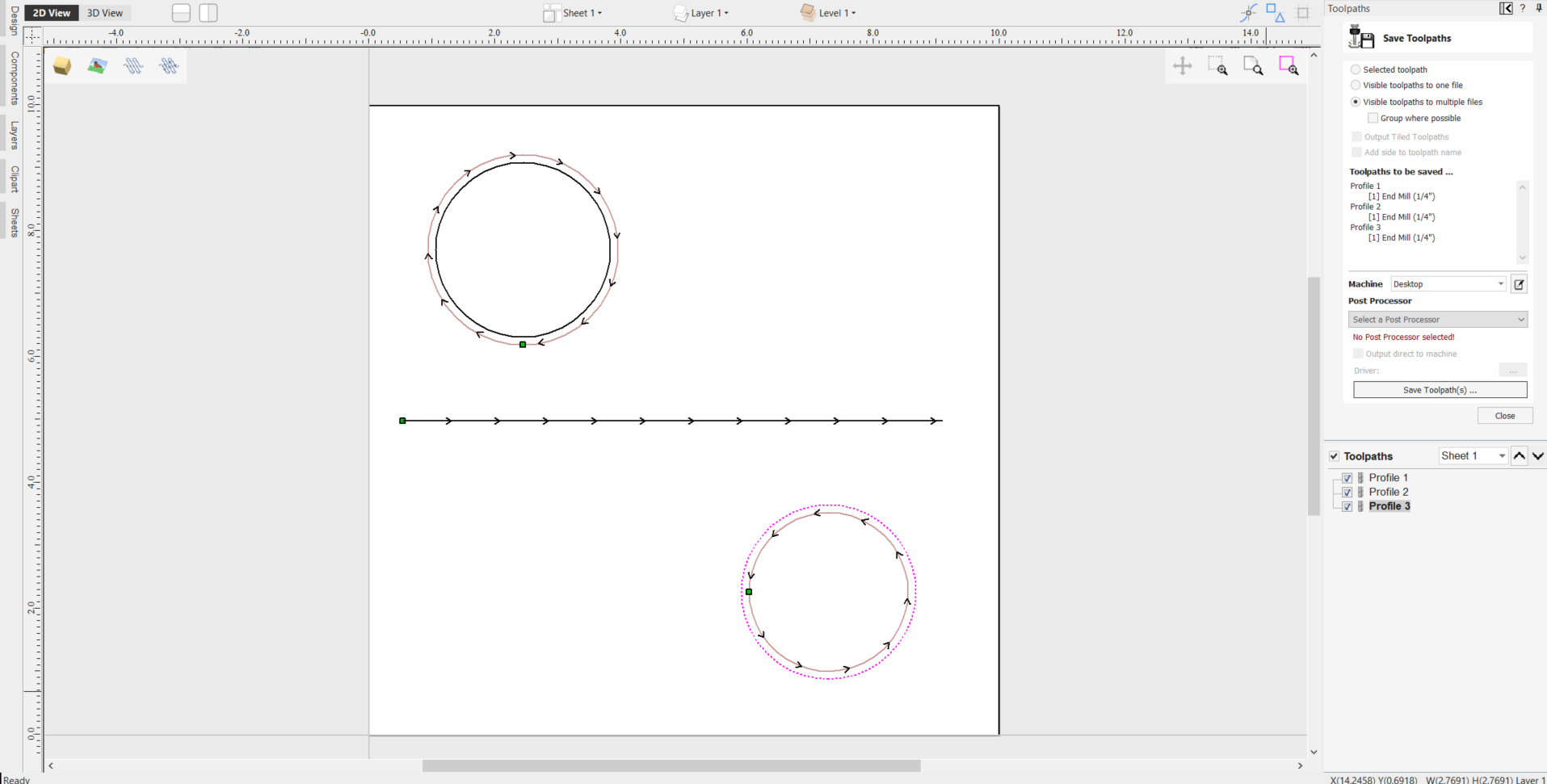

You now need to Post Process your Toolpath to save your toolpath out into a file which your CNC Machine will be able to read.

In this guide we will assume that you have completed the "Machine Configuration" Process either Manually or using one of the existing Online Configurations as seen here.

With that step complete, you just need to now open the "Save Toolpath" form, using the bottom right most icon in the Toolpath Panels icons.

Make sure your machine is currently selected in the Machine

Running Your Toolpath

Every CNC machine and controller is different. At this point you will need to refer to your CNC machine manufacturers instructions for the details of running your toolpath file, but we can provide some generally applicable information about the typical process you should expect.

Secure your material

Your piece of material will need to be secured to the machine's bed. This is typically done by clamping, screwing or gluing your material down (larger or more sophisticated machines may have vacuum hold-down). In the first two cases you must be very careful to avoid cutting into your clamps or screws. As we noted in the Job Setup, the toolpath file does not have to be the same size as the material so the simplest way to avoid clamps and screws is to make sure your job dimensions (and thus your toolpaths) are no larger then the unobstructed area of your material and that it is correctly positioned within this region.

Set your origins (datums)

The movements of all toolpaths are relative to the `XY datum position` you selected when you initially created your job (in our example we set the bottom-left corner, but it can also commonly be the center of your design), these are also often referred to as "origins". Now you must indicate to your CNC machine controller where this datum point is physically located on your material. This process is usually referred to as "setting the XY datum", "setting the XY origin" or "zeroing X & Y".

In effect, setting the XY datum will position where your toolpath will be cut on your material.

You will also need to indicate to your controller how deep into the material your toolpath will cut - the equivalent of positioning your toolpath within the material. This is often known as "setting the Z origin", "setting Z zero" or "zeroing Z".

Again at this point it is important to know what `Z Zero Position` setting you used when you created your Job in the software - in our example we set it to be on the surface of the material, but in some circumstances it is useful to set it to the base of the material block, or your CNC machine's bed.

Because this job was created with the `Z Zero Position` to on the `Material Surface`, you will need to jog your CNC machine so that the tip of the tool is touching the surface of the material and then use its control software to zero the Z position.

Alternatively you may have an automatic Z touch plate or probe to achieve the same result - refer to your CNC manufacturer for instructions on this step.

Note: when wanting to do a test 'air cut' this is your opportunity to back your CNC machine upward in Z to a point in the air where the toolpath's maximum depth will not contact any physical material and set your Z zero 'in the air' instead. Running your toolpath with the Z origin in the air like this is a very useful test of movements of a toolpath if you have any doubts or uncertainties about your setup or toolpath settings before any real cutting.

At this point your CNC machine should be in a state where its position indicators would read X=0, Y=0 & Z=0 when the tip of the tool was at the position you defined when you created your origin job - in our example this would be at the bottom-left corner of the area we will cut and just touching the top surface of the material.

Load your toolpath File

Ready to go?

You should always consider a visual check of at least the initial start point and feedrates of an untested toolpath with an 'air cut' (see note above). Pay particular attention to the movement that will form the first full-depth, full-width cut - as this will be when the tool and CNC machine are under the most stress - to ensure that it looks appropriate for the tool and type of material you are intending to cut.

When you first start using your CNC it is worth considering keeping a simple written checklist at your controller. An example might be:

Have I:

- Run an 'air-cut' to check initial movement?

- Checked the material is firmly secured?

- Checked right type and shape of tool is fitted for this toolpath?

- Set the X,Y origin?

- Set the Z origin?

- Turned the spindle on (if not automatically enabled by your CNC machine's controller)?

OK, time to cut!

Always run any toolpath with untested or unverified tool settings with extra care and caution. When cutting with new tools and or in new materials seek advice from your CNC machine or tool manufacturer about the appropriate feeds and speeds for your machine and tooling.

Check the Calibration Cuts

Troubleshooting

Scale / units

My Design is cutting out much smaller/larger then it designed for.

Double check what distance your machine moves when you manually command the controller to jog from X=0 to X=1

The distance it travels should be exactly 1 Inch or 1mm.

If it moves the 1 Inch then you need to ensure that when you save your toolpaths from Aspire that you use the Inches Post Processor.

Likewise, if it moves 1mm, then use the MM Post Processor instead.

If it moves a different distance, instead of one of these options, then the machine calibration needs to be reviewed with help from the machines supplier.

Double check this on each of the X Y and Z Axis's, and it must move the exact same distance on all Axis.

Backlash

Backlash is a physical issue in the machine where an Axis will move the correct distance for a cut, but then loosness on the Axis motor or screw barings will allow it to slip.

This can build up over time for the machine to graducally become more and more misaligned over the duration of a toolpath. Commonly if you see inaccuracy in cuts only in one direction then it will be backlash issues on that one Axis.

Report the issue to your machiine supplier for advice on how to elliminate backlash in your hardware.

Inverted axis

The most common indicator of an inverted axis is text being mirrored in a single direction. A rarer case can be when the router will raise when it should plunge, resulting in it cutting air, even when Z Zero is correctly set. This can be due to a number of factors, such as:

- Hardware Wiring.

- Controller Setup.

- Post Processor setup.

The Hardware wiring is always the first thing to check in these cases, to ensure that the machines hardware is all connected as intended, and there are no wiring issues. If the positive and negative terminals on a motor are reversed then the motor can go in reverse.

The controller setup is part of the controllers calibration, and if values are reversed here, it can cause the motors to then work in reverse.

Post Processor setup can sometimes require the reversing of an Axis. This will have been required by the machine supplier to fit their machines configuration. The Post Processor should usually not be reversed manually, and is setup to fit the machine suppliers specifications. In rare cases where it is needed to be changed to suit a CNC machines which cannot be corrected with the above points then Editing the Post Processor can help.

06. Intermediate - 2D Design and Management

The 2D View is used to design and manage the layout of your finished part. Different entities are used to allow the user to control items that are either strictly 2D or are 2D representations of objects in the 3D View. A list of these 2D View entities are described briefly below and more fully in later sections of this manual.

Ultimately the point of all these different types of objects is to allow you to create the toolpaths you need to cut the part you want on your CNC. This may mean that they help you to create the basis for the 3D model or that they are more directly related to the toolpath such as describing its boundary shape. The different applications and uses for these 2D items mean that organization of them is very important. For this reason Aspire has a Layer function for managing 2D data. The Layers are a way of associating different 2D entities together to allow the user to manage them more effectively. Layers will be described in detail later in the relevant section of this manual. If you are working with a 2 Sided project you can switch between the 'Top' and 'Bottom' sides in the same session, enabling you to create and edit data on each side, and using the 'Multi Sided View' option you can view the vectors on the opposite side. 2 Sided Setup will be described in detail later in the relevant section of this manual.

Vectors

Vectors

Vectors are lines, arcs and curves which can be as simple as a straight line or can make up complex 2D designs. They have many uses in Aspire, such as describing a shape for a toolpath to follow or creating designs. Aspire contains a number of vector creation and editing tools which are covered in this manual.

As well as creating vectors within the software many users will also import vectors from other design software such as Corel Draw or AutoCAD. Aspire supports the following vector formats for import: *.dxf, *.eps, *.ai, *.pdf, *skp and *svg. Once imported, the data can be edited and combined using the Vector Editing tools within the software.

Bitmaps

Bitmaps

Although bitmap is a standard computer term for a pixel based image (such as a photo) in *.bmp, *.jpg, *.gif, *.tif, *.png and *.jpeg. These file types are images made up of tiny squares (pixels) which represent a scanned picture, digital photo or perhaps an image taken from the internet.

To make 3D models simple to create, Aspire uses a method which lets the user break the design down into manageable pieces called Components. In the 2D View a Component is shown as a Grayscale shape, this can be selected and edited to move its position, change its size etc. Working with the Grayscale's will be covered in detail later in this manual. As with bitmaps, many of the vector editing tools will also work on a selected Component Grayscale.

07. Intermediate - 3D Design and Management

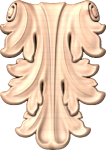

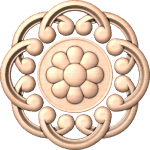

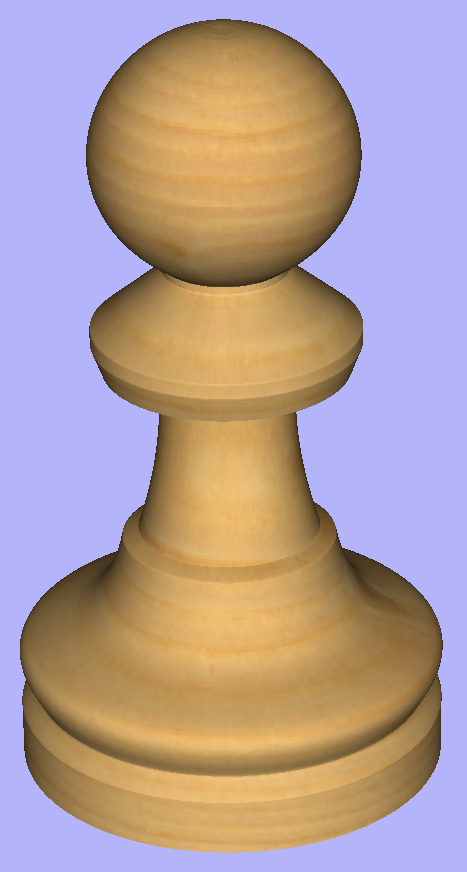

As well as creating toolpaths directly from 2D drawings, Aspire can produce extremely flexible 3D toolpaths. These toolpaths are created from 3D design elements called 3D Components that can be generated from models created in external 3D design packages, imported as 3D clipart or built entirely from within Aspire using 2D artwork as a source.

The 3D View

The 3D View

The 3D View can show you the current Composite Model (which is built from all of the currently visible 3D Components and Levels), the Toolpath Preview (a highly accurate 3D simulation of the resulting physical object that will result from your toolpaths called the Preview Material Block). Which of these is currently displayed will depend on whether or not you have a part which has 3D Components and Toolpaths or are just working on something that only includes 2D Data.

Whenever you have the Preview Toolpaths form open on the Toolpaths tab, the 3D View displays the Preview Material Block instead of the Composite Model. When this is closed if you are working on a part that only includes 2D data and 2D or 2.5D toolpaths it will continue to display the Preview Material Block. If your part contains any visible 3D Components then as soon as the Preview Toolpaths form is closed it will revert to showing the Composite Model in the 3D View and hide the simulation. In addition to these items, you can see line drawings of any calculated toolpaths in the 3D View. The visibility of these calculated toolpaths can be controlled from the Toolpath List on the Toolpaths tab using the check-boxes next to the toolpaths name. If working in a 2 Sided environment you can view both sides of a project in the 3D View using the Multi Sided View option.

The Composite Model

The Composite Model

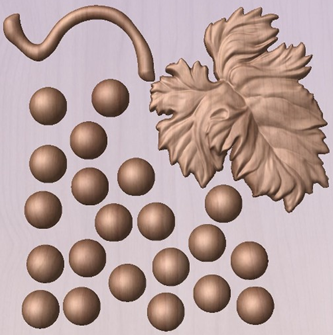

Aspire has been designed to work in a way which enables the user to easily create even very complex projects. In any situation, the best approach to producing something complicated is to break it down into smaller pieces until a level of simplicity is reached that can be understood and managed. In Aspire this is achieved by letting the user work with pieces of the design which are combined to make the finished part. In the terminology of the software these pieces are called Components. To help organize the Components they are assigned to Levels. Step by step, Components and Levels can be created and modified until you have all the elements you need. In the images below you can see an example of how this might work. On the left you can see the separate component for a model of a bunch of grapes and on the right you can see these positioned to make the complete part - we call this resulting combination the Composite Model.

There is no limit to how simple or complex a Component or the Components on a Level can be (this is the user's choice). In the example shown, you can see that a model of a whole bunch of grapes may be made up of smaller individual components but they could also be combined to exist as one single Component (the assembled bunch of grapes) that could then be used to lay-out a more complex part with multiple bunches of grapes. They could also be organized so all the grapes were on one Level and leaf and stem on another to provide a different way of managing and manipulating the shapes. Each user will find a level of using Components and Levels they are comfortable with which may be dependent on the particular job or level of proficiency with the modeling tools.

3D Components and Levels

3D Components and Levels

In Aspire, the aim is to end up with a set of Components and Levels that when combined together will make the finished 3D part. One way to think of this is like building a 3D collage or assembly. As the design evolves, new Levels or shapes may need to be created or existing ones changed. The parts of the collage are managed with the Component Tree which will be covered in more detail later.

Creating and Editing Components

Creating and Editing Components

An existing Component can be copied, scaled and have other edits carried out on it as an object. The user can also change the way it relates to the other Components, for instance whether it sits on top or blends into an overlapping area of another Component. The shape, location and relation of these pieces determine the look of the final part. As the job progresses, the user will need to create brand new Components or edit existing ones by adding new shapes, combining them with others or sculpting them.

Components can be created and edited by:

- Use a modelling tool to create shapes from 2D vectors.

- Import a pre-created 3D model - either a model previously created in Aspire or from another source such as a clipart library or a different modelling package.

- Create a 'texture' Component from a bitmap image.

- Use the Split Components Tool to break an existing Component into multiple pieces.

All of these methods are covered in detail throughout the training material.

Dynamic Properties

Dynamic Properties

As well as having its underlying 3D shape, each component also has a number of dynamic properties that can be freely modified without permanently changing its true shape. These include scaling of the Component's height, the ability to tilt it, or to apply a graduated fade across it.

These dynamic properties can always be reset or altered at any time during your modeling process, which makes them a particularly useful way of 'tweaking 'your components as you combine them together to form your final composite model.

Combine Modes

Combine Modes

The Combine Mode is a very important concept when working with 3D shapes within Aspire. The options for combine mode are presented when creating new shapes and also when deciding how Components and Levels will interact in the Component List. Rather than cover this in every section where it is applicable, it is worth summarizing the options here so the general concept can be understood.

When you have more than one 3D shape, such as the Component pieces of the design or where you have an existing shape and are creating a new one, then you need to have a way to tell the software how the additional entities will interact with the first. This can be an abstract concept for users who are new to 3D but it is an important one to grasp as early as possible. In Aspire this is controlled by a choice called the Combine Mode.

There are four options for this: Add, Subtract, Merge High, Merge Low.

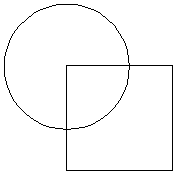

As modeling is an artistic and creative process, there is no general rule to describe when to use each one. As a guide though you can assume that if the second shape's area is completely within the originals one then you will probably be adding or subtracting and if the shapes only partly overlap that you will probably use Merge or, very occasionally, Low.

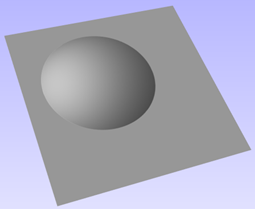

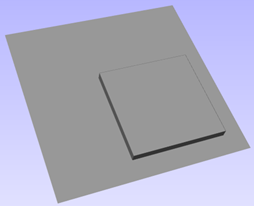

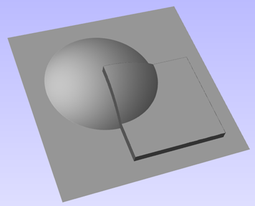

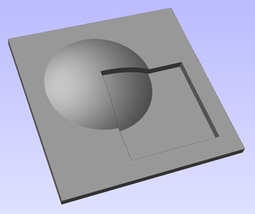

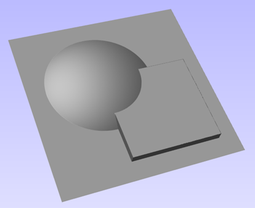

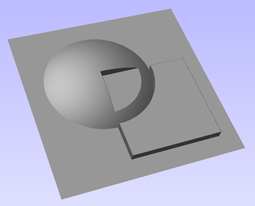

The four options and their specific effects are described on the following pages. To illustrate the different effects a combination of an overlapping beveled square and a dome will be used. You can see in the image top right how these are arranged in the 2D View and how they overlap. Then you can see each individual shape in the images below middle and right. These shapes will be used to demonstrate the different Combine Modes. In every case the Dome will be considered the primary shape and the square is the secondary shape which is being combined with the first. In addition to the dome/square example some images of 'real world' parts will also be included to help to understand how these can be used on actual projects.

As well as working on individual shapes, the Combine Modes are also assigned to Levels. These will govern how the combination of all the individual components on one Level interacts with the result of all the Components on the Level below it in the Component Tree

Note:

There is a 5th Combine Mode available from the right mouse click menu after a component has been created called Multiply. This combine mode has specialist applications which are dealt with in the appropriate tutorial videos. This option will literally multiply the heights of the Component or Levels being combined to create the new Composite 3D shape.

Add

Add

When Add is selected, it takes the first shape and then just adds the height of the second shape directly on top of the first. Any areas which overlap will create a shape which is exactly the height of each shape at that point added together (see below)

Typically the add option is mainly used when the shape being added sits completely within the original shape, this ensures that the uneven transition where the parts only partly overlap (as shown in the example) do not occur.

The example above shows the Maple Leaf and border extrusion Components being Added to the dome Component in the sign example from the Introduction to Modeling document.

Subtract

Subtract

When Subtract is selected it takes the first shape and then removes the height of the second shape from the first. Any areas which overlap will be a combination of the original height/shape less the second shape. Areas where the shape goes into the background will become negative regions. You can see how this looks using the dome and square in the image below:

Typically subtract, like the add option, is mainly used when the shape being removed sits completely within the original shape, this ensures that the uneven transition where the parts only partly overlap (as shown in the example) do not occur.

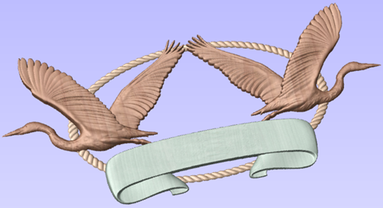

The image shown above has some 'creases' to help define the muscles of the lioness. The shapes to create these recesses were created by using the Subtract option with the Create Shape tool on the vectors representing those recessed areas.

Merge

Merge

When the Merge option is selected any areas of the shapes which do not overlap remain the same. The areas that overlap will blend into each other so that the highest areas of each are left visible. This results in the look of one shape merging into the other and is in effect a Boolean union operation. You can see how this looks using the dome and square in the image below:

Typically the merge option is used when the shape being combined partly overlaps the original shape. This enables a reasonable transition to be made between them.

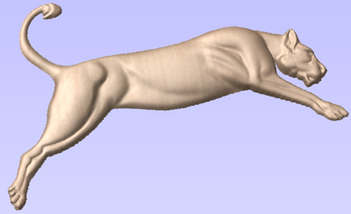

The image above shows 2 Herons, a rope border and banner Components. Each of these overlaps with the others and so they are set to Merge in this areas. Whatever is the higher of the two merged areas is what is prominent. In this case the rope is lower than everything and the Banner is higher than the Herons so the desired effect can be achieved.

Low

Low

The Low option is only available when combining Components (not in the modeling tools). When this mode is selected, any areas which do not overlap are left as they were in the original two shapes. Any areas which overlap will create a new shape which is the lowest points taken from each shape, this is in effect a Boolean intersection operation. You can see how this looks using the dome and square in the image below:

The Low option is used for recessing a shape into a raised shape. An example of this is shown in the image above.

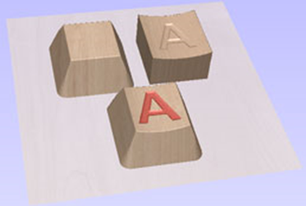

The example shown on the right above uses the Low option to combine the flat topped 'button' component on the left with the curved top face component with the letter 'A' on the right. Combining both components with the merge low option gives the keyboard button with the curved top you see in the bottom row.

Level Mirror Modes

Level Mirror Modes

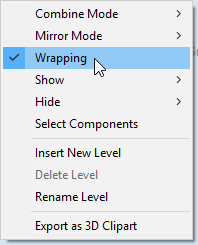

Right-clicking Levels in the component tree will open a pop-up menu offering commands and operations related to the clicked level and Mirror Modes can be set in this way. If a mirror mode is set on a Level, all the components it contains will be continually mirrored dynamically as they are moved, transformed or edited. The mirroring is non-destructive, that is it can be turned off or on at any time and does not alter the underlying components in any permanent way. Working inside a Mirror modes Level is a simple way of achieving a complicated symmetrical pattern by editing only one half (or quarter, see below) of the design.

The available Mirror Modes are broadly divided into two groups. The first group apply one plane of symmetry:

- Left to Right

- Right to Left

- Top to Bottom

- Bottom to Top

These modes allow you to work in one half of your job and the other half will be automatically and dynamically generated for you. For example, in Left to Right mode you would place your components in the left half of your job and a mirrored equivalent of each would be created in the other half of the job. This 'reflection' is updated dynamically as you work.

The other group offer two planes of symmetry (horizontal and vertical):

- Top Left Quadrant

- Top Right Quadrant

- Bottom Left Quadrant

- Bottom Right Quadrant

When using these modes your components should all be in the quadrant (quarter) of the job. Mirrored reflections horizontally and vertically will be created in the other quadrants of the job for you.

Watch this video to see this in action:

Multi Sided View

Multi Sided View

When working in a 2 Sided environment you can create components independently per side or using the Right click option you can copy or move a component to the opposite side. Selecting the option to work in 'Multi Sided View' allows you to view components you may have on the Top and Bottom side in the 3D View. In the Toolpath Preview form of a project that contains toolpaths for the Top and Bottom Sides the multi sided view presents the simulation of the toolpath preview on both sides also, if the multi sided view is not selected you can use the 'Preview all Sides' option in the Toolpath Preview form to display the Top and Bottom Toolpaths in the 3D view. 2 Sided Setup will be described in detail later in the relevant section of this manual.

08. Intermediate - Creating a Rotary Job

Z Origin

Z Origin

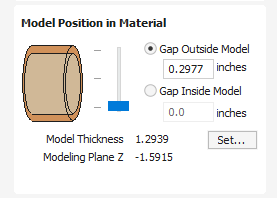

You have the choice of specifying if the tool is being zeroed on the center of the cylinder or the surface. When you are rounding a blank, you cannot set the Z on the surface of the cylinder, as the surface it is referring to is the surface of the finished blank. We would strongly recommend for consistency and accuracy that you always choose 'Center of Cylinder' when outputting wrapped toolpaths as this should always remain constant irrespective of irregularities in the diameter of the piece you are machining or errors in getting your blank centered in your chuck.

Tip:

A useful tip for doing this is to accurately measure the distance between the center of your chuck and a convenient point such as the top of the chuck or part of your rotary axis mounting bracket. Write down this z-offset somewhere, and zero future tools at this point and enter your z-offset to get the position of the rotary axis center. Another reason for choosing 'Center of Cylinder' is that some controls will be able to work out the correct rotation speed for the rotary axis based on the distance from the center of rotation. If the Z value is relative to the surface, the control would need to know the diameter or radius of the cylinder at Z zero.

XY Origin

XY Origin

XY Drawing Origin - Here you can specify where the XY zero origin will be placed on your job. These options correspond to the same fields on the normal 'Job Setup' form within the program. Most people would use the default Bottom Left Corner, but for some jobs you may prefer to have the XY origin in the Center.

- In a job with horizontal orientation (Along X Axis), the X offset will correspond to the length of the cylinder, and the Y offset will be a point along its circumference.

- In a job with vertical orientation (Along Y Axis), it's the opposite. The Y offset will correspond to the length of the cylinder, and the X offset will be a point along its circumference.

Orientation

Orientation

Cylinder Orientation Along - This section is used to tell the program how you have your rotary axis aligned on your machine. If you've already made your design, but just want to change the job for a different machine, then you could flip your design with the material so that all the vectors and components stay the same relative to the job.

Z Origin On - This section determines whether the Z Origin is set to the surface of the material or the base (center of cylinder). These settings can be over-ridden when the toolpath is actually saved, but we would strongly recommend the 'Cylinder Axis' is selected for rotary machining. The reasons for this are detailed in the note below.

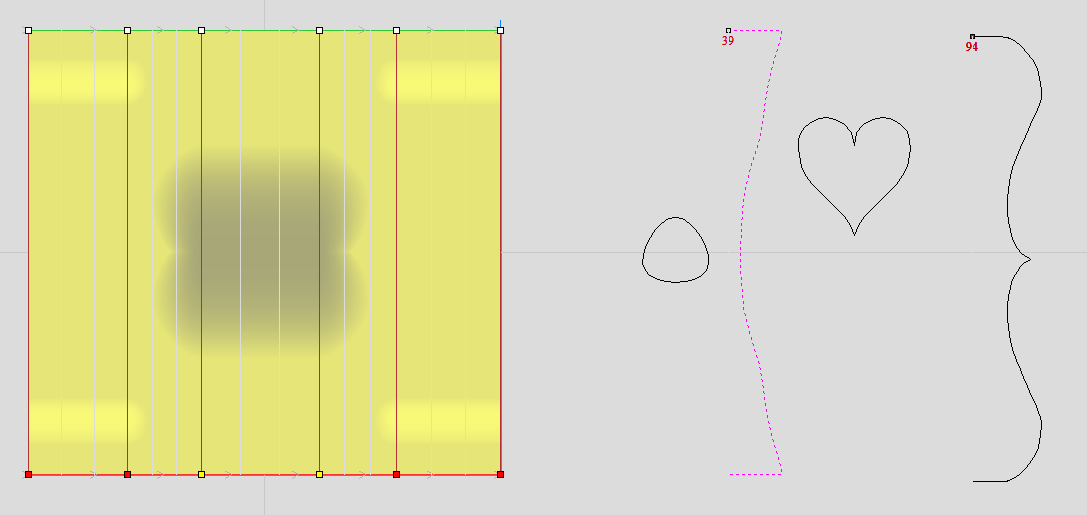

Vector Layout

Vector Layout

As well as creating a job at a suitable size for wrapping toolpaths, when creating the job, it will create a number of vectors which can be very useful when creating your wrapped job.

The vectors are created on their own individual layers and by default these layers are switched off to avoid cluttering up your work area. To switch on the layers, display the 'Layer Control' dialog (Ctrl+ L is the shortcut to show / hide this). To show / hide the layer simply click on the check box next to the layer name.

2Rail Sweep Rails - This layer contains two straight line vectors which can be used to sweep a profile along if you are creating a shaped column.

Bounding Box - This layer contains a rectangular vector covering the entire job area. This vector is useful if you are going to machine the complete surface of the cylinder.

Choosing stock material

Choosing stock material

When setting-up rotary project, software assumes a perfect cylinder with an exact diameter. In practice the stock material may be uneven, or only blank with square profile may be available. In those cases blank needs to be machined into cylinder of desired size, before running toolpaths associated with the actual design.

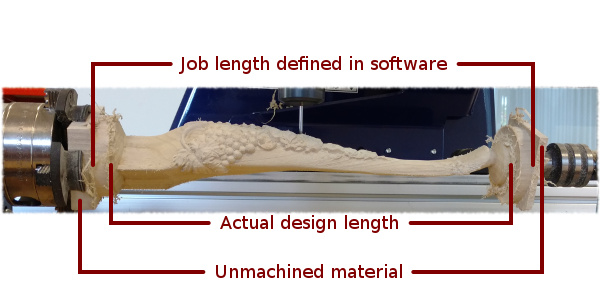

Another consideration is length of the stock material. Typically, part of the blank will be placed within the chuck. It is also important that during machining, the cutting tool is always in safe distance from both chuck and tailstock. For those reasons, the blank has to be longer than the actual design. When setting-up the machine for cutting, one has to pay extra attention to ensure that origin is set accordingly to avoid the tool running into chuck or tailstock!

If the design was created without those considerations in mind, the blank size can always be adjusted in the Job Setup form.

The picture below presents an example of a rotary project layout. As explained above, the actual blank is longer than job defined in Aspire to allow for the chuck and sufficient gaps. The actual design is shorter than job defined in Aspire, to leave some space for tabs, that can be machined with the profile toolpath prior to removing the finished part from the chuck.

When machining 3D shapes with varying thicknesses like on the example shown below, it is a good idea to place the thicker end of the model on the side closest to the driving motor. This way torsional twisting will mostly affect the stronger end of the machined part and help to avoid bending or breaking of the part during machining.

09. Intermediate - Simple Rotary Modelling using 2D Toolpaths

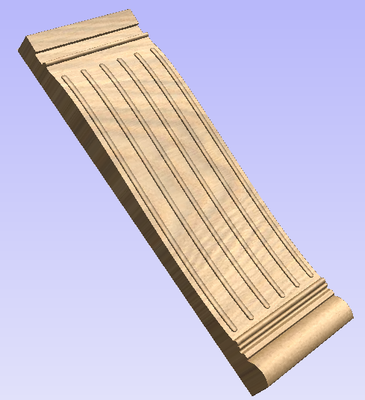

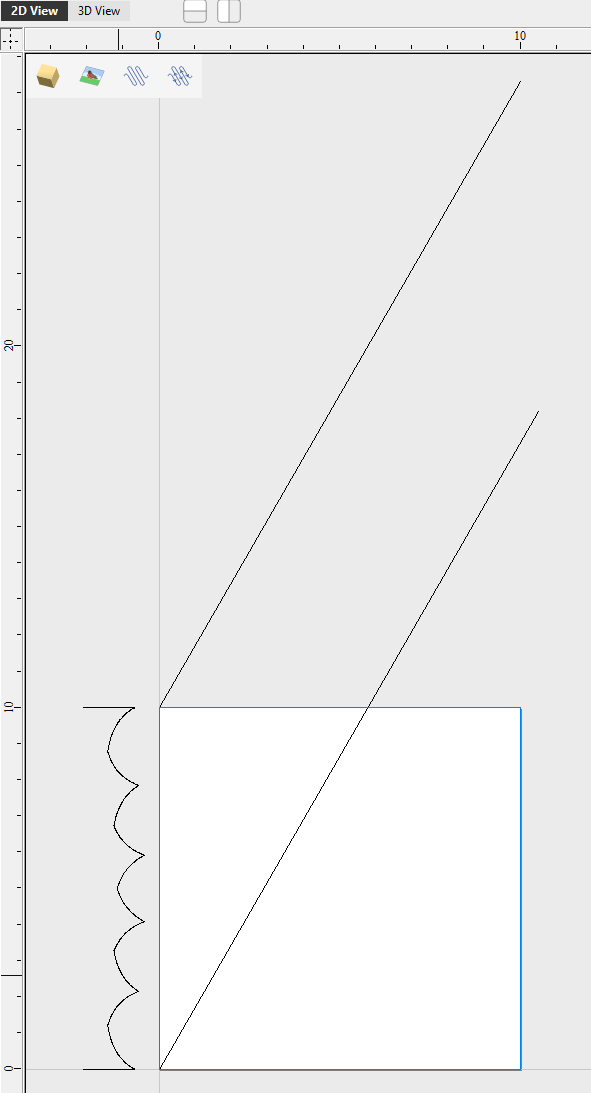

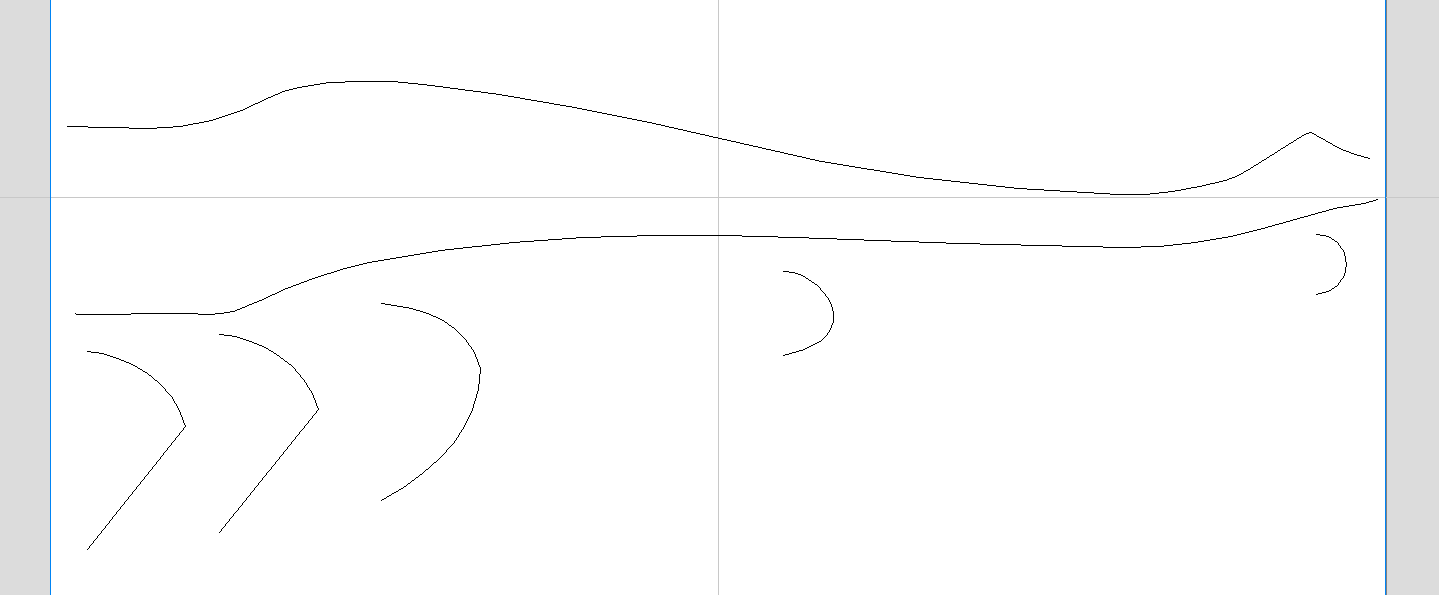

Creating vectors for a basic column

Creating vectors for a basic column

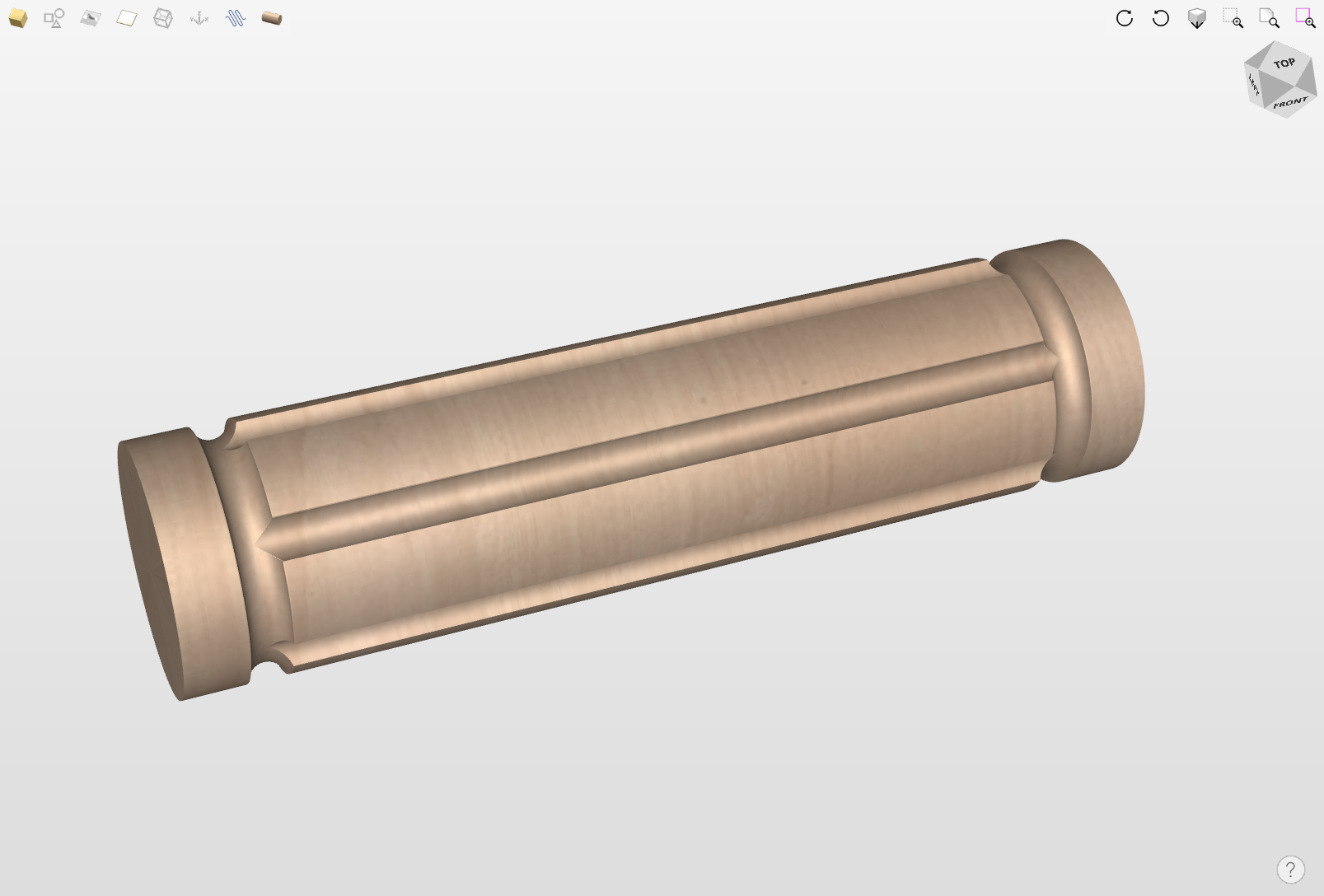

This section will show how to create a simple column, using the profile and fluting toolpaths.

Start by creating a new rotary job. Please note that settings shown here are only an example and should be adapted to match your machine setup and available material.

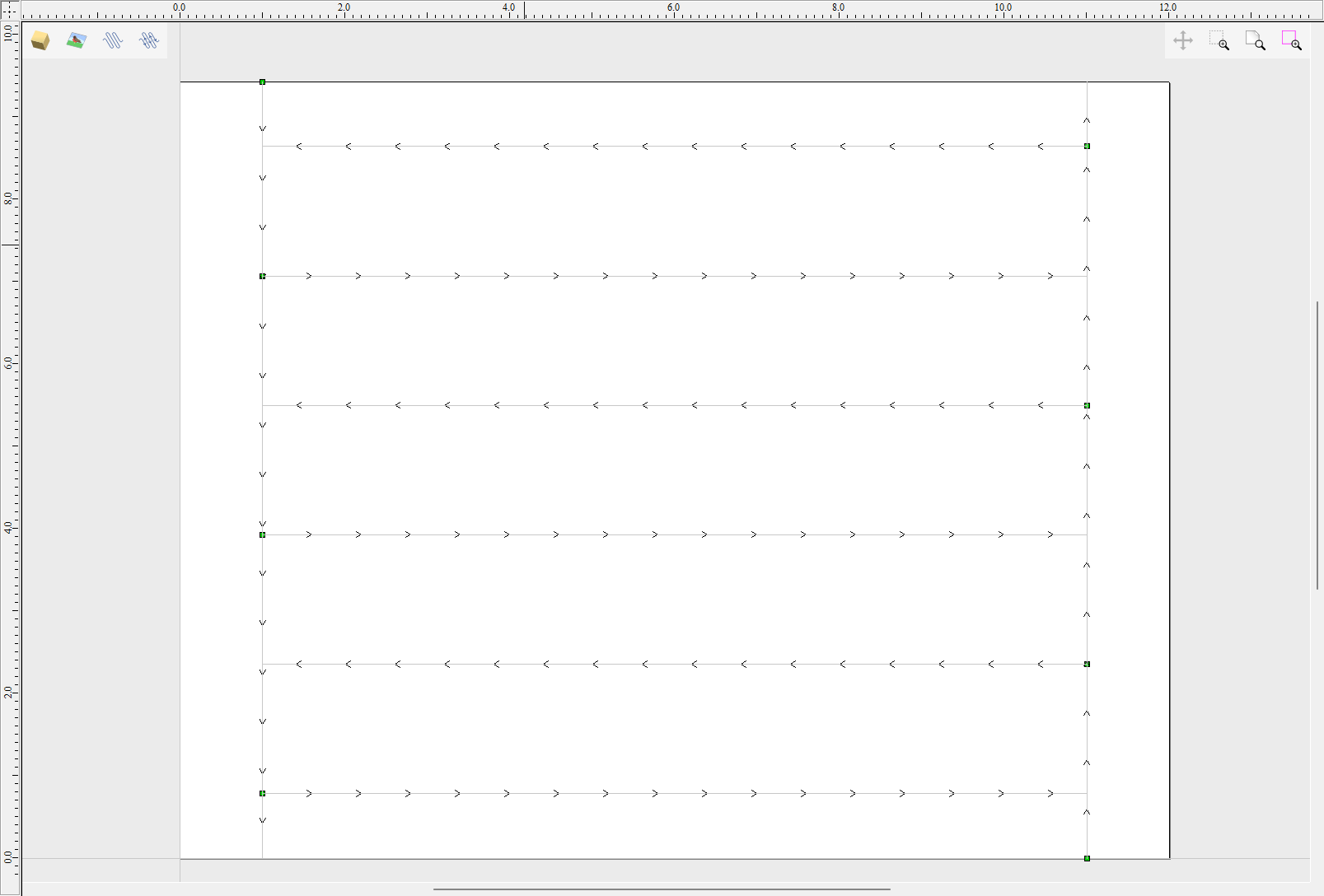

In this example the blank will rotate around X axis. We will refer to it as the rotation axis. The axis that will be wrapped is the Y axis. We will refer to it as the wrapped axis. That means that the top and bottom boundaries of the 2D workspace will actually coincide. We will refer to them as the wrapped boundaries.

First, create the cove vectors using Draw Line/Polyline tool. Those will run along the wrapped axis at both ends of the design. Snapping may be useful to ensure that the created line starts and ends at the wrapped boundaries.

In this example the coves were placed 1 inch from the job boundaries, leaving 10 inches in the middle for the flutes. The flutes will run along rotation axis. Assuming 0.5 inch gap between the cove and the beginning of the flute, the flutes will have the length of 9 inches. This example will use 8 flutes.

To start, create a line parallel to rotation axis that is 9 inches long. Now select the created flute vector and then select one of the cove vectors while holding down Shift. Then use Copy Along Vectors tool to create 9 copies. The original flute vector may now be removed as it is no longer necessary. Note that first and last copy are both created on wrapped boundaries. That means they will coincide, so one of them can be removed. As the last step select all flute vectors and press F9 to place them in the center of design.

Creating rotary toolpaths

Creating rotary toolpaths

The process of creating 2D rotary toolpaths is very similar to creating toolpaths for Single - and Double - models. This example will use the profile toolpath on the cove vectors. To create the toolpath, select the cove vectors and click on the Profile Toolpath from

To create the toolpath for the flutes, select the flute vectors and click on the Fluting Toolpath. This Example used a 1 inch 90deg V-Bit set to Flute Depth 0.2 and using the Ramp at Start and End and Ramp Type Smooth options. Ramp length was set to 0.25 inches. Both toolpaths can be seen below.

Simulating and saving toolpaths

Simulating and saving toolpaths

It is time to simulate toolpaths using Preview Toolpaths. If the option to animate the preview is selected, the simulation will be visualized in flat mode. Once the simulation is complete, the wrapped rotary view will be turned back on automatically.

Contrary to single - and double - sided simulation, rotary simulation is not 100% accurate. For example round holes will appear in rotary view as oval ones, but obviously will be round when part is actually machined.

Although the design can be considered to be finished, in practice it is useful to be able to cut-out the remaining stock. This can be realized by making the design slightly longer and adding profile cuts. In this example the blank length was extended by 2 inches using the Job Setup . Existing vectors can be recentered using F9After that the existing toolpaths have to be recalculated.

The cut-out vectors can be created in the same way as cove vectors. Two extra profiling toolpaths can be created using the suitable End Mill. In this example we used a tab with a 0.5 inch diameter. In order to achieve that, the user can type the following in the Cut Depth box: z-0.25 and then press = and the software will substitute the result of the calculation. Variable 'z' used in the formula will be substituted by the radius of the blank automatically by software. It is also important to specify Machine Vectors Outside/Right or Machine Vectors Inside/Left as appropriate. The cut-out toolpaths and the resulting simulation can been shown below.

The final step is to save the toolpaths in a format acceptable by your machine. Use the Save Toolpaths and select the wrapped post-processor matching your machine.

Note

Tools and values presented in this example are for illustrative purposes only. Size of tools, feed rate, tabs diameter etc. have to be adapted to the material and machine used to ensure safe and accurate machining.

Spiral toolpaths

Spiral toolpaths

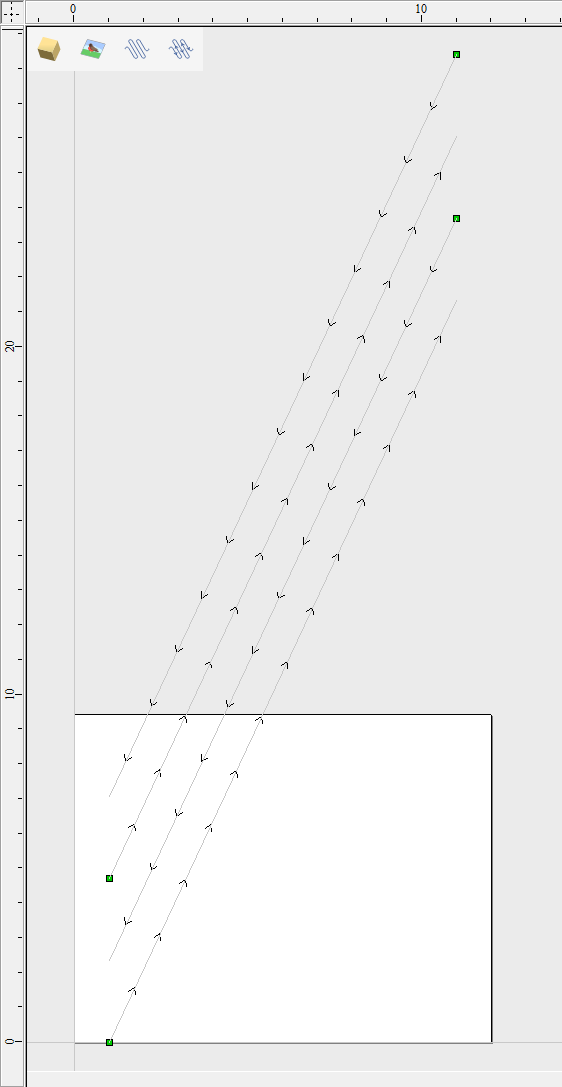

This section will explain how to create and simulate spiral toolpaths.

One way of thinking about spiral toolpaths is to imagine a long, narrow strip of fabric. Such a strip can be wrapped around a roll at a certain angle. In order to create a toolpath that wraps around the blank multiple times, one can create a long vector at a certain angle. Such a vector is an equivalent to the strip of fabric when it is unwrapped from the roll.

Although such a toolpath will exceed the 2D workspace of the rotary job, thanks to the wrapping process during both simulation and machining the toolpath will actually stay within material boundaries.

The most crucial part of designing spiral vectors is to determine the right angle and length of the line that would result in a given number of wraps. Suppose one would like to modify a simple column design to use spiral flutes, rather than parallel to rotation axis. The following example will use flutes wrapping 3 times each, but the method can be adapted to any other number.

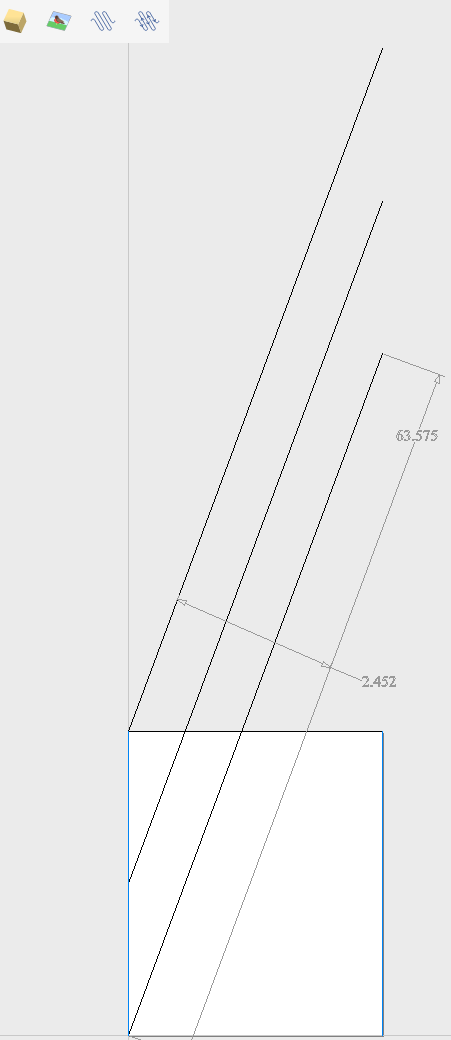

All but one of the existing flute vectors can be removed. Select the Draw Line/Polyline and start a new line by clicking at one end of the existing flute. This line needs to be made along the wrapped axis with the length being 3 times the circumference of the job. In this example that means typing 90 into the Angle box and typing y * 3 into the Length box and pressing =. If the wrapped axis is not the Y axis, but rather the X axis, then the above formula should be x * 3.

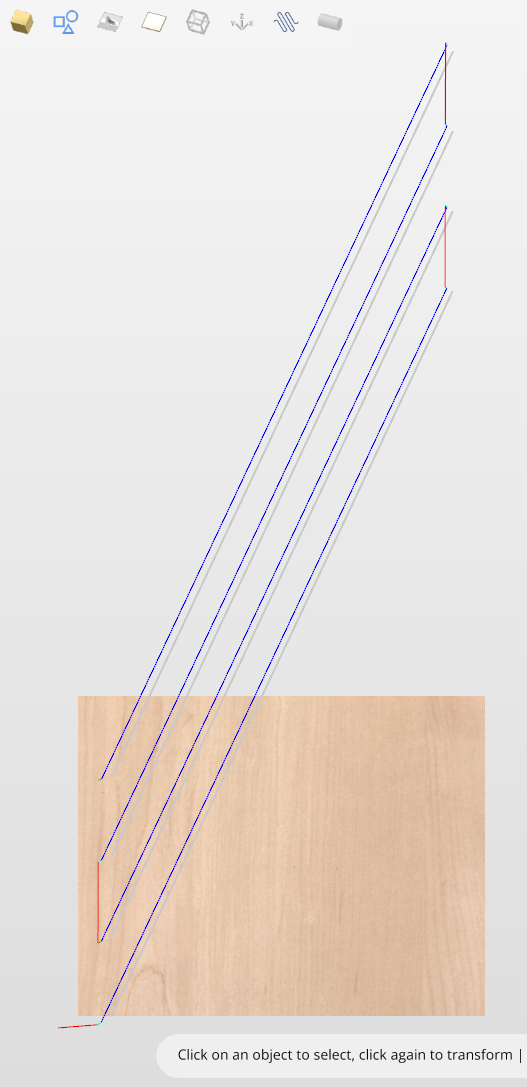

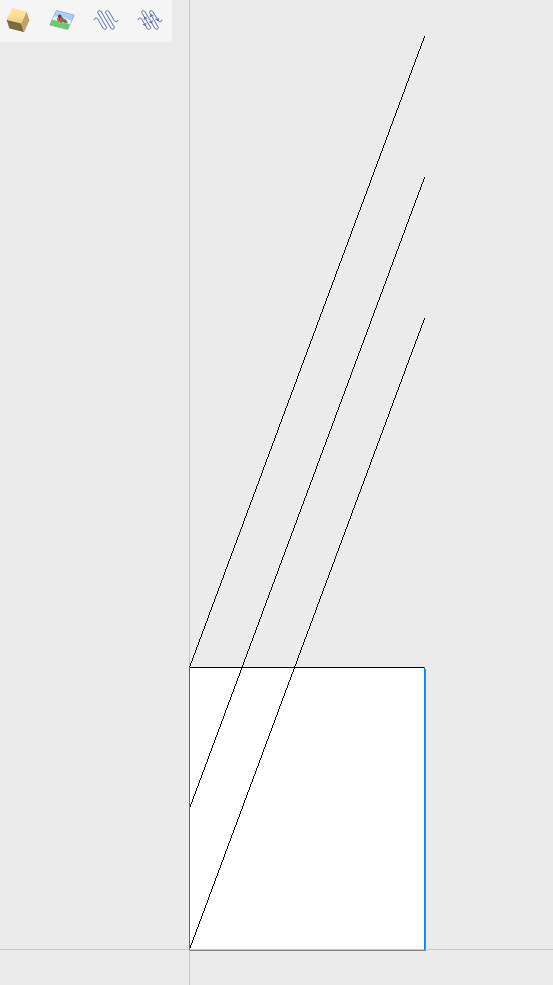

Now one can simply draw a line connecting to the other end of the original flute vector and the newly created one. Using Copy Along Vectors tool this single flute may be copied in the way described earlier. In this example 4 spiral flutes were created, as can be seen below.

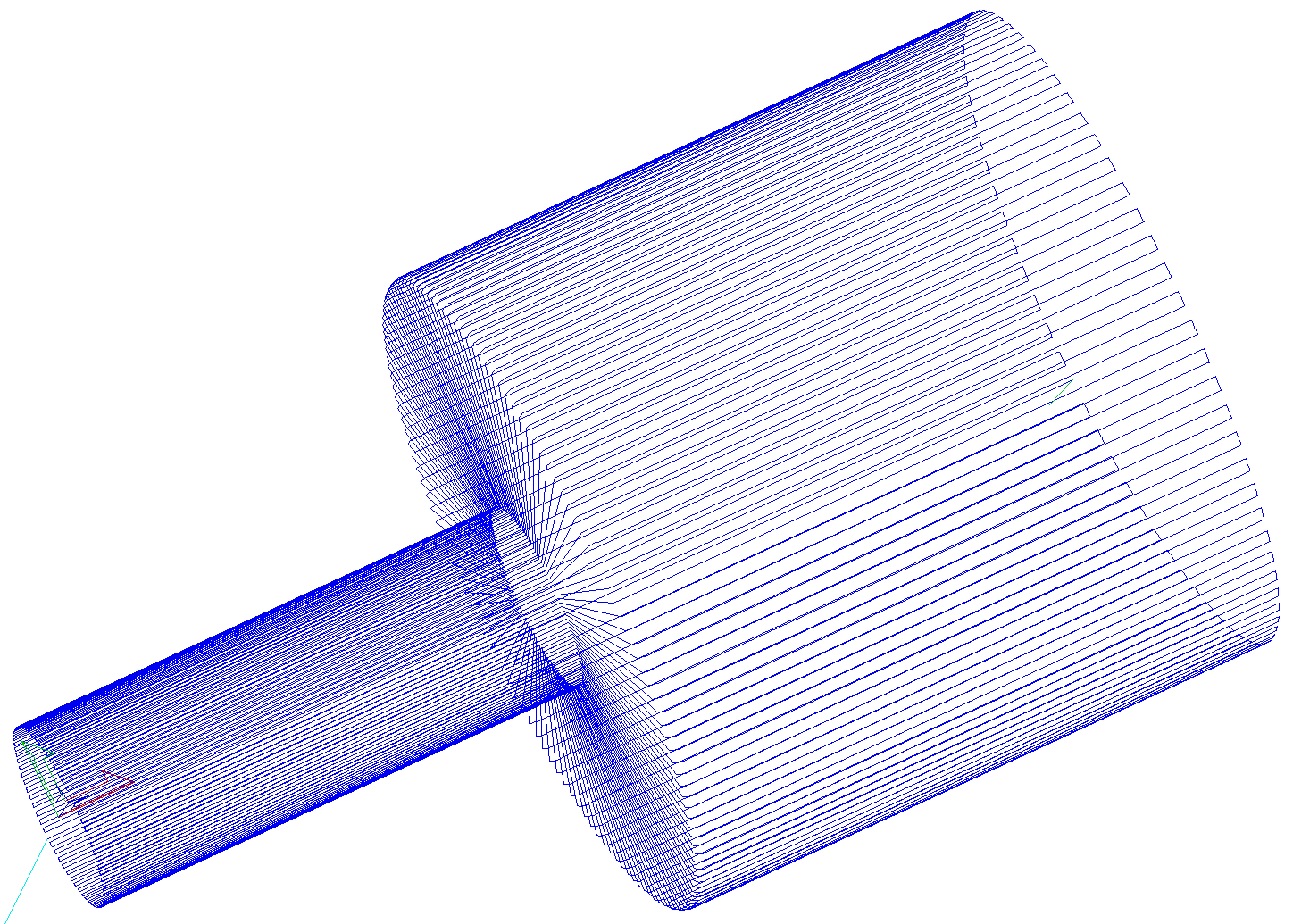

Once the flute vectors are ready, the toolpath can be created again using the Fluting Toolpath. An important thing to note, is the difference between the appearance of spiral toolpaths in the wrapped and flat view. By clicking on Auto Wrapping one can switch from wrapped rotary view to flat view and back again.

As can be seen above, in the flat view the toolpaths will follow the vectors and extend beyond the job boundaries. On the other hand the wrapped view, presented below, will display the toolpaths spiralling around the blank.

This was just a brief overview of general 2D workflow for rotary machining. Remember to also take a look at video tutorials dedicated to rotary machining, which are accessible from the Tutorial Video Browser link when the application first starts.

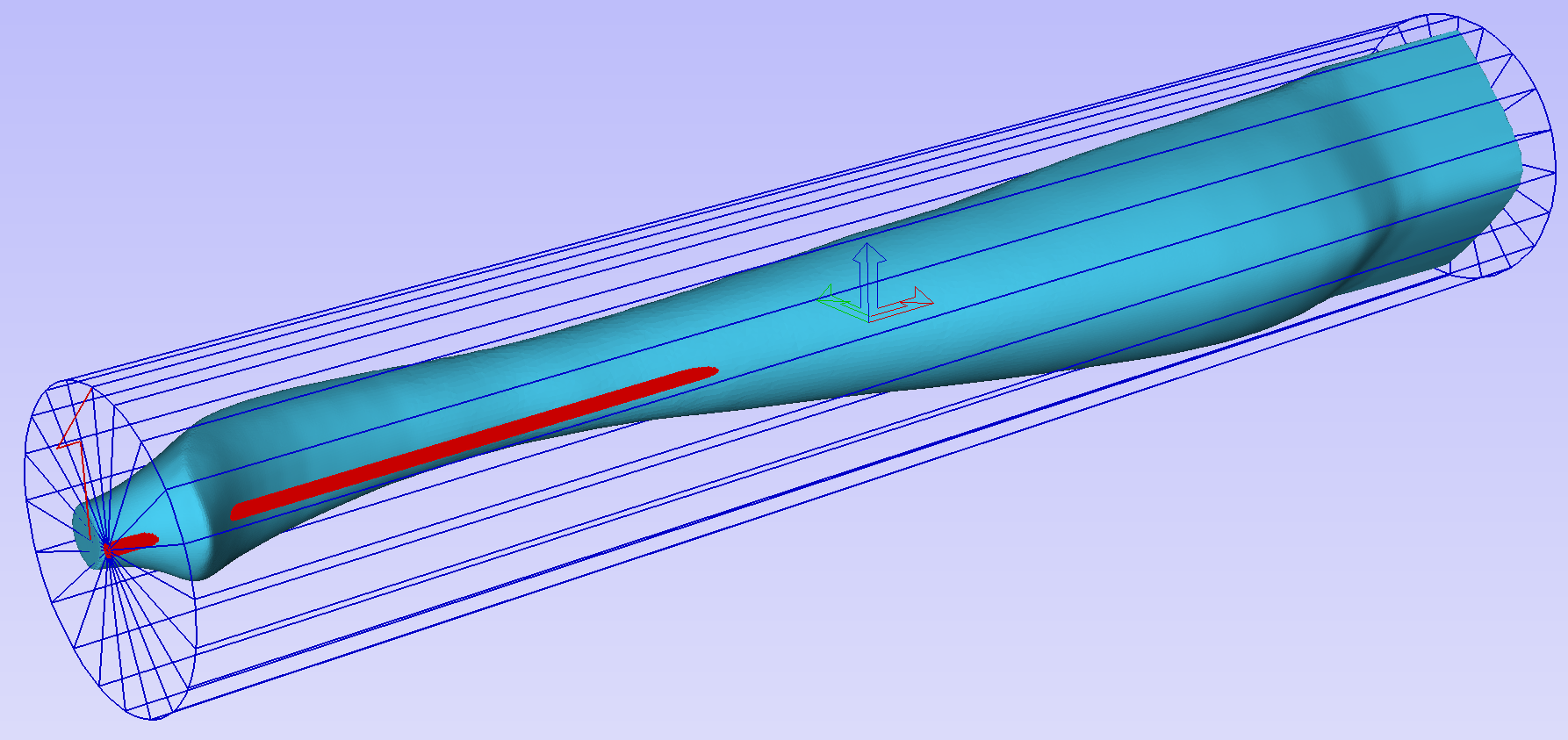

10. Advanced - Rotary Machining and Wrapping

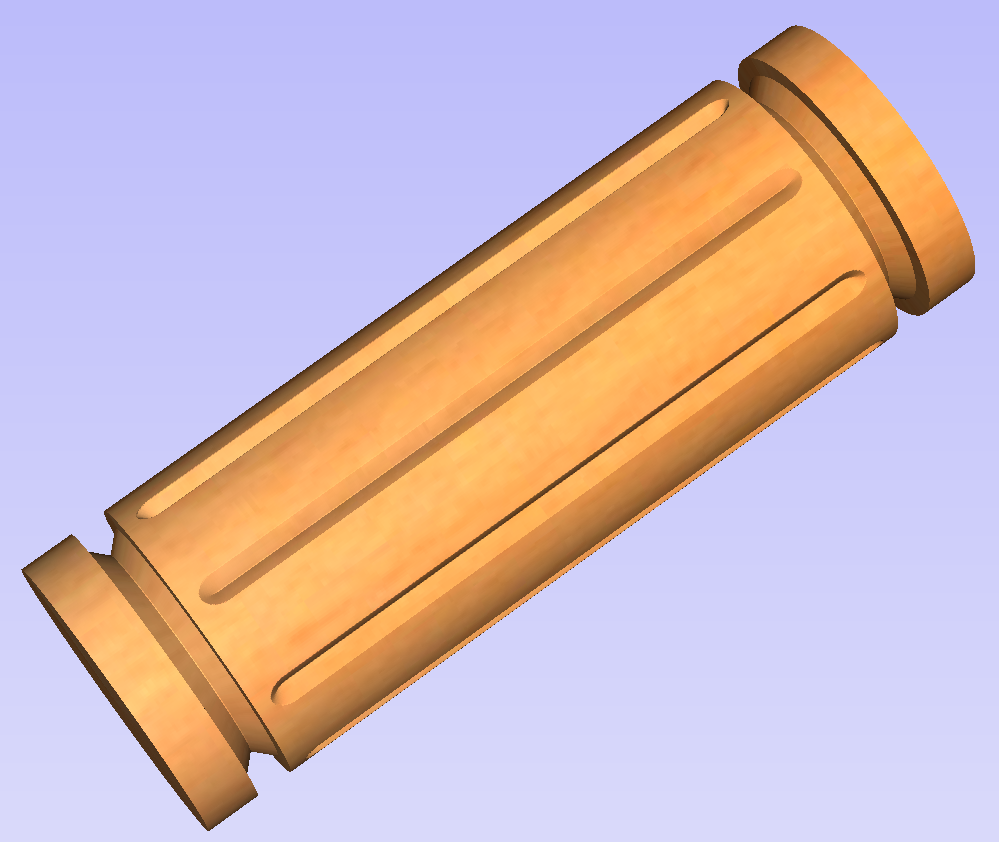

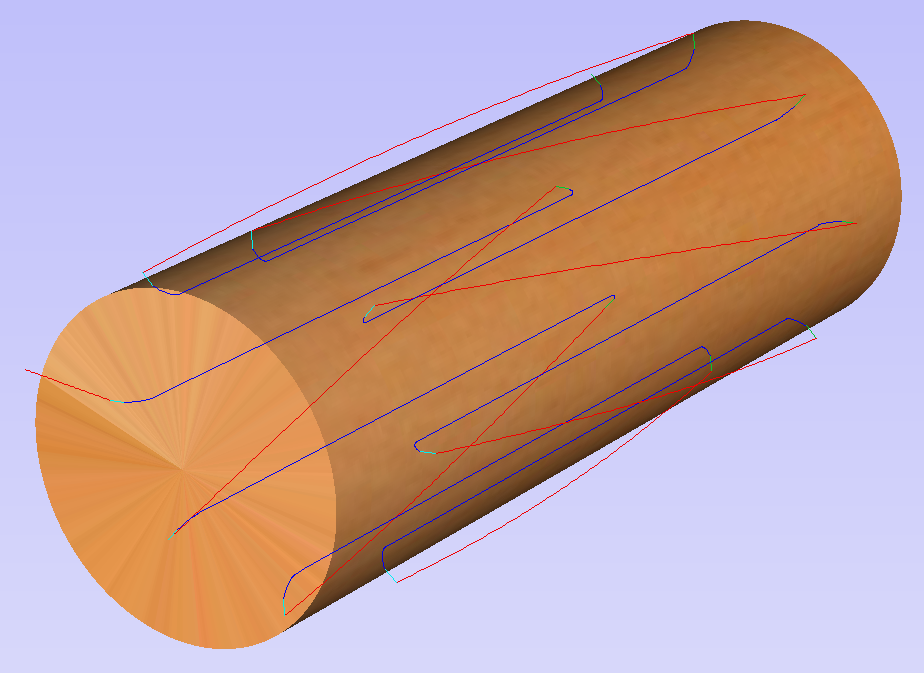

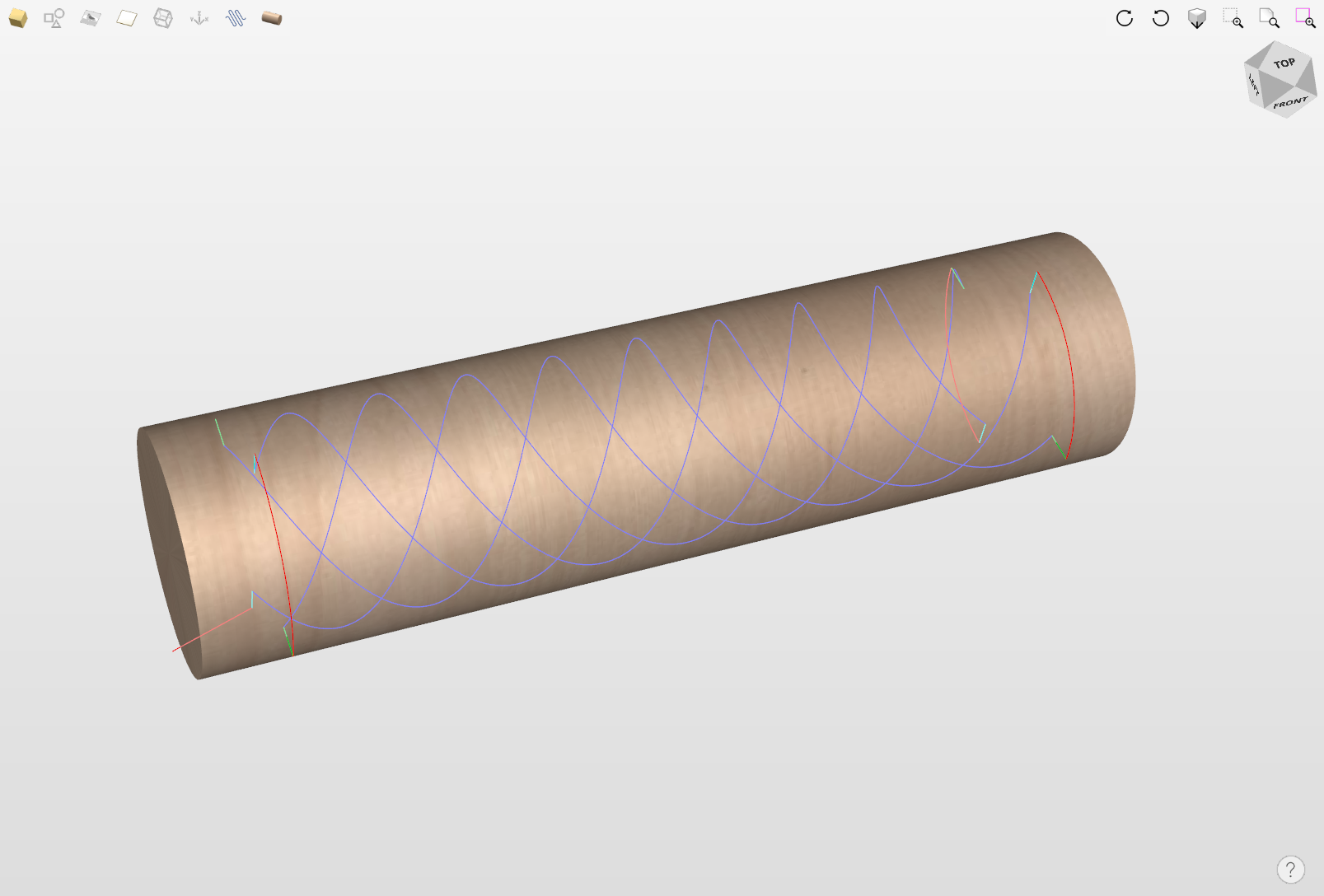

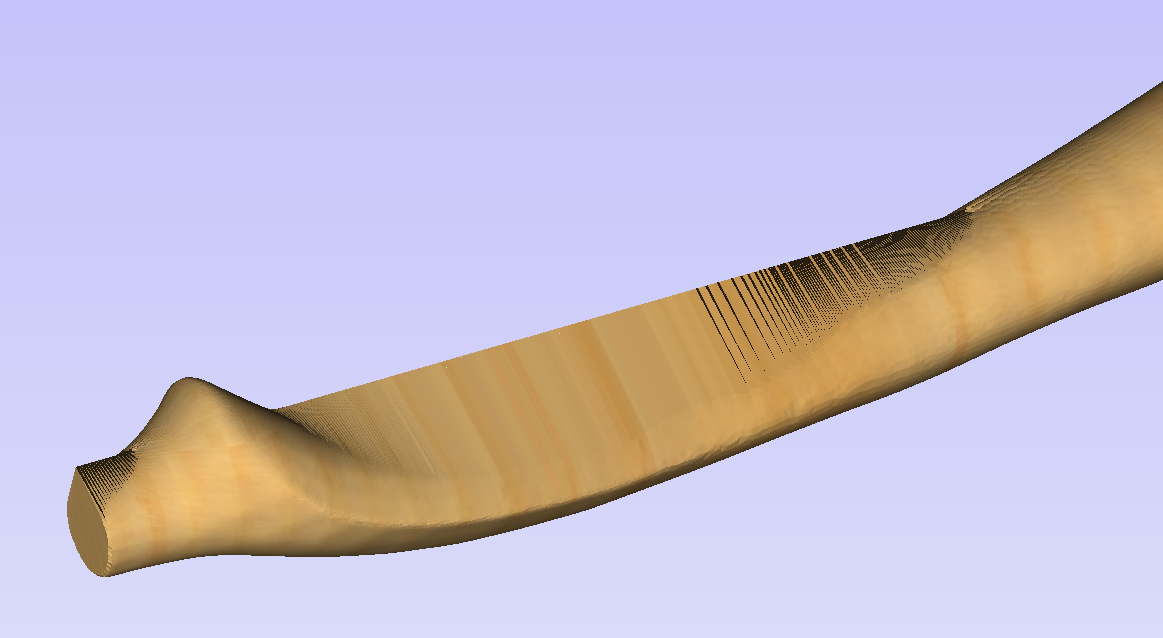

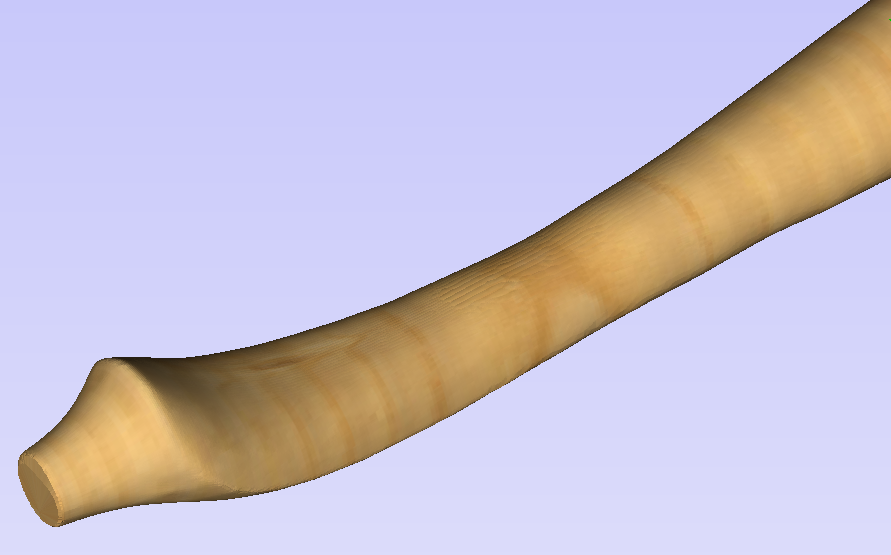

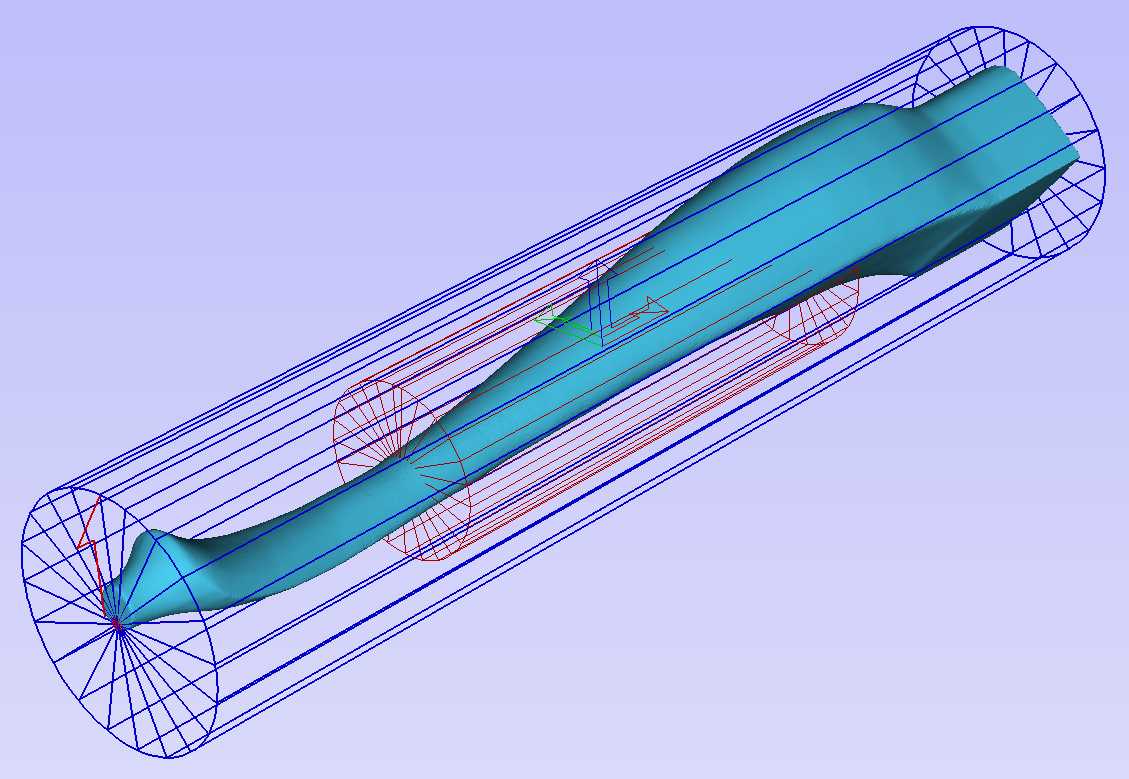

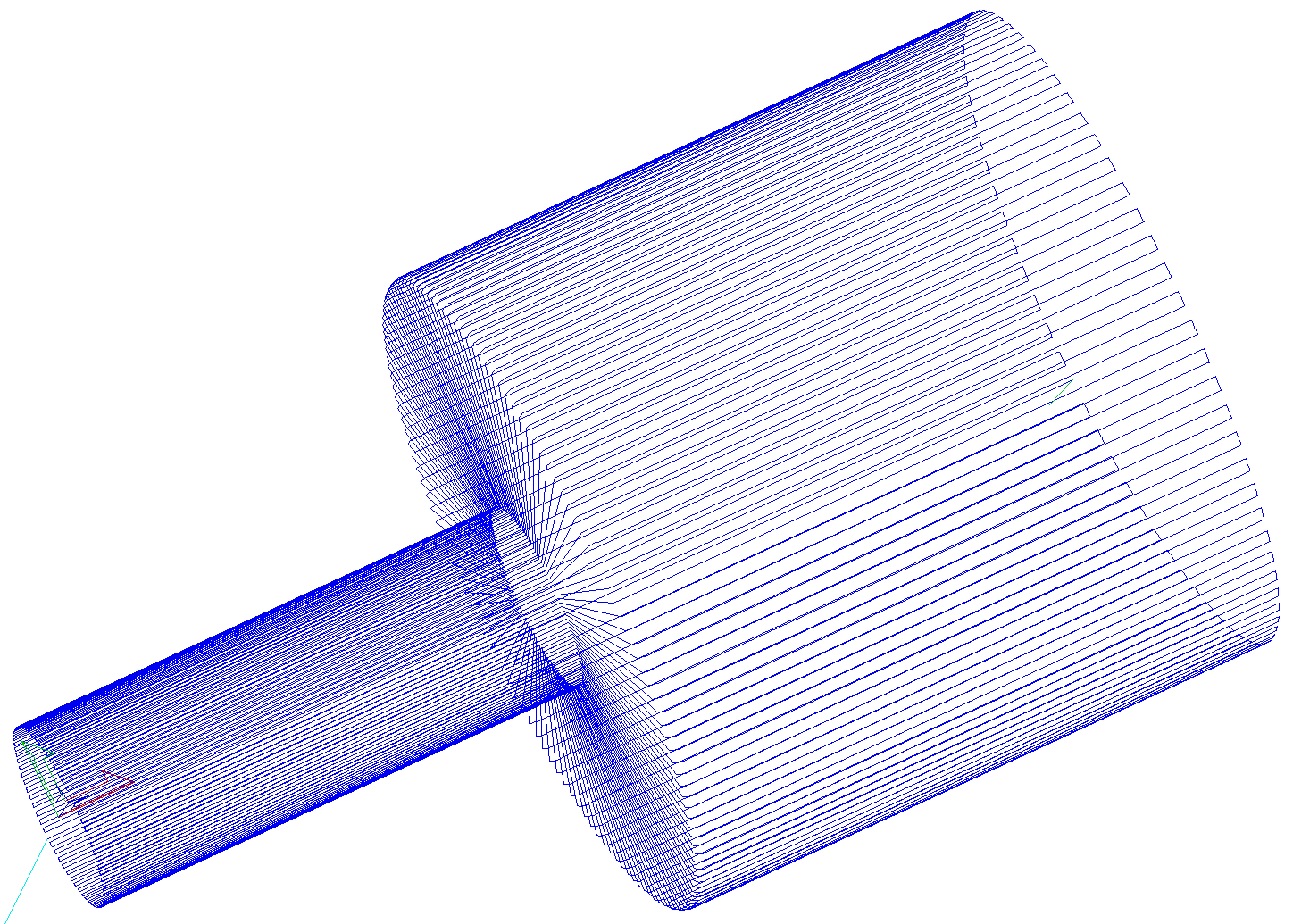

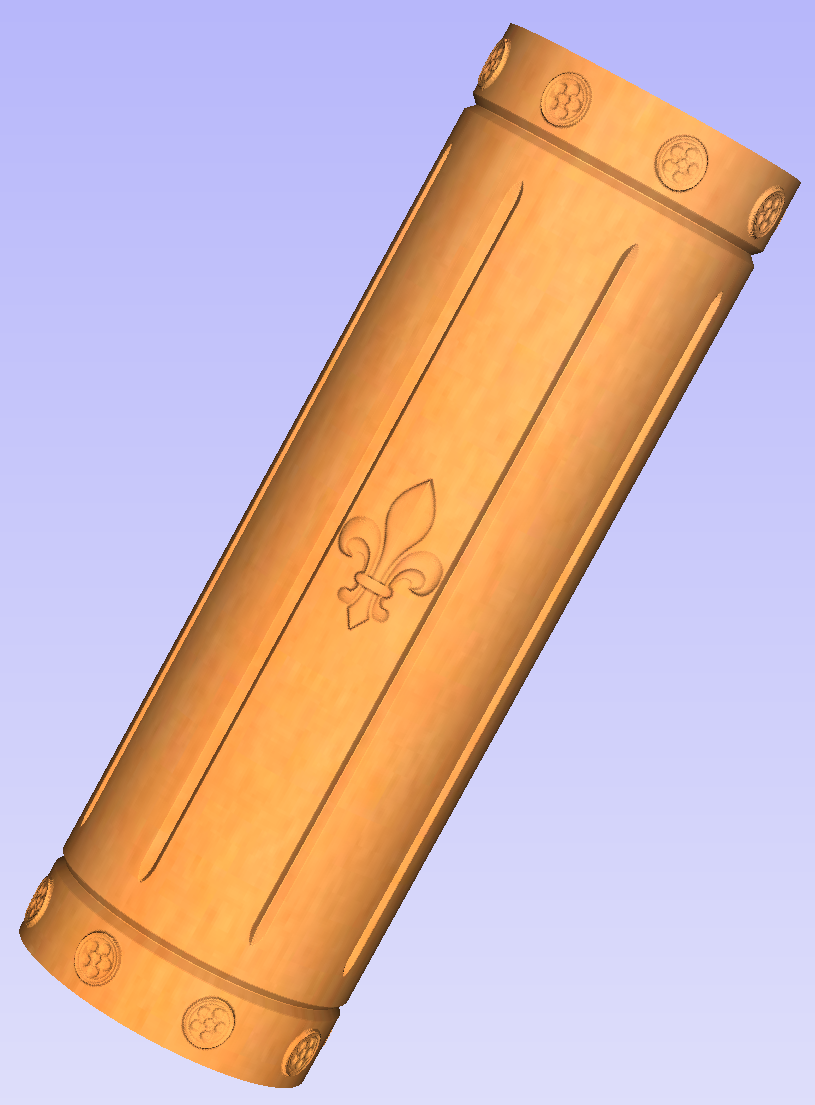

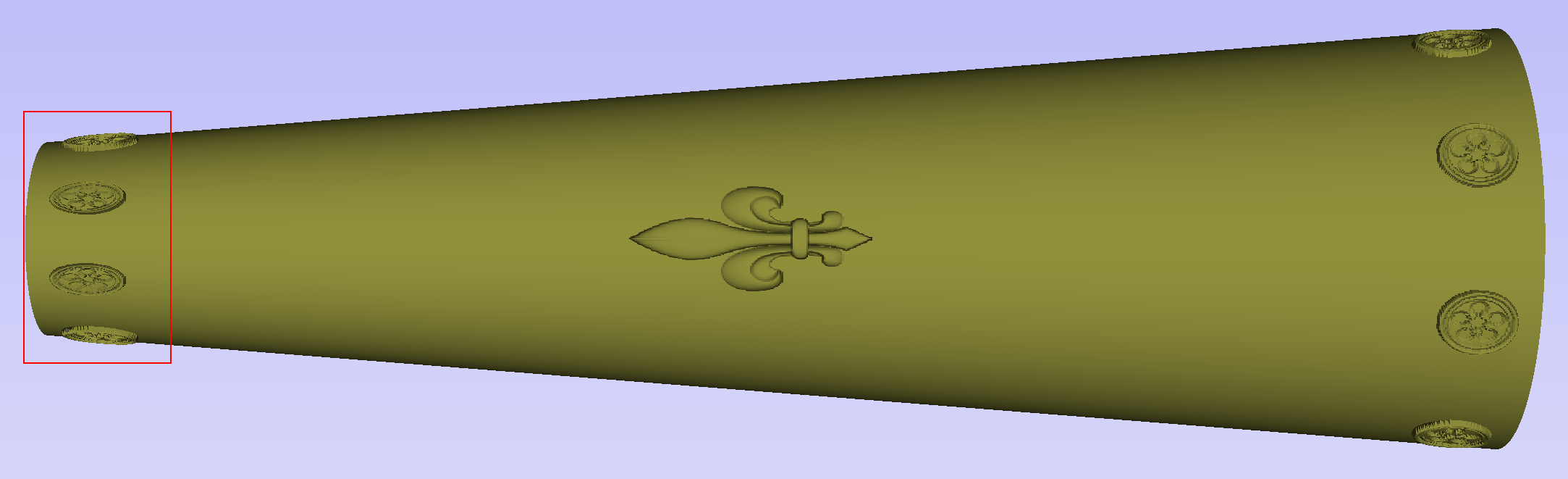

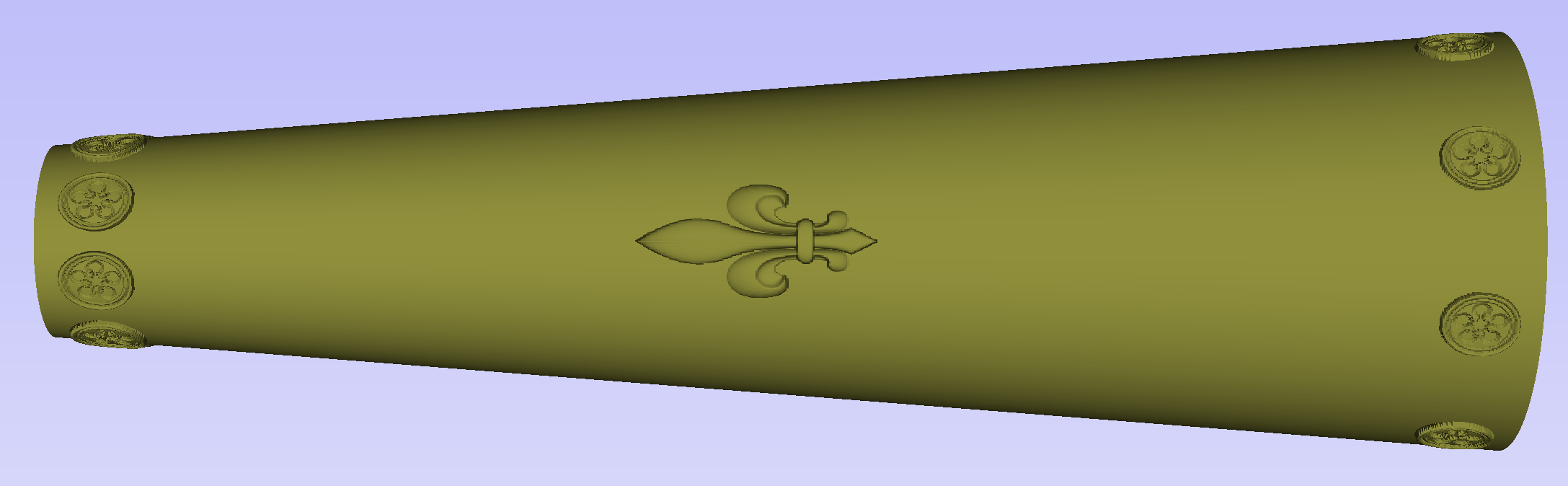

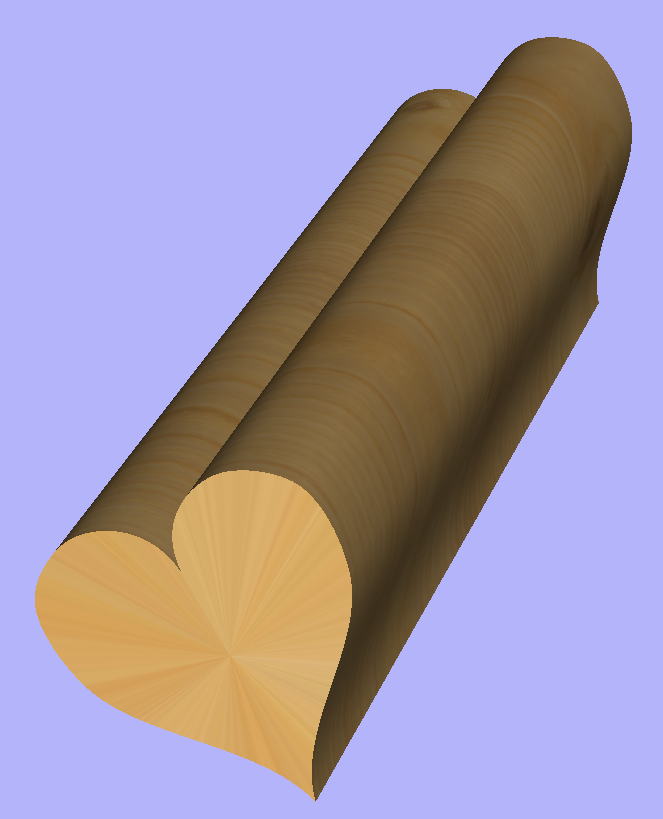

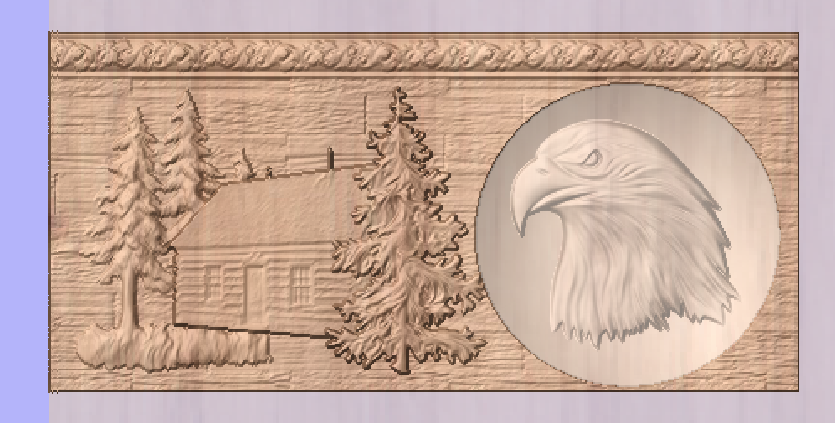

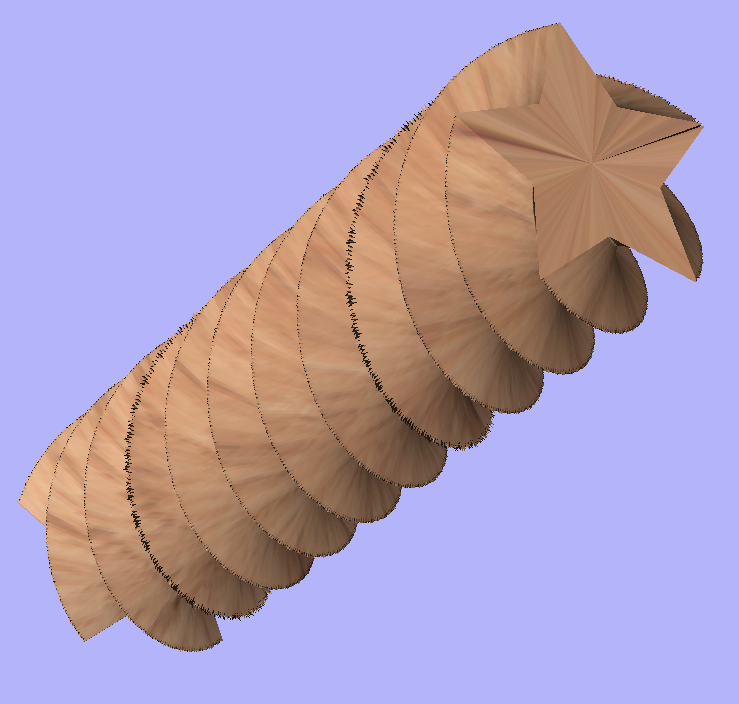

Aspire can 'wrap' flat toolpaths around a cylinder to provide output to CNC machines which are configured with a rotary axis / indexer. The image below shows a flat toolpath wrapped around part of a cylinder.

Note

It is important to note that wrapping works in conjunction with specially configured post-processors which take the XYZ 'flat' toolpaths and wrap them around a rotary axis, replacing either the X or Y moves with angular moves.

The toolpaths can be visualized wrapped within the program when the Auto Wrapping mode is on.

Aspire can also visualize a wrapped model within the program by drawing the shaded composite model wrapped.

Aspire also has the ability to draw the toolpath simulation wrapped. Although this is very useful for getting a feel for how the finished product will look, it is important to realize that the wrapped simulation may not be a 100% accurate representation of how the finished product will look. An example of potential difference would be if you drilled holes in your rotary job. In the actual work piece these will obviously just be round holes, in the wrapped simulation these may appear as distorted ovals due to the 'stretching' process which takes place when we wrap the flat simulation model for display.

Note

If your rotary axis is aligned along your Y axis you would choose the Orientation Along Y Axis option during job setup. All the examples in this document will assume that the rotary axis is aligned along X.

It is important to realize that there are a huge number of possible combinations of machine controller and axis orientations for rotary axis / indexers. This means it is impractical for Vectric to supply a pre-configured post-processor for every possible combination as standard. We include some wrapping post-processors in the software that can be configured when you setup your Machine Configuration.

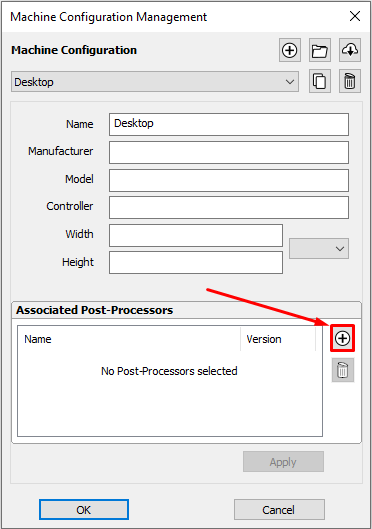

If you need to select a new post, you can do so by accessing the Save Toolpaths menu. To do so, click the 'Manage machine configuration' button as seen in the image below:

This will now open a menu where you can press the button under 'Associated Post-Processors' to access all of the available post-processors within the software and choose the appropriate wrapped post-processor for your machine configuration.

You can also right click the post in this menu and select 'view' to view the contents of the post, should you need to edit it later.

Examining these posts may be helpful if you need to configure a post of your own. If Vectric have not supplied a standard a post for your machine configuration please refer to the Post Processor Editing Guide accessible from the Help menu of the program for information on how to configure a post-processor and also look at the standard rotary posts Vectric supply.

You should also look at the Vectric forum to see if anyone else has already configured a post for your configuration or one similar. If, after looking at these resources you are still unsure of what needs to be done for your machine, please feel free to contact support@vectric.com for help. However, please note that we cannot guarantee to write a custom rotary post-processor for every individual requirement.

11. Advanced - Importing External Models in a Rotary Project

Importing Full-3D models

Importing Full-3D models

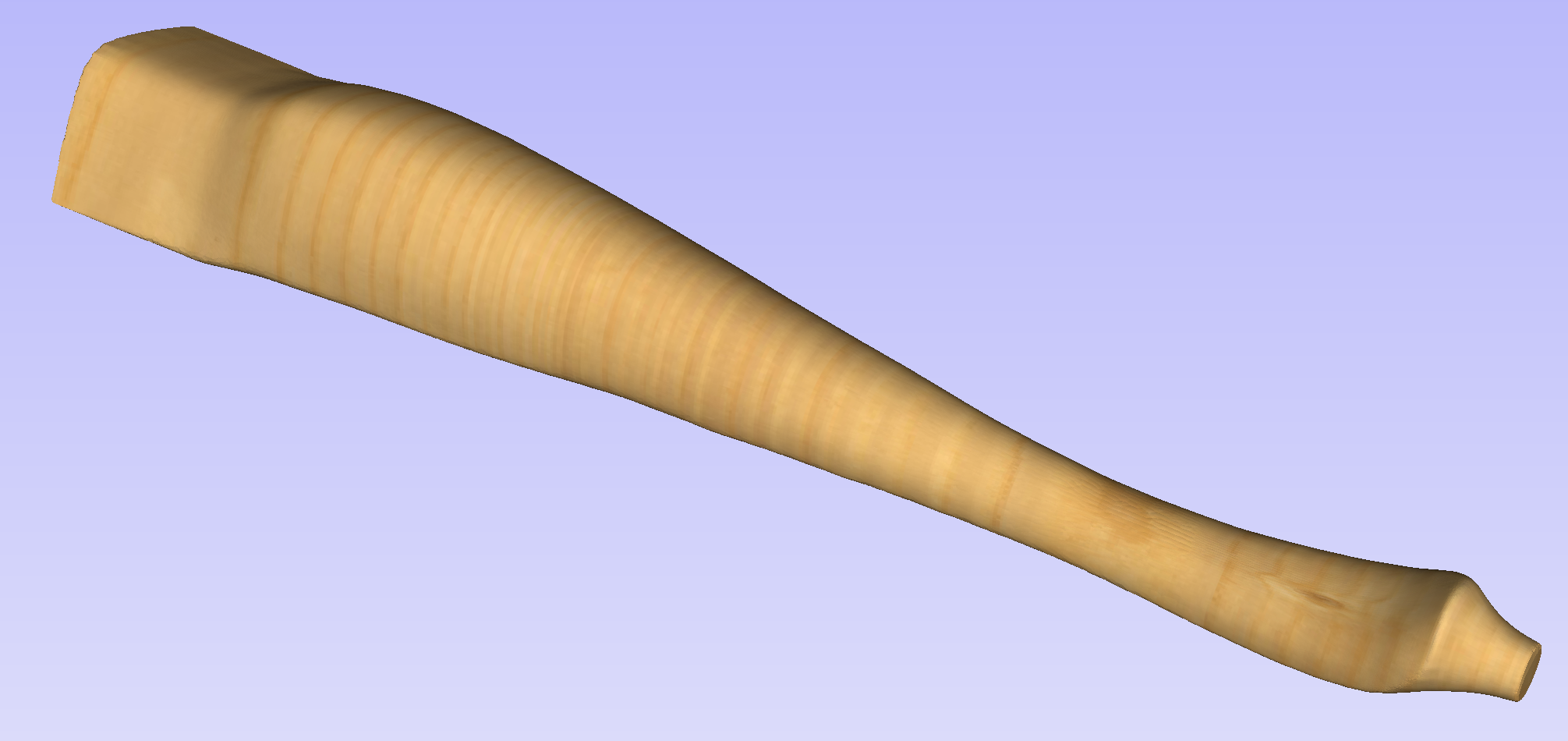

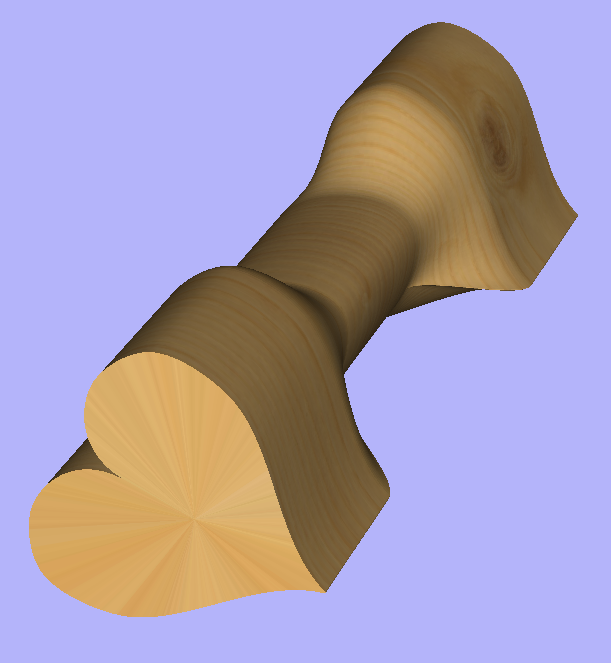

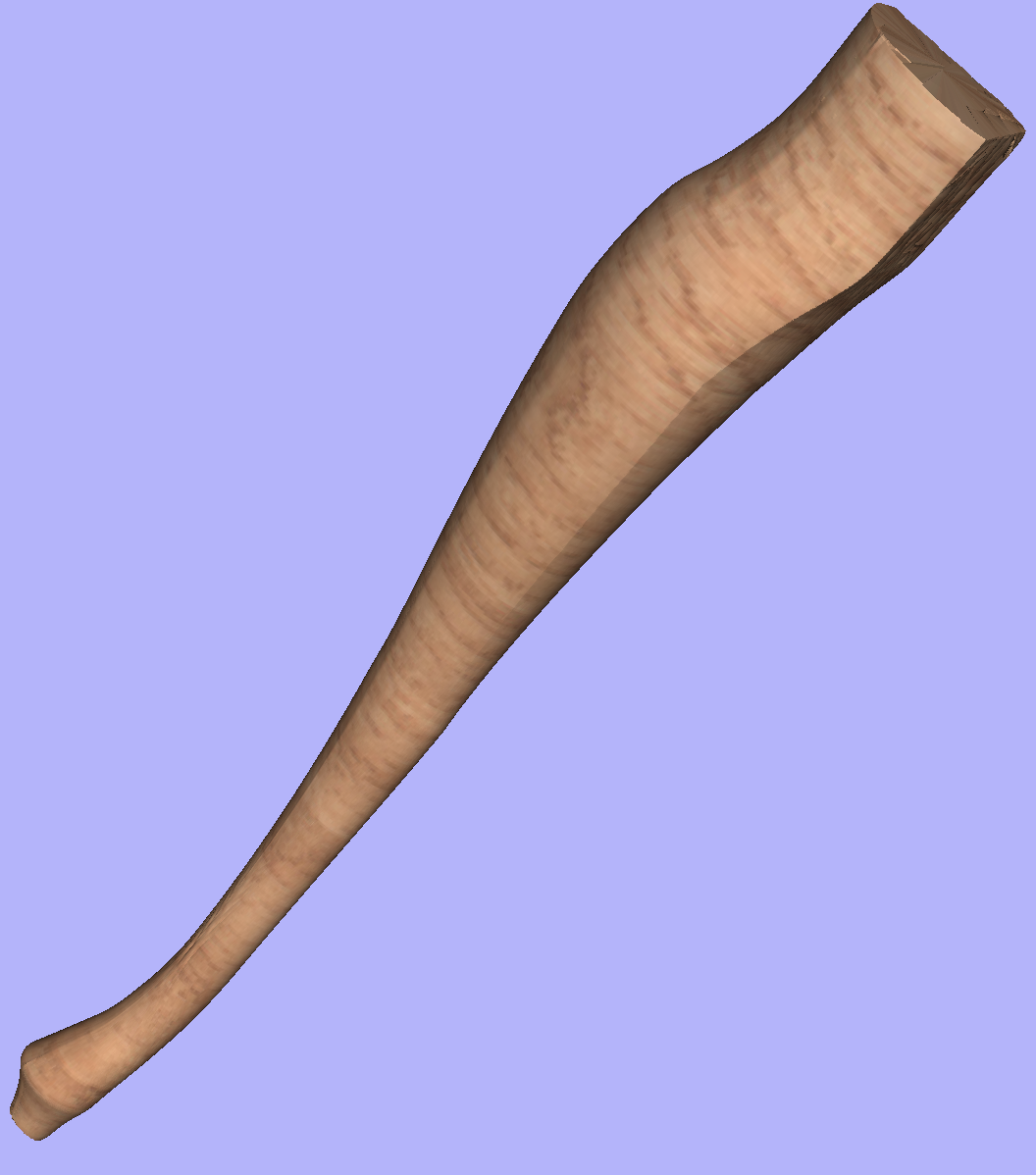

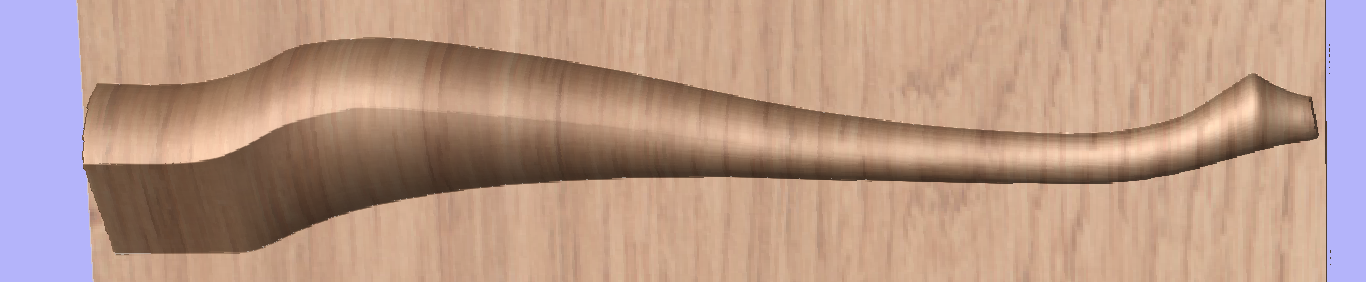

This section will present the process of importing the Full-3D STL model into rotary project, using a table leg as an example.

Overview

Overview

There are two basic use cases when importing an external model into the rotary job. The first case involves bringing a model designed for this particular job in another software. Thus the dimensions of the imported piece may already be correct and it can be desired to use them for the size of project. The second use case is when importing a stock model that would have to be scaled to fit on particular machine.

Aspire uses following workflow that covers both of those cases:

- Setting-up rotary project

- Choosing file for import

- Orientating the model in material block

- Scaling the model

- Finishing the import

Setting up a rotary project

Setting up a rotary project

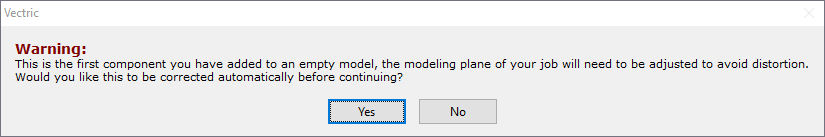

Create a new job using the Job Setup form. It is important to set the job type as rotary to ensure a proper import tool is used in the next step.

If the dimensions of the project are already known, they could be specified directly.

If it is desired to fit the model to a given machine or stock available, set both the diameter and length to maximum. During import the model will be scaled to those limits.

If it is desired to use the imported model size, any size can be specified at this time. During the model import the project can be automatically resized to match the model dimensions.

In this example it was desired to fit the model into a specific stock size with a Diameter of 4 inches and a Length of 12 inches. XY origin was set to centre.

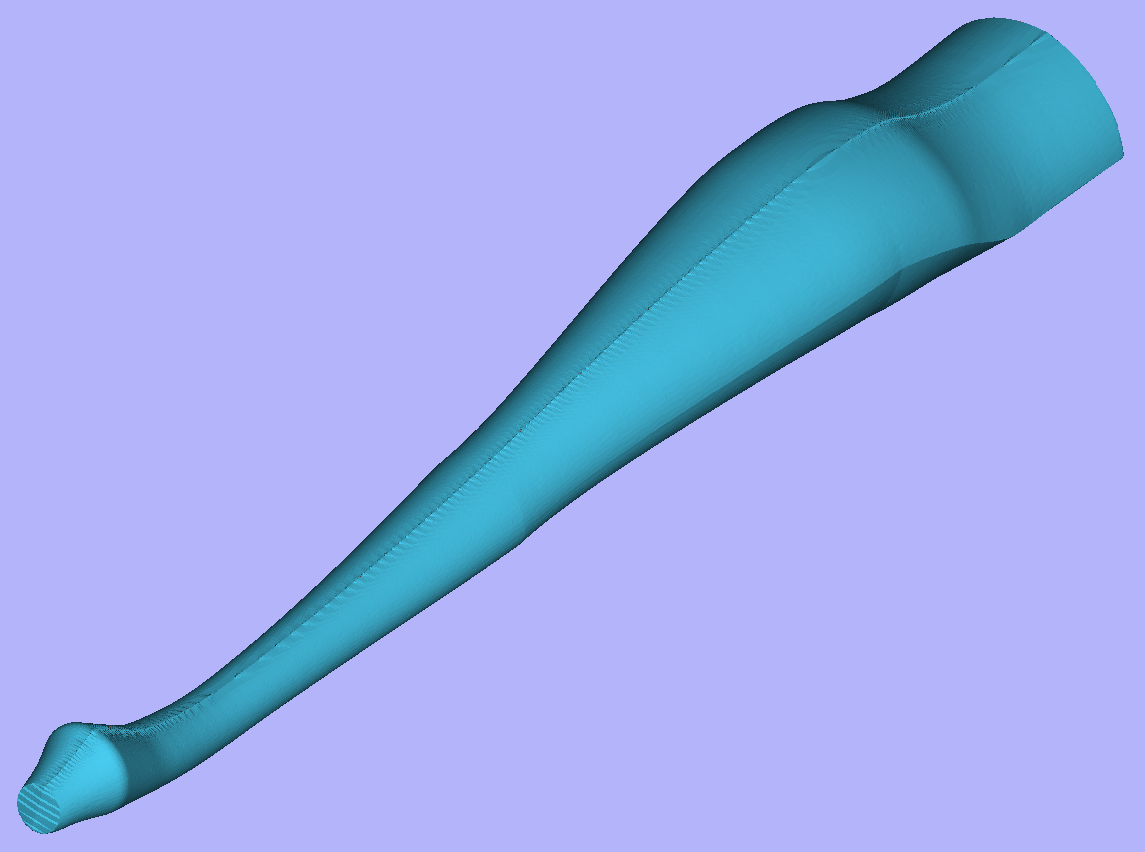

Importing the file and orientating it

Importing the file and orientating it

To start the importing process, use Import a Component or 3D Model tool from the Modelling tab

Make sure that the Imported model type is set to Full 3D model .

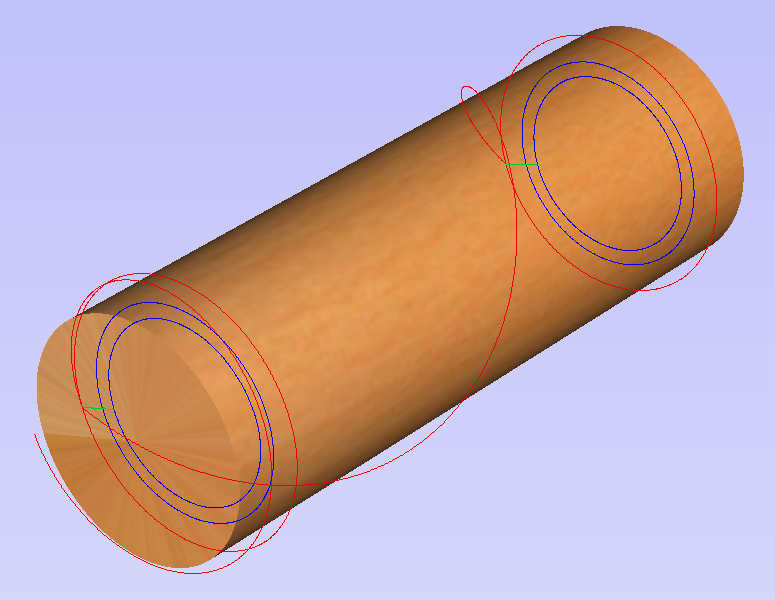

The first step is to position the imported model within the material. This step is necessary as this information is not present in the imported file. When the model was opened, the import tool chose the initial orientation, as can be seen below.

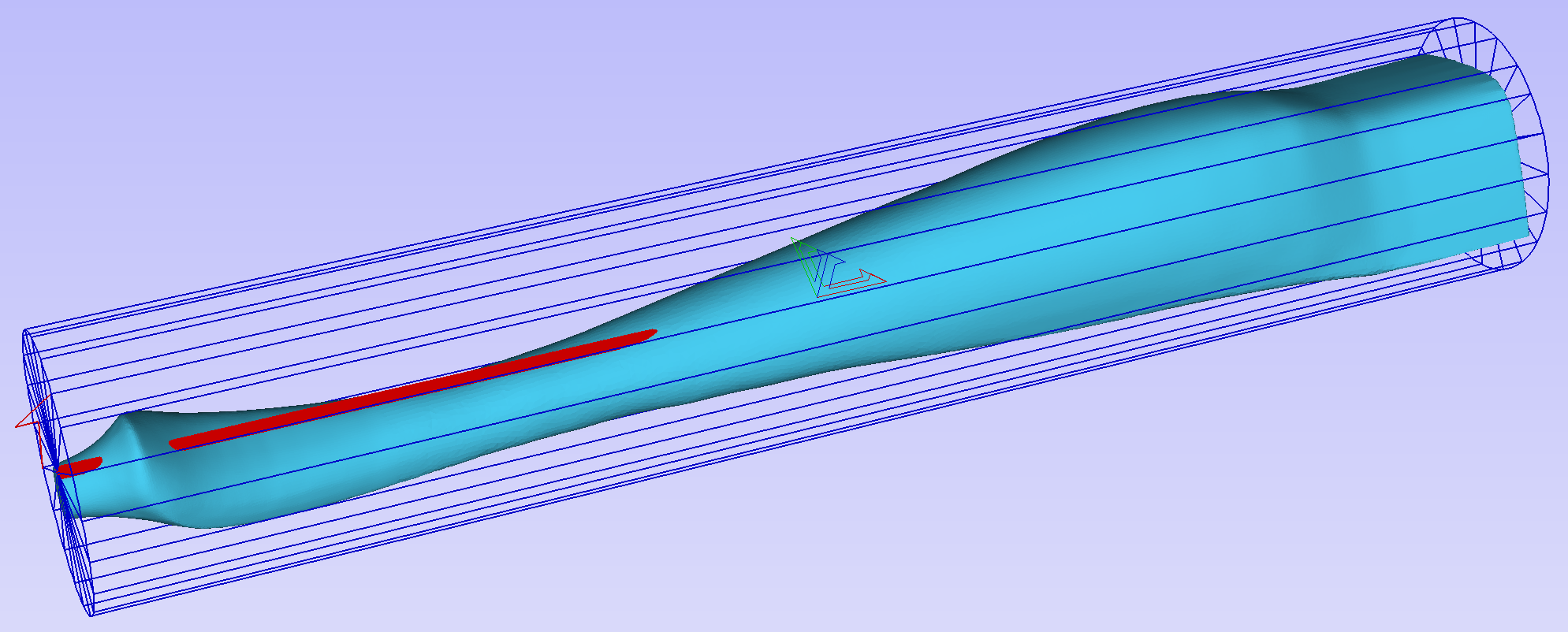

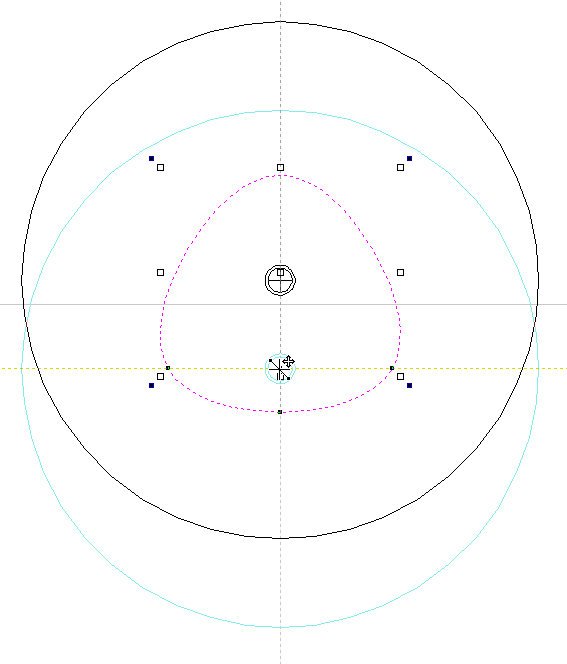

To help with orientating the model, the software displays a blue bounding cylinder. This cylinder has the rotation axis aligned with that defined for the material block and thus can be used as a reference. Its size is just big enough to contain the imported model at the current orientation. When the model orientation is changed, this blue cylinder will shrink or grow so it always contains the model. At this stage its exact dimensions are not important, as we are only interested in positioning the model correctly.

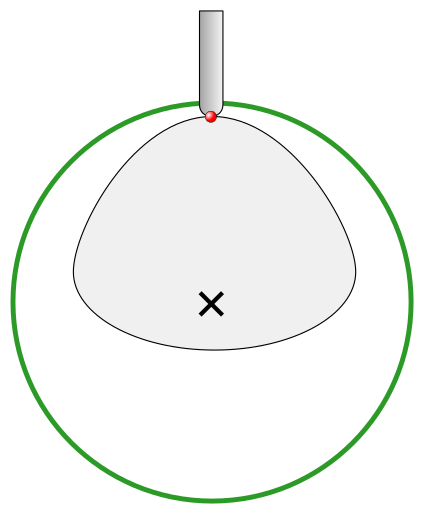

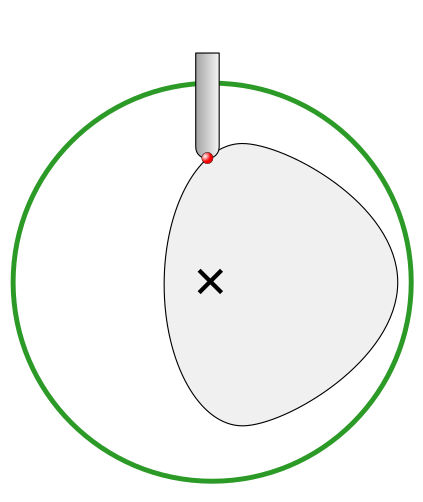

The software also highlights the rotation axis in red. This is particularly important when importing bended models. It is currently not possible to represent areas of model that are entirely below or above the rotation axis. This is the case in the example shown here. If the model was imported as is, the distortion would be created as can be seen below. Therefore it is important to position the model in a way such that the rotation axis is contained within the model.

The last guiding element displayed by the software is the red half arrow on the side of the cylinder. This arrow is indicating the position that corresponds to the center of the wrapped dimension in the 2D view. In this example the model is orientated in such a way, that front of the leg would be placed on side of the 2D view, rather than centre. Thus it is better to rotate model so this arrow points to the front of the imported model.

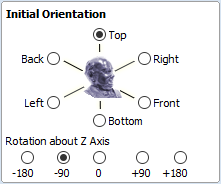

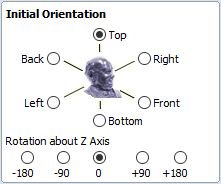

The import tool provides a few ways of adjusting the model orientation. The most basic one is the Initial Orientation. This can be used to roughly align the model with the rotation axis. This can also be combined with the Rotation about Z Axis.In this example the tool chose Left with no rotation. In order to align the front of the leg with the red arrow, one could use the Front and -90 as the Rotation about Z Axis.

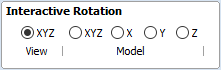

Once the initial orientation is decided, further adjustments can be made using the Interactive Rotation. The default option - XYZ View - disables the interactive rotation. That means that the 3D view can be twiddled with a mouse. Selecting other options enables the rotation around the specified axis.

In this example, instead of changing the initial orientation to align the front of the leg with the red arrow, one could select X Model option and rotate the piece manually. When selecting single axis rotation, the 3D view will be adjusted to show that axis pointing towards the screen. If any mistake is made, it is possible to undo rotation using Ctrl+ Z

Notice that whenever the part is rotated, it is always centered in the cylinder. In this example it is not desired, since we need the rotation axis to be contained within the model. In order to move the model in relation to the rotation axis, one can use the Rotation Axis Movement

Similarly to the previously described tool, when Rotation Axis Movement is set to Off, the 3D view can be panned

Correctly positioning the model for importing may require a combination of the Rotation Axis Movement and the Interactive Rotation to achieve desired results with models that bend. It is important to make sure that rotation axis is hidden in order to avoid distortion. However it is also desirable to have the rotation axis being in the center of each segment of the piece to ensure tool has angle close to the optimal during machining. Usually it is also useful to rotate the model in view around the axis after the adjustment, as this allows us to inspect the model from each side without the need to disable the Interactive Rotation before changing the viewing angle.

It is important to understand that Aspire does not support 4-axis machining. That means that while the machined piece can be rotated and tool moves along the rotation axis and in the Z direction, it is not possible to move the tool in the wrapped dimension and thus the tool is always above the rotation axis and cannot be moved to the side.

This limitation is shown below. The first picture presents correct machining of the point. If the tool moves to another location though, the angle will be incorrect and even worse, the tool side will be touching the stock.

Scaling imported model

Scaling imported model

Once model has been positioned as desired, its size can be taken into account.

By default the tool will assume that imported model is using the same units as the project. If that is not the case, model units can be switched. In this example project was set-up in inches, while imported model was designed in mm. After switching model becomes considerably smaller and a red cylinder, representing current material block is shown, as can be seen below.

At this point it is possible to specify the model size, in terms of diameter and length. This can be done manually by typing desired dimensions, or by fitting to material. If Lock ratio option is selected, the ratio between diameter and length is kept. One can also tick Resize material block option. If it is selected, the material block will be scaled to match current size of the model, after OK is clicked.

If it is desired to use model size as material block size, one can just make sure units are correct, then tick Resize material block option and press OK.

If it is desired for the model to fit material, one could click Scale model to fit material and tick Resize material block.

In this example model was fitted to material. Since in this case length of the piece is limiting factor and lock ratio is maintained, this results in model having considerably smaller diameter than material block. Hence Resize material block option was ticked.

Finishing import

Finishing import

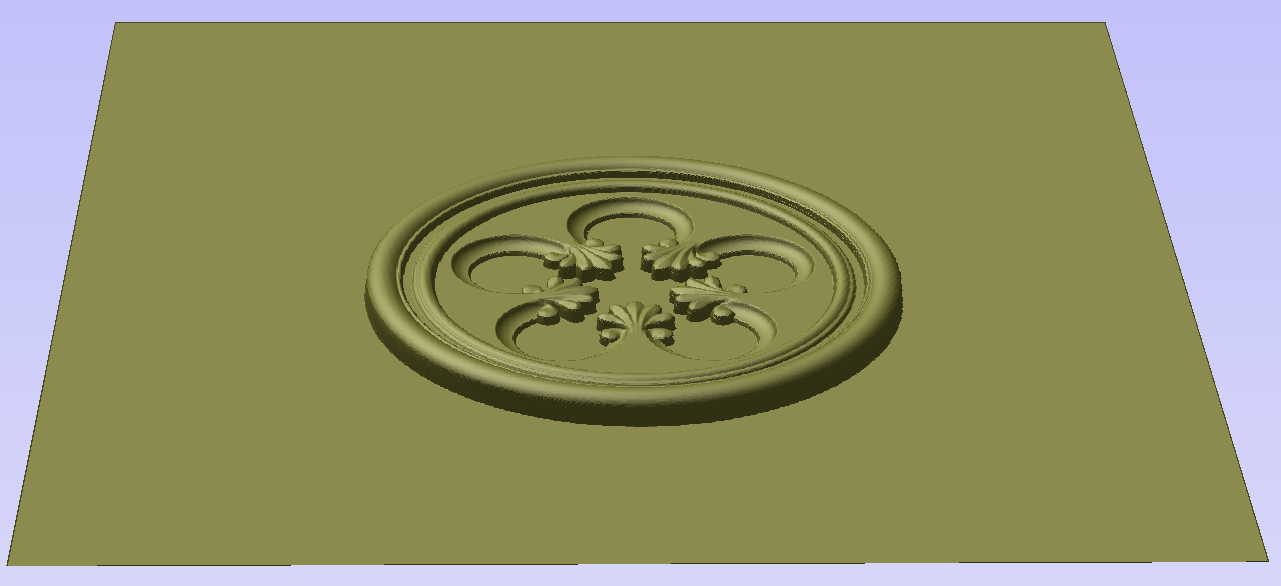

After pressing OK the model will be imported as a component. It is possible to modify it as any other component or add pieces of decorative clipart onto its surface if desired.

It is important to keep in mind the distortion caused by the wrapping process. That means that wrapped toolpaths will match flat toolpaths only at the surface of the blank. The closer to the rotation axis (i.e. deeper) the toolpath is, the more it will be 'compressed'. This fact have a profound implication for 3D toolpaths. Consider the example shown below.

As can be seen if there is substantial difference in diameter in different parts of model, generating one 3D toolpath for whole model will result in wrapped toolpath being overly compressed. Thus it is usually better to create boundaries of regions with significantly different diameter and generate separate toolpaths using correct settings for each diameter.

Importing Flat Models

Importing Flat Models

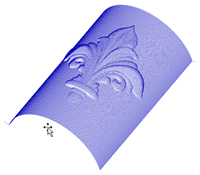

This section will present a process of importing Flat STL model into rotary project. Flat models are similar to decorative clipart pieces provided with Aspire and are supposed to be placed on the surface of modelled shape.

To start the importing process, use Import a Component or 3D Model tool from the Modelling tab

Make sure that Imported model type is set to Flat model

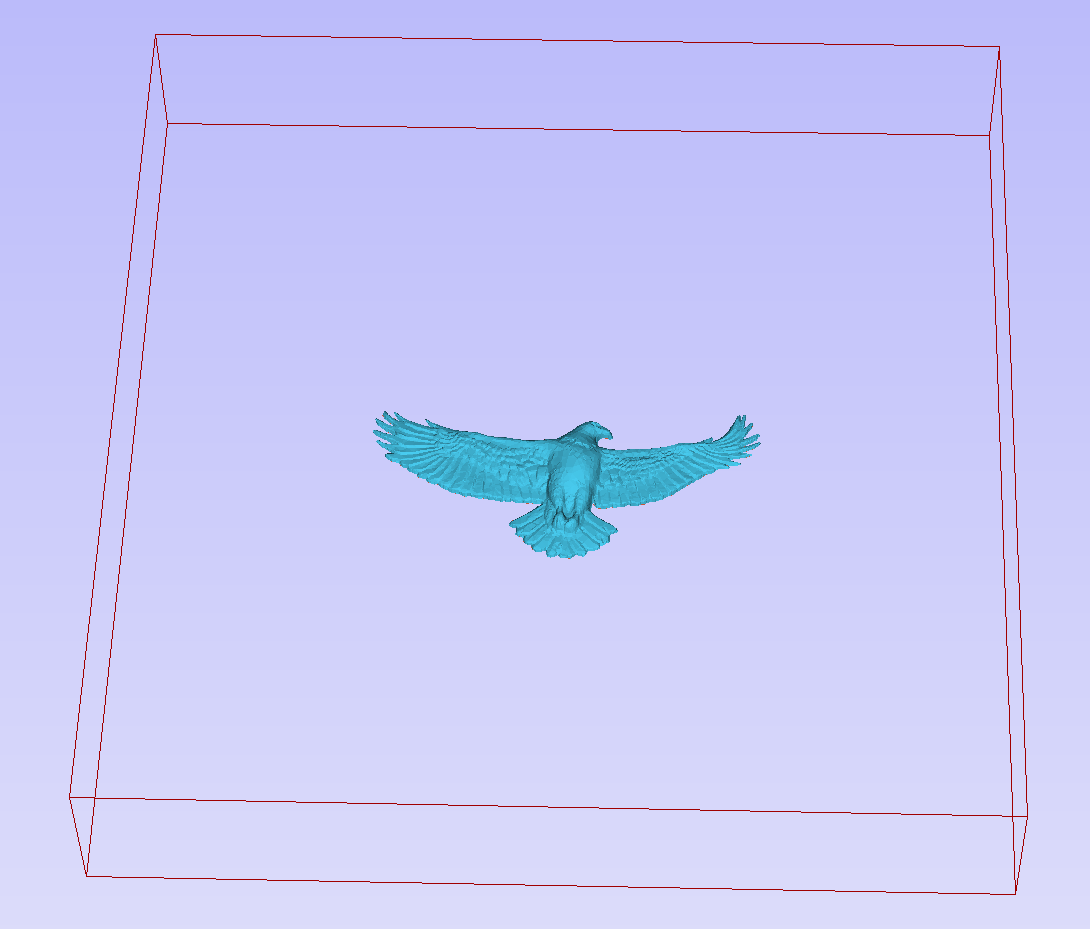

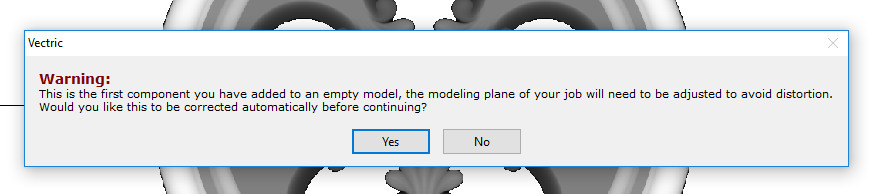

Again the first step is to select proper orientation of model. The tool will chose initial orientation and display model in the red material box. This box corresponds to the 'unwrapped' material block and its thickness is equal to half of the specified diameter of the blank.

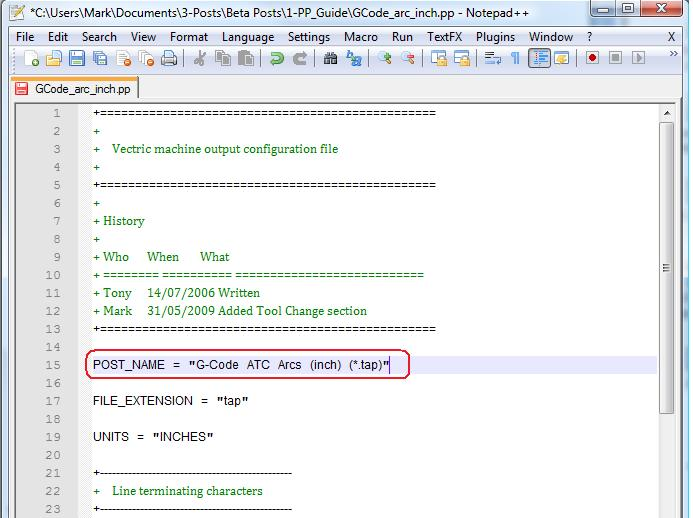

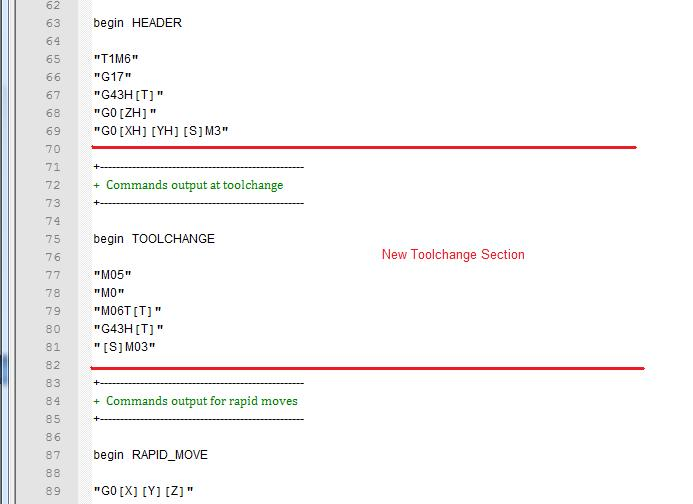

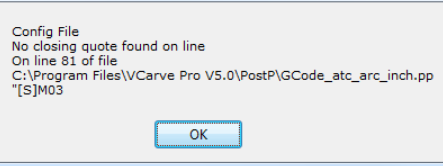

If model is not oriented correctly, that is, does not lie flat on the bottom of the material box, as can be seen above, orientation have to be adjusted. To do that one can change Initial Orientation option and/or Rotation about Z Axis.