Keep-out Zones

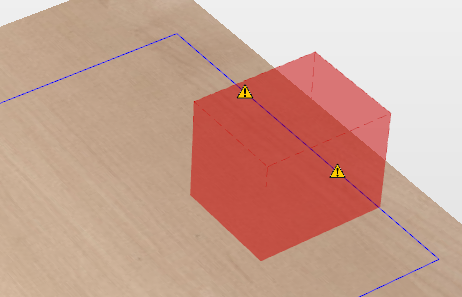

Keep-out Zones are used to define areas of your material which it is not safe for a tool to pass through or over.

These can be used to represent hold downs such as clamps or screws which are protruding above the material and could damage tools should they collide.

Clearance vs Safe height

Keep-out zones will operate on Clearance height moves where the tool is being moved between toolpaths. Once a toolpath is completed, the tool will raise to the Safe Z Home height as set in the "Z Gap Above material" which is found in the Material Setup form and travel to its Home location. Ensure this Z Gap Above material is set high enough to clear clamps or other obstacles.

Watch this video to see this in action:

Zone Creation

Zone Creation

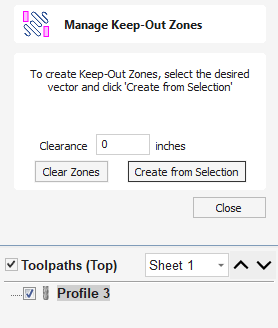

Any vectors selected to represent areas where the machine should not pass over for the Keep-out Zones will need to be closed vectors.

If a vector you want to select for the Keep-out Zones is an open vector you will need to make it a closed vectors before selecting it, you can do this by using one of the close or join vector options in the Design tab.

Clearance

Clearance

Enter a Clearance value if you need to extend the Keep-out Zone area beyond the area covered by the selected vectors.