User Guide

General Workflow

Cut2D Pro has been developed to allow the production of decorative and artistic dimensional carved parts. As well as drawing and modeling tools, it includes both 2D and 3D machining, along with 3D V-Carving / 3D Engraving to allow a huge variety of jobs to be produced as quickly and easily as possible.

Workflow Logic

- Layout 2D Design:

- Import Vectors

- Draw Vectors

- Import Bitmaps

- Create 2D, 2.5D or 3D toolpath:

- Create or edit vector boundaries for toolpaths

- Specify tool details for each strategy

- Preview Final Part:

- Visualize the part as it will actually look.

- Create proof images for customer.

- Check estimate for cutting time

- Save the CNC Code: Save the final cuto file to send to the CNC machine

Design

Cut2D Pro includes drawing and editing tools that allow designs to be created and modified. Functions for vector creation and editing are very easy to use and multiple design elements can also be drawn or imported, scaled, positioned and interactively edited to make a new design. Text can also be created using any TrueType or OpenType fonts installed on your computer, or the single stroke engraving fonts supplied with the software.

Toolpath

A comprehensive set of 2D, V-Carving, Engraving and 3D toolpath strategies provide you with efficient ways to use your tooling to carve the finished part. This process is usually relatively independent of drawing or modeling (although toolpaths are often created directly from some artwork or 3D composite models). Aspire provides simple interface buttons to toggle screen layout to assist the shift in focus from design to toolpathing.

Output

Finally you can use Cut2D Pro's large selection of post-processors to save toolpaths in precisely the format that your particular CNC machine tool requires.

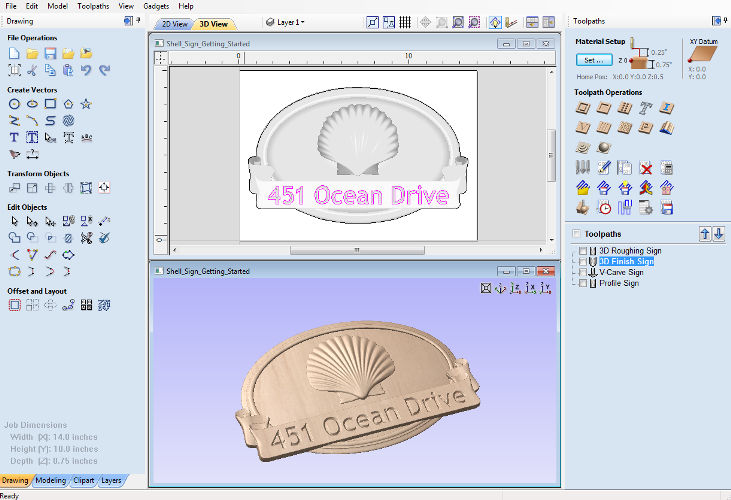

Interface Overview

- The Main Menu Bar (the Drop Down Menus) along the top of the screen (File, Edit, Model, Toolpaths, View, Gadgets, Help) provides access to most of the commands available in the software, grouped by function. Click on any of the choices to show a Drop-Down list of the available commands.

- The Design Panel is on the left side of the screen. This is where the design tabs can be accessed and the icons within the tabs to create a design.

- The Toolpath Tab is on the right side of the screen. The Top section of the toolpaths tab houses all of the icons to create, edit and preview toolpaths. The bottom half shows you toolpaths that you have already created.

- The 2D Design window is where the design is drawn, edited and selected ready for machining. Designs can be imported or created directly in the software. This occupies the same area as the 3D View and the display can be toggled between the two using F2 and F3 or the tabs at the top of the window.

- The 3D View is where the composite model, toolpaths and the toolpath preview are displayed.

- If you wish to see the 2D and 3D views simultaneously, or you wish to switch your focus to the Toolpaths tab at a later stage of your design process, you can use the interface layout buttons (accessible in the 2D View Control section on the Drawing Tab) to toggle between the different preset interface layouts.

Managing the Interface

The tool pages have Auto-Hide / Show behavior which allows them to automatically close when not being used, thus maximizing your working screen area.

The software includes two default layouts, one for designing and one for machining, which can automatically and conveniently set the appropriate auto-hide behavior for each of the tools pages. Toggle layout buttons on each of the tools pages allow you to switch the interface as your focus naturally shifts from the design stage to the toolpathing stage of your project.

Accessing Auto-hidden tabs

If a tools page is auto-hidden (because it is currently unpinned, see pinning and unpinning tools pages, below), then it will only appear as a tab at the side of your screen. Move your mouse over these tabs to show the page temporarily. Once you have selected a tool from the page, it will automatically hide itself again.

Pinning and unpinning tools pages

The auto-hide behavior of each tools page can be controlled using the push-pin icons at the top right of the title area of each page.

Default layout for Design and Toolpaths

Aspire has two default tool page layouts that are designed to assist the usual workflow of design, followed by toolpath creation.

In all three of the tools tabs there are 'Switch Layout' buttons. In the Drawing and Modeling tabs, these buttons will shift the interface's focus to toolpath tasks by 'pinning-out' the Toolpaths tools tab, and 'unpinning' the Drawing and Modeling tools tabs. In the toolpaths tab, the button reverses the layout - unpinning the toolpaths page, and pinning-out the Drawing and Modeling pages.You can toggle between these two modes using the F11 and F12 shortcut keys.

2D Design and Management

The 2D View is used to design and manage the layout of your finished part. Different entities are used to allow the user to control items that are either strictly 2D or are 2D representations of objects in the 3D View. A list of these 2D View entities are described briefly below and more fully in later sections of this manual.

Ultimately the point of all these different types of objects is to allow you to create the toolpaths you need to cut the part you want on your CNC. This may mean that they help you to create the basis for the 3D model or that they are more directly related to the toolpath such as describing its boundary shape. The different applications and uses for these 2D items mean that organization of them is very important. For this reason Aspire has a Layer function for managing 2D data. The Layers are a way of associating different 2D entities together to allow the user to manage them more effectively. Layers will be described in detail later in the relevant section of this manual. If you are working with a 2 Sided project you can switch between the 'Top' and 'Bottom' sides in the same session, enabling you to create and edit data on each side, and using the 'Multi Sided View' option you can view the vectors on the opposite side. 2 Sided Setup will be described in detail later in the relevant section of this manual.

Vectors

Vectors are lines, arcs and curves which can be as simple as a straight line or can make up complex 2D designs. They have many uses in Aspire, such as describing a shape for a toolpath to follow or being a controlling 2D shape for use with one of the 3D modeling functions such as the 2 Rail Sweep. Aspire contains a number of vector creation and editing tools which are covered in this manual.

As well as creating vectors within the software many users will also import vectors from other design software such as Corel Draw or AutoCAD. Aspire supports the following vector formats for import: *.dxf, *.eps, *.ai, *.pdf, *skp and *svg. Once imported, the data can be edited and combined using the Vector Editing tools within the software.

Bitmaps

Although bitmap is a standard computer term for a pixel based image (such as a photo) in *.bmp, *.jpg, *.gif, *.tif, *.png and *.jpeg. These file types are images made up of tiny squares (pixels) which represent a scanned picture, digital photo or perhaps an image taken from the internet.

To make 3D models simple to create, Aspire uses a method which lets the user break the design down into manageable pieces called Components. In the 2D View a Component is shown as a Grayscale shape, this can be selected and edited to move its position, change its size etc. Working with the Grayscale's will be covered in detail later in this manual. As with bitmaps, many of the vector editing tools will also work on a selected Component Grayscale.

3D Design and Management

As well as creating toolpaths directly from 2D drawings, Aspire can produce extremely flexible 3D toolpaths. These toolpaths are created from 3D design elements called 3D Components that can be generated from models created in external 3D design packages , imported as 3D clipart or built entirely from within Aspire using 2D artwork as a source.

The 3D View

The 3D View can show you the current Composite Model

The Composite Model

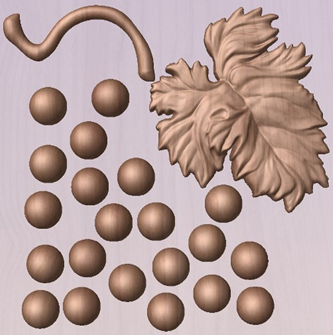

Aspire has been designed to work in a way which enables the user to easily create even very complex projects. In any situation, the best approach to producing something complicated is to break it down into smaller pieces until a level of simplicity is reached that can be understood and managed. In Aspire this is achieved by letting the user work with pieces of the design which are combined to make the finished part. In the terminology of the software these pieces are called Components. To help organize the Components they are assigned to Levels. Step by step, Components and Levels can be created and modified until you have all the elements you need. In the images below you can see an example of how this might work. On the left you can see the separate component for a model of a bunch of grapes and on the right you can see these positioned to make the complete part - we call this resulting combination the Composite Model.

There is no limit to how simple or complex a Component or the Components on a Level can be (this is the user's choice). In the example shown, you can see that a model of a whole bunch of grapes may be made up of smaller individual components but they could also be combined to exist as one single Component (the assembled bunch of grapes) that could then be used to lay-out a more complex part with multiple bunches of grapes. They could also be organized so all the grapes were on one Level and leaf and stem on another to provide a different way of managing and manipulating the shapes. Each user will find a level of using Components and Levels they are comfortable with which may be dependent on the particular job or level of proficiency with the modeling tools.

3D Components and Levels

In Aspire, the aim is to end up with a set of Components and Levels that when combined together will make the finished 3D part. One way to think of this is like building a 3D collage or assembly. As the design evolves, new Levels or shapes may need to be created or existing ones changed. The parts of the collage are managed with the Component Tree

Creating and Editing Components

An existing Component can be copied, scaled and have other edits carried out on it as an object. The user can also change the way it relates to the other Components, for instance whether it sits on top or blends into an overlapping area of another Component. The shape, location and relation of these pieces determine the look of the final part. As the job progresses, the user will need to create brand new Components or edit existing ones by adding new shapes, combining them with others or sculpting them.

Components can be created and edited by:

- Use a modeling tool to create shapes from 2D vectors.

- Import a pre-created 3d model - either a model previously created in Aspire or from another source such as a clipart library or a different modeling package.

- Create a 'texture' Component from a bitmap image.

- Use the Split Components Tool to break an existing Component into multiple pieces.

All of these methods are covered in detail throughout the training material.

Dynamic Properties

As well as having its underlying 3D shape, each component also has a number of dynamic properties that can be freely modified without permanently changing its true shape. These include scaling of the Component's height, the ability to tilt it, or to apply a graduated fade across it.

These dynamic properties can always be reset or altered at any time during your modeling process, which makes them a particularly useful way of 'tweaking 'your components as you combine them together to form your final composite model.

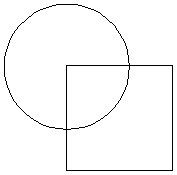

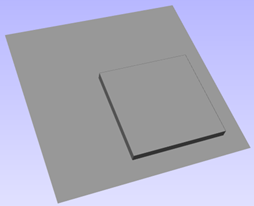

Combine Modes

The Combine Mode is a very important concept when working with 3D shapes within Aspire. The options for combine mode are presented when creating new shapes and also when deciding how Components and Levels will interact in the Component List. Rather than cover this in every section where it is applicable, it is worth summarizing the options here so the general concept can be understood.

When you have more than one 3D shape, such as the Component pieces of the design or where you have an existing shape and are creating a new one, then you need to have a way to tell the software how the additional entities will interact with the first. This can be an abstract concept for users who are new to 3D but it is an important one to grasp as early as possible. In Aspire this is controlled by a choice called the Combine Mode.

There are four options for this: Add, Subtract, Merge High, Merge Low.

As modeling is an artistic and creative process, there is no general rule to describe when to use each one. As a guide though you can assume that if the second shape's area is completely within the originals one then you will probably be adding or subtracting and if the shapes only partly overlap that you will probably use Merge or, very occasionally, Low.

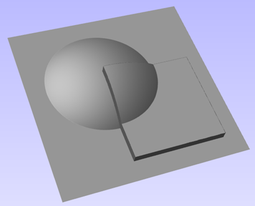

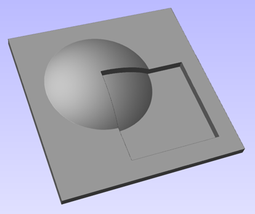

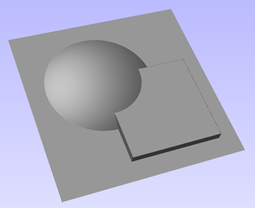

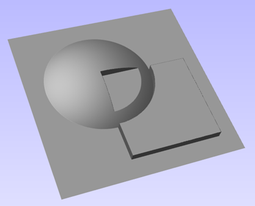

The four options and their specific effects are described on the following pages. To illustrate the different effects a combination of an overlapping beveled square and a dome will be used. You can see in the image top right how these are arranged in the 2D View and how they overlap. Then you can see each individual shape in the images below middle and right. These shapes will be used to demonstrate the different Combine Modes. In every case the Dome will be considered the primary shape and the square is the secondary shape which is being combined with the first. In addition to the dome/square example some images of 'real world' parts will also be included to help to understand how these can be used on actual projects.

As well as working on individual shapes, the Combine Modes are also assigned to Levels. These will govern how the combination of all the individual components on one Level interacts with the result of all the Components on the Level below it in the Component Tree

Note:

There is a 5th Combine Mode available from the right mouse click menu after a component has been created called Multiply. This combine mode has specialist applications which are dealt with in the appropriate tutorial videos. This option will literally multiply the heights of the Component or Levels being combined to create the new Composite 3D shape.

Add

When Add is selected, it takes the first shape and then just adds the height of the second shape directly on top of the first. Any areas which overlap will create a shape which is exactly the height of each shape at that point added together (see below)

Typically the add option is mainly used when the shape being added sits completely within the original shape, this ensures that the uneven transition where the parts only partly overlap (as shown in the example) do not occur.

The example above shows the Maple Leaf and border extrusion Components being Added to the dome Component in the sign example from the Introduction to Modeling document.

Subtract

When Subtract is selected it takes the first shape and then removes the height of the second shape from the first. Any areas which overlap will be a combination of the original height/shape less the second shape. Areas where the shape goes into the background will become negative regions. You can see how this looks using the dome and square in the image below:

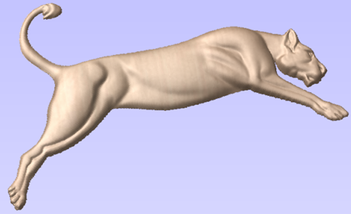

Typically subtract, like the add option, is mainly used when the shape being removed sits completely within the original shape, this ensures that the uneven transition where the parts only partly overlap (as shown in the example) do not occur.

The image shown above has some 'creases' to help define the muscles of the lioness. The shapes to create these recesses were created by using the Subtract option with the Create Shape tool on the vectors representing those recessed areas.

Merge

When the Merge option is selected any areas of the shapes which do not overlap remain the same. The areas that overlap will blend into each other so that the highest areas of each are left visible. This results in the look of one shape merging into the other and is in effect a Boolean union operation. You can see how this looks using the dome and square in the image below:

Typically the merge option is used when the shape being combined partly overlaps the original shape. This enables a reasonable transition to be made between them.

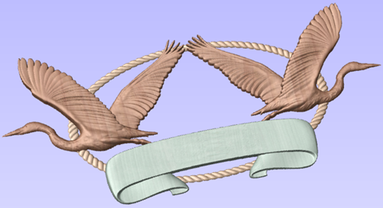

The image above shows 2 Herons, a rope border and banner Components. Each of these overlaps with the others and so they are set to Merge in this areas. Whatever is the higher of the two merged areas is what is prominent. In this case the rope is lower than everything and the Banner is higher than the Herons so the desired effect can be achieved.

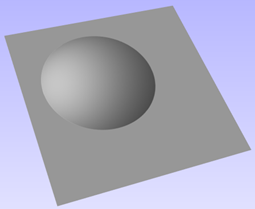

Low

The Low option is only available when combining Components (not in the modeling tools). When this mode is selected, any areas which do not overlap are left as they were in the original two shapes. Any areas which overlap will create a new shape which is the lowest points taken from each shape, this is in effect a Boolean intersection operation. You can see how this looks using the dome and square in the image below:

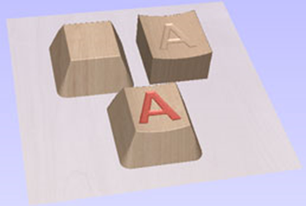

The Low option is used for recessing a shape into a raised shape. An example of this is shown in the image above.

The example shown on the right above uses the Low option to combine the flat topped 'button' component on the left with the curved top face component with the letter 'A' on the right. Combining both components with the merge low option gives the keyboard button with the curved top you see in the bottom row.

Level Mirror Modes

Right-clicking Levels in the component tree will open a pop-up menu offering commands and operations related to the clicked level and Mirror Modes can be set in this way. If a mirror mode is set on a Level, all the components it contains will be continually mirrored dynamically as they are moved, transformed or edited. The mirroring is non-destructive, that is it can be turned off or on at any time and does not alter the underlying components in any permanent way. Working inside a Mirror modes Level is a simple way of achieving a complicated symmetrical pattern by editing only one half (or quarter, see below) of the design.

The available Mirror Modes are broadly divided into two groups. The first group apply one plane of symmetry:

- Left to Right

- Right to Left

- Top to Bottom

- Bottom to Top

These modes allow you to work in one half of your job and the other half will be automatically and dynamically generated for you. For example, in Left to Right mode you would place your components in the left half of your job and a mirrored equivalent of each would be created in the other half of the job. This 'reflection' is updated dynamically as you work.

The other group offer two planes of symmetry (horizontal and vertical):

- Top Left Quadrant

- Top Right Quadrant

- Bottom Left Quadrant

- Bottom Right Quadrant

When using these modes your components should all be in the quadrant (quarter) of the job. Mirrored reflections horizontally and vertically will be created in the other quadrants of the job for you.

Multi Sided View

When working in a 2 Sided environment you can create components independently per side or using the Right click option you can copy or move a component to the opposite side. Selecting the option to work in 'Multi Sided View' allows you to view components you may have on the Top and Bottom side in the 3D View. In the Toolpath Preview form of a project that contains toolpaths for the Top and Bottom Sides the multi sided view presents the simulation of the toolpath preview on both sides also, if the multi sided view is not selected you can use the 'Preview all Sides' option in the Toolpath Preview form to display the Top and Bottom Toolpaths in the 3D view. 2 Sided Setup will be described in detail later in the relevant section of this manual.

3D Toolpath Files

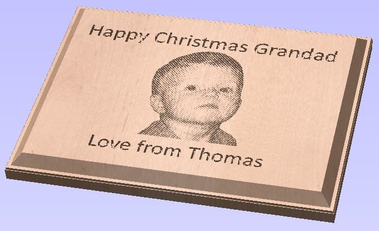

Files from Vectric's Cut3D, PhotoVCarve and Design and Make Machinist that include 3D toolpaths can be imported into Cut2D Pro using the main menu command: File ► Import ► PhotoVCarve, Machinist or Cut3D Toolpaths.

The 3D file must first be scaled to the required size before toolpaths are calculated, and then the complete file saved ready for importing into Cut2D Pro. These files can only be moved and positioned inside Cut2D Pro but cannot be scaled.

A Grayscale thumbnail of the 3D job is drawn in the 2D View with the X0 Y0 origin at the position it was set in Cut3D, PhotoVCarve or Design and Make Machinist. The associated toolpath(s) are also drawn in the 3D window and the names appear in the Toolpath list.

Positioning

To move the 3D design toolpaths open the 2D Window, click the Left mouse Twice on grayscale image (turns light Blue to indicate it's selected), then drag to the required position, or use the Move or Alignment tools for accurate positioning.

The toolpath(s) are automatically moved in the 3D window to the same XY position as the image.

Toolpaths for the example above have been calculated with the X0 Y0 in the middle of the 3D design. When imported into Cut2D the data is automatically positioned using the same coordinates, which places three quarters of the design off the job. In the second image the grayscale image has been moved to the middle of the job.

The 2D mirror and rotate drawing tools can also be used to edit the 3D data set.

3D toolpaths can also be copied using the Duplicate Toolpath command on the Toolpaths Tab making it very easy to use multiple elements from a single design on a job. The thumbnail preview is also copied for each toolpath, making it very easy to position additional copies of a 3D toolpath.

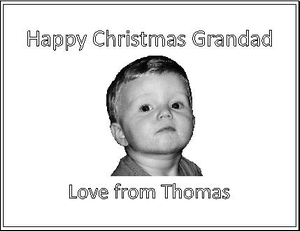

For example, a single design can be copied and mirrored to create Left and Right versions of a 3D design or to place multiple copies of a decorative design in the corners of a cabinet door panel as shown below.

![[object Object]](https://cdn.sanity.io/images/i7cqi3ri/production/34de49c9e1d4e062758f8feea7febccdbe024a6e-234x350.png)

Toolpaths for the 3D elements can be previewed along with the conventional Profile, Pocketing and Drilling toolpaths, and everything will be saved ready for machining.

A good example of where this functionality might be used in conjunction with PhotoVCarve is for making personalized picture frames that include the PhotoVCarve grooves plus descriptive engraved text and a decorative Profiled or Beveled border. As shown below:

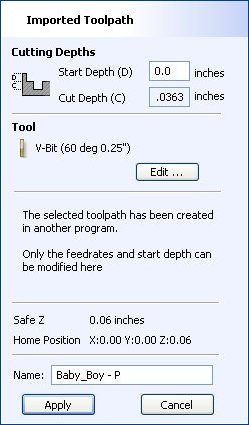

Options

Imported toolpaths can also be edited to position them inside the material or to change the cutting parameters - speeds and feed rates can be changed.

Design and Make Machinist

When using a Design and Make Machinist file that includes multiple toolpaths, you must remember to edit the Start Depth for all of the imported 3D toolpaths.

Click the Edit toolpath icon or Double click on the toolpath name to open the edit form.

For example, after machining a half-inch deep pocket a PhotoVCarve design can then be edited to have a Start Depth = 0.5 inches and this will carve the photograph onto the base of the pocket surface.

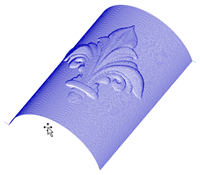

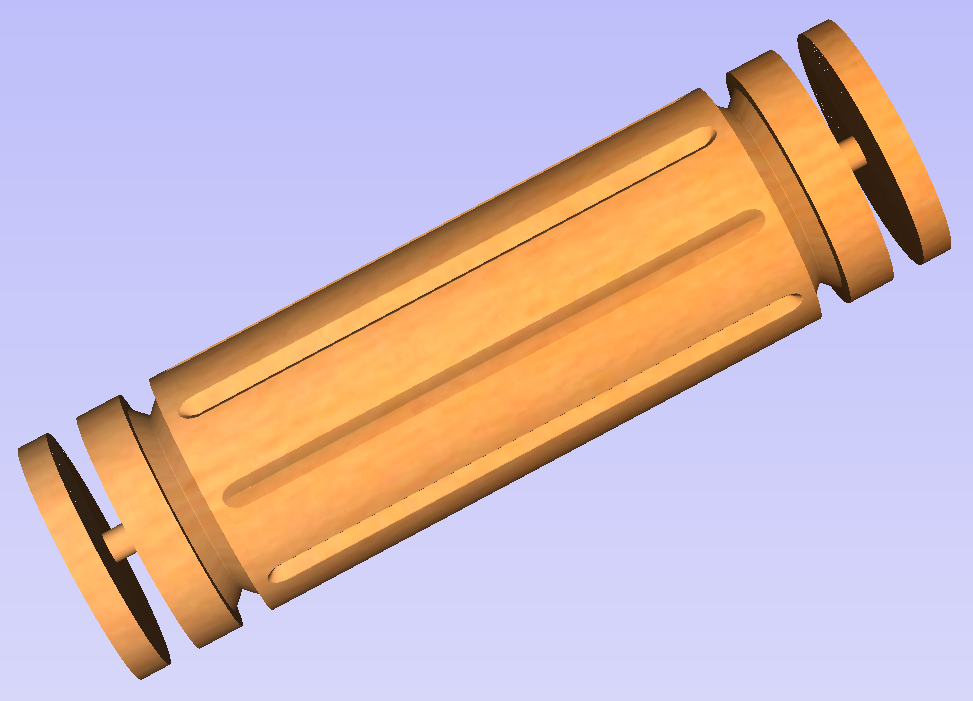

Rotary Machining and Wrapping

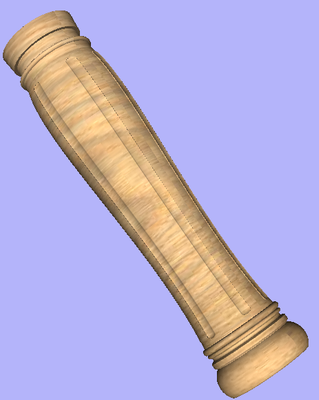

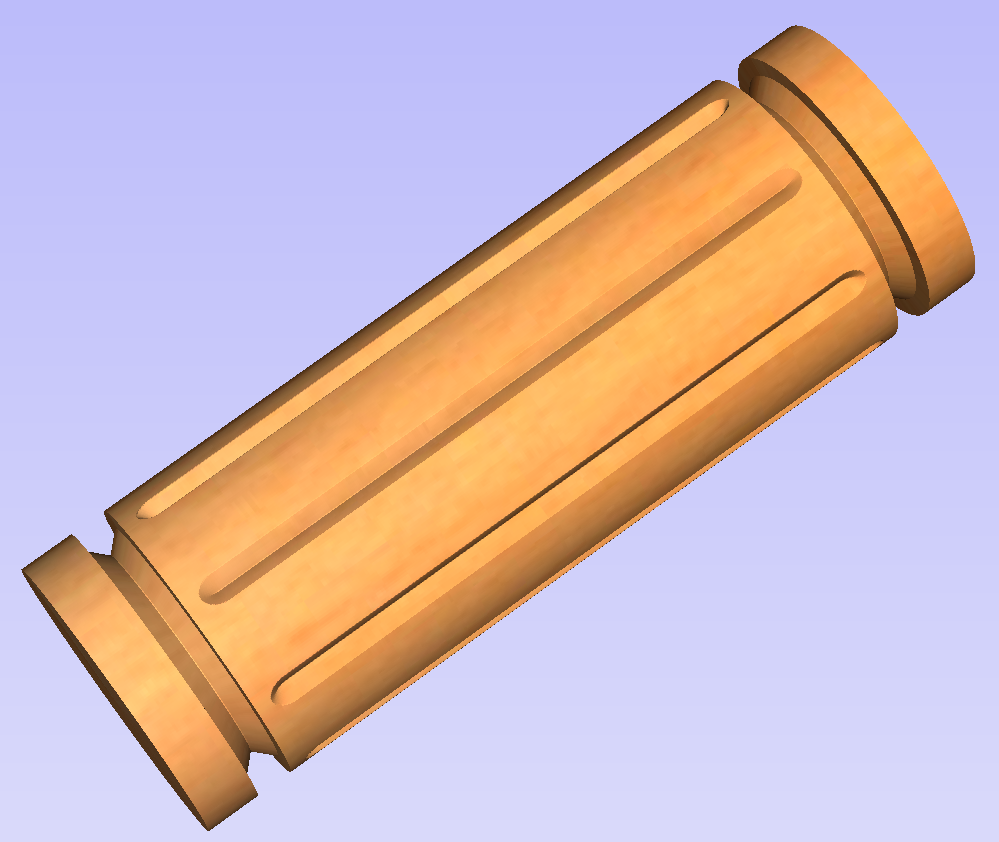

Cut2D Pro can 'wrap' flat toolpaths around a cylinder to provide output to CNC machines which are configured with a rotary axis / indexer. The image below shows a flat toolpath wrapped around part of a cylinder.

Note

It is important to note that wrapping works in conjunction with specially configured post-processors which take the XYZ 'flat' toolpaths and wrap them around a rotary axis, replacing either the X or Y moves with angular moves.

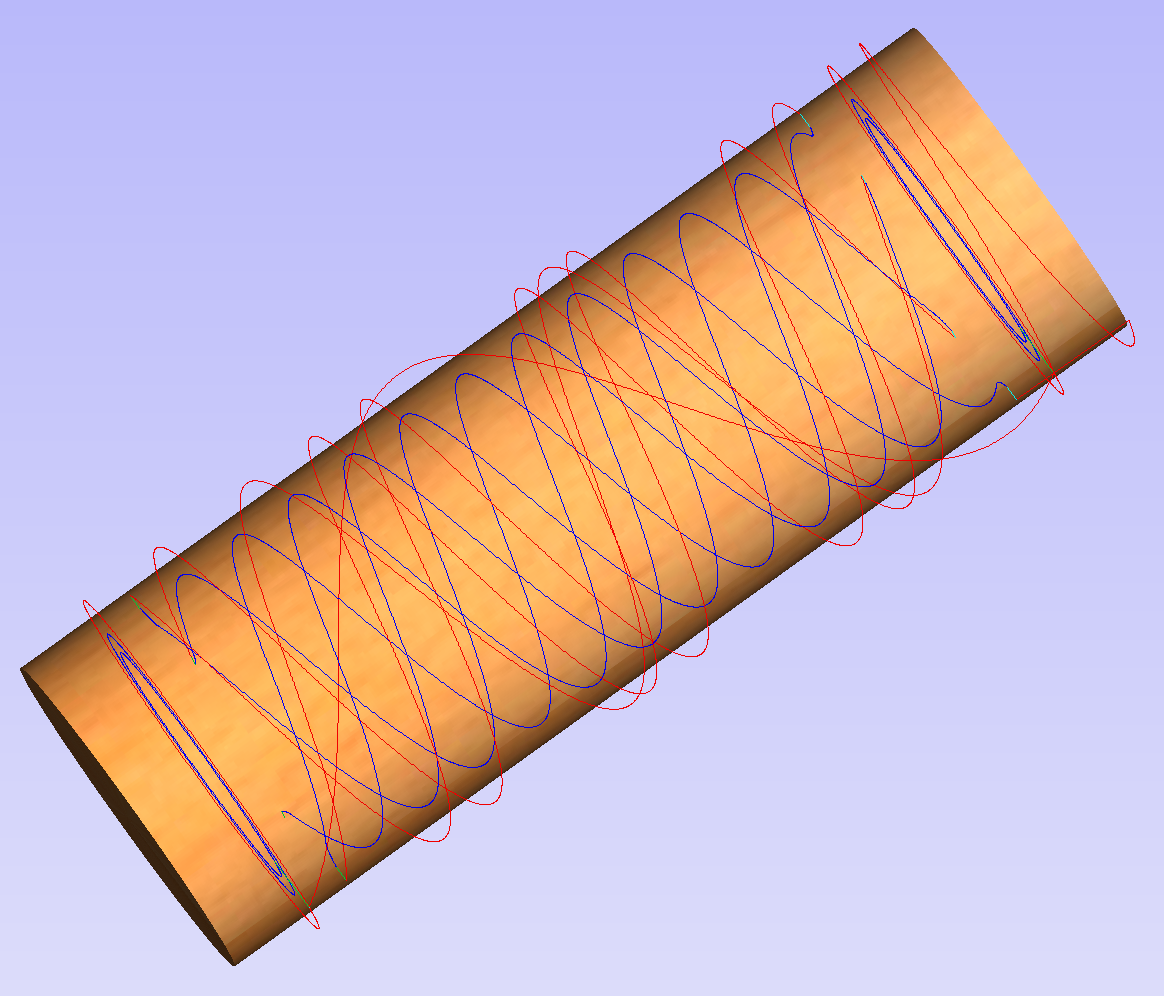

The toolpaths can be visualized wrapped within the program when the Auto Wrapping mode is on.

Cut2D Pro can also visualize a wrapped model within the program by drawing the shaded composite model wrapped.

Cut2D Pro also has the ability to draw the toolpath simulation wrapped. Although this is very useful for getting a feel for how the finished product will look, it is important to realize that the wrapped simulation may not be a 100% accurate representation of how the finished product will look. An example of potential difference would be if you drilled holes in your rotary job. In the actual work piece these will obviously just be round holes, in the wrapped simulation these may appear as distorted ovals due to the 'stretching' process which takes place when we wrap the flat simulation model for display.

Note

If your rotary axis is aligned along your Y axis you would choose the Orientation Along Y Axis option during job setup. All the examples in this document will assume that the rotary axis is aligned along X.

It is important to realize that there are a huge number of possible combinations of machine controller and axis orientations for rotary axis / indexers. This means it is impractical for Vectric to supply a pre-configured post-processor for every possible combination as standard. We include some wrapping post-processors in the default post-processor list as standard.

We also ship a copy of those post-processors in the Application Data Folder which can be accessed from the File Menu ► Open Application Data Folder.

The example below uses wrapped post-processors in sub-folder '05-Wrapped' under C:\ProgramData\Vectric\Aspire\V[ProductVersion]\PostP\05-Wrapped.

Examining these posts may be helpful if you need to configure a post of your own. If Vectric have not supplied as standard a post for your machine configuration please refer to the Post Processor Editing Guide accessible from the Help menu of the program for information on how to configure a post-processor and also look at the standard rotary posts Vectric supply.

You should also look at the Vectric forum to see if anyone else has already configured a post for your configuration or one similar. If, after looking at these resources you are still unsure of what needs to be done for your machine, please feel free to contact support@vectric.com for help. However, please note that we cannot guarantee to write a custom rotary post-processor for every individual requirement.

Creating a Rotary Job

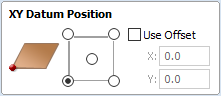

XY Origin

XY Drawing Origin - Here you can specify where the XY zero origin will be placed on your job. These options correspond to the same fields on the normal 'Job Setup' form within the program. Most people would use the default Bottom Left Corner, but for some jobs you may prefer to have the XY origin in the Center.

- In a job with horizontal orientation (Along X Axis), the X offset will correspond to the length of the cylinder, and the Y offset will be a point along its circumference.

- In a job with vertical orientation (Along Y Axis), it's the opposite. The Y offset will correspond to the length of the cylinder, and the X offset will be a point along its circumference.

Orientation

Cylinder Orientation Along - This section is used to tell the program how you have your rotary axis aligned on your machine. If you've already made your design, but just want to change the job for a different machine, then you could flip your design with the material so that all the vectors and components stay the same relative to the job.

Z Origin On - This section determines whether the Z Origin is set to the surface of the material or the base (center of cylinder). These settings can be over-ridden when the toolpath is actually saved, but we would strongly recommend the 'Cylinder Axis' is selected for rotary machining. The reasons for this are detailed in the note below.

Z Origin

You have the choice of specifying if the tool is being zeroed on the center of the cylinder or the surface. When you are rounding a blank, you cannot set the Z on the surface of the cylinder, as the surface it is referring to is the surface of the finished blank. We would strongly recommend for consistency and accuracy that you always choose 'Center of Cylinder' when outputting wrapped toolpaths as this should always remain constant irrespective of irregularities in the diameter of the piece you are machining or errors in getting your blank centered in your chuck.

Tip:

A useful tip for doing this is to accurately measure the distance between the center of your chuck and a convenient point such as the top of the chuck or part of your rotary axis mounting bracket. Write down this z-offset somewhere, and zero future tools at this point and enter your z-offset to get the position of the rotary axis center. Another reason for choosing 'Center of Cylinder' is that some controls will be able to work out the correct rotation speed for the rotary axis based on the distance from the center of rotation. If the Z value is relative to the surface, the control would need to know the diameter or radius of the cylinder at Z zero.

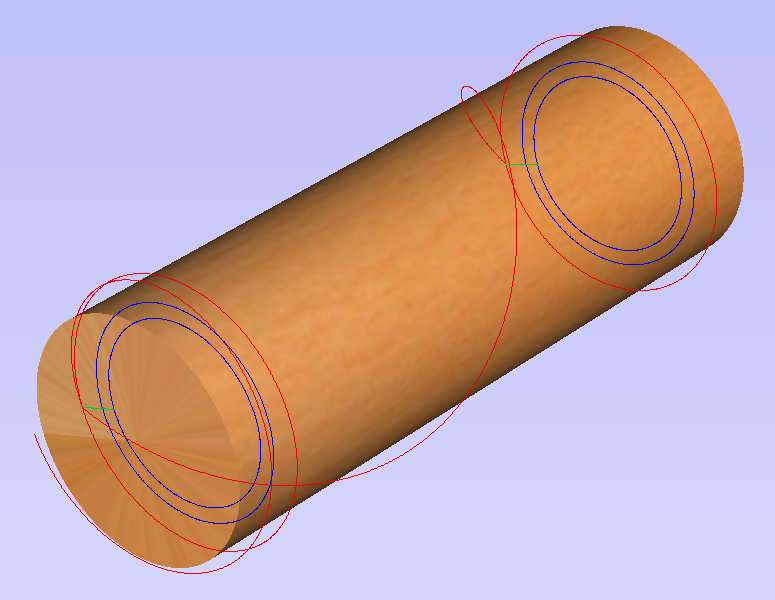

Vector Layout

As well as creating a job at a suitable size for wrapping toolpaths, when creating the job, it will create a number of vectors which can be very useful when creating your wrapped job.

The vectors are created on their own individual layers and by default these layers are switched off to avoid cluttering up your work area. To switch on the layers, display the 'Layer Control' dialog (Ctrl+ L is the shortcut to show / hide this). To show / hide the layer simply click on the check box next to the layer name.

2Rail Sweep Rails - This layer contains two straight line vectors which can be used to sweep a profile along if you are creating a shaped column.

Bounding Box - This layer contains a rectangular vector covering the entire job area. This vector is useful if you are going to machine the complete surface of the cylinder.

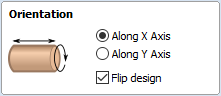

Choosing stock material

When setting-up rotary project, software assumes a perfect cylinder with an exact diameter. In practice the stock material may be uneven, or only blank with square profile may be available. In those cases blank needs to be machined into cylinder of desired size, before running toolpaths associated with the actual design.

Another consideration is length of the stock material. Typically, part of the blank will be placed within the chuck. It is also important that during machining, the cutting tool is always in safe distance from both chuck and tailstock. For those reasons, the blank has to be longer than the actual design. When setting-up the machine for cutting, one has to pay extra attention to ensure that origin is set accordingly to avoid the tool running into chuck or tailstock!

If the design was created without those considerations in mind, the blank size can always be adjusted in the Job Setupform.

The picture below presents an example of a rotary project layout. As explained above, the actual blank is longer than job defined in Aspire to allow for the chuck and sufficient gaps. The actual design is shorter than job defined in Aspire, to leave some space for tabs, that can be machined with the profile toolpath prior to removing the finished part from the chuck.

When machining 3D shapes with varying thicknesses like on the example shown below, it is a good idea to place the thicker end of the model on the side closest to the driving motor. This way torsional twisting will mostly affect the stronger end of the machined part and help to avoid bending or breaking of the part during machining.

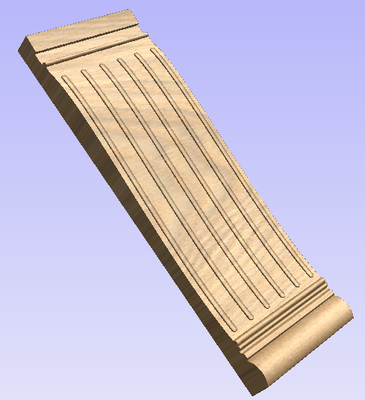

Simple Rotary Modelling using 2D Toolpaths

Creating vectors for a basic column

This section will show how to create a simple column, using the profile and fluting toolpaths.

Start by creating a new rotary job. Please note that settings shown here are only an example and should be adapted to match your machine setup and available material.

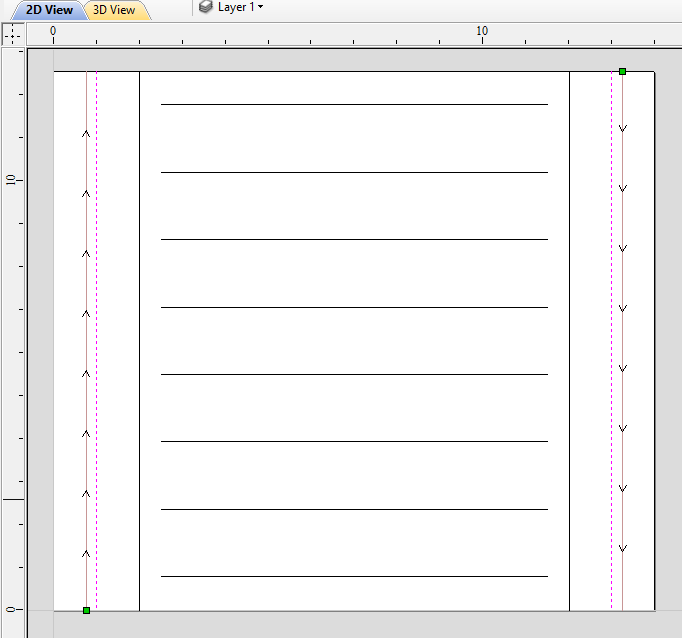

In this example the blank will rotate around X axis. We will refer to it as the rotation axis. The axis that will be wrapped is the Y axis. We will refer to it as the wrapped axis. That means that the top and bottom boundaries of the 2D workspace will actually coincide. We will refer to them as the wrapped boundaries.

First, create the cove vectors using Draw Line/Polyline tool. Those will run along the wrapped axis at both ends of the design. Snapping may be useful to ensure that the created line starts and ends at the wrapped boundaries.

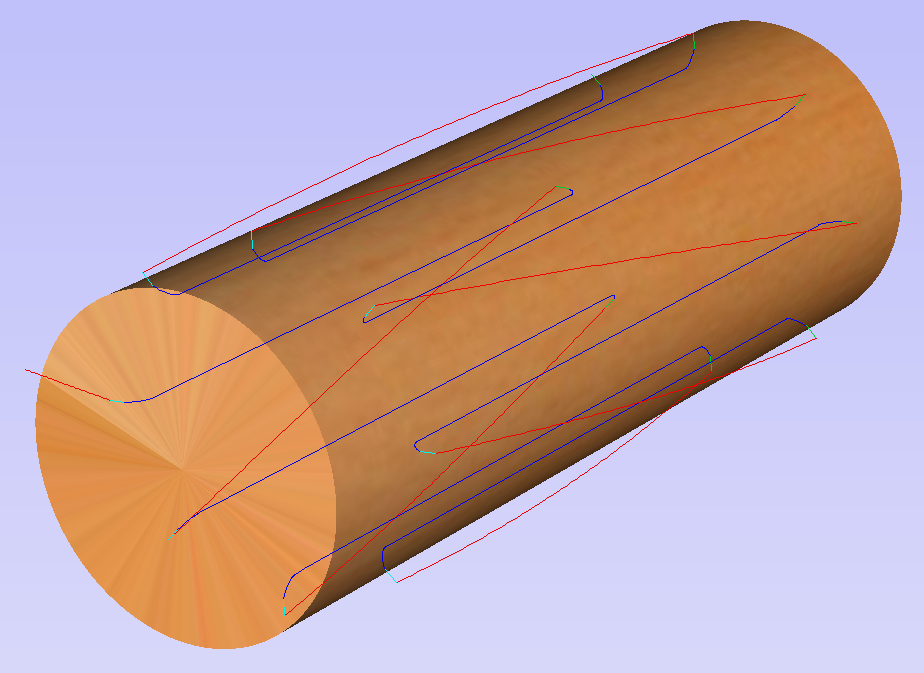

In this example the coves were placed 1 inch from the job boundaries, leaving 10 inches in the middle for the flutes. The flutes will run along rotation axis. Assuming 0.5 inch gap between the cove and the beginning of the flute, the flutes will have the length of 9 inches. This example will use 8 flutes.

To start, create a line parallel to rotation axis that is 9 inches long. Now select the created flute vector and then select one of the cove vectors while holding down Shift. Then use Copy Along Vectors tool to create 9 copies. The original flute vector may now be removed as it is no longer necessary. Note that first and last copy are both created on wrapped boundaries. That means they will coincide, so one of them can be removed. As the last step select all flute vectors and press F9 to place them in the center of design.

Creating rotary toolpaths

The process of creating 2D rotary toolpaths is very similar to creating toolpaths for Single- and Double- models. This example will use the profile toolpath on the cove vectors. To create the toolpath, select the cove vectors and click on the Profile Toolpath from

To create the toolpath for the flutes, select the flute vectors and click on the Fluting Toolpath. This Example used a 1 inch 90deg V-Bit set to Flute Depth 0.2 and using the Ramp at Start and End and Ramp Type Smooth options. Ramp length was set to 0.25 inches. Both toolpaths can be seen below.

Simulating and saving toolpaths

It is time to simulate toolpaths using Preview Toolpaths. If the option to animate the preview is selected, the simulation will be visualized in flat mode. Once the simulation is complete, the wrapped rotary view will be turned back on automatically.

Contrary to single- and double- sided simulation, rotary simulation is not 100% accurate. For example round holes will appear in rotary view as oval ones, but obviously will be round when part is actually machined.

Although the design can be considered to be finished, in practice it is useful to be able to cut-out the remaining stock. This can be realized by making the design slightly longer and adding profile cuts. In this example the blank length was extended by 2 inches using the Job Setup . Existing vectors can be recentered using F9. After that the existing toolpaths have to be recalculated.

The cut-out vectors can be created in the same way as cove vectors. Two extra profiling toolpaths can be created using the suitable End Mill. In this example we used a tab with a 0.5 inch diameter. In order to achieve that, the user can type the following in the Cut Depth box: z-0.25 and then press = and the software will substitute the result of the calculation. Variable 'z' used in the formula will be substituted by the radius of the blank automatically by software. It is also important to specify Machine Vectors Outside/Right or Machine Vectors Inside/Left as appropriate. Cutout toolpaths and the resulting simulation has been shown below.

The final step is to save the toolpaths in a format acceptable by your machine. Use the Save Toolpaths and select the wrapped post-processor matching your machine.

Note

Tools and values presented in this example are for illustrative purposes only. Size of tools, feed rate, tabs diameter etc. have to be adapted to the material and machine used to ensure safe and accurate machining.

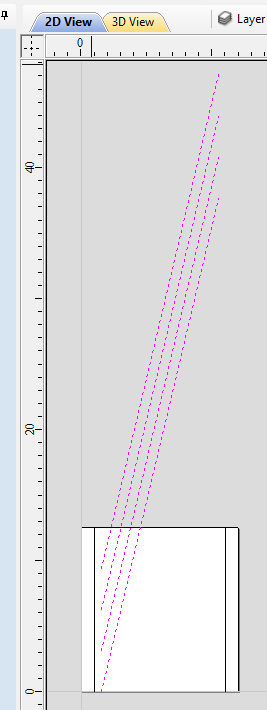

Spiral toolpaths

This section will explain how to create and simulate spiral toolpaths.

One way of thinking about spiral toolpaths is to imagine a long, narrow strip of fabric. Such a strip can be wrapped around a roll at a certain angle. In order to create a toolpath that wraps around the blank multiple times, one can create a long vector at a certain angle. Such a vector is an equivalent to the strip of fabric when it is unwrapped from the roll.

Although such a toolpath will exceed the 2D workspace of the rotary job, thanks to the wrapping process during both simulation and machining the toolpath will actually stay within material boundaries.

The most crucial part of designing spiral vectors is to determine the right angle and length of the line that would result in a given number of wraps. Suppose one would like to modify a simple column design to use spiral flutes, rather than parallel to rotation axis. The following example will use flutes wrapping 3 times each, but the method can be adapted to any other number.

All but one of the existing flute vectors can be removed. Select the Draw Line/Polyline and start a new line by clicking at one end of the existing flute. This line needs to be made along the wrapped axis with the length being 3 times the circumference of the job. In this example that means typing 90 into the Angle box and typing y * 3 into the Length box and pressing =. If the wrapped axis is not the Y axis, but rather the X axis, then the above formula should be x * 3.

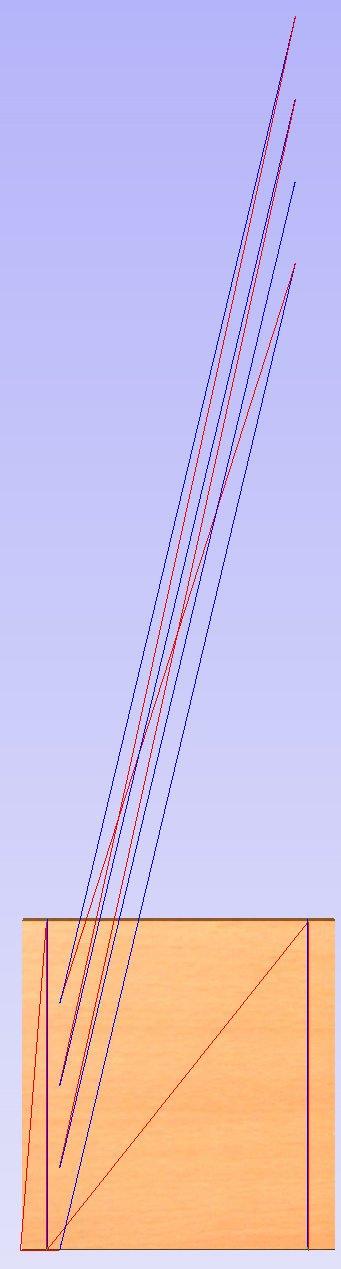

Now one can simply draw a line connecting to the other end of the original flute vector and the newly created one. Using Copy Along Vectors tool this single flute may be copied in the way described earlier. In this example 4 spiral flutes were created, as can be seen below.

Once the flute vectors are ready, the toolpath can be created again using the Fluting Toolpath. An important thing to note, is the difference between the appearance of spiral toolpaths in the wrapped and flat view. By clicking on Auto Wrapping one can switch from wrapped rotary view to flat view and back again.

As can be seen above, in the flat view the toolpaths will follow the vectors and extend beyond the job boundaries. On the other hand the wrapped view, presented below, will display the toolpaths spiralling around the blank.

This was just a brief overview of general 2D workflow for rotary machining. Remember to also take a look at video tutorials dedicated to rotary machining, which are accessible from the Tutorial Video Browser link when the application first starts.

Post Processor Editing

What does the Post Processor Do?

The post processor is the section of the program that converts the XYZ coordinates for the tool moves into a format that is suitable for a particular router or machine tool. This document details how to create and edit the configuration files that customize the output from the program to suit a particular machine control.

Below are sections of a typical program that has been post processed into both G-Code and HPGL

G-Code Output

T1 M6

G17

G0 Z4.5000

G0 X0.0000 Y0.0000 S12000 M3

G0 X2.4567 Y7.8342 Z0.2500

G1 Z-0.0500 F5.0

G3 X3.3784 Y8.7559 I0.0000 J0.9218 F66.0

G3 X2.4567 Y9.6777 I-0.9218 J0.0000

G3 X1.5349 Y8.7559 I0.0000 J-0.9218

HPGL Output

IN;PA;

PU2496,7960;

PD2496,7960;

AA2496,8896,90.000

AA2496,8896,90.000

AA2496,8896,90.000

AA2496,8896,90.000

PU2496,7960;

PU2496,6096;

Machine controller manufacturers will often customize the file format required for programs to run on a particular machine in order to optimize the control to suit the individual characteristics of that machine.

The Vectric post processor uses simple text based configuration files, to enable the user to tailor a configuration file, should they wish to do so.

Post Processor Sections

Vectric post processors are broken down into sections to aid clarity, try to write your post processors in a similar style to aid debugging.

File Comments

A section where you can describe the post processor and record any changes to the post processor, each line is a comment and starts with a ‘+’ character or a ‘|’ character.

+ History

+ Who When What

+ ======== ========== ===========================

+ Tony 14/07/2006 Written

+ Mark 26/08/2008 Combined ATC commands, stop spindle on TC

+================================================

Global File Statements

Statements are items that are either used only once, or have static values throughout the file. Write statement names in upper case letters for clarity.

Statement | Result |

|---|---|

| The name that will appear in the post processor list |

| The file extension that the file will be given |

| The units that the file outputs (INCHES or MM) |

| The machine tool manufacturer has supplied a driver (usually a printer driver) thatn can directly accept the NC file output (For example see Generic HPCL_Arcs.pp) |

| Indicates that plunge moves to Plunge (Z2) height (that is set on the material setup form) are rapid moves |

| The control software uses a document interface that can directly accept the NC file output. |

| The moves in the Y axis are to be wrapped around a cylinder of the specified diameter. The "Y" values will be output as "A" |

| The moves in the X axis are to be wrapped around a cylinder of the specified diameter. The "X" values will be output as "B" |

| Spindle speed for this machine is output as a range of integer numbers between 1 and 15 representing the actual speed in RPM of the spindle, (between 4500 and 15000 RPM in the quoted example). For an example, see the file: Roland_MDX-40_mm.pp |

| This command allows you to substitute a character output within the variables (such as The characters are entered in pairs, Original - Subsititued. For example MACH 3 control software uses parentheses as comment delimiters, and does not allow nested comments. Most tools within the Vectric Tool Database have parentheses within the “Name” section; if these names are output, this would cause an error within Mach3. The command |

| Rotary: Enables / Disables output of the feedrate F in Inverse Time Feed Mode. In this mode, we're expected to complete a move in one divided by the F number of minutes. In GCode, this would G93 to switch on, or G94 to switch off and use units mode. |

Tape Splitting Support

A section that describes how a long toolpath output will be split:

TAPE_SPLITTING=MAX_NUM_LINES LINE_TOL "FILENAME_FORMAT" START_INDEX INDEX_ON_FIRST_FILE

For example a command of:

TAPE_SPLITTING=1000 100 "%s_%s.tap" 1 "YES"

would lead to...

Output will be split into multiple files of a maximum of 1000 lines (+ however many lines in there are within the footer section of the post processor), if a retract move exists after line 900 (1000 – 100), the file will be split at that move. If the file was called "toolpath" the split files would be named toolpath_1.tap, toolpath_2.tap etc. The first toolpath output will be "toolpath_ 1.tap" there will be no file named "toolpath" without an index number, (as INDEX_ON_FIRST_FILE= YES is used), unless the file was less than 1000 lines long, in which case the file would not be split.

Note

Some controllers that require NC files to be split, also have limitations on the number of characters within a filename. For example they may require the file to be named with the MSDOS style 8.3 filename format. This should be considered when naming the output file.

Line Terminating Characters

LINE_ENDING="[13][12]"

Decimal values of the characters appended to each separate line of the post processed file. (Will usually be [13][10]) (Carriage return, line feed) for any controller that can read a windows or MSDOS format text file.

Block Numbering

If you wish to add line numbers to the output file, the current line number is added with the variable [N]. The behaviour of this line number variable is controlled by the following variables:

Statement | Result |

|---|---|

| Value at which the line numbering should start |

| Incremental value between line numbers |

| The maximum line number to output, before cycling to the Important - Some controllers have a limit to the number of lines that can be displayed on the control |

Variables

Variable Name | Output using | Value | Example File |

|---|---|---|---|

|

| Current Feed Rate. | Mach2_3_ATC_Arcs_inch.pp |

|

| Current Cut Feed Rate. | CNCShark-USB_Arcs_inch.pp |

|

| Current Plunge Feed Rate. | CNCShark-USB_Arcs_inch.pp |

|

| Current Spindle Speed in R.P.M. | GCode_arc_inch.pp |

|

| Current power setting for jet-based tools (e.g. lasers) | grbl_mm.pp |

|

| Current Tool Number. | Mach2_3_ATC_Arcs_inch.pp |

|

| Previous Tool Number. | NC-Easy.pp |

|

| Current Line Number in file. | Mach2_3_ATC_Arcs_inch.pp |

|

| Name of Current Tool. | MaxNC_inch.pp |

|

| Text from Note field in ToolDB for current tool | Busellato_Jet3006_arc_inch.pp |

|

| Name of Current Toolpath. | Viccam_ATC_Arcs_inch.pp |

|

| Filename (Produced by “Save Toolpath(s)”). | ez-Router_inch.pp |

|

| Folder Toolpath File was saved to. | Woodp_arc_mm.pp |

|

| Toolpath File Extension. | TekcelE_Arc_ATC_3D.pp |

|

| Toolpath Folder Pathname. | WinPC-NC_ATC_Arcs_mm.pp |

|

| Current coordinate of tool position in X axis. | GCode_arc_inch.pp |

|

| Current coordinate of tool position in Y axis. | GCode_arc_inch.pp |

|

| Current coordinate of tool position in Z axis. | GCode_arc_inch.pp |

|

| Current coordinate of tool position in A axis. | |

|

| Arc centre in X Axis (relative to last X,Y position). | Mach2_3_ATC_Arcs_inch.pp |

|

| Arc centre in Y Axis (relative to last X,Y position). | Mach2_3_ATC_Arcs_inch.pp |

|

| Arc centre in X Axis (absolute coordinates). | Isel_arc_mm.pp |

|

| Arc centre in Y Axis (absolute coordinates). | Isel_arc_mm.pp |

|

| Start position of an arc in X axis. | TextOutput_Arcs_mm.pp |

|

| Start position of an arc in Y axis. | TextOutput_Arcs_mm.pp |

|

| Mid-point of arc in X (absolute coordinates). | TextOutput_Arcs_mm.pp |

|

| Mid-point of arc in Y (absolute coordinates). | TextOutput_Arcs_mm.pp |

|

| Mid-point of arc in X (incremental coordinates). | TextOutput_Arcs_mm.pp |

|

| Mid-point of arc in Y (incremental coordinates). | TextOutput_Arcs_mm.pp |

|

| The radius of an arc. | Bosch_ATC_Arcs_mm.pp |

|

| The angle of an arc. | Generic HPGL_Arcs.pp |

|

| Home tool position for X axis. | CAMTech_CMC3_mm.pp |

|

| Home tool position for Y axis. | CAMTech_CMC3_mm.pp |

|

| Home tool position for Z axis. | CAMTech_CMC3_mm.pp |

|

| Safe Z Height / Rapid Clearance Gap. | EMC2 Arcs(inch)(*.ngc) |

|

| Diameter of cylinder that axis is wrapped around. | Mach2_3_WrapY2A_ATC_Arcs_mm.pp |

|

| Length of material in X. | Mach2_3_ATC_Arcs_inch.pp |

|

| Length of material in Y. | Mach2_3_ATC_Arcs_inch.pp |

|

| Length of material in Z. | Mach2_3_ATC_Arcs_inch.pp |

|

| Minimum value of material in X. | MaxNC_inch.pp |

|

| Minimum value of material in Y. | MaxNC_inch.pp |

|

| Minimum value of material in Z. | MaxNC_inch.pp |

|

| Maximum value of material in X. | MaxNC_inch.pp |

|

| Maximum value of material in Y. | MaxNC_inch.pp |

|

| Maximum value of material in Z. | MaxNC_inch.pp |

|

| Origin Position in X. | TextOutput_Arcs_mm.pp |

|

| Origin Position in Y. | TextOutput_Arcs_mm.pp |

|

| Z Zero Position, Table or Material Surface. | TextOutput_Arcs_mm.pp |

|

| X, Y Origin. | TextOutput_Arcs_mm.pp |

|

| List of tools used (In order of use). | Mach2_3_ATC_Arcs_inch.pp |

|

| List of toolpaths used in file (in order of use). | Mach2_3_ATC_Arcs_inch.pp |

|

| Toolpath Notes (Toolpath Control form). | Mach2_3_ATC_Arcs_inch.pp |

|

| File Notes (Edit > Notes). | Mach2_3_ATC_Arcs_inch.pp |

|

| File creation time. | Mach2_3_ATC_Arcs_inch.pp |

|

| File creation date. | Mach2_3_ATC_Arcs_inch.pp |

|

| Dwell time in seconds when drilling. | Mach2_3_Arcs_inch.pp |

|

| Name of the product used to output file, including version number. | |

|

| Tool diameter. | |

|

| Rotary: Current Inverse Time Rate | AvidCNC_WrapX2A_G93_inch.pp |

Format of Variables

Values for tool position, feed rates, spindle speeds etc. are inserted into the file using variables. Variables are used throughout the file; the variables are replaced with the current value for that item when the file is post processed. For example, the current X, Y and Z tool positions at any time, are inserted into the file by using the variable output, [X], [Y] and [Z] respectively.

Write variable names in upper case letters for clarity.

A Variable is formatted as follows:

VAR VARIABLE = [VO|WO|CS|VF|MX]

where

VO= Variable output for example X, XF or F.WO= When output, A=Always, C=Only when changed.CS= Character string output before value .VF= Value format, determines the format that the value is output with.MX= Multiplier Value.

A typical variable

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

VAR- This line is a Variable.- Variable Name.

- Equals Sign.

- Open Square bracket - (start of variable formatting parameters).

- Variable label - i.e. label that is substituted with the variable value.

- Vertical Bar - Parameter separator.

A= Always output value,C= Only output value when it changes- Vertical Bar - Parameter separator.

- Character string to print before variable value.

- Vertical Bar - Parameter separator.

- Optional Format Flags - for details see below.

- Value Format - units and number of decimal places to output.

- Vertical Bar - Parameter separator.

- Output multiplier - for details see below.

- Close Square Bracket - End of formatting parameters.

Formatting the Output Value

The values format string should be formatted as follows:

FORMAT_FLAGS FIELD_WIDTH DECIMAL_SEPARATOR DECIMAL_PLACES

The format flags are optional and only needed by a small number of controllers they will be described shortly.

Field Width The Field width represents the minimum number of characters that are output. The field width is usually set to “1” a value greater than 1 is typically only required if a controller expects to see a fixed number of characters for the value. If this is the case, a number greater than 1 can be entered. The number entered will ensure that that number of characters is output. The number that represents the field width includes the full floating-point number for the output value, (including the decimal separator character).

Decimal Separator The decimal separator character is almost always just a period character, but there are some controllers that expect to see a comma character. (For an example of a post processor that does not use a period character, see the file: Heidenhain_inch.pp)

Decimal Places The number of decimal places output following the decimal separator. The values are often set at 3 for controllers operating in Metric, or 4 for controllers operating in Inches.

Optional Format Flags

The output values can be further modified by using the optional format flags:

Flag | Function | Default (without flag) |

|---|---|---|

| Left Justify the output | Values are right justified |

| Prefix the value with '+' or '-' | Only negative values are prefixed |

| If value has fewer characters than the set minimum, the value is prefixed with zeroes | Values is prefixed with blanks spaces |

| Values is always output with a separator character ( in practive this would only change the output value if the value is set to output integer values only) | When output is set to integer only, separator charactor is not appended to value. |

Default Formatting For Variables

Most variables have a default format; (shown below) to set a different format for a variable, enter the line below in your post processor and alter the parameters to suit your controller.

Default | Example |

|---|---|

|

The line number will always be output. An 'N' character will be inserted before the line number. It will be output as an integer number |

|

The spindle speed will always be output. An 'S' character will be inserted before the value and it will be output as an integer number. |

|

The feed rate will be output with an F character before the value, and will only be output when it changes. The value will be output to 1 decimal place Note In this format string there is an option extra parameter. This is the value multiplier. |

VAR PLUNGE_RATE = [FP|A||1.0] |

The plunge rate will be output with an F character before the value, and will only be output when it changes. The value will be output to 1 decimal place. Note In this format string there is an option extra parameter. This is the value multiplier. |

|

The cut rate will be output with an F character before the value, and will only be output when it changes. The value will be output to 1 decimal place. Note In this format string there is an option extra parameter. This is the value multiplier. |

|

The position value will be output with an ‘X’ character before the value, the position will Always be output, and will be output to 3 decimal places, this would typically be suitable for a control that requires metric output. If you wished to output the values to 4 decimal places as would be more typical for a controller operating in inches. You would format the line as follows.

|

|

The home position value will be output with an ‘X’ character before the value, the position will Always be output, and will be output to 3 decimal places, this would typically be suitable for a control that requires metric output. If you wished to output the values to 4 decimal places as would be more typical for a controller operating in inches. You would format the line as follows.

|

|

The value will be output with an ‘X’ character before the value, the position will Always be output, and will be output to 3 decimal places, this would typically be suitable for a control that requires metric output. If you wished to output the values to 4 decimal places as would be more typical for a controller operating in inches. You would format the line as follows.

Note In this format string there is an option extra parameter. This is the value multiplier. |

|

The value will be output with an ‘Y’ character before the value, the value will Always be output, and will be output to 3 decimal places, this would typically be suitable for a control that requires metric output. If you wished to output the values to 4 decimal places as would be more typical for a controller operating in inches. You would format the line as follows.

|

|

The value will be output with a ‘J’ character before the value, the value will Always be output, and will be output to 3 decimal places, this would typically be suitable for a control that requires metric output. If you wished to output the values to 4 decimal places as would be more typical for a controller operating in inches. You would format the line as follows.

|

|

The value will be output with a ‘J’ character before the value, the value will Always be output, and will be output to 3 decimal places, this would typically be suitable for a control that requires metric output. If you wished to output the values to 4 decimal places as would be more typical for a controller operating in inches. You would format the line as follows.

Note In this format string there is an option extra parameter. This is the value multiplier. |

|

The value will be output with a ‘X’ character before the value, the value will Always be output, and will be output to 3 decimal places, this would typically be suitable for a control that requires metric output. If you wished to output the values to 4 decimal places as would be more typical for a controller operating in inches. You would format the line as follows.

|

|

The value will be output with a ‘X’ character before the value, the value will Always be output, and will be output to 3 decimal places, this would typically be suitable for a control that requires metric output. If you wished to output the values to 4 decimal places as would be more typical for a controller operating in inches. You would format the line as follows.

|

|

The value will be output with a ‘R’ character before the value, the value will Always be output, and will be output to 3 decimal places, this would typically be suitable for a control that requires metric output. If you wished to output the values to 4 decimal places as would be more typical for a controller operating in inches. You would format the line as follows.

|

|

The value will be output with a ‘A’ character before the value, the value will Always be output, and will be output to 3 decimal places, this would typically be suitable for a control that requires metric output. If you wished to output the values to 4 decimal places as would be more typical for a controller operating in inches. You would format the line as follows.

|

|

The value will be output with an ‘X’ character before the value, the value will Always be output, and will be output to 3 decimal places. |

Multiplier Value

The multiplier value is used to multiply the value to output a different value. Common reasons for wishing to do this are:

To convert the default output of an Inch post processor, from inches per minute to inches per second, (Multiply by 0.01666).

To convert the default output of a Metric post processor, from mm per minute to mm per second, (Multiply by 0.0166).

To make positive values negative (and vice versa), (Multiply by -1).

To convert the output of an arc angle from radians to degrees, (Multiply by 57.2957795).

To multiply or divide by a fixed factor (I.E. produce 1:4 scale model, Multiply by 0.25)

Post Processor Blocks

HEADER

+---------------------------------------------------

+ Commands output at the start of the file

+---------------------------------------------------

begin HEADER

"Commands"

The header is the location for the instructions that are output once, at the start of the file, these generally setup modal commands for the controller.

For example, the Header might contain a command to display the filename on the controller and a series of “G-Codes” to set the machine up, for instance G20 to tell the control that the moves are in inches, or G21 to tell the control that the moves are in millimetres.

Variables that you might wish to be within the header section, could include:

Information about the Material Block

- Minimum extent in X = [XMIN]

- Minimum extent in Y = [YMIN]

- Minimum extent in Z = [ZMIN]

- Maximum extent in X = [XMAX]

- Maximum extent in Y = [YMAX]

- Maximum extent in Z = [ZMAX]

- Length of material in X = [XLENGTH]"

- Length of material in Y = [YLENGTH]"

- Depth of material in Z = [ZLENGTH]"

Home Position Information

- Home X = [XH]

- Home Y = [YH]

- Home Z = [ZH]

- Rapid clearance gap or Safe Z = [SAFEZ]

Details of the first tool to be used.

- Tool Number = [T]

- Tool name = [TOOLNAME]

Initial cutting speeds

- Feed Rate used for cutting and plunging into the material = [F]

- Feed Rate whilst tool is Cutting the material = [FC]

- Feed Rate whilst tool is plunging into the material = [FP]

Actual values depend on the UNITS set (see Global File Settings) Defaults are either MM/Minute or Inches/Minute, but the output can be changed to suit by setting the appropriate “VAR FEED_RATE” formatting.

Spindle Speed

- Spindle Speed = [S] R.P.M.

TOOLCHANGE

+---------------------------------------------------

+ Commands output at toolchange

+---------------------------------------------------

begin TOOLCHANGE

"Commands"

Commands that are output when a change of tool is required. Variables and commands that might be used include:

- Previous Tool Number = [TP]

- Tool Number = [T]

- Tool name = [TOOLNAME]

- Toolpath Name = [TOOLPATH_NAME]

- Toolpath Pathname = [PATHNAME]

- Toolpath File Name = [TP_FILENAME]

- Toolpath File Directory = [TP_DIR]

- Toolpath Extension = [TP_EXT]

- Spindle Speed = [S] R.P.M.

- M3 M Code often used to turn spindle on (Clockwise rotation).

- M5 M Code often used to turn spindle off.

NEW_SEGMENT

+---------------------------------------------------

+ Commands output for a new segment ( new toolpath with current toolnumber)

+---------------------------------------------------

begin NEW_SEGMENT

"Commands"

For an example of a NEW_SEGMENT section, see the file: Mach2_3_ATC_Arcs_inch.pp

Commands that are output when a new toolpath uses the currently selected tool, but perhaps a different spindle speed is required or the machine requires additional instructions.

Any commands that are used in the NEW_SEGMENT section should not need to be included within the TOOLCHANGE section as a tool-change will also automatically call the instructions in the NEW_SEGMENT section.

Variables that are commonly used include.

- Spindle Speed = [S] R.P.M.

- M3 M Code often used to turn spindle on (Clockwise rotation).

- M5 M Code often used to turn spindle off.

INITIAL_RAPID_MOVE

+---------------------------------------------------

+ Commands output for Initial rapid move

+---------------------------------------------------

begin INITIAL_RAPID_MOVE

"Commands"

For an example of a INITIAL_RAPID_MOVE section, see the file: Saom_OSAI_Arc_inch.pp

Commands that are output when the very first rapid move is made following the header or a tool change. A Section not used for most posts, but useful if the very first rapid move, needs to output different information to subsequent rapid moves. This section is sometimes required for HPGL variants.

RAPID_MOVE

+---------------------------------------------------

+ Commands output for rapid moves.

+---------------------------------------------------

begin RAPID_MOVE

"Commands"

Commands that are output when rapid moves are required.

FIRST_FEED_MOVE

+---------------------------------------------------

+ Commands output for first feed rate move in a series of feed moves.

+---------------------------------------------------

begin FIRST_FEED_MOVE

"Commands"

This section is commonly used where controllers require that the Feed Rate is set at the first feed move, this rate would then be used for subsequent cut moves.

For an example of a FIRST_FEED_MOVE section, see the file: Axyz_Arcs_ATC_inch.pp

FEED_MOVE

+---------------------------------------------------

+ Commands output for feed rate moves

+---------------------------------------------------

begin FEED_MOVE

"Commands"

Used to output information required at every move, or all feed moves except for the First Feed Move, if a FIRST_FEED_MOVE section is present within the post processor.

FIRST_CW_ARC_MOVE

+---------------------------------------------------

+ Commands output for the first clockwise arc move in a series of cw arc moves

+---------------------------------------------------

begin FIRST_CW_ARC_MOVE

"Commands"

Similar to the FIRST_FEED_MOVE section, but for clockwise arc segments. This section is commonly used where controllers require that the Feed Rate is set for the first arc segment, this rate would then be used for subsequent arc moves in the same direction.

For an example of a FIRST_CW_ARC_MOVE section, see the file: Centroid_Arcs_inch.pp

FIRST_CW_HELICAL_ARC_PLUNGE_MOVE

+---------------------------------------------------

+ Commands output for clockwise helical arc plunge move in a series of moves.

+---------------------------------------------------

begin FIRST_CW _HELICAL_ARC_MOVE

"Commands"

Similar to the FIRST_CW_ARC_MOVE section, but for moves that also move in Z. Feed rates output are from Plunge rate set for the tool.

For an example of a CW_HELICAL_ARC_PLUNGE_MOVE section, see the file: Mach2_3_ATC_Arcs_inch.pp

FIRST_CW_HELICAL_ARC_MOVE

+---------------------------------------------------

+ Commands output for clockwise helical arc move in a series of moves.

+---------------------------------------------------

begin FIRST_CW_HELICAL_ARC_MOVE

"Commands"

Similar to the FIRST_CW_ARC_MOVE section, but for moves that also move in Z.

For an example of a CW_HELICAL_ARC_MOVE section, see the file: Mach2_3_ATC_Arcs_inch.pp

CW_ARC_MOVE

+---------------------------------------------------

+ Commands output for clockwise arc moves.

+---------------------------------------------------

begin CW_ARC_MOVE

"Commands"

Similar to the FEED_MOVE section, but for clockwise arc segments.

For an example of a CW_ARC_MOVE section, see the file: Centroid_Arcs_inch.pp

CW_HELICAL_ARC_MOVE

+---------------------------------------------------

+ Commands output for clockwise helical arc moves

+---------------------------------------------------

begin CW_HELICAL_ARC_MOVE

"Commands"

Similar to the CW_ARC_MOVE section, but for moves that also move in Z.

For an example of a CW_HELICAL_ARC_MOVE section, see the file: Mach2_3_ATC_Arcs_inch.pp

FIRST_CCW_ARC_MOVE

+---------------------------------------------------

+ Commands output for the first counter-clockwise arc move in a series of ccw arc moves.

+---------------------------------------------------

begin FIRST_CCW_ARC_MOVE

"Commands"

Similar to the FIRST_FEED_MOVE section, but for counter-clockwise arc segments. This section is commonly used where controllers require that the Feed Rate is set for the first arc segment, this rate would then be used for subsequent arc moves in the same direction.

For an example of a FIRST_CCW_ARC_MOVE section, see the file: Centroid_Arcs_inch.pp

FIRST_CCW_HELICAL_ARC_PLUNGE_MOVE

+---------------------------------------------------

+ Commands output for counter- clockwise helical arc plunge move in a series of moves.

+---------------------------------------------------

begin FIRST_CCW_HELICAL_ARC_MOVE

"Commands"

Similar to the FIRST_CCW_ARC_MOVE section, but for moves that also move in Z. Feed rates output are from Plunge rate set for the tool.

For an example of a CCW_HELICAL_ARC_PLUNGE_MOVE section, see the file: Mach2_3_ATC_Arcs_inch.pp

FIRST_CCW_HELICAL_ARC_MOVE

+---------------------------------------------------

+ Commands output for first counter-clockwise helical arc move in a series of moves.

+---------------------------------------------------

begin FIRST_CCW_HELICAL_ARC_MOVE

"Commands"

Similar to the FIRST_CCW_ARC_MOVE section, but for moves that also move in Z.

For an example of a CCW_HELICAL_ARC_MOVE section, see the file: Mach2_3_ATC_Arcs_inch

CCW_ARC_MOVE

+---------------------------------------------------

+ Commands output for counter-clockwise arc moves.

+---------------------------------------------------

begin CCW_ARC_MOVE

"Commands"

Similar to the FEED_MOVE section, but for counter-clockwise arc segments.

For an example of a CCW_ARC_MOVE section, see the file: Centroid_Arcs_inch.pp

CCW_HELICAL_ARC_MOVE

+---------------------------------------------------

+ Commands output for counter-clockwise helical arc moves

+---------------------------------------------------

begin CCW_HELICAL_ARC_MOVE

"Commands"

Similar to the CCW_ARC_MOVE section, but for moves that also move in Z.

For an example of a CCW_HELICAL_ARC_MOVE section, see the file: Mach2_3_ATC_Arcs_inch.pp

FOOTER

The footer is the section of the post processor for instructions that are sent to the controller at the end of a file. These might be instructions to return the tool to the home position, switch the spindle off or switch the power off to the drives.

+---------------------------------------------------

+ Commands output at the end of the file

+---------------------------------------------------

begin FOOTER

"Commands"

Variables that are commonly used include.

- G00 [XH] [YH] [ZH] Rapid to X,Y,Z Home position.

- M05 M Code often used to turn spindle off.

- M30 M Code often used to signify the end of the file.

Jet Support Sections

These sections are for supporting jet-based cutting tools such as lasers, plasmas and waterjets.

JET_TOOL_POWER

+---------------------------------------------------

+ Commands output when the cutter's power is set

+---------------------------------------------------

begin JET_TOOL_POWER

"Commands"

For an example of a JET_TOOL_POWER section, see the file: Grbl.pp

Commands that are output when the power setting associated with a laser 'tool' is issued.

JET_TOOL_ON

+---------------------------------------------------

+ Commands output when the cutter's power is turned ON

+---------------------------------------------------

begin JET_TOOL_ON

"Commands"

For an example of a JET_TOOL_ON section, see the file: Grbl.pp

Commands that are output when the jet tool is powered on. This is broadly equivalent to SPINDLE_ON, but is typically issued a the end of a plunge move when the jet cutter is already at the intended cutting height, instead of before the plunge move as required by a spindle based cutter.

JET_TOOL_OFF

+---------------------------------------------------

+ Commands output when the cutter's power is turned OFF

+---------------------------------------------------

begin JET_TOOL_OFF

"Commands"

For an example of a JET_TOOL_OFF section, see the file: Grbl.pp

Commands that are output when the jet tool is powered off.

Other Less Frequently Used Sections

FEED_RATE_CHANGE

+---------------------------------------------------

+ Commands output when feed rate changes

+---------------------------------------------------

begin FEED_RATE_CHANGE

"Commands"

For an example of a FEED_RATE_CHANGE section, see the file: Gravograph_IS200.pp

Commands that are output when the feed rate is changed. This section is not often used as many controllers will accept feed rate changes appended to other instructions, but sometimes used with HPGL variants.

FIRST_PLUNGE_MOVE

+---------------------------------------------------

+ Commands output for the First Plunge Move, in a series of plunge moves.

+---------------------------------------------------

begin FIRST_PLUNGE_MOVE

"Commands"

For an example of a FIRST_PLUNGE_MOVE section, see the file: Holz-Her_7123_ATC_Arcs_mm.pp

This section is often used on machines that do not fully support simultaneous 3D movement, for example the Z Axis cannot travel as fast as the X & Y Axis. Another use of this section might be to include commands that you wish to output whenever the first plunge move occurs. For example, commands to switch on a plasma torch. Multiple plunges would normally only be output within a ramping move, so this command would be useful for controls that automatically rapid between cuts and where instructions such as revised speeds and feed need to be specified on the first plunge move and these instructions are not required for subsequent plunge moves within the ramping operation.

PLUNGE_MOVE

+---------------------------------------------------

+ Commands output for Plunge Moves

+---------------------------------------------------

begin PLUNGE_MOVE

"Commands"

For an example of a PLUNGE_MOVE section, see the file: Burny_arc_inch.pp

This section is often used on machines that do not fully support simultaneous 3D movement, for example the Z Axis cannot travel as fast as the X & Y Axis. Another use of this section might be to include commands that you wish to output whenever a plunge move occurs. For example, commands to switch on a plasma torch.

RETRACT_MOVE

+---------------------------------------------------

+ Commands output for Retract Moves

+---------------------------------------------------

begin RETRACT_MOVE

"Commands"

For an example of a RETRACT _MOVE section, see the file: Burny_arc_inch.pp

A use of this section might be to include commands to switch off a plasma torch.

DWELL_MOVE

+---------------------------------------------------

+ Commands output for Dwell Commands

+---------------------------------------------------

begin DWELL_MOVE

"Commands"

For an example of a DWELL_MOVE section, see the file: Mach2_3_Arcs_inch.pp

This command was introduced for VCarve Pro 7.5 and Aspire 4.5 and later. It is used with a drilling toolpath, when a Dwell time has been specified in the program. If this section is not defined any dwell commands are ignored, but the rest of the drilling toolpath will be output as normal. The DWELL variable is documented in the Variables section.

Special Characters

Most characters can be output within the confines of the post processor output statements; however, certain characters have special meaning within the post processor configuration files and cannot be output directly.

These are, the Square brackets [ ], and the double quote character “ It may be the case that you need to output one of these characters within your output file.

If you wish to output one of these characters, you can do so by enclosing the decimal equivalent of the ASCII value of the special character that you wish to output, within square brackets, as shown below. This method can also be used to insert any ASCII value, even non-printable characters.

- [91] Outputs a left hand square bracket.

- [93] Outputs a right hand square bracket.

- [34] Outputs a double quote character.

- [13] Outputs a carriage return.

- [10] Outputs a line feed.

For an example of a file that uses special characters, please see: Biesse_Rover_Arcs_mm.pp

Example: Adding Tool-Change Commands

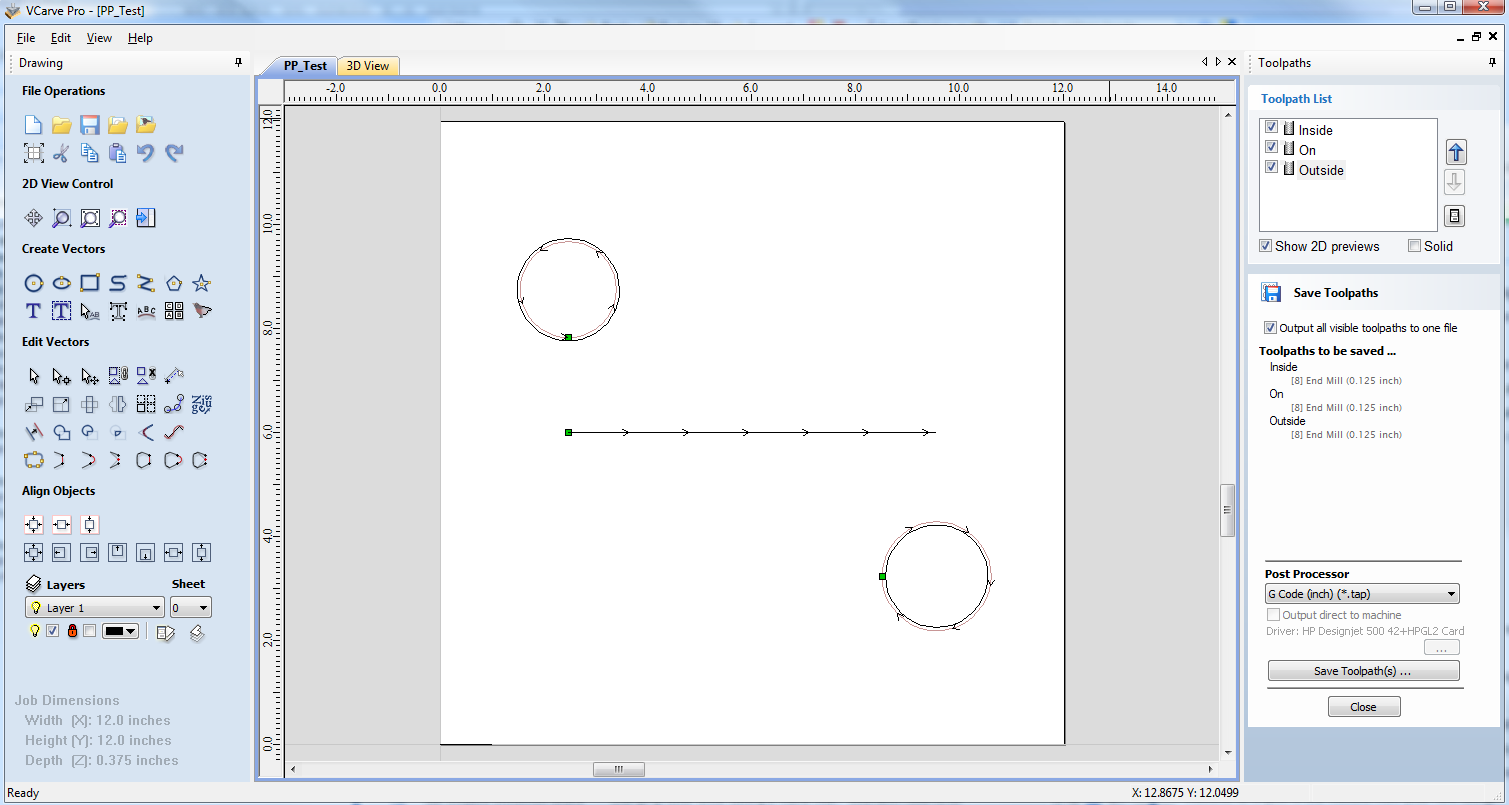

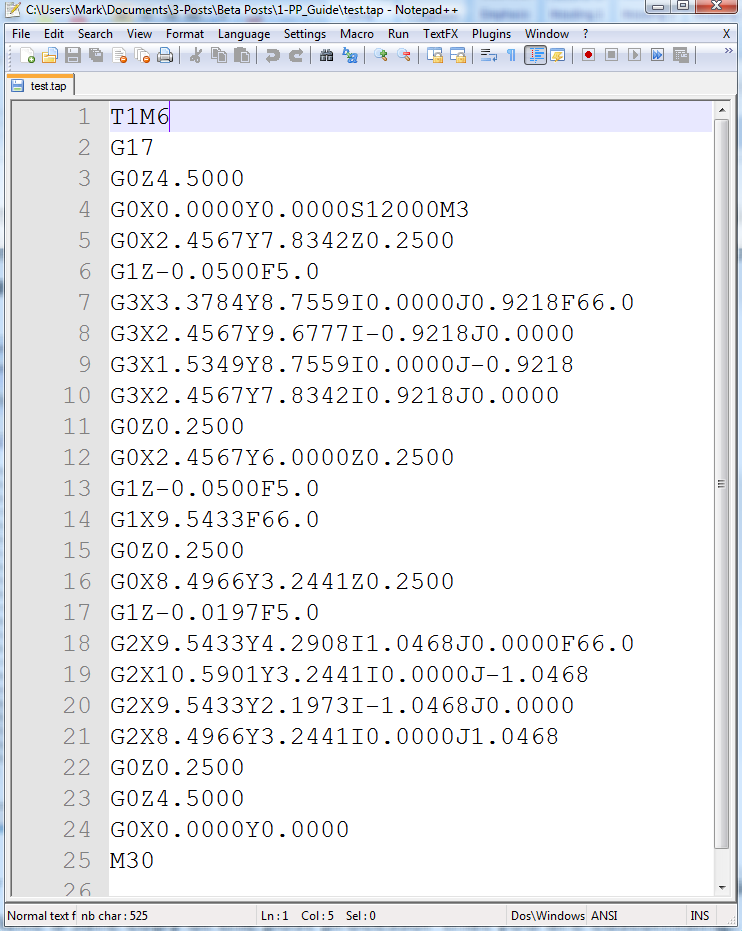

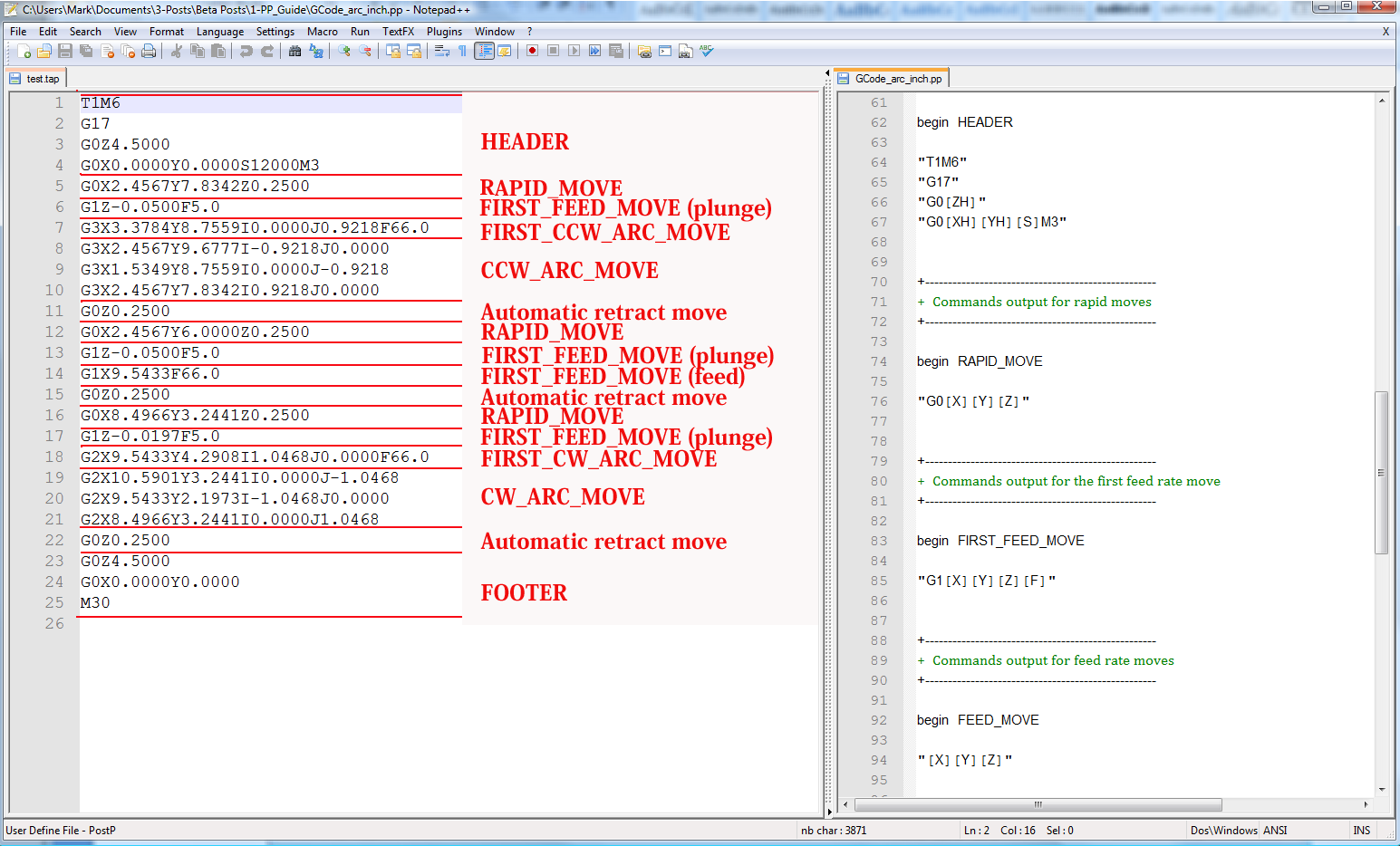

For the majority of cases, the quickest and easiest way of producing a customised post processor to suit your controller, will be to edit an existing post processor. To do this, first create a simple test file that you can use to test the output of your post processor. A simple file might consist of a line, and two circles. Produce a shallow cutting profile toolpaths for each of the shapes, machining “On” the line, “Inside” one of the circles and “Outside” the other circle.

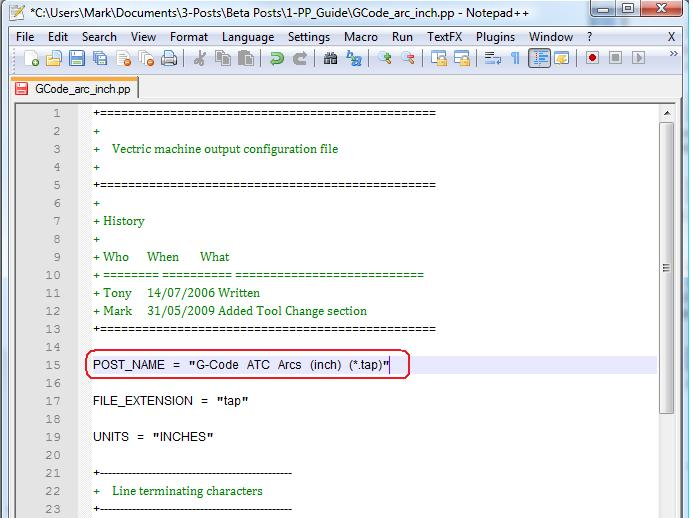

Save a toolpath using your base post processor and take a look at it using your favourite text editor. Below is an example of the test file posted using the "G-Code Arcs (inch) (*.tap)" post processor The example below is displayed using the popular Notepad ++ editor.

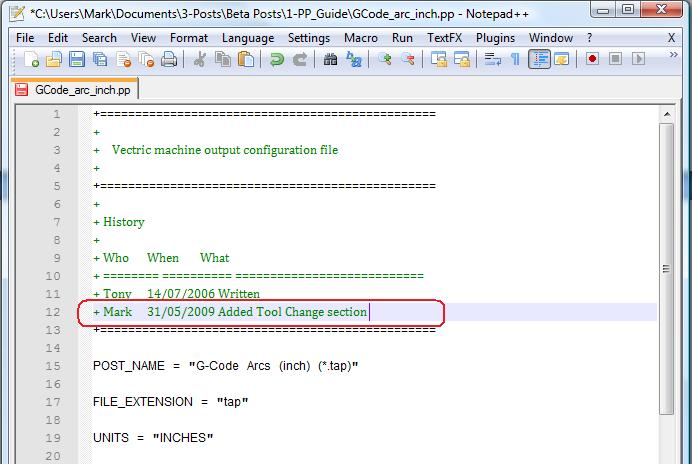

For our example, we will add a tool-change section to this post processor. First, make a safe copy of the post processor that you are customising. If you open the post processor that you are editing in a text editor, you will be able to see the lines of text within the post processor that formatted the output of your test file.

The PostP folder can be reached from within the application, by clicking “File > Open Application Data Folder” from the main menu of the application.

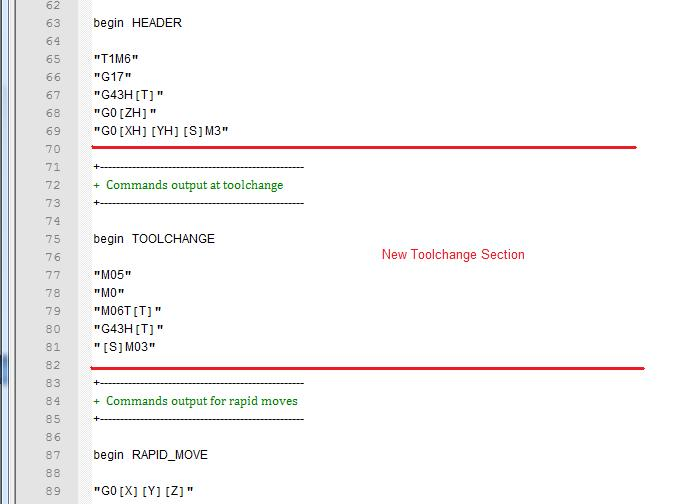

To add a Tool Change section to the post processor, you will need to consult the documentation for the control of the machine tool (or control software). For this example, we will assume that the instructions that you need to add to perform a tool change for your particular machine tool are as follows:

- M05 Instruction to turn off the spindle prior to tool change.

- M0 Instruction to return existing tool to tool holder.

- M06TTool_Number n Instruction to select new tool Tool_Number n

- G43HTool_Number n Instruction for control to use Tool length offset for tool n

- Sxxx M03 Set spindle speed to xxx; Turn on spindle (clockwise rotation).

Edit the post processor using your favourite text editor.

If the operating system on your computer is Microsoft Vista and User Access Control is enabled, copy or move the Post Processor that you are editing from the PostP folder to a folder below your user area.

The first thing that you should edit within the file is the History Comment section; So that you have a record of the changes.

Next edit the POST_NAME to reflect that this post processor outputs automatic tool change (ATC) commands, the new post will be displayed as “G-Code ATC Arcs (inch)(*.tap)” in the list of post processors.

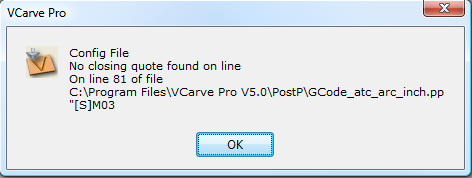

Next add a Tool Change Section that will include the instructions. The location of the new section within the file is not important, but a good place to insert it is between the Header and Rapid Move sections.

Add some comment lines at the top of the new section, (beginning with the + character) to describe the section and make the file as a whole, easier to read. Next enter the line “begin TOOLCHANGE” to instruct the post processor that the following instructions are to be output for every tool-change, (except the initial tool selection, the commands for these are contained within the header section).