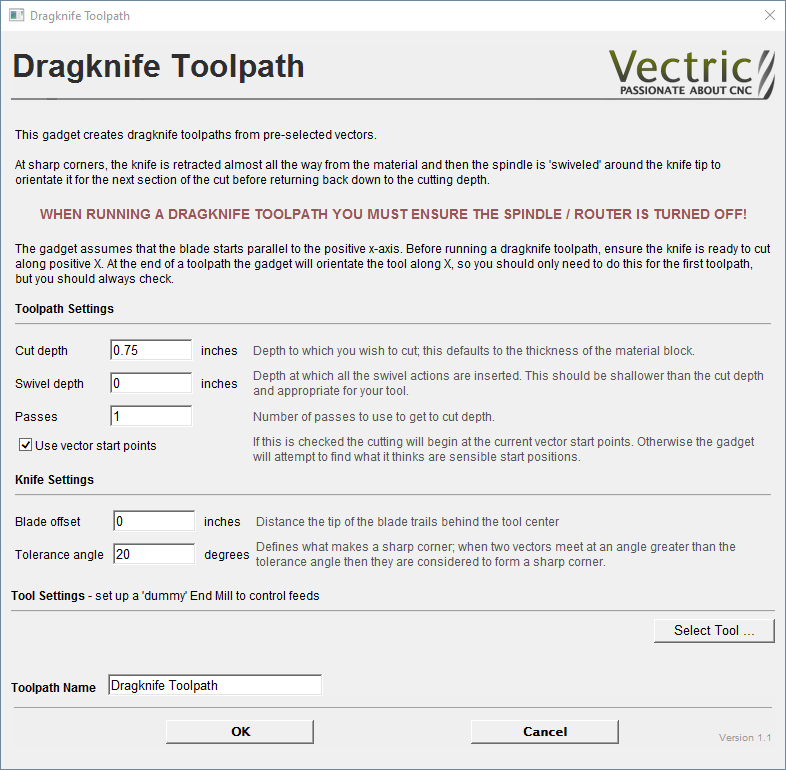

Drag Knife Toolpath

This Gadget supports drag knife tooling in your CNC machine. It uses the selected vectors in the 2D View as the basis of a centerline profile-type toolpath that incorporates swivel moves at corners to ensure the drag knife blade remains properly aligned throughout the cut.

Warning

When machining please ensure you have the spindle switched off.

Blade Offset

The tip of a drag knife is offset by a small amount from the pivot center of the tool to allow it to swivel as it cuts. This value specifies the distance and will be provided by your tool manufacturer.

Tolerance angle

This value determines when a swivel move needs to be used on a corner. Changes in tool direction, or corners, with angles less than this value will not generate swivel moves.

Cut Depth

This value sets the final cut depth of the toolpath. It defaults to be the current material thickness.

Swivel Depth

The knife must remain in some contact with the material in order to swivel correctly, but a small retraction is generally used to lift the knife blade slightly to minimize marking the material during the swivel action. This value must, therefore, be less than the cut depth and appropriate for your tool and material.

Passes

This value determines the number of passes used to cut down to full depth. The depth of each cut will be specified cut depth divided by the number of passes.

Use Vector Start Points

If Use Vector Start Points is checked ✓ then the gadget will use the existing vector start points to begin cutting vectors. Please note that this gadget assumes that the blade starts parallel to the positive x-axis. If this is option not checked the gadget will attempt to find what it thinks are sensible start positions.

Feed and Plunge Rates

These are the rates that the machine will push the knife through the material during a cutting pass, and the rate of descent of the tool into the material at the beginning of a cutting pass. Please ensure that the values are appropriate for your machine tool and the material you are cutting.